AdBlue CDI-H27 User manual

CDI-H27 AD BLUE PUMP

Before Installing And Use Please Read The Instruction Manual Carefully

USER MANUAL

SECTION

1

2

3

4

5

6

7

8

9

10

SECTION 1 SAFETY INSTRUCTIONS

This instruction manual contains essential information that must be observed during

installation, operation and servicing. It is therefore important that the installer and

the responsible technician/operator read this instruction manual before the

equipment is installed and put into operation. The manual must always be available

at the location where the pump or the plant is installed. Failure to observe the safety

instructions can lead to the loss of all warranty.

In this instruction manual, safety information is distinctly labelled with particular

symbols. Disregarding this Information can be dangerous.

ATTENTION

General danger to people

DANGER - ELECTRIC SHOCK RISK

Warning of electrical voltage

QUALIFICATION AND TRAINING OF PERSONNEL

All personnel involved with the operation, servicing, inspection and installation of the

equipment must be suitably qualified for this work and must have studied the

instruction manual in depth to ensure that they are sufficiently conversant with its

contents. The supervision, competence and areas of responsibility of the personnel

must be precisely regulated by the operator. If the personnel do not have the

necessary skills, they must be instructed and trained accordingly.

SAFETY CONSCIOUS WORKING

The safety instructions in this instruction manual, the existing national regulations

regarding accident prevention, and any internal working, operating and safety

regulations must be followed

SAFETY INSTRUCTIONS FOR THE USER

All legal regulations, local directives and safety regulations must be followed. Legal

regulations must be observed

WARRANTY

ELECTRICAL CONNECTION

DIMENSIONAL DRAWING

DISASSEMBLY AND DISPOSAL

TROUBLE SHOOTING

MAINTENANCE

OPERATION

INSTALLATION

APPLICATION

SAFETY INSTRUCTIONS

DESCRIPTION

CDI-H27 AD BLUE PUMP

SAFETY INSTRUCTIONS FOR INSTALLATION, INSPECTION AND MAINTENANCE

WORKS

As a basic principle, works may only be carried out to the equipment when it is shut

down. Pumps or plant that convey harmful substances must be decontaminated. All

safety and protection components must be re-fitted and/or made operational

immediately after the works have been completed. Their effectiveness must be

checked before restarting, taking into account the current regulations and

stipulations.

UNAUTHORISED MODIFICATIONS, MANUFACTURE OF SPARE PARTS

The equipment may only be modified or altered in agreement with the manufacturer.

The use of original spare parts and accessories approved by the manufacturer is

important for safety reasons. The use of other parts can result in liability for

consequential damage being rescinded. All materials in contact with water have been

tested and approved, therefore only original replacement parts should be used.

UNAUTHORISED OPERATING METHODS

The operational safety of the supplied equipment is only guaranteed if the

equipment is used for its intended purpose. The limiting values given in the

“Technical Data” section may not be exceeded under any circumstances

INSTRUCTIONS REGARDING ACCIDENT PREVENTION

Never work alone. Always wear a hard hat, safety glasses and safety shoes and, if

necessary, a suitable safety belt. Before carrying out welding works or using electrical

devices, check to ensure there is no danger of explosion.

For the sake of your health, be sure to pay meticulous attention to cleanliness

wherever you are working. Make sure that there are no toxic gases in the working

area

Observe the relevant occupational health and safety regulations and keep first aid

materials available.

In some cases, the pump and the pumping medium may be hot and could cause

burns. For installations in areas subject to explosion hazards, special regulations

apply!

DANGER - ELECTRIC SHOCK RISK

230v Pumps - The pump must only be connected to sockets that have been installed

properly in accordance with the regulations and are protected with safety switch

(RCD,30mA)

Only qualified electricians may carry out electrical works to the pump or the controls

Always pull out the mains plug before carrying out any work on the pump

Check the rubber hose for mechanical or chemical damage. A damaged or kinked

hose must be replaced.

SECTION 2 APPLICATION

The CDI-H27 pump is a five chamber positive displacement diaphragm pump.

Designed for pumping AD Blue (AUS32-DEF-ADBLUE) with no solid suspended

particles, fibres or abrasive materials. NOT FOR PUMPING PETROL!

DANGER

Never use the pump for flammable and/or explosive liquids

Improper use of the pump can lead to physical injury and/or material damage.

Improper use of the product will render the warranty null and void

SOUND PRESSURE LEVEL

The sound pressure level is below 70dB (LpA) on all models

TRANSPORT AND STORAGE

On delivery, check that the electric pump has not been subject to damage during

transport; in this case notify the retailer immediately. Check procedure phases -

check the exterior of the packaging - remove all product packaging material - inspect

the product for possible damaged parts - contact the retailer if any defects are found.

Use the original packaging to return the product to the retailer in the event of

defects; otherwise dispose of all packaging materials according to current local

standards

If after use the pump will be stored away for a long period, wash the pump body out

with clean water. Ad Blue if left in the pump body will crystalise and may cause

problems on next use

DANGER

Handle the product in observance of current accident prevention standards

During storage, protect the product from humidity, dust, heat sources, mechanical

damage and external contaminants in order to conserve the quality of the water

subsequently placed in contact with the pump

SECTION 3 INSTALLATION

Install the pump on a flat surface and secure to prevent movement during start-up

and operation, ensuring that there are no obstructions to the regular flow of cooling

air delivered by the motor fan. Clean the pump prior to installation if left unused for

prolonged periods of time

Ensure that the installation site is sufficiently sized to enable assembly of the pump

on the system and future maintenance operations. Ensure that the pump installation

room or site is not subject to the risk of flooding by the leakage of liquids or other

events that may cause submersion of the pump itself.

ATTENTION

To avoid breakdown of the system with the risk of physical injury, use pipelines,

connectors and accessories suited to the maximum operating pressure values

All pipeline connections must be made by qualified personnel in conformity with

current local standards.

To avoid the need to drain the system in the event of pump maintenance, the

installation of a shutoff valve is recommended, on the suction and delivery pipelines

If the pump remains in operation with the delivery valve closed, the liquid will start to

overheat. Never use the pump with the shutoff valve closed on the delivery side

The pump should be installed in such a way to avoid the risk of air pockets in the

body or pipelines, in particular on the suction side of the pump

Pipelines and valves must be correctly sized according to the installation. Pipelines

must not cause excessive mechanical stress on pump suction or delivery with

excessive loads and torque values

If flexible hoses are used, fit a semi-rigid pipe on suction to avoid the risk of shrinkage

due to negative pressure on suction

It is recommended to fit a filter on the inlet of the suction pipeline where the pump is

used for pumping AD Blue from a tank

Periodically check the condition of the filter and regularly clean or replace this

element

Correct pump installation is essential to ensure priming

Position the pump in the vicinity of the well or tank to ensure that the suction pipe is

as short as possible. In this way, the priming time is reduced, above all in the case of

large differences in height between the liquid and suction point.

Use a pipeline that is at least the same diameter as that of the pump suction port and

no longer than 2 metres vertical

To avoid the formation of air vortexes, immerse the suction pipe by at least 0.5m in

the liquid to be pumped. Install a foot valve with filter at the end of the suction pipe

or check valve on the suction port in the case

Ensure complete sealing of the suction pipe including all connections

Do not run the pump dry for more than 10 minutes. This can cause damage to the

pump components

Operating conditions with duty cycles longer than 20 minutes can cause the motor

temperature to rise. Allow the pump and motor to cool for 20 minutes

The by-pass valve allows the pump to continue with the dleivery outlet closed but

only for short periods. Maximum 3 minutes. To avoid damaging the pump make sure

it is switched off after use

Use wide bends on the suction section

SECTION 4 ELECTRICAL CONNECTION

DANGER - ELECTRIC SHOCK RISK

Ensure that the rated voltage and frequency correspond to those of the specifications

of the mains power available.

The electrical connection must be made according to current local standards.

Before any intervention on the pump - 230v pumps, disconnect the electrical mains.

Low voltage pumps - Disconnect from the low voltage power source. Ensure that the

electrical power supply cannot be restored inadvertently.

The electrical cables must be protected, in particular from high temperatures,

vibrations and impact, which could cause mechanical or chemical damage.

The electrical power line (230v pumps) must be fitted with a short circuit protection

device, and a residual current device RCD with high sensitivity (30mA)

The electric power line (230v) must be fitted with an external main switch with a

contact opening gap compliant with current local standards.

SINGLE PHASE MOTORS

The single phase motors are protected against temperature and current overload by

means of thermal cutout devices in the winding. The motor protection is reset

automatically on elapse of the time required for the electric motor to cool down.

ELECTRICAL CONNECTIONS

230v model is supplied with a 1.5m power cable and plug

Low Voltage DC models are supplied with 1.5m power cable and clamps

SECTION 5 OPERATION

ATTENTION

The pump must never be operated with the shut off valve on the delivery side closed.

The discharge valve must be opened as soon as the pump has been started up, to

prevent damage to the latter by an excessive increase in liquid temperature

Use the electric pump according to the performance specifications as stated on the

data plate. Before using the pump, read application chapter for a proper use

Always avoid operation of the pump with the upline shut off valve closed (suction

side). Dry running of the pump can lead to over heating and damage to the pump

itself.

Never run the pump with the shut off valve downline (delivery side) completely

closed. In this case, the water in the system reaches very high temperatures, with the

risk of damage to equipment and scalding in the event of liquid escaping. In this

situation, turn off the pump and leave the system to cool.

Operating with duty cycles longer than 20 minutes can cause the motor temperature

to arise and damage the motor. For each running time of 20 minutes, switch off the

pump and allow the motor to cool for 20 minutes.

If an automatic nozzle is installed on the delivery line when first starting the pump

note that is may be difficult to prime because of air trapped in the hose. Open the

trigger so air can escape

SECTION 6 MAINTENANCE

DANGER - ELECTRIC SHOCK RISK

Before any intervention on the pump, disconnect the electrical power supply. Ensure

that the electrical power supply cannot be restored inadvertently

ATTENTION

Refer to safety instructions

In normal conditions, the electric pumps do not require any scheduled maintenance.

With a view to prevention of possible faults, it is recommended to periodically check

the pressure delivered and current absorption. A reduction in pressure is

symptomatic of pump wear. An increase in current absorption is symptomatic of

abnormal mechanical friction in the pump

Special maintenance may be required to clean the pump if it not used for prolonged

periods (e.g. for an entire season) it should be drained completely rinsed with clean

water and stored in a dry location

SECTION 7 TROUBLESHOOTING GUIDE

ATTENTION

Refer to safety instructions

THE PUMP DOES NOT WORK

No power supply - Turn off the switch and check that no electrical connections are

loose or defective

Check the mains voltage (230v)

Check the DC low voltage (12v / 24v)

Fuse blown - Check that the cables and relative connections are not defective and

replace the fuse if necessary

The 230v single phase motor thermal cut out has tripped this is reset automatically

once the motor has cooled

Motor overload cut out has tripped - Check that the cables and relative connections

are not defective, check that the pump is not blocked mechanically, or whether the

pump motor winding is damaged

THE PUMP STOPS AFTER A SHORT INTERVAL OF OPERATION DUE TO A TRIPPED

MOTOR PROTECTION DEVICE

Excessive current absorption check the operating condition of the pump

If foreign bodies are present, blocking hydraulics = clean the hydraulic components

The 230v single phase motor thermal cutout has tripped = this is reset automatically

once the motor has cooled; check installation conditions

Thermal cutout protection setting or fuses not suitable = check protection devices

with respect to rated current of pump

Power cable damaged = replace component

THE PUMP STARTS UP BUT DOES NOT DELIVER LIQUID

The pump takes in air, check the liquid level, operation of the foot valve and the

suction pipeline, check connections are air tight

PUMP PERFORMANCE IS REDUCED

Pipelines obstructed check pipelines, check valves

Suction pipe is partially obstructed with impurites, clean suction pipe

Leak from suction pipe, repair or replace

SECTION 8 DISASSEMBLY AND DISPOSAL

DANGER - ELECTRIC SHOCK RISK

Before any intervention on the pump, disconnect the electrical mains. Ensure that

the electrical power supply cannot be restored inadvertently

Disconnect the pump electrically from the system according to safety standards

Open the tap nearest to the pump to decrease the system's pressure

Before disassembly, close the shutoff valves on the delivery side, and if present also

close the shutoff valve on the suction side

This product or any part of the latter must be disposed of in accordance with local

standards using the public or private waste collection authorities as required

SECTION 9 DIMENSIONAL DRAWINGS

CDI-H27 230v

CDI-H27 12v & 24v

SECTION 10 WARRANTY

Conditions of Warranty Terms

Products are covered by Warranty relating to manufacturing defect or failing and/or

those of the material used. The components subject to fair wear and tear, such as

bearings, seal housing bushes, seals and o rings are not covered under the

manufactures warranty.

The Warranty right starts from the date of sale and must be certified by the sale’s

receipt and is covered for 12 months (1 Year) from sale against fault of manufacture.

The warranty is not accepted in case of:

Failures due to wrong treatment or operation.

Failures due to wrong implementation or storage.

Failure due to wrong hydraulic or electrical connections or installations.

Failures due to by a lack of an adequate protection.

Failures to reasons of force of nature or other uncontrollable factors.

Failures due to abrasive, or corrosive liquids or different from those allowed.

The use of the item beyond the limits indicated on the plate or in wrong conditions.

Failures due to lack of maintenance.

Failures due to incorrect user’s actions.

Failure due to wear and tear in certain applications.

In case of pumps the warranty is void if they have not been installed with accurate

motor over load protection.

The Warranty consists of repair or replacement by the service centre or supplier at

their discretion for the defective pump or parts.

The Warranty is a return to base warranty. Faulty or defective pumps will need to be

inspected at the service centre or supplier before repair or replacement is issued.

Pumps found to be not covered under warranty will be assessed and quoted for

repair.

ONLY FOR EU COUNTRIES Do not dispose of electric tools together with household

waste material! In observance of European Directive 2002/96/EC on waste electrical

and electronic equipment and its implementation in accordance with national law,

electric tools that have reached the end of their life must be collected separately and

returned to an environmentally compatible recycling facility

Table of contents

Popular Water Pump manuals by other brands

Clarke

Clarke C10 Product application, installation and service manual

Hitachi

Hitachi WT-P Series Operation manual

Burcam

Burcam 400505TW installation instructions

Duro

Duro DUROJET DSW500 Operating & installation instructions

Aquagarden

Aquagarden 1450 user manual

Grundfos

Grundfos LS 500-300-490E Installation and operating instructions

Sears

Sears Pro-Form R-930 user manual

Becker

Becker U 4.190 operating instructions

Grundfos

Grundfos CME Series Installation and operating instructions

Oerlikon

Oerlikon Sogevac SV40 BI operating instructions

GORMAN-RUPP

GORMAN-RUPP 86B3-B Installation, operation, and maintenance manual with parts list

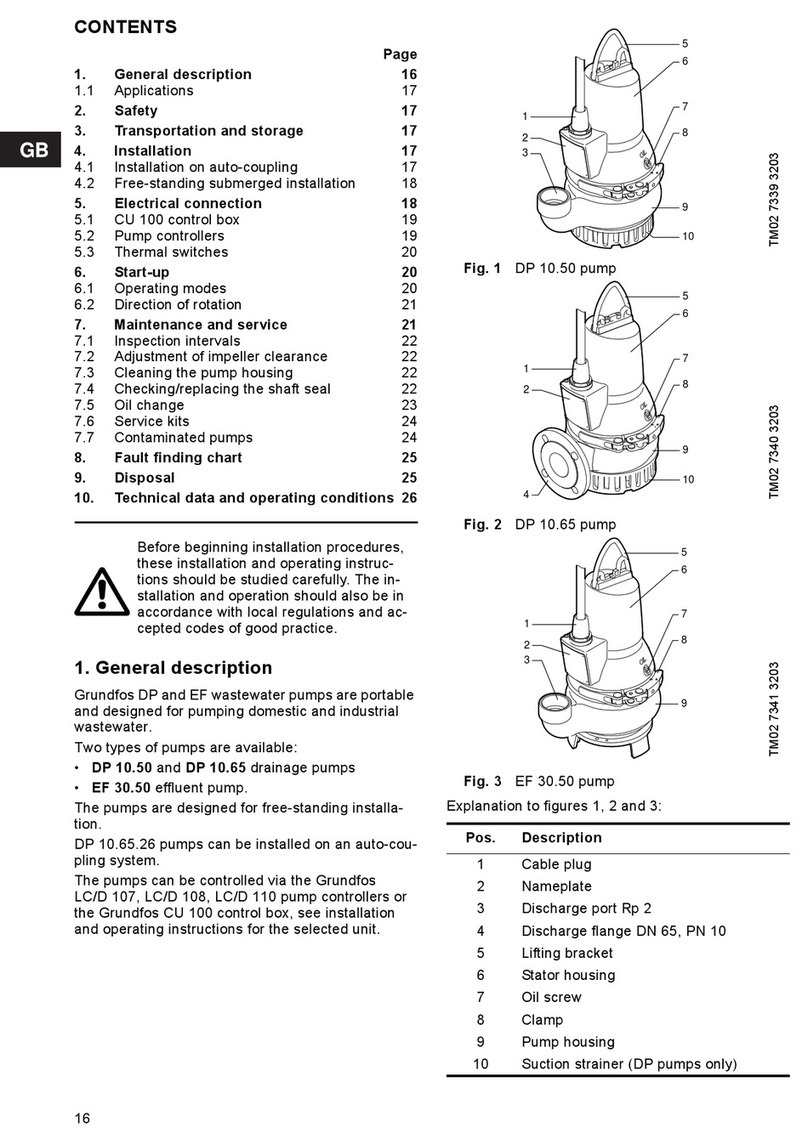

Grundfos

Grundfos DP 10.50 manual