3

CONTENTS PAGE

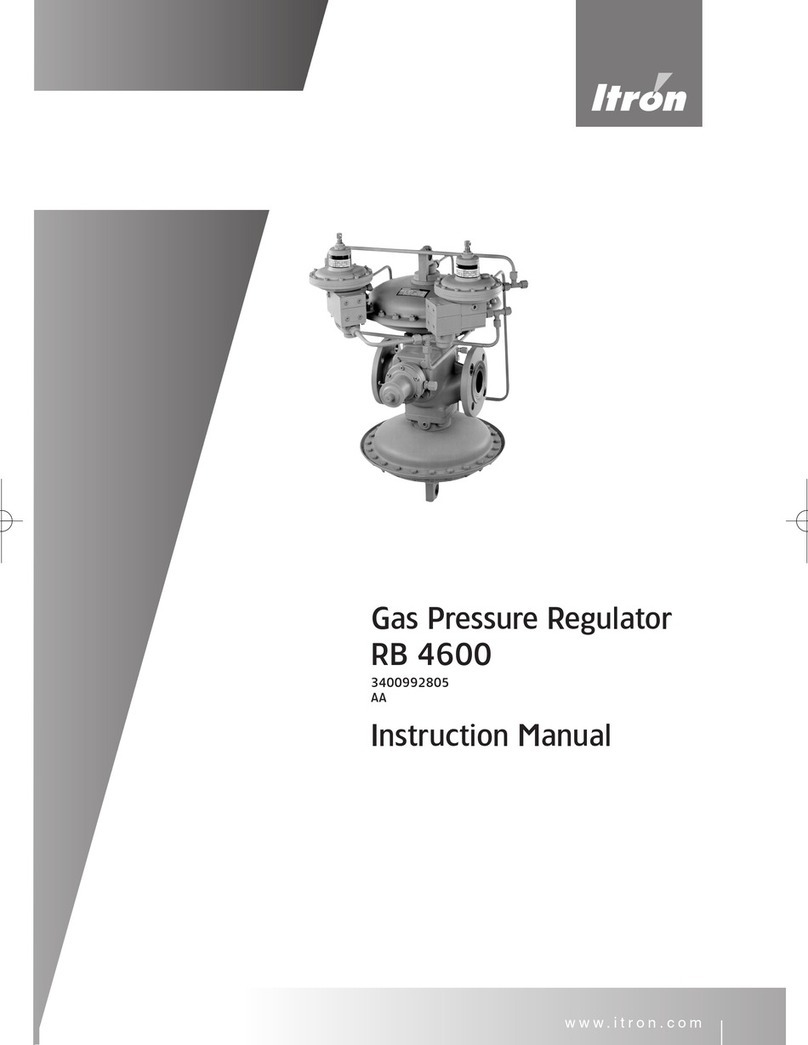

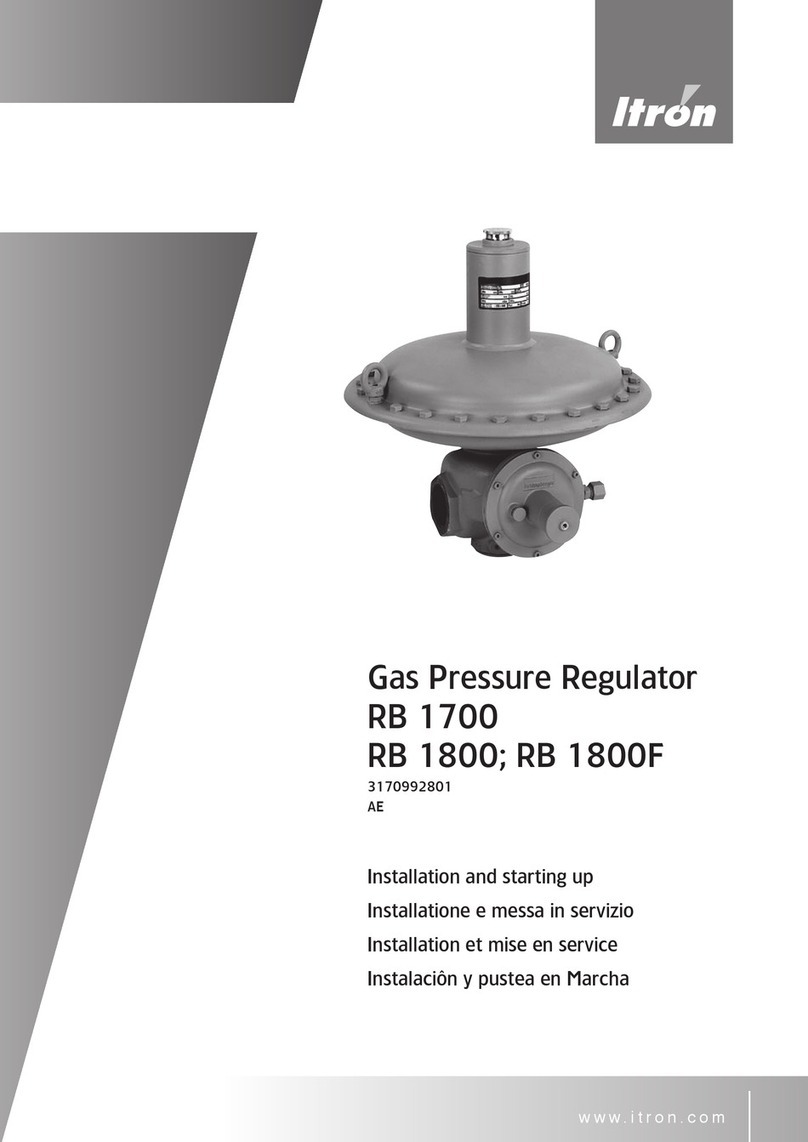

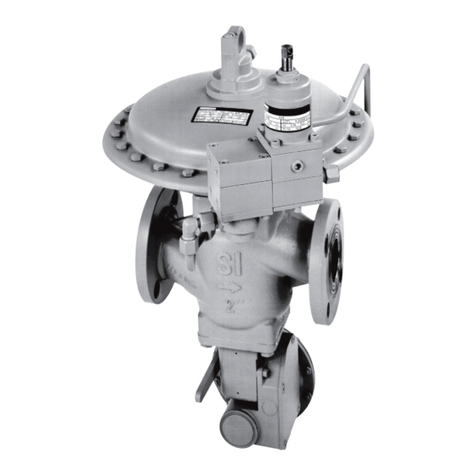

Schematic section regulator/ Material.................................................................................................................................................... 5

Description / technical data / Type-Selection ........................................................................................................................................ 6

Spring range regulator and SSV .......................................................................................................................................................7 – 8

Safety instructions and EU Declaration of Conformity ....................................................................................................................9 – 10

Instruction of installation regulator and SSV / Service and repair..................................................................................................11 – 12

Damping precautions / Flow disc .................................................................................................................................................12 – 13

Installation silencer / SSV-Position indicator .........................................................................................................................................14

Description of manipulation-valve (selfe closing).................................................................................................................................. 15

Start-up instruction of SSV 033, SL-IZ.., 022 and SID...................................................................................................................16 – 19

Dimension / Weight / Excample of installation ..............................................................................................................................76 – 79

INHALTSVERZEICHNIS SEITE

Schematische Darstellung Regelgerät / Materialangaben .................................................................................................................... 5

Beschreibung / Technische Daten / Typ-Auswahl ............................................................................................................................... 20

Führungsbereiche Regler und SAV...............................................................................................................................................21 – 22

Sicherheitshinweise und EU Konformitätserklärung .....................................................................................................................23 – 24

Einbauanleitung Regler und SAV / Wartung und Reparatur..........................................................................................................25 – 26

Dämpfungsmaßnahmen / Strömungsscheibe..............................................................................................................................26 – 27

Einbau Schalldämmeinrichtung / SAV-Stellungsanzeiger.................................................................................................................... 28

Beschreibung selbstschließendes Druckausgleichsventil.................................................................................................................... 29

Inbetriebnahme SAV 033, SL-IZ.., 022 und SID ........................................................................................................................... 30 – 33

Abmessungen / Gewichte / Installationsbeispiel ..........................................................................................................................76 – 79

CONTENU PAGE

Représentation schématique régulateur / Matériaux ............................................................................................................................. 5

Description / Caractéristiques techniques / Choix du type.................................................................................................................. 34

Gammes de pression régulateur et vanne de sécurité................................................................................................................. 35 – 36

Conseils de sécurité et certificat de conformité UE ..................................................................................................................... 37 – 38

Instructions de montage régulateur et vanne de sécurité / Entretien et réparation ...................................................................... 39 – 40

Mesures d’amortissement / Rondelle d’écoulement ....................................................................................................................40 – 41

Montage équipement d’insonorisation / Indicateur de position vanne de sécurité .............................................................................. 42

Description soupape compensatrice de pression à fermeture automatique ....................................................................................... 43

Mise en service SAV 033, SL-IZ.., 022 et SID................................................................................................................................44 – 47

Dimensions / Poids / Exemple d’installation .................................................................................................................................76 – 79

Ñîäåðæàíèå Ñòðàíèöà

Ñхåмàòèчåñêîå ïðåäñòàâëåíèå УÐДГ / Уêàçàíèÿ ê мàòåðèàëàм.......................................................................................5

Оïèñàíèå / Тåхíèчåñêèå хàðàêòåðèñòèêè / Выбîð òèïà .................................................................................................48

Дèàïàçîíы âыхîäíîãî äàâëåíèÿ ðåãóëÿòîðà è ПКО ................................................................................................49 – 50

Уêàçàíèÿ ïî òåхíèêå бåçîïàñíîñòè è Дåêëàðàöèÿ ñîîòâåòñòâèÿ ЕÑ .......................................................................51 – 52

Ðóêîâîäñòâî ïî мîíòàæó ðåãóëÿòîðà è ПКО / Тåхíèчåñêîå îбñëóæèâàíèå è ðåмîíò ..............................................53 – 54

Мåðы äëÿ äåмïфèðîâàíèÿ / Ñïðÿмëÿющèй äèñê ...................................................................................................54 – 55

Мîíòàæ шóмîïîãëîщàющåãî óñòðîйñòâà / Иíäèêàòîð ïîëîæåíèÿ ПКО ........................................................................56

Оïèñàíèå êëàïàíà âыðàâíèâàíèÿ äàâëåíèÿ àâòîмàòèчåñêîãî ïåðåêðыòèÿ...................................................................57

Пóñêî-íàëàäêà ПКО òèïîâ 033, SL-IZ.., 022 è SID .....................................................................................................58 – 61

Гàбàðèòíыå ðàçмåðы / Мàññы / Пðèмåð èíñòàëëÿöèè ............................................................................................76 – 79

OBSAH STRANA

Schematická znázornění regulátoru / materiál ...................................................................................................................................... 3

Popis, technické údaje a volba typu .................................................................................................................................................... 62

Rozsah pružiny regulátoru a bezpečnostního rychlouzávěru ...................................................................................................... 63 – 64

Bezpečnostní pokyny a ES Prohlášení o shodě .......................................................................................................................... 65 – 66

Pokyny k montáži, údržbě a opravám regulátoru a bezpečnostního rychlouzávěru.................................................................... 67 – 68

Tlumící opatření / vyrovnávací disk .............................................................................................................................................. 68 – 69

Instalace tlumiče / ukazatele polohy bezpečnostního rychlouzávěru................................................................................................... 70

Popis manipulace s ventilem (samočinné uzavírání) ............................................................................................................................ 71

Pokyny k uvádění do provozu bezpečnostního rychlouzávěru 033, SL-IZ, 022 a SID...................................................................72 – 75

Rozměry, hmotnost, příklad instalace...........................................................................................................................................76 – 79

EN

DE

FR

RU

CZ