ADB Safegate CRE 2.5 User manual

A.07.370e Edition 2.0

Installation Manual

Constant Current Regulator

Type CRE

2A.07.370e - Edition 2.0

© ADB Safegate

This manual or parts thereof may not be reproduced, stored in a retrieval system, or transmitted, in any form

or by any means, electronic, mechanical, photocopying, recording, nor otherwise, without ADBs prior written

consent.

This manual could contain technical inaccuracies or typographical errors.

ADB Safegate reserves the right to revise this manual from time to time in the contents thereof without

obligation of ADB Safegate to notify any person of such revision or change.

Details and values given in this manual are average values and have been compiled with care. They are not

binding, however, and ADB Safegate disclaims any liability for damages or detriments suffered as a result of

reliance on the information given herein or the use of products, processes or equipment to which this manual

refers. No warranty is made that the use of the information or of the products, processes or equipment to

which this manual refers will not infringe any third party’s patents or rights. The information given does not

release the buyer from making their own experiments and tests.

ADB Safegate Address: Leuvensesteenweg 585, B-1930 Zaventem, Belgium

Tel.: +32 2 722 17 11, Fax: +32 2 722 17 64

Email: marketing@adbsafegate.com

Internet: www.adbsafegate.com

A.07.370e - Edition 2.0 3

Table of contents

1 About this manual

1.1 How to work with the manual...................................................................................................... 7

1.2 Record of changes ..................................................................................................................... 7

1.3 Icons used in the manual............................................................................................................ 7

1.4 Abbreviations and terms ............................................................................................................. 8

2Safety

2.1 Use ............................................................................................................................................. 9

2.2 Safety symbols ........................................................................................................................... 9

2.3 Signs on the equipment............................................................................................................ 10

2.4 Skilled personnel ...................................................................................................................... 10

2.5 Liability.......................................................................................................................................11

2.6 Installation..................................................................................................................................11

2.7 Operation.................................................................................................................................. 12

2.8 Use of the optional circuit selector cabinet ............................................................................... 12

2.9 Action in the event of an equipment malfunction...................................................................... 12

2.10 Maintenance and repair............................................................................................................ 12

2.11 CE certification ......................................................................................................................... 13

2.12 Guarantee................................................................................................................................. 13

3 Description

3.1 Series circuit system overview.................................................................................................. 15

3.2 Intended use............................................................................................................................. 15

3.3 Working principle ...................................................................................................................... 16

3.4 Lay-out of the equipment cabinet ............................................................................................. 17

3.4.1 Outside - stackable cabinet 2.5 kVA............................................................................... 17

3.4.2 Inside - stackable cabinet 2.5 kVa .................................................................................. 18

3.4.3 Outside - small cabinet: 2.5 to 15 kVA............................................................................ 19

3.4.4 Inside - small cabinet: 2.5 to 15 kVA .............................................................................. 20

3.4.5 Outside - small cabinet: 2.5 to 15 kVA with CS (option CS) ........................................... 21

3.4.6 Inside - small cabinet: 2.5 to 15 kVA with CS (option CS).............................................. 22

3.4.7 Outside - big cabinet 20 to 30 kVA ................................................................................. 23

3.4.8 Inside - big cabinet 20 to 30 kVa .................................................................................... 24

3.4.9 Outside - big cabinet: 20 to 30 kVA with CS (option CS)................................................ 25

3.4.10Inside - big cabinet: 20 to 30 kVA with CS (option CS) .................................................. 26

3.5 Components ............................................................................................................................. 27

3.5.1 Line input........................................................................................................................ 27

3.5.2 Input filter........................................................................................................................ 29

4A.07.370e - Edition 2.0

3.5.3 IGBT power bridge .........................................................................................................30

3.5.4 Hall sensor, big cabinet ..................................................................................................32

3.5.5 Output filter..................................................................................................................... 32

3.5.6 Main transformer, all cabinets......................................................................................... 33

3.5.7 Output measure PCB (EPS422), all cabinets................................................................. 33

3.5.8 Power output .................................................................................................................. 33

3.5.9 CPU PCB (EPS479), all cabinets ................................................................................... 34

3.5.10Remote control PCB (EPS495), all cabinets .................................................................. 34

3.5.11 Power supply PCB (EPS480), all cabinets ..................................................................... 34

3.5.12Lamp Fault Detection (LFD) ........................................................................................... 35

3.5.13Earth Fault Detection (EFD) ........................................................................................... 35

3.6 Options ..................................................................................................................................... 35

3.6.1 Remote control ............................................................................................................... 35

3.6.2 Ethernet PCB (EPS542), all cabinets............................................................................. 35

3.6.3 Circuit selector (CS) ....................................................................................................... 36

3.6.4 Lightning arrestors (option CS) ...................................................................................... 36

3.6.5 Interface PCB (PCB1702) (option CS) ........................................................................... 36

3.6.6 CS PCB (PCB1619) (option CS) .................................................................................... 36

3.6.7 HMI SIN PCB (PCB1703) (option CS)............................................................................ 37

3.6.8 Remote control SIN PCB (PCB1694) (option CS).......................................................... 37

3.6.9 CS relay (option CS) ......................................................................................................37

3.6.10Current sensor (option CS) ............................................................................................ 38

3.6.11 Series Connector Box (SCB), all cabinets...................................................................... 38

3.6.12Series CutOut (SCO), all cabinets.................................................................................. 38

3.6.13Rolling castors ................................................................................................................ 39

3.7 HMI ........................................................................................................................................... 39

3.8 HMI of an equipment with CS (option CS)................................................................................ 39

3.9 Nameplate ................................................................................................................................ 40

4 Inspection and transport

4.1 Inspect equipment on delivery .................................................................................................. 41

4.2 How to transport the crate ........................................................................................................ 41

4.3 Unpack at installation area ....................................................................................................... 41

4.4 Transport the unpacked equipment .......................................................................................... 42

4.4.1 Transport the equipment with lifting lugs ........................................................................ 42

4.4.2 Transport - small and big cabinet with wheels................................................................ 43

5 Pre-installation

5.1 How to pre-install - general procedure......................................................................................45

5.2 Prepare substation.................................................................................................................... 45

A.07.370e - Edition 2.0 5

5.2.1 Procedure ....................................................................................................................... 45

5.2.2 Substation specifications ................................................................................................ 46

5.2.3 Provide heat dissipation ................................................................................................. 47

5.2.4 Ventilation ....................................................................................................................... 47

5.2.5 External fuse .................................................................................................................. 47

5.2.6 Circuit breakers .............................................................................................................. 47

5.2.7 Disconnection devices.................................................................................................... 48

5.3 Prepare lightning protection...................................................................................................... 48

5.4 Install power supply .................................................................................................................. 48

5.5 Plan cables and lay-out of cables ............................................................................................. 48

5.5.1 Procedure ....................................................................................................................... 48

5.5.2 Plan the cable slack, stackable cabinet.......................................................................... 48

5.5.3 Plan the cable slack, big and small cabinet.................................................................... 48

5.5.4 Plan the cable slack, big and small cabinet (option CS)................................................. 49

5.5.5 Power supply cables and earthing cables ...................................................................... 49

5.5.6 Plan cables to the remote control interface .................................................................... 49

5.5.7 Cables for series circuit .................................................................................................. 50

6 Installation

6.1 Main installation procedure....................................................................................................... 51

6.2 Check pre-installation ............................................................................................................... 51

6.3 Required tools and equipment.................................................................................................. 51

6.3.1 Required safety items.....................................................................................................51

6.3.2 Required meters ............................................................................................................. 52

6.3.3 Required tools ................................................................................................................ 52

6.3.4 Required cables ............................................................................................................. 52

6.4 Inspection ................................................................................................................................. 52

6.5 Switch OFF the power supply................................................................................................... 52

6.6 Remove lower rear panel, big and small cabinet...................................................................... 53

6.7 Install additional earthing, stackable cabinet ............................................................................ 54

6.8 Install additional earthing, big and small cabinet ...................................................................... 54

6.9 Connect power input supply, stackable cabinet........................................................................ 55

6.10 Connect power input supply, big and small cabinet.................................................................. 56

6.11 Connect power input supply, big and small cabinet with CS (option) ....................................... 57

6.12 Connect output to series circuit ................................................................................................ 58

6.12.1Connect output to series circuit with SCB ...................................................................... 58

6.12.2Connect output to series circuit with SCO...................................................................... 59

6.12.3Connect output to series circuit (option CS) ................................................................... 61

6.13 Connect remote control cables................................................................................................. 62

6.13.1Connect multiwire or J-Bus (option) ............................................................................... 62

6.13.2Connect ethernet cable(s) (option) ................................................................................. 63

6.13.3Connect the multiwire cables to the interface PCB (PCB1702) (option CS) .................. 63

6.14 Install lower rear panel.............................................................................................................. 63

6A.07.370e - Edition 2.0

7 Technical data

7.1 Specifications............................................................................................................................ 65

7.2 Applicable standards ................................................................................................................ 66

7.3 ElectroMagnetic Compatibility (EMC) ....................................................................................... 66

7.4 Ambient conditions ................................................................................................................... 67

7.5 Dimensions and mass .............................................................................................................. 68

7.6 Substation layout ...................................................................................................................... 70

7.6.1 Substation layout, stackable cabinet .............................................................................. 70

7.6.2 Substation layout, big and small cabinets ...................................................................... 71

7.7 Protection devices .................................................................................................................... 71

7.8 Remote control PCB (EPS495) ................................................................................................ 73

7.8.1 Printed Circuit Board (PCB) ........................................................................................... 73

7.8.2 Jumper settings .............................................................................................................. 73

7.8.3 Multiwire / J-Bus connection scheme ............................................................................. 75

7.9 Interface PCB (PCB1702) (option CS) ..................................................................................... 80

A.07.370e - Edition 2.0 7

About this manual

1 About this manual

The manual shows the information necessary to:

-install

the CRE 2.5 to 30 kVA:

- 2.5 kVA: stackable cabinet.

- 2.5 to 15 kVA: small cabinet.

- 20 to 30 kVA: big cabinet.

If in the manual the term equipment is used, this refers to the stackable, the small and the big cabinet.

1.1 How to work with the manual

1. Familiarize yourself with the structure and content.

2. Carry out the actions completely and in the given sequence.

1.2 Record of changes

1.3 Icons used in the manual

For all WARNING symbols, see chapter § 2.

Edition Editor Check Date Description

1.0 MR AHU,

MAW,

VDV

09/2011 New

2.0 TWE 2017 Added information about stackable cabinet. Added information

about new in- and output filters. Added CS. Added other

mechanical improvements. Layout changes.

CAUTION

Can cause damage to the equipment.

NOTE

Gives further information.

8A.07.370e - Edition 2.0

About this manual

1.4 Abbreviations and terms

Table: 1.1 Terms and abbreviations

Term or abbreviation Description

AC Alternating Current

AGL Airfield Ground Lighting

CENELEC Comitée Eruopéen de Normalisation ELECtrotechniqe (European Committee

for Electrotechnical Standardization)

CS Circuit Selector

CSM Circuit Selector Module

DC Direct Current

DSP Digital Signal Processor

EFD Earth Fault Detection

EMC Electro Magnetic Compatibility

Equipment The stackable, the small cabinet and big cabinet, if the information is the

same

FAA Federal Aviation Administration

FDT Flash Development Toolkit

HMI Human-Machine Interface

HV High Voltage

ICAO International Civil Aviation Organisation

IGBT Insulated Gate Bipolar Transistor

LFD Lamp Fault Detection

MW Multiwire

PC Personal Computer

PCB Printed Circuit Board

PIC A controller from Microchip.

PVC PolyVinylChloride

PWM Pulse Width Modulation

PE Protective Earth

Remote control system The remote control system in the airport to control the equipment on the field.

RMS Root Mean Square

SCB Series Connector Box

SCO Series Cut Out

SHVS Servo High Voltage Switch

A.07.370e - Edition 2.0 9

Safety

2 Safety

Read all warnings carefully. Failure to do so may result in personal injury, death, or property damage.

2.1 Use

To use the equipment safely:

Refer to the International Standard IEC 61820, Electrical installation for lighting and beaconing of

aerodromes - Constant current series circuits for aeronautical ground lighting - System design and

installation requirements, and to the International Standard IEC 61821, Electrical installations for lighting

and beaconing of aerodromes - Maintenance of aeronautical ground lighting circuits for instructions on

safety precautions.

See FAA Advisory Circular AC 150/5340-26, Maintenance of Airport Visual Aids Facilities, for additional

instructions on safety precautions.

Observe all safety regulations. To avoid injuries, always remove power prior to making any wire

connections and touching any live part. Refer to the International Standards IEC 61820 and IEC 61821.

In addition for a parallel power supply also take into account the International Standard IEC 60598 (for

class I equipment).

Read and become familiar with the general safety instructions provided in this chapter before you install,

operate, maintain or repair the equipment.

Read and carefully follow the instructions given throughout this manual before installing, operating,

maintaining, or repairing the equipment.

Store this manual within easy reach of personnel installing, operating, maintaining or repairing the

equipment.

Follow all applicable safety procedures required by your company, industry standards, and government

or other regulatory agencies.

Obtain and read Material Safety Data Sheets (MSDS) for all materials used.

2.2 Safety symbols

Become familiar with the safety symbols presented in this chapter. These symbols will alert you to safety

hazards and conditions that may result in personal injury, death, or property and equipment damage.

WARNING 1: Failure to observe this warning may result in personal injury, death, or equipment

damage.

WARNING 2: Risk of electrical shock. Disconnect equipment from line voltage. Failure to

observe this warning may result in personal injury, death, or equipment damages.

WARNING 3: Wear personal protective equipment. Failure to observe may result in serious

injury.

WARNING 4: Do not touch. Failure to observe this warning may result in personal injury, death,

or equipment damage.

10 A.07.370e - Edition 2.0

Safety

2.3 Signs on the equipment

The signs on the equipment are part of the safety provisions. Do not cover or remove the signs. The signs

must be present and legible during the entire life of the equipment.

2.4 Skilled personnel

The term skilled personnel is defined here as individual who thoroughly understand the equipment and its

safe operation, maintenance, and repair. Skilled personnel are physically capable of performing the required

tasks, familiar with all relevant safety rules and regulations and have been trained to safely install, operate,

maintain, and repair the equipment. It is the responsibility of the company operating the equipment to see

that its personnel meet these requirements.

DANGER

HAUTE TENSION HIGH VOLTAGE

COUPER LE REGULATEUR

SWITCH REGULATOR OFF

UNLOCK BEFORE OPENING

LINE VOLTAGE : 5000 V.AC. MAX

SERIES CURRENT : 20A.AC. MAX

PN : 1475 92.030

CUTOUT TYPE SCO

DANGER

HAUTE TENSION HIGH VOLTAGE

COUPER L’ALIMENTATION AVANT

TOUTE VERIFICATION OU REPARATION

ALWAYS SWITCH EQUIPMENT OFF

BEFORE INSPECTION OR REPAIR

High leakage current!

Earth connection

essential before connecting

supply and load

Warning!

Switch off the CCR before

connecting or disconnecting

the remote control link

A.07.370e - Edition 2.0 11

Safety

2.5 Liability

ADB Safegate cannot be held responsible for injuries or damages resulting from non-standard, unintended

uses of its equipment. The equipment is designed and intended only for the purpose described in the

manual. Uses not described in the manual are considered unintended uses and may result in serious

personal injury, death or property damage.

Unintended uses includes the following actions:

Making changes to equipment that have not been recommended or described in this manual or using

parts that are not genuine ADB Safegate replacement parts or accessories.

Failing to make sure that auxiliary equipment complies with approval agency requirements, local codes,

and all applicable safety standards if not in contradiction with the general rules.

Using materials or auxiliary equipment that are inappropriate or incompatible with your ADB Safegate

equipment.

Allowing unskilled personnel to perform any task on or with the equipment.

2.6 Installation

Read the installation section of all system component manuals before installing your equipment. A thorough

understanding of system components and their requirements will help you install the equipment safely and

efficiently.

Allow only skilled personnel to install ADB Safegate and auxiliary equipment. Use only approved

equipment. Using unapproved equipment in an approved system may void agency approvals and will

void the warranty.

Make sure all equipment is rated and approved for the environment in which you are using it.

Follow all instructions for installing components and accessories.

Install all electrical connections to local code provided they are not in contradiction with the general rules.

Use only electrical wire of sufficient gauge and insulation to handle the rated current and voltage

demand. All wiring must meet local codes.

Route electrical wiring along a protected path. Make sure they will not be damaged by moving equipment

and animals (e.g. rodents).

Protect components from damage, wear, and harsh environment conditions.

Allow ample room for maintenance, panel accessibility (power products), and cover removal (power

products).

Protect equipment with safety devices as specified by applicable safety regulations.

If safety devices must be removed for installation, install them immediately after the work is completed

and check them for proper functioning.

WARNING

Use of the equipment in ways other than described in the catalogue leaflet and the manual

may result in personal injury, death, or property and equipment damage. Use this

equipment only as described in the manual.

WARNING

Failure to follow these safety procedures can result in personal injury or death.

12 A.07.370e - Edition 2.0

Safety

2.7 Operation

Only skilled personnel, physically capable of operating the equipment and with no impairments in their

judgment or reaction times, should operate this equipment.

Read all system component manuals before operating the equipment. A thorough understanding of system

components and their operation will help you operate the equipment safely and efficiently.

Before starting this equipment, check all safety interlocks and protective devices such as panels and

covers. Make sure all devices are fully functional. Do not operate the equipment if these devices are not

working properly. Do not deactivate or bypass automatic safety interlocks or locked-out electrical

disconnects or pneumatic valves.

Never operate equipment with a known malfunction.

Do not attempt to operate or service electrical equipment if standing water is present.

Use the equipment only in the environments for which it is rated. Do not operate the equipment in humid,

flammable, or explosive environments unless it has been rated for safe operation in these environments.

Never touch exposed electrical connections on equipment while the power is ON. Make sure the exposed

electrical connections are proven to be dead.

2.8 Use of the optional circuit selector cabinet

If the optional circuit selector cabinet is installed below the cabinet of the equipment, prevent situations

where the equipment can tilt and fall. The circuit selector cabinet has an effect on the weight balance of the

equipment. A falling equipment can result in personal injury or death.

2.9 Action in the event of an equipment malfunction

Do not operate a system that contains malfunctioning components. If a component malfunctions, turn the

system OFF immediately.

1. Disconnect and lock out electrical power.

2. Allow only skilled personnel to make repairs. Repair or replace the malfunctioning component according

to instructions provided in its manual.

2.10 Maintenance and repair

Allow only skilled personnel to perform maintenance, troubleshooting, and repair tasks. Only persons who

are properly trained and familiar with ADB Safegate equipment are permitted to service the equipment.

Always use safety devices when working on the equipment.

Follow the recommended maintenance procedures in your equipment manuals.

Do not service or adjust any equipment unless another person trained in first aid and Cardio Pulmonary

Resuscitation (CPR) is present.

Connect all disconnected equipment ground cables and wires after servicing equipment. Ground all

conductive equipment.

Use only approved ADB Safegate replacement parts. Using unapproved parts or making unapproved

modifications to equipment may void agency approvals, impair specified performance and create safety

hazards.

Check interlock systems periodically to ensure their effectiveness.

Do not attempt to service electrical equipment if standing water is present. Use caution when servicing

electrical equipment in a high-humidity environment.

Use tools with insulated handles when working with electrical equipment.

A.07.370e - Edition 2.0 13

Safety

2.11 CE certification

The equipment is CE certified. It means that the product complies with the essential requirements

concerning health and safety. The directives that have been taken into consideration in the design are

available on written request to ADB Safegate.

2.12 Guarantee

ADB Safegate guarantees that the performance of the equipment described in this manual, when sold by

ADB or its licensed representatives, meets the corresponding requirements of FAA, ICAO and IEC.

Refer to the document ‘General Conditions for Deliveries and Services by ADB Safegate.

14 A.07.370e - Edition 2.0

Safety

Description

A.07.370e - Edition 2.0 15

3 Description

3.1 Series circuit system overview

A Input power supply

B Manual switch

C Remote control system

D Equipment

E Output disconnection device (optional)

F Series circuit

The equipment is a microprocessor-controlled constant current regulator with an optional output

disconnection device (circuit selector).

3.2 Intended use

The equipment is designed to convert an AC sine wave input voltage into an adjusted output current

selected in brightness steps to supply a series AGL circuit.

Any other or additional use will be considered not to be in conformity with the purpose.

Do not operate the equipment outside the limits of the specifications or outside the specified ambient

conditions.

ABD

C

EF

16 A.07.370e - Edition 2.0

Description

3.3 Working principle

A Line input.

B Input filter. See § 3.5.2.

C Diode bridge and sensing PCB, components of the IGBT power bridge. See § 3.5.3.

D IGBT module and IGBT PCB, components of the IGBT power bridge. See § 3.5.3.

E Output filter. See § 3.5.5.

F Main transformer. See § 3.5.6.

G Output measure PCB. See § 3.5.7.

H Lightning arrestors. See § 3.5.8.

I Circuit selector (optional). See § 3.6.3.

J Series output connection. See § 3.6.

K CPU PCB. See § 3.5.9.

L HMI. See § 3.7.

M Remote control PCB. See § 3.5.10.

N Power supply PCB. See § 3.5.11.

Legend

- Red lines: current

- Green lines: signal wires connections

- Black lines: low voltage connections

Current regulation

The equipment converts the single phase input voltage line into a rectified current and voltage. Then, the

equipment converts this DC current and voltage into a pure sine wave with a defined power rating.

Main feedback loop

The output measure PCB sends the measured output to the CPU PCB. Depending on the output, the CPU

PCB automatically generates a signal to adjust the regulation.

1

5

9

5

9

2

6

0

3

7

.

4

8

CANCEL

ON

REMOTE

OFF

ENTER

LOCAL

ACBDEFG

H

I

OUT

J

M

KN

L

IN

A.07.370e - Edition 2.0 17

Description

3.4 Lay-out of the equipment cabinet

3.4.1 Outside - stackable cabinet 2.5 kVA

A Ventilation grids

BHMI

C Serial communication port

D Manual switch

E Remote control connector

F Series output connection. The illustration shows the SCB.

G Output to Series Circuit

H Power supply connector

A

B C D E

A

A

A A H

F G

A

18 A.07.370e - Edition 2.0

Description

3.4.2 Inside - stackable cabinet 2.5 kVa

A Lightning arrestors

B Input filter

C Output filter

D Manual switch

E Sensing transformer

F Power supply transformer

GIGBTs

H IGBT-PCBs (EPS477)

I Diode bridge + sensing PCB (EPS476)

J CPU PCB (EPS479)

K Power supply PCB (EPS480)

L Remote control PCB (EPS495)

M Line filter

N Main transformer

O Output measure PCB (EPS442)

P Main contactor

Q Main fuses

A B C D L

GHIHG

KJ

Q P O M

N

F E

A.07.370e - Edition 2.0 19

Description

3.4.3 Outside - small cabinet: 2.5 to 15 kVA

A Ventilation grids

BHMI

C Serial communication port

D Manual switch

E Remote control connector

F Series output connection. The illustration shows the SCO.

G Output to Series Circuit

H Ethernet connector

I Power supply cable entry

C

A

A

B

D

A

A

I

G

F

E

H

AA

20 A.07.370e - Edition 2.0

Description

3.4.4 Inside - small cabinet: 2.5 to 15 kVA

A Output filter

BCPU PCB

C Main fuses

D Main contactor

E Sensing transformer

FIGBT

G IGBT PCB (EPS477)

H Diode bridge and sensing PCB (EPS476 / EPS507)

I Power supply PCB (EPS480)

J Input filter

K Remote control PCB (EPS495)

L Lightning arrestors

M Output measure PCB (EPS442)

N Input terminals

O Line filter

P Main transformer

Q Power supply transformer

Note

The illustrations show the 10 kVA cabinet.

KK

L

M

N

O

PQ

B

A

J

C

D

E

F

H

I

G

G

F

This manual suits for next models

8

Table of contents

Other ADB Safegate Controllers manuals

Popular Controllers manuals by other brands

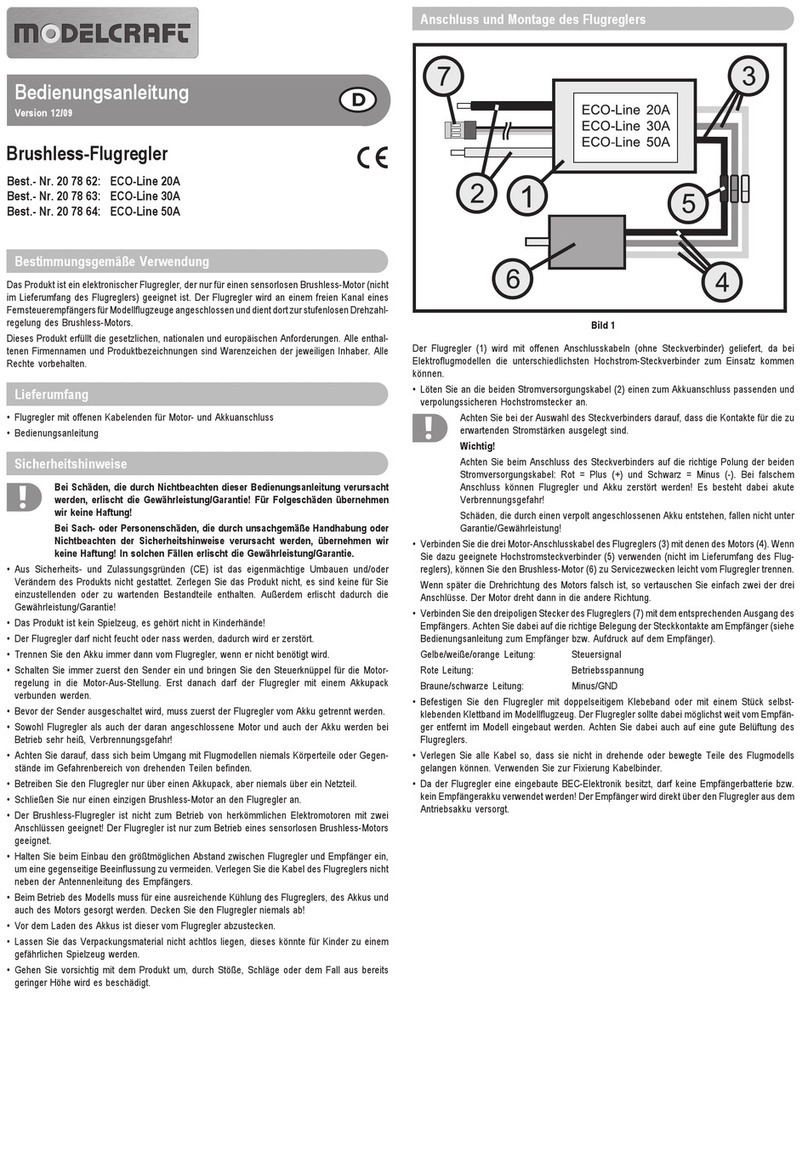

ModelCraft

ModelCraft ECO-Line 20A operating instructions

Profelmnet

Profelmnet 6033 installation manual

Johnson Controls

Johnson Controls IQ Keypad-PG installation manual

AIMS Power

AIMS Power SCC-20A MPPT Installation and operation manual

Gelec

Gelec DLLC7000 User's & technical manual

Parkside

Parkside PDWE 8 B2 Translation of the original instructions

Festo Pneumatic

Festo Pneumatic SDK-3-PK-3 operating instructions

Sysmac

Sysmac CQM1 Operation manual

Crane Source

Crane Source Space Vector SV100 Installation, Programming & Service manual

AAON

AAON MUA II Technical guide

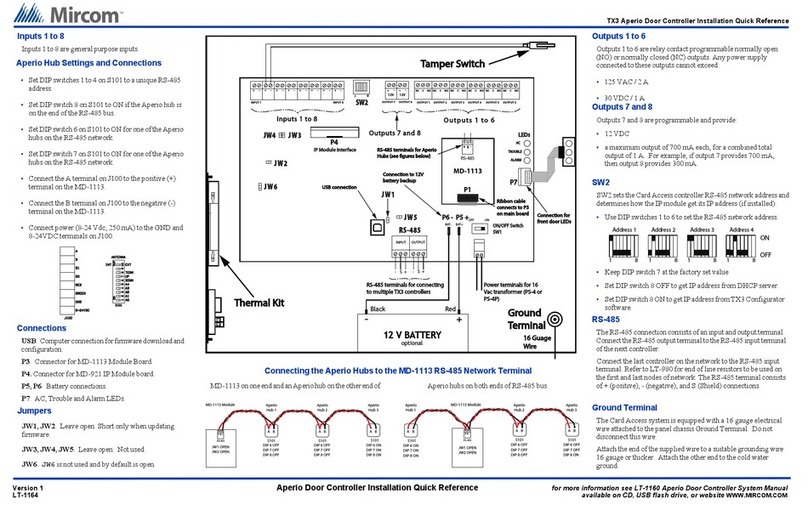

Mircom

Mircom TX3 Series Installation quick reference

Sit

Sit 810 ELETTROSIT quick start guide