107

DANSK DEUTSCH

ENGLISH FRANCAIS

Elektroniske regulatorer

EKC 201: Til indbygning i tavle.

EKC 301: Til montering på DIN-

skinne.

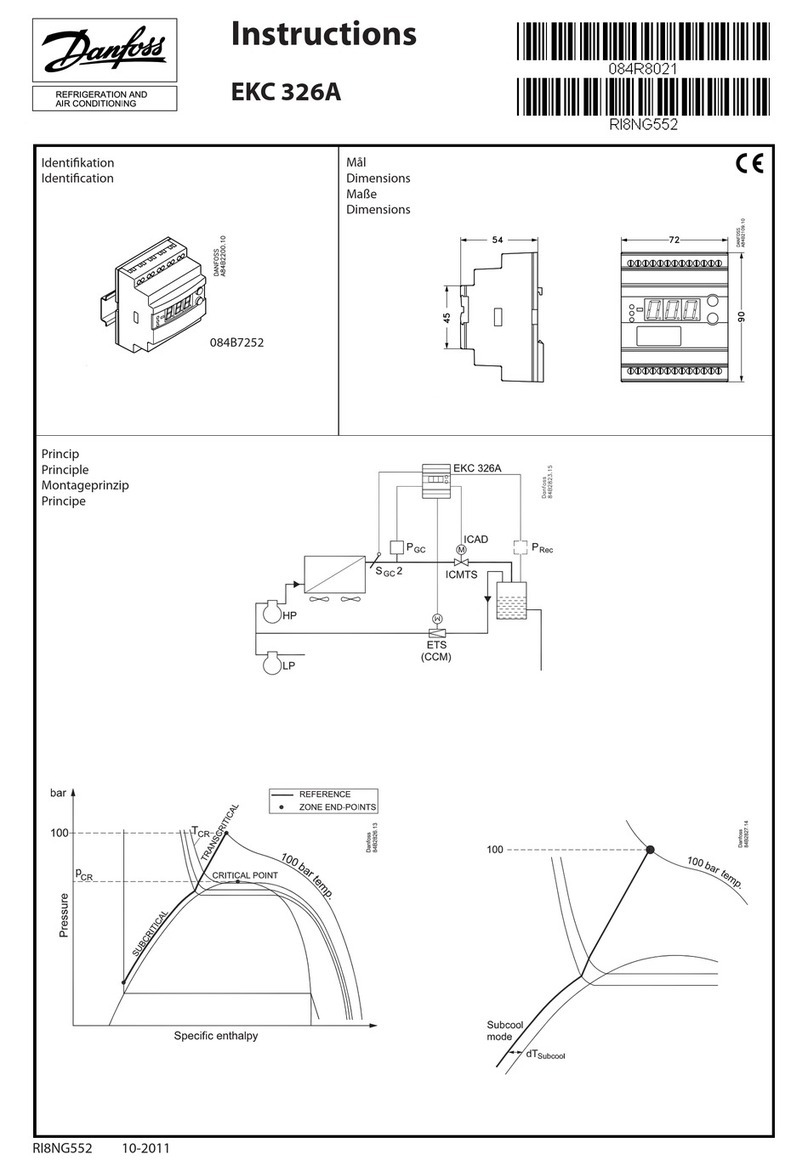

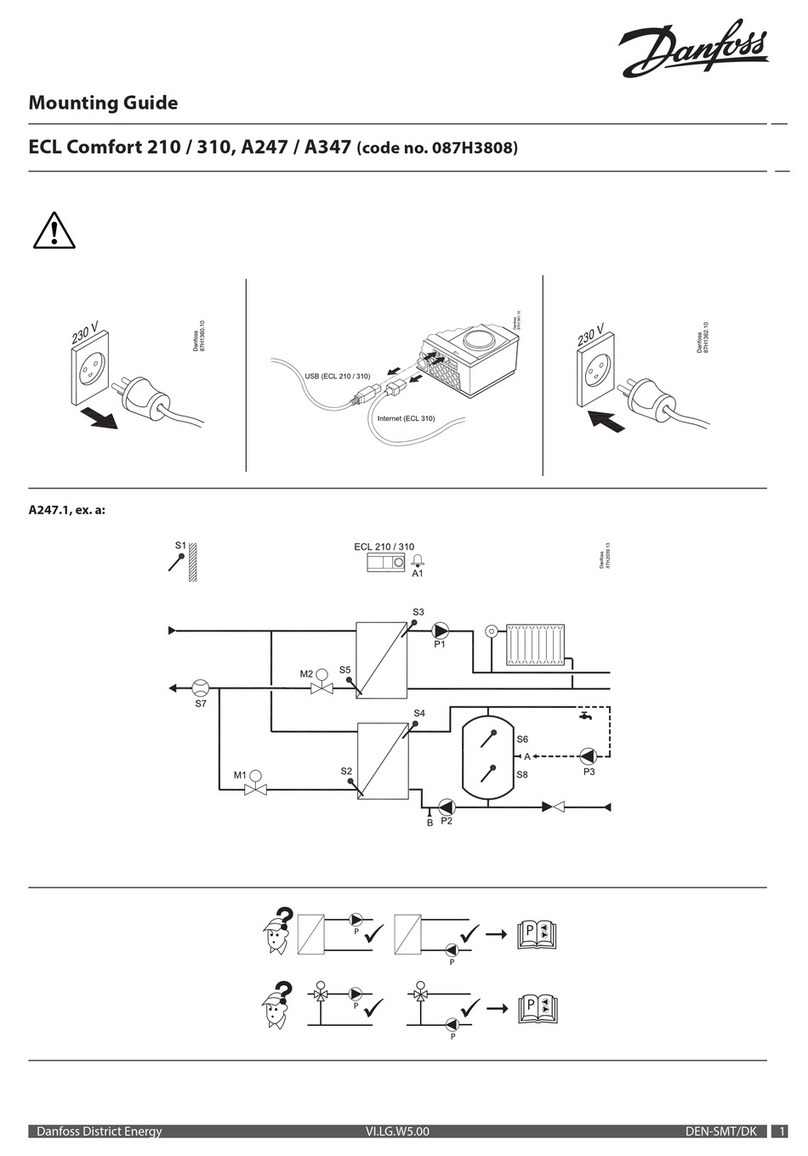

Montering Se fig. 1-4 og fig. 8.

El-tilslutning

Se fig. 5-7 samt el-diagram på

apparatet.

12 V regulatorerne skal tilsluttes

separat transformer på min. 3 VA.

Betjening

(Se fig. 9).

1. Lysdiode

= køling

= afrimning

= ventilator i gang

Blinker langsomt ved indstilling

Blinker hurtigt ved alarm

2. Minustegn.

3. Display.

(Blinker når indstillingsværdien

for rumtemperaturen vises).

4. Taster til programmering og

indstilling

(se programmeringsvejledning).

Programmering og indstilling

Se programmeringsvejledningen og

indstillinger.

Tryk på øverste tast i 2 s.

Tryk på nederste tast i 2 s.

Tryk på begge taster samtidigt.

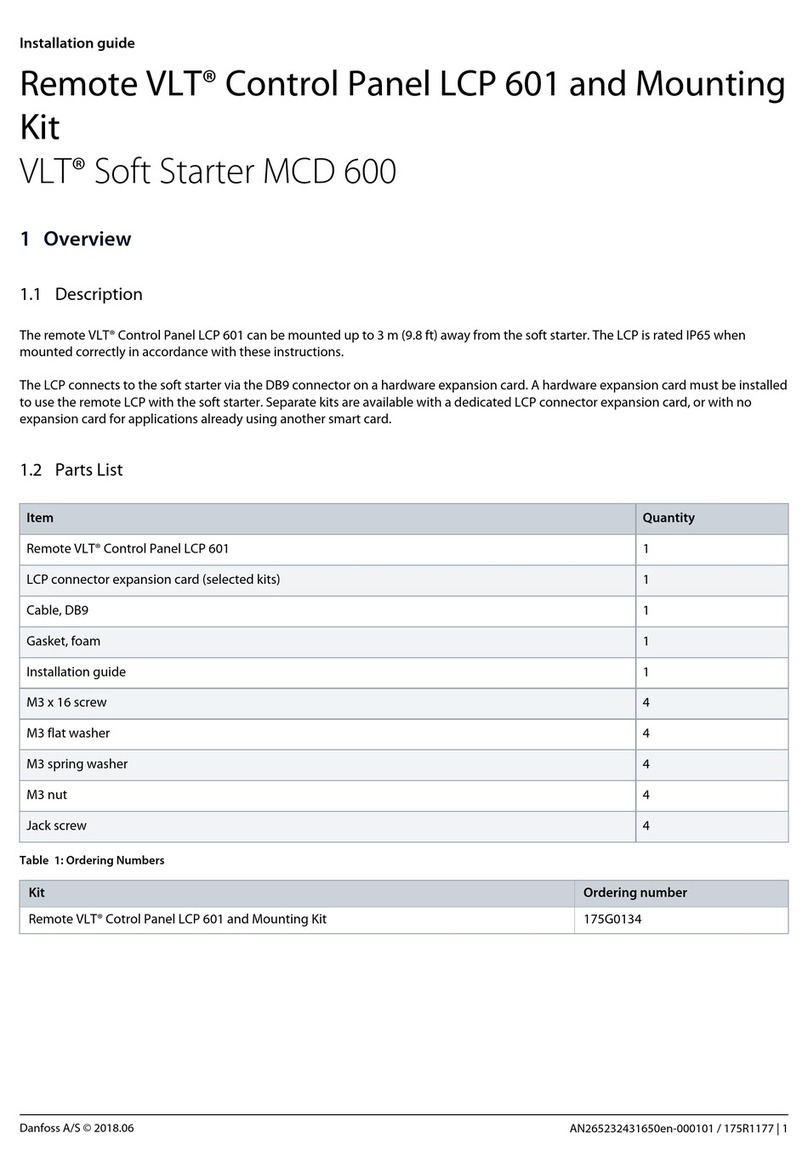

Electronic controllers

EKC 201: For panel mounting

EKC 301: For DIN-rail mounting

Installation See figs. 1-4 and fig. 8.

Electrical connection

See figs 5-7 and electrical diagram

on unit.

The 12 V controllers must be con-

nected separately: transformer of

min. 3 VA.

Operation

(See fig. 9).

1. Light emitting diode

= refrigeration

= defrost

= fan running

Flashes slowly at setting

Flashes fast at alarm

2. Minus sign

3. Display

(Flashes when setting value for

room temp. is displayed).

4. Keys for programming and

setting

(see programming instructions).

Programming and setting

see programming instructions and

settings.

Press upper key for 2 s.

Press lower key for 2 s.

Press both keys at the same

time.

Elektronische Regler

EKC 201: Für den Schalt-

tafeleinbau.

EKC 301: Für die Montage auf

DIN-Schiene.

Montage Siehe Abb. 1 - 4 und

Abb. 8.

Elektrischer Anschluß

Siehe Abb. 5-7 sowie Schaltplan

am Regler.

12 V-Regler müssen an separaten

Trafo von min. 3 VA angeschlossen

werden.

Bedienung

(Siehe Abb. 9).

1. Leuchtdiode

= Kühlung

= Abtauung

= Lüfter läuft

Blinkt langsam bei Einstellung

Blinkt schnell bei Alarm

2. Minuszeichen

3. Display

(Blinkt, wenn der Einstellwert

der Raumtemperatur angezeigt

wird).

4. Tasten zur Programmierung

und Einstellung. (Siehe

Programmierungsanleitung).

Programmierung und

Einstellung

Siehe Programmierungsanleitung

und Einstellungen.

Obere Taste für 2 s betätigen.

Untere Taste für 2 s betätigen.

Beide Tasten gleichzeitig

betätigen.

Régulateurs électroniques

EKC 201 : pour montage sur tableau

EKC 301 : pour montage sur rail DIN

Montage

Voir fig. de 1 à 4 et fig. 8.

Connexion électrique

Voir fig. 5-7 ainsi que le diagramme

électrique sur l’appareil.

Les régulateurs de 12 V doivent se

brancher sur un transformateur

séparé d’au moins 3 VA.

Utilisation

(Voir fig. 9).

1. Diode lumineuse

= refroidissement

= dégivrage

= ventilateur en fonction

Clignotement lent pendant le

réglage

Clignotement rapide en cas

d‘alarme

2. Signe moins (-).

3. Affichage.

(Clignote quand la température

de réglage est atteinte).

4. Touches pour programmation et

réglage (voir instructions de

programmation).

Programmation et réglage

Consulter les instructions de

programmation et les réglages.

Presser sur la touche

supérieure pendant 2 sec.

Presser sur la touche inférieure

pendant 2 sec.

Presser sur les deux touches en

même temps.

Fig. 9

ESPAÑOL ITALIANO

Controllore elettronico

EKC 201: per montaggio su

pannello

EKC 301: per montaggio su barra

DIN

Installazione Vd. Fig. 1-4 e fig. 8.

Connessioni elettriche

Vedi fig. 5-7 e gli schemi elettrici

I regolatori 12 V devono essere

collegati ad un trasformatore

singolo da 3VA.

Funzionamento

(vd Fig. 9).

1. Led luminoso

= refrigerazione

= sbrinamento

= ventilatore

Il led lampeggia lentamente

durante l‘impostazione

parametri

Il led lampeggia velocemente

durante un allarme

2. Segno meno

3. Display

(lampeggia durante

l’impostazione temp.

ambiente).

4. Tasti per programmare e tarare

(vedi le istruzioni di

programmazione)

Programmare e tarare

Vedi le istruzioni di

programmazione

Premi il tasto superiore per

2 secondi

Premi il tasto inferiore per

2 secondi

Premi entrambi i tasti allo

stesso tempo

Controlador electrónico

EKC 201: Para montaje en panel

EKC 301: Para montaje en rail DIN

Instalación Ver fig. 1-4 y fig. 8.

Conexionado eléctrico

Ver fig. 5-7 y diagrama electrico de

la unidad.

Los controladores de 12 V se

deben conectar por separado:

transformador minimo de 3VA.

Operación

(Ver fig. 9).

1. LED Diodo luminoso

= refrigeración

= desescarche

= marcha de ventiladores

Parpadea ligeramente al

ajustarse

Parpadea rapidamente en

estado de alarma

2. Signo menos

3. Pantalla

(Parpadea cuando se realiza el

ajuste de la temperatura).

4. Botones de programación y

ajustes

(ver instrucciones de

programación).

Programación y ajustes

Ver instrucciones de programación

y ajustes.

Pulsar el boton superior durante

dos segundos

Pulsar el boton inferior durante

dos segundos

Pulsar los dos botones a la vez