MegaSquirt DBWX2 User manual

Users manual

DBWX2 Controller

Not For Release (BETA)

Table of contents

1. Introduction

2. I/O and pinout

3. Wiring

a. Crimping the connector pins

b. Assembling the connector

4. Wiring diagrams

a. Power and CAN-bus

b. Accelerator pedal

c. Throttlebody

5. Updating the controller

6. Understanding fault codes

a. ARM fault codes

b. AVR fault codes

7. PID Settings

a. Operating modes

b. Throttlebody specific settings

8. Configuring fault output

9. Step by step initial configuration guide

a. Setting up DBW throttle to MegaSquirt 3

Trademark Legal Notice. All product names, trademarks and registered trademarks are property

of their respective owners. All company, product and service names used in this document are

for identification purposes only. Use of these names,trademarks and brands does not imply

endorsement.

1

Introduction

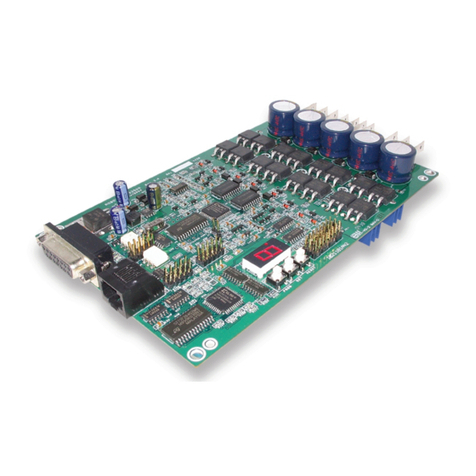

DBWX2 controller

Features include 2 independent channels for drive by wire throttles. Both channels have

independent PID controller that is user configurable.

Safety is handled by using dual cpus. The redundant cpu architecture makes the controller one of

the safest in the industry. Both cpus monitor the pedal and throttle butterfly positions

independently and will disable the throttle if a malfunction in the system is detected.

2

I/O and pinout

The controller has six 0-5V analog inputs for pedal and drive by wire throttle body position

sensors. These inputs are protected from short to ground and +12V.

The controller has four 5V reference voltage outputs to be used as pedal and dbw position

sensor reference voltage. These outputs are protected from short to ground.

Two full bridge outputs to be used to drive the brushed DC motors in DBW throttlebodies. These

outputs are protected from short to ground and +12V.

Gray connector

1:DBW1

motor -

2: DBW1

motor +

3: DBW1 ref

5v out

4: DBW2 ref

5v out

5: DBW2

motor -

6: DBW2

motor +

7: DBW1 ref

gnd

8: DBW1

main sense

in

9: DBW1

secondary

sense in

10: DBW2 ref

gnd

11: DBW2

main sense

12: DBW2

secondary

sense

Black connector

1: +12V IN

2: +12V in

3: Pedal main

5v out

4: Pedal main

sense in

5: CAN-L

6: CAN-H

7: GND IN

8: GND IN

9: Pedal

secondary 5v

out

10: Pedal

secondary

sense in

11: Pedal

reference

gnd

12: DBW

fault output

3

Wiring

Steps to take for a good install with custom wiring

1. Make sure that you have the proper crimping tools

2. Use proper gauge wire

Connector and pin part numbers:

Molex MX150 Black connector: 33472-1201

Molex MX150 Gray connector: 33472-1202

Molex MX150 Pins for 22AWG: 33012-2003

Molex MX150 Pins for 18-20AWG: 33012-2002

Molex MX150 Pins for 14-16AWG: 33012-2001

Wire gauge:

Use 14AWG or 16AWG wire as the power input and ground input to the controller. Motor wires to

the throttlebodies can be smaller but recommendation is 16AWG. Sensor wires do not carry large

currents so they can be freely selected by the installer / loom maker. Use correct pin sizing to the

wiring as per Molex connector specifications.

Proper crimping:

As the currents that flow through the controller are large, it is extremely important to have the

best possible connections from the wires to the controller, battery and throttlebody. If a

connection exceeds the nominal connection resistance (read: badly crimped), it will reap havoc to

the analog signals and cause unstable operation!

4

Crimping wires to connector pins

Step 1:

Strip the correct amount of insulation from the wire. The stripped copper must be slightly longer

than the tab that will be crimped over it.

Step 2:

Crimp the tab that holds the wires copper strands in place.

Note how the copper protrudes from the crimped portion. If no copper is showing the crimp is

faulty and must be dismissed. Tug on the wire to verify proper crimp. The wire should not be

loose!

5

Step 3:

Crimp the tab that holds on to the insulation of the wire.

Now the wire has been properly crimped to the connector pin and can be inserted to the

connector.

Note:

It is necessary to use a proper crimping tool. This ensures correct power transfer between wire

and connector. It is not possible to crimp these connectors with regular pliers that are not

intended for crimping. The pictured connector was crimped with “Hozan P-706” crimpers that are

affordable even for the hobbyist. Added bonus is that the crimpers can be utilized with most of

the open barrel automotive connectors.

Soldering:

Do not solder! Soldering the connectors may result in the wires cracking at the connector end.

Also if solder gets inside the pin, it will lock the spring in the pin connector resulting intermittent

failures. This type of failure is especially nasty because it will not show up when measuring the

loom with a continuity tester, as the actual failure point is in the mated connector. It is best to use

50 bucks to get the proper crimp tool than to pay big money to a shop to troubleshoot your

install.

6

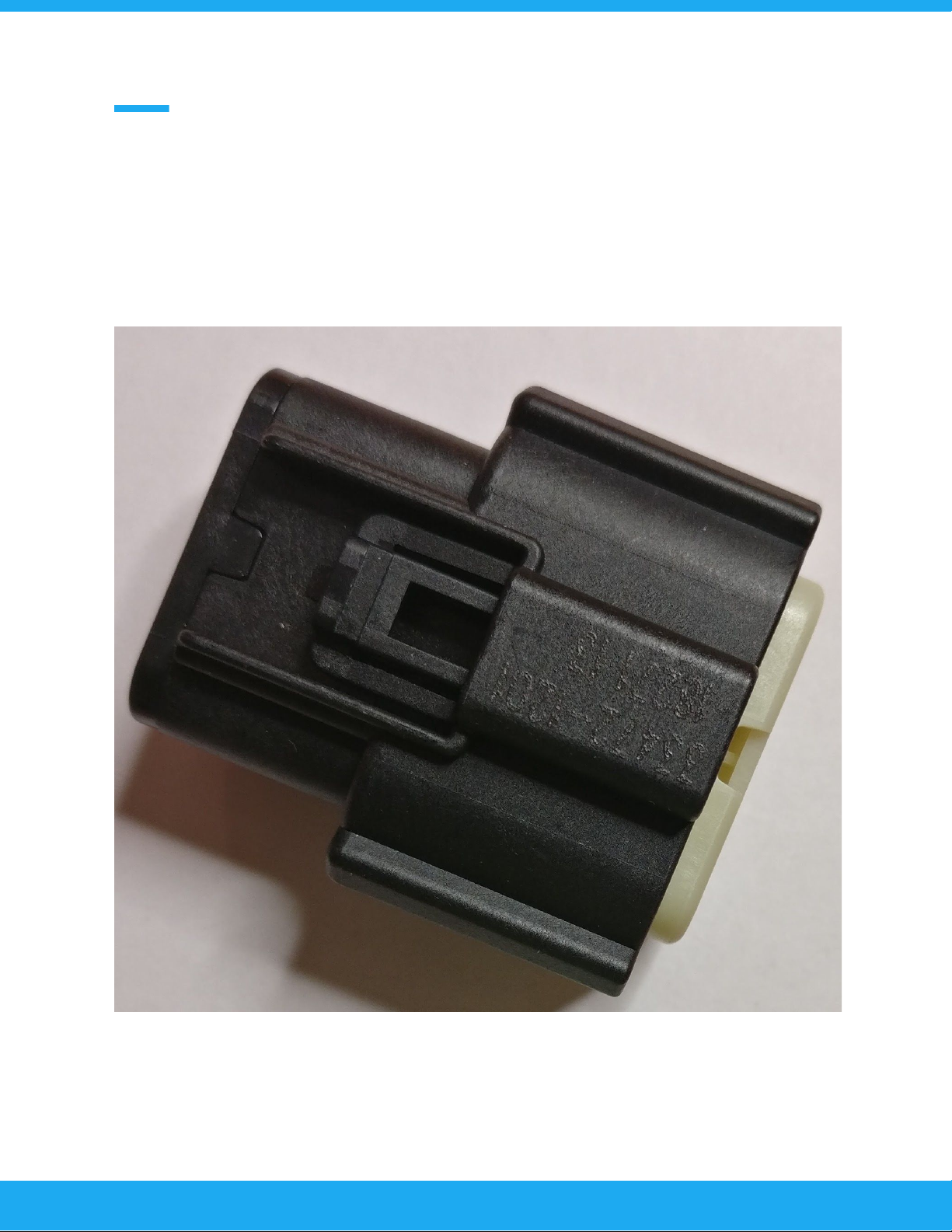

Inserting the crimped pin into the connector body

Step1:

Make sure that the “white” plastic part from inside the connector is pulled out. This can be

verified by making sure that the plastic piece is protruding from the connector. If the plastic is not

showing, you can use a small screwdriver to pry it out from the connector.

7

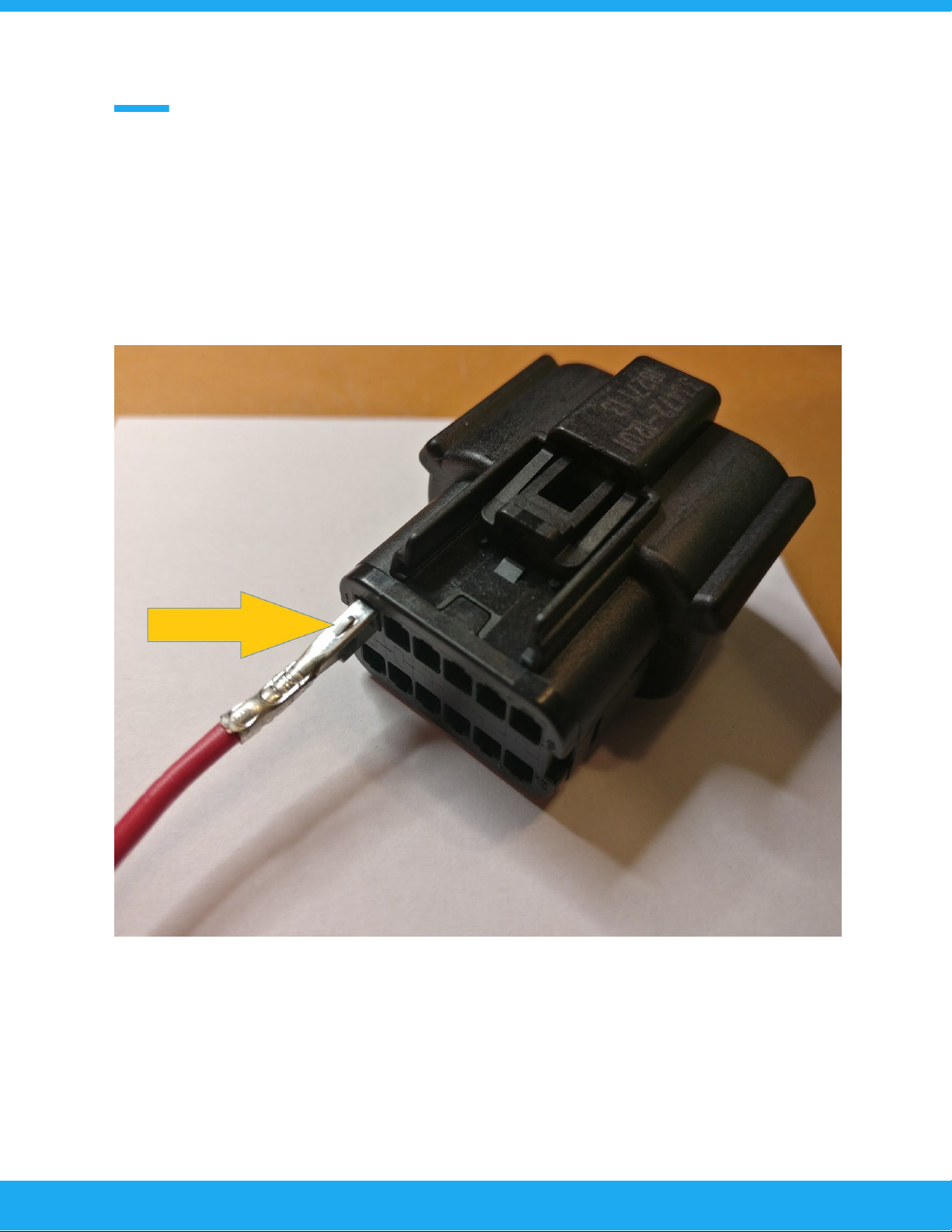

Step 2:

Insert the crimped pin from behind the connector body. There is a small dimple on the pin that

marks the correct orientation of the pin. Top row has the dimple on top and bottom row at

bottom. You can hear an audible click as the connector is seated. Tug on the wire to confirm

proper pin seating.

After all pins have been inserted push the “white” plastic piece in to the connector to lock all the

pins in place. Now the wiring of the connector is complete.

8

Wiring diagrams

Power and CAN-bus wiring

Use a 10A fuse. The controller will use the fuse as part of the polarity protection.

GND connections should be connected to the battery negative terminal without interrupts. This

results in the best operation.

From electronics revision C onvard controller has a user programmable CAN-bus termination

resistor that can be enabled from the tuning software. Also an open collector output has been

added. This is a grounding type output. This is intended to be used as a “main power” for the

engine to provide an additional layer of safety. Installer can configure this output to be normally

open / normally closed or PWM.

9

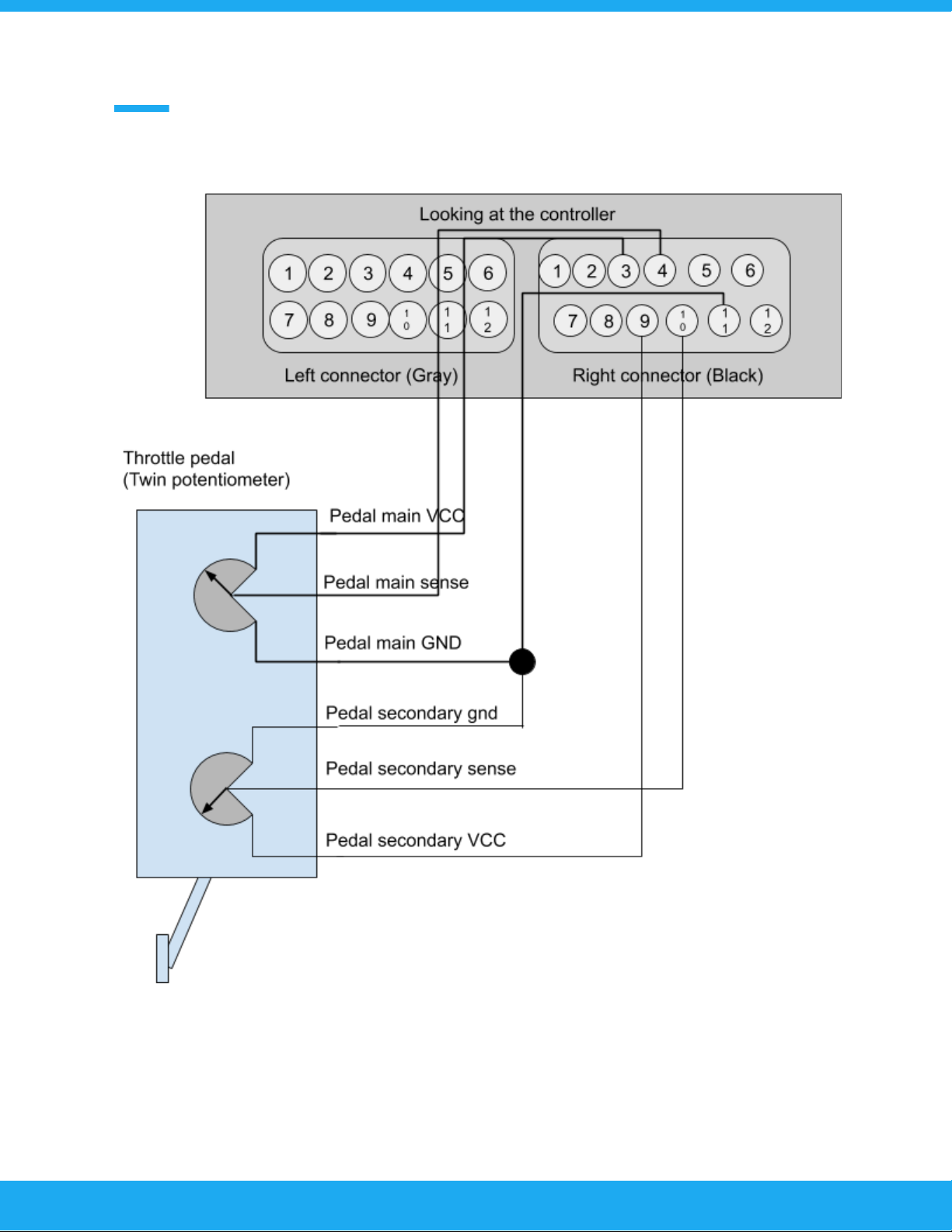

Wiring the accelerator pedal

10

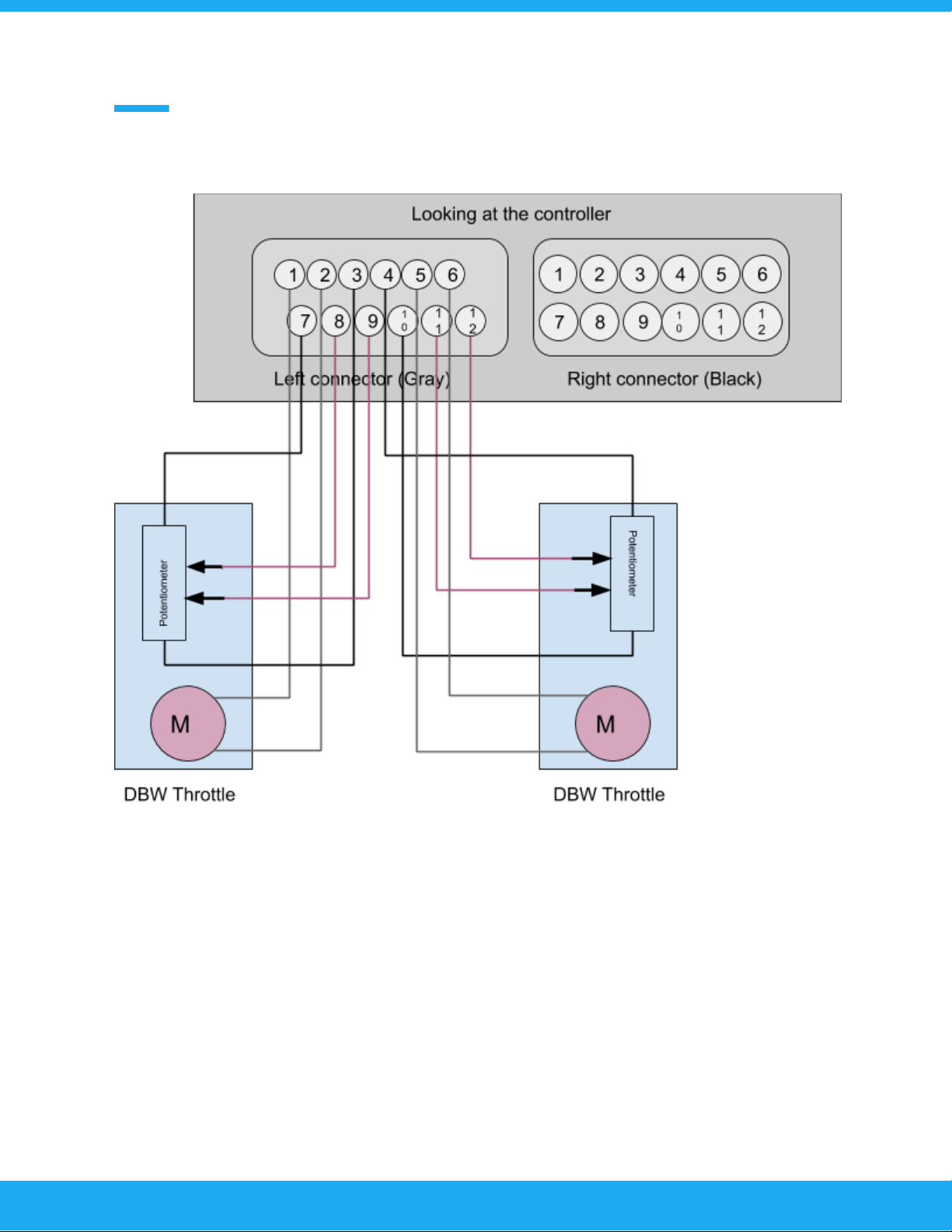

DBW connections

11

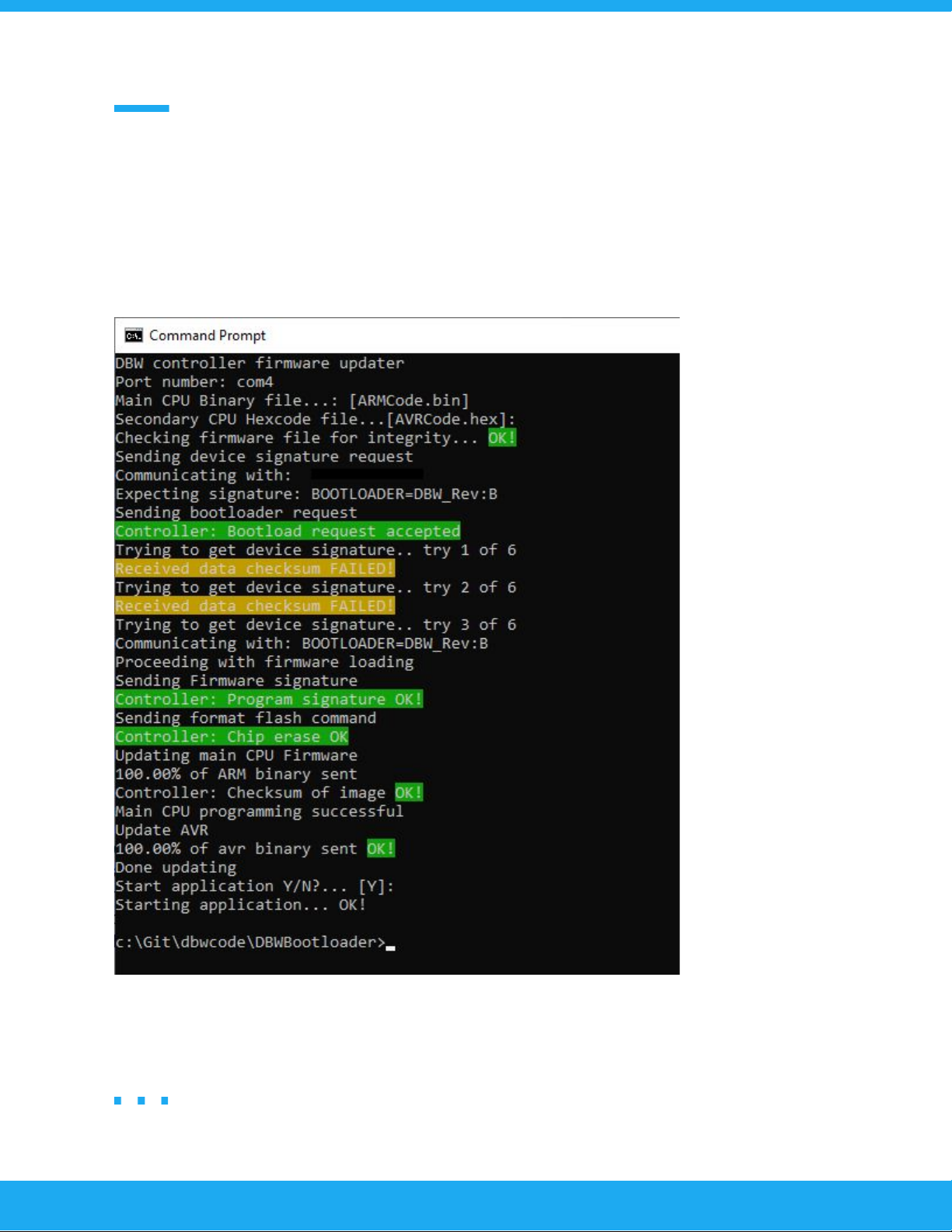

Updating the controller

To update the controller it must be powered from a 12V source. Shut down Tunerstudio if its

running. After unzipping the firmware update you should see firmwareupdater.exe (or similar

name). Double click on it to start the update.

You can press [ENTER] for every question so that defaults will be selected. Successful update can

be verified by connecting to the controller with Tunerstudio.

12

Understanding fault codes

ARM Fault codes

Fault code system was added to aid in fault finding. It is

important to understand what causes a particular error

condition in the controller.

BOD error: This is a CPU error that is caused by a low

voltage condition to reset the cpu. Causes include

external error on 5V reference voltage output and internal

power supply failure.

WDT error: This is a CPU error. The CPU has taken too

long to do a task and that has triggered the internal

watchdog timer. The firmwares are tested and it is not

normal to see this error.

Input voltage error: This warning is tripped if the input

voltage goes momentarily below 11 volts. This is an aid to

the installer to check the wiring to the controller if this

warning is shown.

Pedal main and secondary sensor error: This error is

triggered if the input voltage from the accelerator pedal sensor is out of calibrated specification.

Pedal sync error: This error is triggered if the calculated percentage values from main and

secondary sensors differ by a user set amount. This is only done in “linear” throttle calibration

mode. If the “table” calibration is done this error is set if the secondary sensor voltage differs

from the value read from the table.

DBW sensor errors are exactly same as pedal errors.

DBW tracking error: If the DBW actual position does differ too much from the target position this

error is set.

13

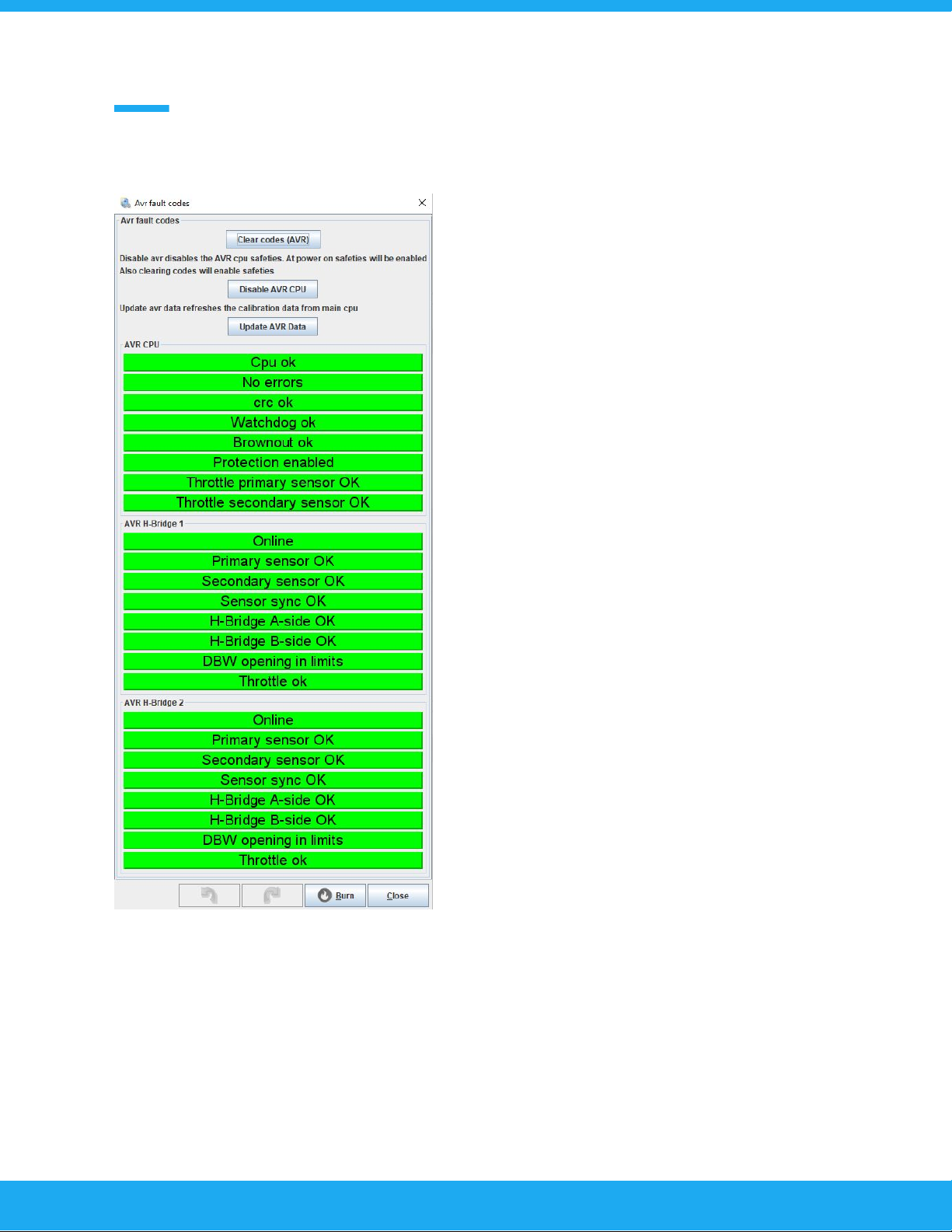

AVR Fault codes

The AVR cpu has the same fault diagnosis as the

main ARM cpu. The reason behind the addon of a

secondary CPU is redundancy. If the main cpu failed

such that it would command the throttle(s) open, the

secondary cpu will still be able to save the situation

by disabling the DBW(s) completely.

Clear codes button: Self explanatory.

Disable AVR CPU button: This disables the fault

checking of the secondary CPU. This is mandatory

for calibration purposes. The disabled status is

shown by the “protection enabled / disabled”

indicator.

Update AVR data button: This button makes the

main CPU to resend the calibration data to the AVR

CPU. If a fault condition is not cleared by clear

button, try to update the avr data to see if the fault

condition was caused by calibration data mismatch.

The sensor fault codes are the same as in the ARM

fault code menus.

Compared to the ARM codes there are a few extras.

The AVR CPU monitors the H-bridge statuses and

these can be seen from this menu. If a H-Bridge

error status is flagged and nothing else it means that

the H-Bridge output has a short or the bridge driver

has overheated. This error may also be displayed

when the h-bridge is disabled from other error

sources.

DBW opening in limits: If the DBW is opened more that what has been defined in the “DBW

Maximum opening” tables triggers this error.

14

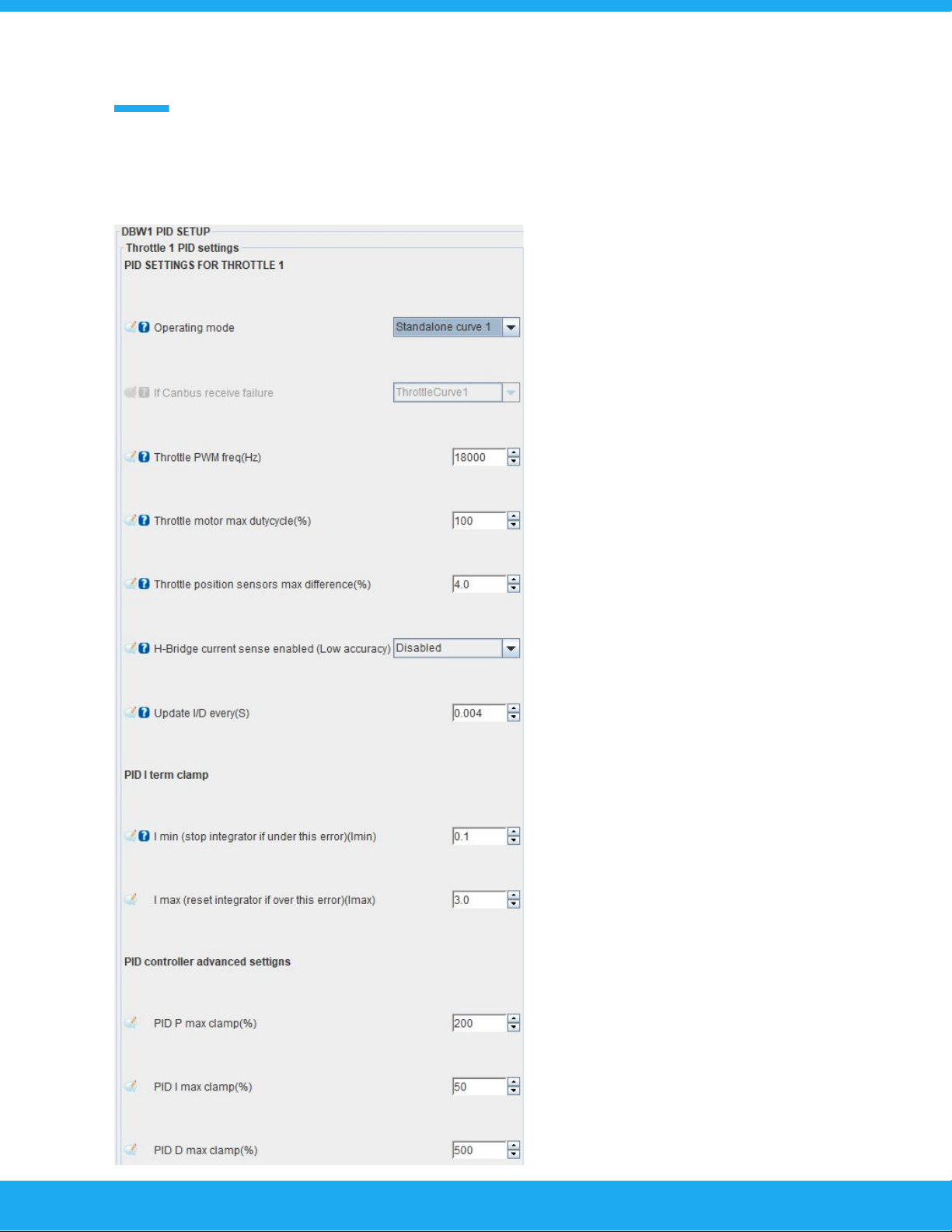

PID Settings

Operating modes:

-Off : Channel is offline

-Standalone curve 1 & 2: Controller is in

standalone mode and will use throttle

curve 1 or 2 to map the opening of the

DBW throttlebody to the accelerator

pedal position.

-MS Can: Controller will receive the

DBW throttlebody opening request from

CAN-bus. The next setting below is

what will the controller do if the

CAN-bus message is not received for

any reason. Selectable options are “off”

or one of the throttle curves.

Throttlebody specific

settings:

-Throttle PWM Frequency: This setting

selects the operating frequnecy. Range

is from 750Hz to 20000Hz. The

H-Bridge works at better efficiency if a

lower frequency is selected, but there

will be an audible noise from the DBW

throttlebody.

Throttle motor max dytycycle: This

setting can be used to limit the

maximum current that the DBW motor

can take. Usually left at 100%

Throttle sensor max difference: This

setting tells the controller at what

15

sensor difference will a fault be triggered. Default value is 4%

H-Bridge current sense enable: This setting enables the current sense circuitry in the H-Bride.

This circuitry is around 15% accuracy from full scale (30A). This means that it cannot be used for

precision measurement, but it can measure relative changes in current. Enabling this will enable

logging of the current and the current gauge. If this setting is disabled the current gauge will

display 0A.

Update I/D: This is the PID controller update frequency.

PID I MIN: Often referred as “deadband”. The PID integrator is paused when the position error is

smaller than what is set.

I MAX: To prevent PID controller integrator windup this setting can be used to reset the integrator

to 0 when position error is larger that set value. To disable this put in 100%.

PID clamp settings:

This setting can limit the maximum PID calculation outputs. The PID controllers internal register

are logged, and can be viewed from the logs. These values will clamp the calculated values to

the set values.

BIAS

The DBW controller also has a table that is called either “bias” or “feed forward” table. This is

basically an open loop of the control strategy. We have found that a well tuned PID control may

not need this table at all, but it is provided. The “bias” value is a duty cycle value that is given to

the DBW throttlebody for a given “target” opening. The dytycyle can be from -100 to +100.

Negative values driving the butterfly closed and vice versa.

Throttle body sensor calibration

The position sensors of the DBW throttlebody are calibrated automatically by the controller. User

needs to disable AVR protection from the AVR fault code menu. Then press “Calibrate” button

and the controller will drive the butterfly first fully open and the fully closed and records the

sensor readings. This works only for regular DBW throttlebodys that have linear sensors.

16

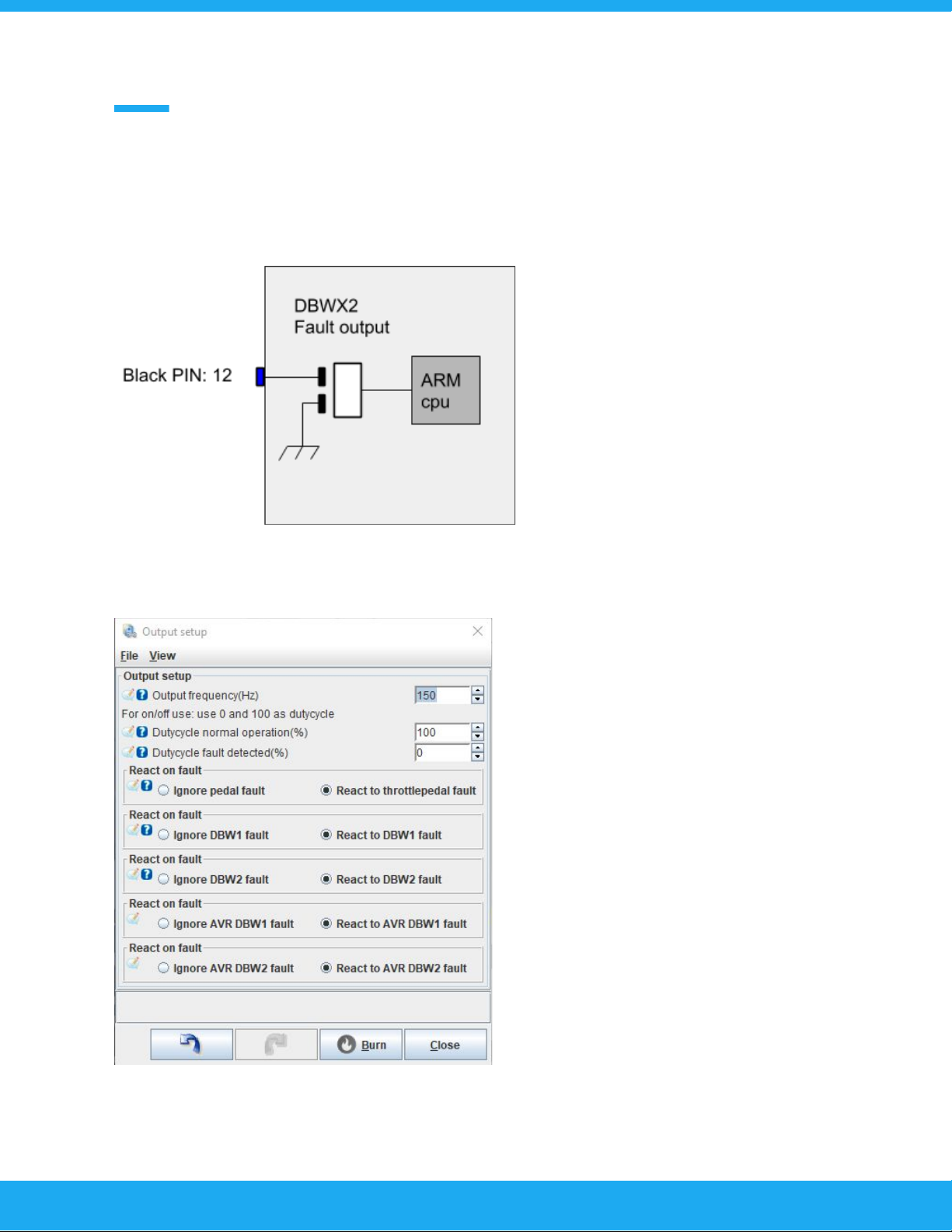

Configuring fault output

Circuit:

Fault output is an open collector low side output. Current is limited to 10A but it is not

recommended to load the output beyond 5Amps because of thermal concerns.

User can configure the outputs PWM

frequency and dutycycle in normal and fault

operation.

Also the configuration makes possible to

ignore faults in channels that are used as

auxiliary channels that does not require the

fault output to be tripped.

Default state of the channel is high

impedance (0% duty). It is recommended to

make the connected external circuit operate

so that fault state is 0% duty.

17

Step by step initial configuration guide

At this point the controller should be wired correctly.

Now open TunerStudio and start a new project. After you have successfully connected to the

DBWX2 controller the first thing to do is calibrate the DBW throttlebody.

1. Open the “DBW1” or “DBW2” menu and click on the “DBW auto min/max”

When you open this setting you will find that it says ready to

calibrate and AVR protection enabled. This means that the

throttlebody cannot yet be calibrated as the AVR co-cpu will

interfere with the calibration. We will now disable the AVR

co-cpu, so that we can proceed with the DBW throttlebody

calibration.

This is done from “Fault Codes” -> AVR Fault codes. You will

find a button that is labeled “Disable AVR CPU”. Click on it and

you will see the text in the throttlebody calibration menu

change to “AVR Protection disabled” and change color to blue

from yellow. Also you will get a faultcode in the AVR indicating

that the protection features is disabled.

Now you can press on the “Calibrate DBW” button and the

controller will automatically drive the DBW throttlebody to the

maximum and minimum positions and save the calibrated sensor settings.

Do this for both DBW throttlebodies if you have more than one connected.

NOTE: When calibrating the DBW Throttle butterly should first go in to the fully open position and

after that it should fully close. If you have the motor positive and negative wires crossed it will

calibrate the throttlebody so that 0% is fully open and vice versa. It is the responsibility of the

installer to check that the operation is correct.

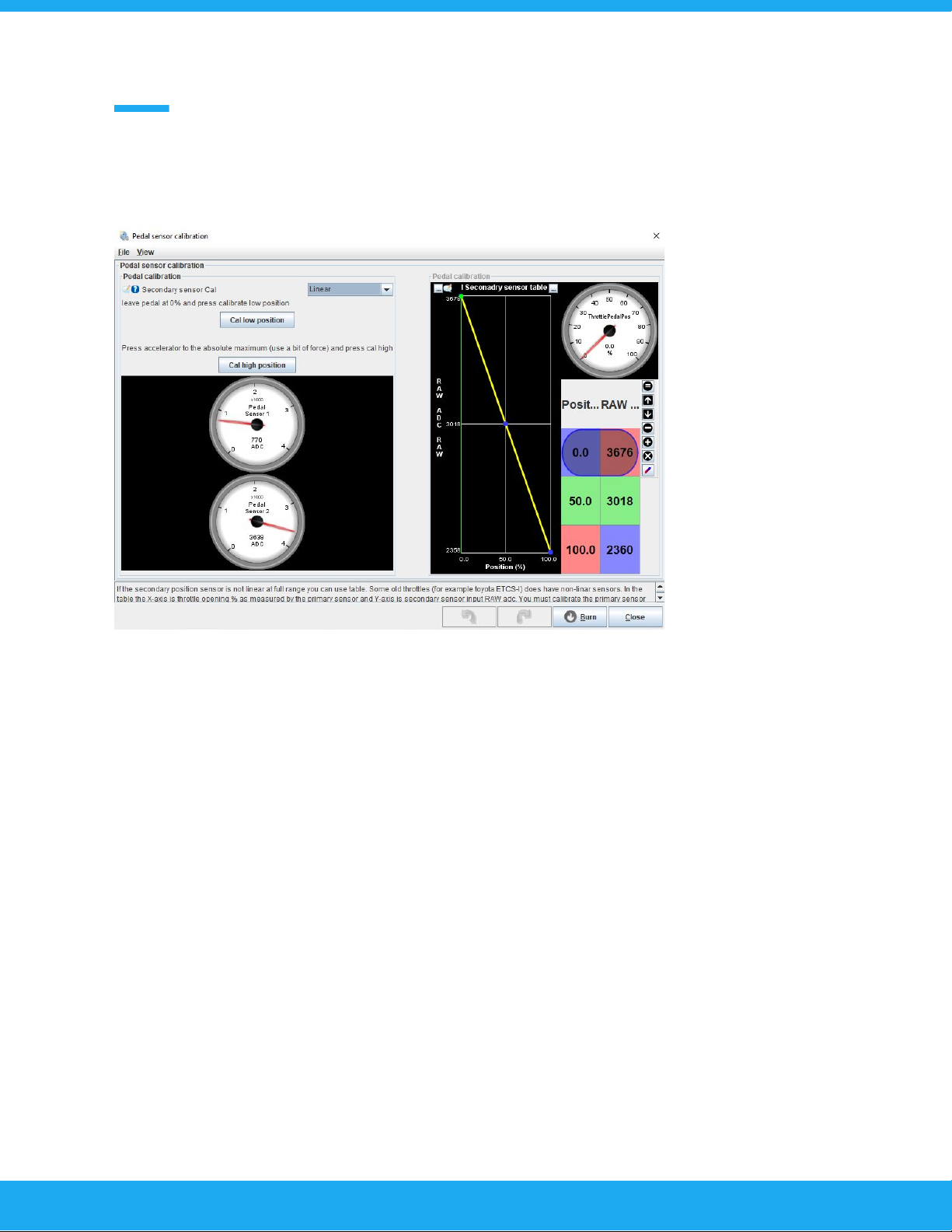

Next step is to calibrate the accelerator pedal.

18

2. Calibrate the accelerator pedal

Open the “Setup” menu and click on the “Pedal calibration”

Now leave the throttle untouched and click on the “Cal low position”.

Now the 0% position has been calibrated. Fully depress the accelerator pedal with some force.

Press “Cal high position”. This is so that when driving the car in anger the driver can stomp on the

accelerator and it will read past 100%. This will cause an error code and will result in the

controller entering limp mode.

Make sure that the secondary sensor cal is “Linear”. The “table” is only used with uncommon

sensors from the early 2000 era.

Now we have calibrated all of the sensors. You will probably have fault codes registered in the

controller. Go in to the “Fault Codes” menu and clear all coder from the ARM and AVR cpu’s.

Next step is PID setup for the throttlebody.

19

Table of contents