Addi-Data CPCI-8004 Quick start guide

Manual revision: 15/092015

www.addi-data.com

POSITIONING AND CONTOURING

CONTROL SYSTEM

APCI-8001, APCI-8008 AND

CPCI-8004

COMMISSIONING MANUAL /CM

Copyright

The copyright for this manual belongs to ADDI-DATA GmbH.

These operating instructions consist of the OM, CM and PM parts and are only intended for use by the

operator and the operator’s staff. They include regulations and notes, which must not be

•duplicated

•published or

•otherwise distributed, either in part or in full.

Non-compliance with this could lead to criminal proceedings.

Warranty and liability

Warranty and liability claims for personal injury and damage to property shall be excluded, if they are

attributable to one or more of the following causes:

•Use of the board not in accordance with the regulations

•Improper installation, commissioning, operation and maintenance of the board

•Operation of the board in defective security installations or in improperly fitted or non-operational

security and protection appliances

•Non-compliance with the notes in the operating instructions regarding transport, storage, installation,

commissioning, operation, thresholds, maintenance of the board, standard software

•Arbitrary changes to the board

•Arbitrary changes to the source code files

•Insufficient monitoring of parts which are subject to wear

•Catastrophes due to effects by foreign bodies or acts of God.

ADDI-DATA software product licence

Please read this licence carefully before using the standard software. The customer is only granted the right

to use this software if he/she agrees with the conditions of this licence.

•The standard software must only be used to set up the ADDI-DATA boards

•Reproduction of the software is forbidden (except for back-up and for exchange of faulty data

carriers)

•Disassembly, decompilation, decryption and reverse engineering of the software are forbidden.

•This licence and the software may be transferred to a third party if this party has acquired a board by

purchase, has agreed to all the conditions in this licence contract and the original owner does not

keep any copies of the software.

Trademarks

Borland C++ and Borland Delphi are registered trademarks of Borland Software Corporation.

MIPS is a registered trademark of Mips Technologies, Inc.

RM5231 is a registered trademark of PMC Sierra, Inc.

Microsoft, MS-DOS, Visual Basic, Visual C and Windows are registered trademarks of Microsoft Corporation.

Warning!

The following risks result from the improper implementation of the

board and from use contrary to the regulations:

Personal injury

Damage to the board, the PC and peripherals

Pollution of the environment.

Protect yourself, others and the environment!

Read the safety precautions (yellow leaflet) carefully!

If this leaflet is not enclosed with the documentation, please contact us

and ask for it.

Observe the instructions of this manual!

Make sure that you do not forget or skip any step!

We are not liable for damages resulting from the wrong use of the board.

Pay attention to the following symbols:

NOTICE!

Designates hints and other useful information.

NOTICE!

Designates a possibly dangerous situation.

If the instructions are ignored, the board, the PC and/or

peripherals may be destroyed.

WARNING!

Designates a possibly dangerous situation.

If the instructions are ignored, the board, the PC and/or

peripherals may be destroyed and persons may be endangered.

CONTENTS 5

Warning! ............................................................................................................................................................3

1Introduction..................................................................................................................................................8

2Intended use.................................................................................................................................................9

2.1 Special notes for the APCI-8001 and APCI-8008..........................................................................9

2.2 Special notes for the APCI-8008-STP-EVAI..................................................................................9

2.3 Special notes for the CPCI-8004 .................................................................................................10

2.4 Limits of use.................................................................................................................................10

2.5 USERS.........................................................................................................................................10

2.5.1 Qualification .................................................................................................................................10

2.5.2 Personal protection equipment....................................................................................................10

2.6 Handling the board.......................................................................................................................11

2.7 Important!.....................................................................................................................................11

3Installing and configuring the xPCI-800x TOOLSET software ..............................................................12

3.1 Scope of delivery of the xPCI-800x TOOLSET software.............................................................12

3.2 Installing the miniport (rnwmc device driver)................................................................................12

3.3 Installing MCFG ...........................................................................................................................12

3.4 Installing FWSETUP ....................................................................................................................12

3.5 Starting FWSETUP......................................................................................................................13

3.6 Creating a system directory .........................................................................................................13

3.7 Setting up the MCFG project environment...................................................................................14

3.8 Booting the xPCI-800x controller.................................................................................................15

3.9 Configuration errors .....................................................................................................................16

3.10 New calling of fwsetup.exe...........................................................................................................17

3.11 Entering and storing system data ................................................................................................18

3.12 Control system hardware environment variables.........................................................................19

3.12.1The environment variable MT (MotorType)..................................................................................20

3.12.1.1 SSI motor type (2).........................................................................................................21

3.12.1.2 INC PWM motor type (3) ..............................................................................................21

3.12.1.3 STEPPER SSI motor type (4).......................................................................................21

3.12.1.4 ANALOG PWM motor type (5)......................................................................................21

3.12.1.5 STEPPER NDX motor type (6).....................................................................................22

3.12.1.6 ANALOG/ANALOG motor type (7) ...............................................................................22

3.12.1.7 Encoder Emulation motor type (8)................................................................................22

3.12.1.8 Piezo-Motor motor type (9)...........................................................................................22

3.12.1.9 PSM motor type (10).....................................................................................................22

3.12.1.10ENDAT motor type (11+16)..........................................................................................22

3.12.1.11INC_PULSE motor type (12) ........................................................................................22

3.12.1.12VIRTUAL motor type (13) .............................................................................................23

3.12.1.13GEOADD motor type (14).............................................................................................23

3.12.1.14UPDOWNSIGNALS motor type (15) ............................................................................23

3.12.1.15ANA_SIGN motor type (19)..........................................................................................23

3.12.1.16CI / ANALOG and CD / ANALOG motor types (20+21) ...............................................23

3.12.1.17STEPPER_ENDAT2_2 motor type (22) .......................................................................23

6 CONTENTS

3.12.1.18ETM motor type (23).....................................................................................................24

3.12.1.19ANA_SIGN_SSI motor type (24) ..................................................................................24

3.12.1.20ANA_SIGN_ENDAT2_2 motor type (25)......................................................................24

3.12.2The environment variable NumberAxis........................................................................................24

3.12.3The environment variable SampleTime.......................................................................................24

3.12.4The environment variable SZTSK?..............................................................................................25

3.12.5APCI-8001: Configuration of the analog input voltage ranges.....................................................25

3.12.6APCI-8008: Configuration of the analog input voltage ranges.....................................................25

3.12.7The environment variable FBCH?................................................................................................26

3.13 Special features for system parameters for servo and stepper motor axes................................26

3.14 Additional installation information for Windows NT......................................................................27

3.15 Updating the xPCI-800x Flash firmware (PMON)........................................................................27

3.16 Trouble-shooting..........................................................................................................................27

4How to install the motion control board in the PC.................................................................................28

4.1 Installing the xPCI-800x controller...............................................................................................28

4.1.1 Installation under W98 .................................................................................................................29

5Configuring and wiring the motion control board..................................................................................30

5.1 Installation, commissioning and replacement..............................................................................30

5.2 Environment.................................................................................................................................30

5.2.1 Connector X1: 50-pin SUB-D male connector APCI-8001 / APCI-8008......................................31

5.2.2 Counting for the 50-pin SUB-D male connector X1.....................................................................32

5.2.3 Connector X1: 78-pin SUB-D female connector CPCI-8004.......................................................33

5.2.4 Connector X1: 78-pin SUB-D female connector APCI-8008-STP-EVAI......................................35

5.2.5 Counting for the 78-pin SUB-D female connector X1..................................................................36

5.2.6 Setpoint value channels...............................................................................................................37

5.2.6.1 Setpoint value channel for servo motor axes APCI-8001 / APCI-8008........................38

a) Pin assignment for connector X1, axis channel 1 ...................................................38

b) Pin assignment for connector X1, axis channel 2 ...................................................38

c) Pin assignment for connector X1, axis channel 3 ...................................................38

5.2.6.2 Setpoint value channel for stepper motor axes APCI-8008 / APCI-8008.....................38

a) Pin assignment for connector X1, axis channel 1 ...................................................39

b) Pin assignment for connector X1, axis channel 2 ...................................................39

c) Pin assignment for connector X1, axis channel 3 ...................................................39

5.2.6.3 Analog outputs with the APCI-8008..............................................................................39

5.2.6.4 Setpoint value channels for CPCI-8004 .......................................................................40

5.2.7 Pulse acquisition channels...........................................................................................................40

5.2.7.1 SSI absolute encoder ...................................................................................................40

5.2.7.2 Endat absolute encoder................................................................................................41

5.2.7.3 Incremental encoders with inverted signals (symmetrical circuitry) .............................41

5.2.7.4 Incremental encoders without inverted signals (asymmetrical circuitry) ......................42

5.2.7.5 Optical decoupling of the pulse acquisition channels...................................................43

5.2.7.6 Pin assignment for the pulse acquisition channels with incremental encoders............43

a) Pin assignment X1, channel 1.................................................................................43

b) Pin assignment X1, channel 2.................................................................................43

c) Pin assignment X1, channel 3.................................................................................43

5.2.7.7 Pulse acquisition with the CPCI-8004 ..........................................................................43

5.2.8 Pin assignment connector X1, Digital inputs (APCI-8001 / APCI-8008)......................................44

5.2.8.1 Basic wiring diagram of xPCI-800x digital inputs I1 … I13...........................................44

5.2.8.2 Basic wiring diagram of xPCI-800x digital inputs I14 … I16.........................................44

5.2.9 Pin assignment connector X1, digital outputs (APCI-8001 / APCI-8008)....................................45

5.2.9.1 Basic wiring diagram of the xPCI-800x digital outputs O1..O8.....................................45

5.2.10APCI-8001 pin assignment connector P5, release relay .............................................................45

CONTENTS 7

5.2.11CPCI-8004 pin assignment connector P1, release relay.............................................................46

5.2.12Connection and wiring instructions ..............................................................................................46

5.2.12.1 Earth and current supplies............................................................................................46

5.2.12.2 Potential equalisation....................................................................................................46

5.2.12.3 Fitting shields................................................................................................................47

5.3 Using several xPCI-800x controllers in a PC...............................................................................47

5.4 APCI-8001 component mounting diagram...................................................................................48

5.5 APCI-8001 component mounting diagram (bottom side).............................................................49

5.6 APCI-8008 component mounting diagram...................................................................................50

5.7 APCI-8008 component mounting diagram (bottom side).............................................................51

5.8 CPCI-8004 component mounting diagram...................................................................................52

5.9 APCI-8008-STP-EVAI component mounting diagram.................................................................53

5.10 APCI-8008-STP-EVAI component mounting diagram (bottom side)...........................................54

5.11 Technical data of APCI-8001 / CPCI-8004..................................................................................55

6Settings and plans.....................................................................................................................................57

6.1 Isolating output for power output stage........................................................................................57

6.2 Determining the PIDF filter parameters .......................................................................................57

6.2.1 Speed controllers.........................................................................................................................57

6.2.2 Current amplifier...........................................................................................................................58

6.2.3 Voltage amplifier ..........................................................................................................................58

6.2.4 Stepper motor power amplifiers...................................................................................................58

6.2.4.1 Stepper motor system without position feedback.........................................................58

6.2.4.2 Power amplifier with step/direction setpoint value input and position control ..............58

6.2.5 Pre-control....................................................................................................................................58

6.2.5.1 Determining the coefficients .........................................................................................59

8 CM /COMMISSIONING MANUAL

1 Introduction

What is this

manual for? This manual describes how to commission all the necessary system components for

using the xPCI-800x positioning and contouring control system. The complete

manual is made up of three parts: OM (Operating Manual), CM (Commissioning

Manual) and PM (Programming and Reference Manual).

What devices

belong to the

xPCI-800x range?

The xPCI-800x range of products are third-generation positioning and contouring

control systems. At present, these include the APCI-8001, APCI-8008 and

CPCI 8004 positioning and contouring control systems.

Other remarks Where the functions described in this manual do not apply for all xPCI-800x

products, this is marked clearly. In this case, the corresponding function only

applies for the product indicated.

CM /COMMISSIONING MANUAL 9

2 Intended use

The xPCI-800x motion control boards (APCI-8001, APCI-8008 and CPCI-8004) form the interface between

industrial process, automation and drive technology and a personal computer (PC).

The board is suitable for use in a PC that has been fitted with free PCI slots. The PC is subject to EU

directive 898/336/EEC and must satisfy the corresponding EMC protection requirements.

Products which satisfy these requirements carry the symbol.

2.1 Special notes for the APCI-8001 and APCI-8008

Data exchange between the APCI-8001 and APCI-8008 boards and the periphery takes place via a shielded

cable. This cable must be connected to the 50-pin SUB-D male connector of the APCI-8001 or APCI-8008.

The APCI-8001 or APCI-8008 also has digital outputs for processing 24 V signals. An external 24 V supply

voltage is required to operate these outputs.

The PX8000 screw terminal board enables connection of the 24 V supply voltage via a shielded cable.

The use of the APCI-8001 or APCI-8008 in combination with external screw terminal boards requires

technical installation in a closed switch cupboard. Check the screen attenuation measure of PC housing and

cable shield before commissioning the device.

Use of the standard ST8001 cable satisfies the minimum requirements:

•metallised connector shells,

•shielded cable,

•cable screen folded back over insulation and screwed down on both sides with the connector shell.

2.2 Special notes for the APCI-8008-STP-EVAI

The board APCI-8008-STP-EVAI enables the user to control 6 stepper axes with encoder verification.

For this purpose, the board is equipped with 16 digital inputs and a maximum of 8 digital outputs.

The inputs and outputs are shared for all 6 axes. Hardware latch inputs are:

I11 for axis 1

I12 for axis 2

I13 for axis 3

I14 for axis 4

I15 for axis 5

I16 for axis 6

The outputs are optional. The +24 V supply at pin 59 of X1 is required only if digital outputs are used. At the

respective pins (digital outputs), also CNC ready relays or analog inputs can be made available.

The corresponding configuration is fitted ex works. The external components are connected via a 78-pin

SUB-D female connector (X1). The OPMF-8008 cannot be used for this board version.

The scope of software is more or less identical to that of the other xPCI-800x boards. However, an

interpolation is only possible with the first 4 axes. The SMLA and SMLR commands can be called up for axes

5 and 6 as well, but only as single-axis traversing commands.

10 CM /COMMISSIONING MANUAL

2.3 Special notes for the CPCI-8004

Data exchange between the CPCI-8004 boards and peripherals takes place via a shielded cable. This cable

should be connected to the 78-pin SUB-D connector on the CPCI-8004.

The CPCI-8004 also has digital outputs for processing 24 V signals. An external 24 V supply voltage is

required to operate these outputs.

2.4 Limits of use

By using the boards in a PC, the resistance to interference and emission values of the PC may change.

Increased emissions or reduced resistance to interference can mean that the conformity of the system is no

longer ensured.

EMERGENCY STOP functions must not be taken over by any of the above-mentioned modules.

The EMERGENCY functions must be protected separately. This protection must not be influenced by the

boards and the PC.

The board must remain in its anti-static packaging until it is installed.

The warranty claim becomes invalid if the identification numbers are deleted or changed.

2.5 USERS

2.5.1 Qualification

The following activities must only be executed by trained electronics employees:

•Installation

•Commissioning

•Operation

•Maintenance

2.5.2 Personal protection equipment

Please note the national regulations regarding:

•Accident prevention

•Installation of electrical and mechanical equipment

•Electromagnetic compatibility (EMC).

CM /COMMISSIONING MANUAL 11

2.6 Handling the board

Fig. 2.1: How to handle the board correctly

Please note:

The following procedures must be observed during commissioning:

yInstalling the xPCI-800x TOOLSET software [section 3] – Installing the board [section 4]

yConfiguring and wiring the xPCI-800x board [section 5]

ySettings and planning as described in section 6 and section [OM / section 4.2].

2.7 Important!

Before installing or removing any modules, ensure that the PC and the external power supplies have been

switched off.

If this instruction is ignored, the board or computer could be destroyed.

The manufacturer shall not be liable for damage which could result from the use or implementation

of its products.

The manufacturer shall not be liable for errors of any type, which may be contained in these

manuals. The manufacturer further reserves the right to alter this manual, and the specifications of

the product described, without having to divulge or announce these alterations in any form to any

person or persons.

12 CM /COMMISSIONING MANUAL

3 Installing and configuring the xPCI-800x TOOLSET

software

3.1 Scope of delivery of the xPCI-800x TOOLSET software

The xPCI-800x TOOLSET software [TSW] is delivered on a CD. This essentially contains the following parts:

•INF file with Miniport device driver

•mcfg utility program

•fwsetup utility program

•Command line program

•Firmware program and files

•Libraries + programming examples

•Documentation

3.2 Installing the miniport (rnwmc device driver)

The sub-directory \Inf\WIN_2K_XP_Vista_7 of the xPCI-800x TOOLSET CD contains the file rnwmc.inf.

This file has to be specified as an installation file for the plug&play installation and accordingly in the device

manager. Thus the current hardware driver version will be installed.

For earlier operating systems, the INF file of the respective directory has to be indicated. In addition, the

Miniport driver needs to be installed using ksetup.exe.

3.3 Installing MCFG

Call the setup.exe installation program in the mcfg sub-directory of the xPCI-800x TOOLSET CD. This is an

installation package based on the Microsoft Installer.

3.4 Installing FWSETUP

Call the setup.exe installation program in the fwsetup sub-directory of the xPCI-800x TOOLSET CD. This is

an installation package based on the Microsoft installer.

CM /COMMISSIONING MANUAL 13

3.5 Starting FWSETUP

Start the fwsetup.exe application. The following screen output or any identical one should be displayed on

the "Monitor" page:

The header line of the fwsetup application includes information on the number of identified xPCI-800x

controllers and the board type, among other things. The version of the monitor program PMON stored for the

control system, the CPU frequency and the memory status for the control sydem are displayed in the

window. You can reset the xPCI-800x controller by pressing the soft reset button. In this case, the screen

output in the monitor window should be filled in with other screen messages. Environment variables can be

set for the control system for parameterising the specifications of the control system. You will find further

information in section 3.12.

3.6 Creating a system directory

•Create a file for storing the most important system files.

•In this folder, generate a system.dat file using one of the 3 methods outlined below:

By creating a new file using the sysgen.exe help program from the Toolset sub-directory of the xPCI-

800x TOOLSET CD or

by copying a file from the firmware and system.dat files sub-directory\{Controller name of the xPCI-

800x TOOLSET CD (Note: Delete read only attribute after the copying process) or

by converting an existing system.dat file using the sysconv.exe help program from the Toolset sub-

directory of the xPCI-800x TOOLSET CD.

•Likewise, copy the RWMOS.ELF file from the Firmware and system.dat files sub-directory\

{ Controller name } into this newly created system directory.

14 CM /COMMISSIONING MANUAL

Important note: The RWMOS.ELF and SYSTEM.DAT files are specifically configured for the various

module types. The SYSTEM.DAT file can be converted where required.

The RWMOS.ELF file requires the right type to be selected from the Toolset software. This also applies to

the SYSTEM.DAT file, but where applicable, this file may as well be adapted through conversion using

sysconv.exe.

3.7 Setting up the MCFG project environment

•Start the mcfg.exe application

•In the [File][Project Parameter] menu, update the entries according to the system directory you have

selected (see above).

•Save the project settings via [File][Save As] or [File][Save].

CM /COMMISSIONING MANUAL 15

3.8 Booting the xPCI-800x controller

•Open the dialogue box [Tools][System Boot]

•Press the [Boot System] button

•After a few seconds, the [System Booted] check box must be marked and the [Online Mode] entry

should appear in the header line of the mcfg application.

16 CM /COMMISSIONING MANUAL

3.9 Configuration errors

If the following error message is displayed on the screen after you have booted the control system, this is

caused by the following:

The system file (system.dat) and system data selected in the project, which are stored residually in the flash

memory of the xPCI-800x controller control system, are different. This error can be cleared through a storage

procedure as described in the next section.

CM /COMMISSIONING MANUAL 17

3.10 New calling of fwsetup.exe

By calling the program fwsetup again an output identical to the following examples is displayed in the monitor

page:

In addition to the screen displayed in section 3.5 the footer indicates that rwMos is running. In the monitor

window data about the started operating system variant RWMOS.ELF are listed. These are first the software

options available in the booted RwMos variant. Then the operating system version with creation date and

information about the hardware equipment of the control variants (here ACEX EP1K50). This display is to be

noticed when errors occurs by booting or during the operation. You can find here in most cases indications

with which the problem cause can be found.

18 CM /COMMISSIONING MANUAL

3.11 Entering and storing system data

In the next step, you should edit the system data for the axis channel being used in the programm mcfg.

To do this, proceed as follows:

•The control system must be booted [Online Mode in the header line of the mcfg.exe application]

•mcfg.exe: [File] [System Data] enter the axis parameters for the respective axes

•Save the new system data using the [File][Save] command.

•During the save process, the different parameters are stored residually in the flash memory of the

xPCI-800x controller. If a configuration error was displayed, this must not be displayed again after

the system data has been stored.

•The save process is finished after a few seconds.

CM /COMMISSIONING MANUAL 19

3.12 Control system hardware environment variables

Environment variables can be set in the control system hardware environment, to configure the control

system hardware or software. These environment variables are set and reset using the fwsetup.exe

configuration program when the system is not booted. To set environment variables, the instruction:

set variable value

is entered in the data window of the “Monitor” tab page. A repeated assignment overwrites a previous

assignment. To delete the environment variables, the instruction:

unset variable

is entered. Note that the spelling of these instructions and parameters must be exactly right (high/low case).

The current status of the environment variables can be displayed by entering the instruction

set

(without parameters). If the display is not complete, press “Enter” to display another environment variable

until all the variables have been listed in the monitor window.

From RWMOS.ELF V2.5.3.37 andmcug3.dll V2.5.3.25 on, in the PCAP programming environment,

environment variables of the control can be read out. Hereto the function getEnvStr() is available. However,

in this way the setting of environment variables is not possible.

Important note:The status of the environment variable is an important characteristic of the respective

control system and must be documented. For example before using a replacement device or by reproduction

of a system, the entries made by the user must be restored. The screen contents can be copied into a text

file via the Windows clipboard, for documentation purposes.

Please note also that the formatting of these instructions and parameters must be exactly correct in terms of

upper and lower-case, or the entry will be invalid.

These environment variables are only required in special cases. For normal servo and stepper motor

axes, environment variables do not need to be set. Incorrect use of these variables may compromise the

operation of the module.

20 CM /COMMISSIONING MANUAL

3.12.1 The environment variable MT (MotorType)

This environment variable can adapt the control system to different axis systems. The axis allocation occurs

by attaching the axis index to MT (z.B. MT0). The different configurations possible are listed in the table

below. To select an option, enter the value of the corresponding system variable MT.

Important note: The following system variables are only needed in special cases (e.g. where an SSI

absolute value encoder is used). For standard applications with stepper motor systems, servo systems and

incremental encoder systems, these variables need not, and in fact must not, be set.

Table: Motor types

Value Name Description

2 SSI Axis with actual value acquisition of SSI encoder SSI encoder and

analog manipulated variable output.

3 INC PWM Axis with PWM manipulated value signal (RS 422) to the pulse

output and actual value acquisition through incremental encoder.

The directional signal is transmitted to the outputs Sign.

4 STEPPER SSI Axis with actual value acquisition of SSI encoder and manipulated

variable output of stepper motors.

5 ANALOG PWM Axis with PWM manipulated value signal (RS 422) to pulse output

and actual value acquisition through analog input. The directional

signal is transmitted to the outputs Sign.

6 STEPPER NDX This axis type enables to transmit the directional signal of the

stepper motor to a digital output (24V). The pins NDX/Sign are inputs

and can be used for the evaluation of a zero track (index).

7 ANALOG /

ANALOG Axis with analog manipulated variable output and actual value

acquisition through analog input.

8 Encoder emulation With this axis type, an incremental signal is output as manipulated

value (Encoder simulation). The axis must also be defined in mcfg as

stepper motor axis.

9 Piezo motor This motor type is optimised for driving Piezo motors of the Nano-

Motion Company.

10 PSM Axis with digital performance final level PSM-1150 over PSM bus.

11 ENDAT2.1 Axis with ENDAT encoder (serial data interface) and with

incremental actual value acquisition and analog manipulated variable

output.

12 INC_PULSE Servo axis with pulse direction interface and incremental encoder

actual value acquisition.

13 VIRTUAL Virtual axes: Virtual axes cannot be used for axes control, but they

can be used for profile generator calculation.

14 GEOADD Axis type for the graphical view of trackdata of virtual axes.

15 UPDOWNSIGNALS Option for presenting encoder signals of an axis channels as UP or

DOWN counting signals.

16 ENDAT 2.2 Axis with ENDAT encoder (serial data interface) without incremental

actual value acquisition and analog manipulated variable output.

19 ANA_SIGN Axis with analog manipulated variable output and actual value

acquisition through incremental encoder. The analog output signal is

always positive; the directional information is output through the

digital output.

20 CI / ANALOG Axis with analog manipulated variable output and actual value

acquisition through Common Integer variable (CI).

21 CD / ANALOG Axis with analog manipulated variable output and actual value

acquisition through Common Double variable (CD).

22 STEPPER /

ENDAT 2.2 Axis with step/direction output and ENDAT 2.2 encoder verification

This manual suits for next models

2

Table of contents

Other Addi-Data Control System manuals

Popular Control System manuals by other brands

Emerson

Emerson FB2100 Safe use instructions

Extron electronics

Extron electronics TLI Pro 201 user guide

Thermon

Thermon TraceNet TCM18 Installation, Start-Up, and Maintenance Guide

iKarus

iKarus C42 Maintenance manual

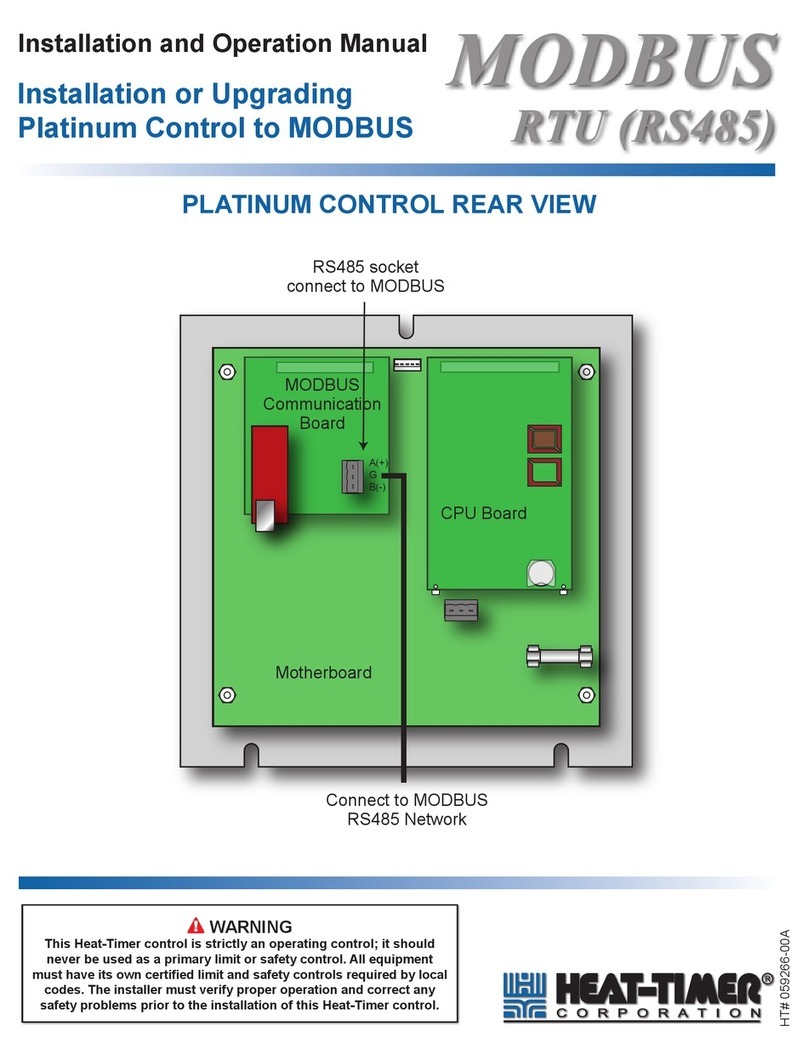

heat-timer

heat-timer MODBUS RTU RS485 Installation and operation manual

GEZE

GEZE E 260 N4 Installation and operating manual