ADDIMP 3D CURTISS H-75 User manual

ADDIMP 3D

Une création originale ADDIMP 3D

CURTISS H-75

Assembly userguide

ADDIMP 3D Original

Version 1.0

ADDIMP 3D

Une création originale ADDIMP 3D

This model reproduces the Curtiss Hawk H-75 in these two versions A-1 to A-3 and A-4 / A-5 for

manufacturing in 3D printing.

It is your responsibility to manufacture all of the parts necessary for the construction of this model.

All files are provided in stl format, compatible with the majority of slicers softwares in the 3D

printing market.

1- History

The Curtiss H-75 Hawk was developed in the USA in the mid-1930s on the basis of the Curtiss P-36.

It was of the same generation as the Hawker Hurricane and Messerschmitt Bf 109. It was then part

of the generation of modern single-plane fighters, of all-metal construction.

The Model 75 was designed by engineer Donovan Berlin using Curtiss' own funds. The first

prototype was assembled in 1934, it was equipped with a 900 hp Wright XR-1670-5 engine and an

armament consisting of a 7.62 mm machine gun and another 12.7 mm, pulling through the

propeller disc. The landing gear was half embedded in the wing and rotated 90 °.

The prototype made its initial flight in May 1935, reaching 452 km / h at 10,000 feet (3,050 m) from

the first flights. He was escorted to Wright Field in May 1935 to participate in a competition

organized by the USAAC to choose his future fighter. The contest was postponed due to an accident

of the contestant proposed by Seversky. Curtiss took the opportunity to replace the engine with a

950 hp Wright XR-1820-39 Cyclone and to rework the fuselage.

The competition finally took place in April 1936. Unfortunately, the plane did not exceed 460 km/h,

the new engine being unable to provide the necessary power. The Seversky P-36, although more

expensive than the Curtiss fighter, and also showing disappointing performance, was still declared

the winner and ordered by the USAAC.

With the European context deteriorating very quickly, the USAAC feared that Seversky would be

unable to deliver his aircraft on time and decided to acquire a second fighter model. In June 1936

Curtiss received an order for three prototypes, designated Y1P-36. The new aircraft, designated

Model 75E, was powered by a 900 hp Pratt & Whitney R-1830-13 Twin Wasp and a canopy with

further improved rear visibility. His performance was such that he won the 1937 competition of the

USAAC, which ordered two hundred and ten P-36A fighters. The export version is designated H-75.

Obsolete even before the start of the Second World War, it was used by the British Commonwealth

(Mohawk), Argentina, Brazil, China, Finland, France, Iran, Norway, the Netherlands, Peru, Portugal

and Thailand. Over a thousand planes were built.

ADDIMP 3D

Une création originale ADDIMP 3D

2- Caracteristics

scale ~ 1:12

Length : H-75A-1 / A-3 : 676 mm , H-75A-4 / A-5 : 666 mm

Wingspan : 950 mm

Surface : 15.2 dm²

Weight of the 3D printed parts with std PLA : ~750g,

Inflight weight between 1000 and 1300 g, as per equipment

Wing loading : entre 70 et 90 g/dm²

Center of gravity at 52 mm from the leading edge at root.

Construction skill

Experience with building some wood or fiber kits

Flying skill

Flying experience like aerobatic aircraft

Versions History

Version 1.0

2021, january

First Version

ADDIMP 3D

Une création originale ADDIMP 3D

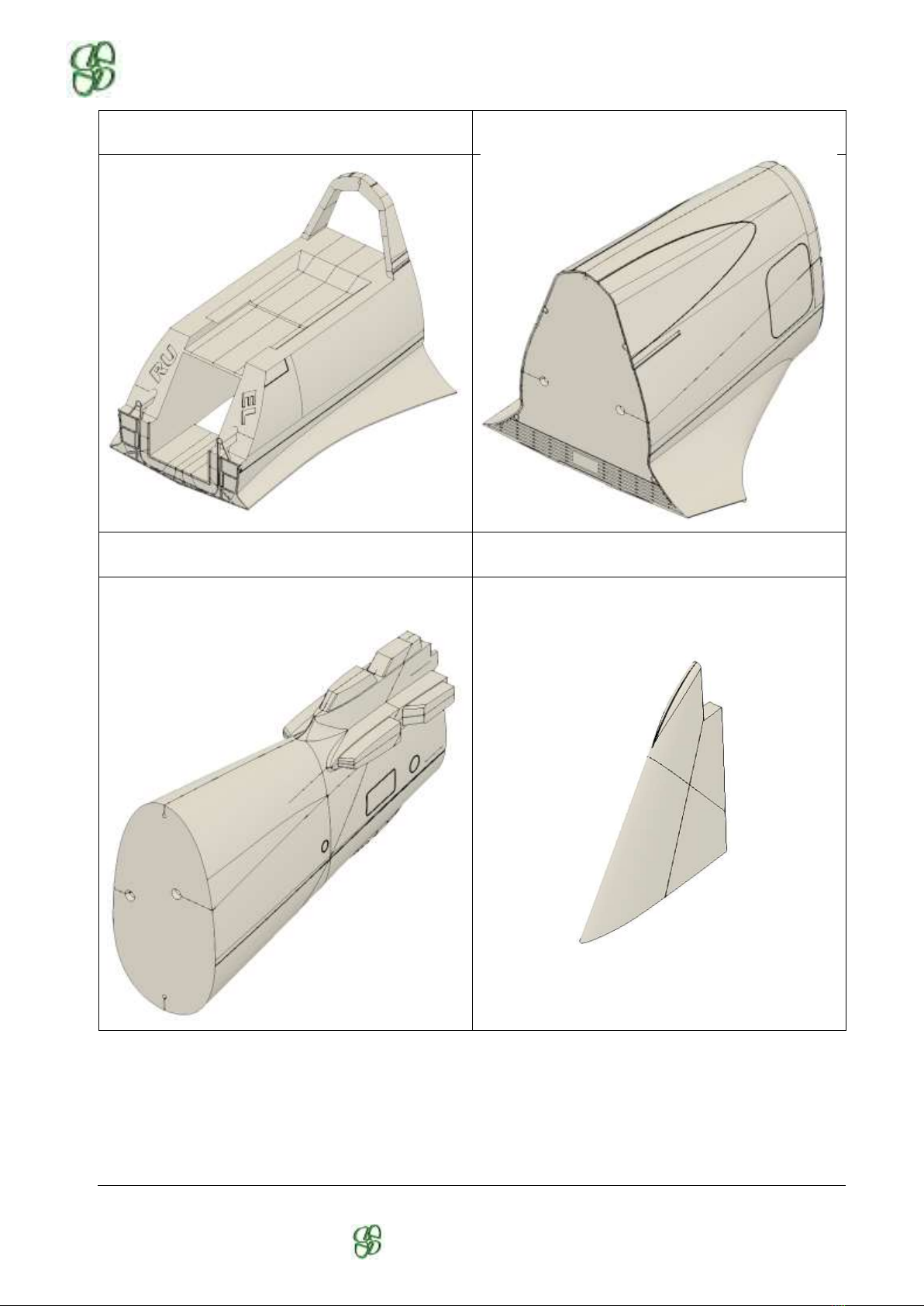

3- Content of the pack

L’ensemble des fichiers STL, ainsi que les fichiers factory (Simplify 3D) et G-Codes

This version can be made for 3 channels ; aileron, elevator and engine, or 4 channels (+ rudder).

There are two variants, the Wright R-1830 engine version, type A-1 to A-3 with the rounded engine cover

and the Wright R-1820 engine version, type A-4 and A-5 with the more angular engine cover.

H-75 A-1 to A-3

H-75 A-4 and A-5

ADDIMP 3D

Une création originale ADDIMP 3D

4- Balance

5- Material and equipment

All the parts could be printed on a 200 x 200 x 200 mm volume 3D printer with a 0.4 mm nozzle.

The slicer is Simplify 3D. Factory and G-code files are provided for 1.75mm diameter PLA filament. All parts

require less than 0.75kg of PLA.

A profile for Simplify 3D is proposed as exemple in the directory ../factory (MK3PLA-3DP.fff)

The design is also compliant with the use of PETG, LW-PLA or LW-ASA.

Equipment :

-Brushless motor between 250 and 300 W, example :

o3S :

▪engine Pro-tronick DM 2810 - 950 kV

▪engine Roxxy C3542 –810 kV

oESC 30 A to 50 A

oBattery LiPo 3S - 1800 à 2200 mA –45C, dimensions maxi : L 140 x l 55 x h 55 mm

Pay attention to the connectors between the ESC and the battery.

Center of gravity at 52mm

Recess for balance

ADDIMP 3D

Une création originale ADDIMP 3D

-It is possible to use powerplant with 4s or 6s. This type of sports engine is intended for experienced

model builders and will not be the subject of any particular recommendation.

Equipment

-3 or 4 servos 9 to 16 g type Savox SH-0255 MG or HXT900

-2x rubber band 120 x 10 mm or 1x nylon screw + nut M6 (option for wing fixture)

-Wire pushrod Ø0.8 or Ø1mm for elevator and rudder

-Wire pushrod Ø 1.5 for ailerons

-Ø2mm carbon rod for the hinges

-glue CA medium

-1x Velcro strap length 200 mm

-2x servo extension cable for aileron, length 150 mm minimum.

-Option ;

o1 carbon tube Ø3 mm x 500 mm for the wing spare (length should be adjust in place)

o2x Ø1mm carbon rod for the rear fuselage

-2x self-tapping screw Ø3 x 20 (motor mount)

All accessories could be found at : http://www.rcjetshobby.com/fr/10000493-sets-addimp-3d

Pro-tronik motors: http://www.rcjetshobby.com/fr/10000450-pro-tronik

Pro-tronik ESC: http://www.rcjetshobby.com/fr/81-controleurs

6- Paramètres d’impression

!! the use of the LW-PLA from Colorfab is explain in a specific file in the factory directory !!

Few quantity of parts needs special parameters, they are describe when needed.

G-Codes are based on Prusa Mk3 & Mk 3S, Ø1.75mm PLA.

The use with other 3D printer or filament will have different results. Even in the same brand of filament,

color may change results.

As often as possible use the factory files to adapt to your 3D printer and your filament.

Example of parameters :

Nozzle diameter = 0.4 mm

General layer thickness = 0.25 mm

Extrusion width = 0.42 mm

Default printing speed = 60 mm/s

1st layer thickness = 80% or 0.2 mm

1st layer width = 105%

ADDIMP 3D

Une création originale ADDIMP 3D

1st layer speed = 50 to 66%

Retraction distance, depend of the filament, ~ 1 to 2 mm, to be adjust

Retraction speed = 30 mm/s

Extra restart distance (distance to begin extrusion before printing the part) = 0.05 to 0.1 mm

Vertical lift (avoid collision between nozzle & part during travel moves) = 0.4mm

Possible wipe option activated, may replace a part of retraction.

Temperatures

-Bed = 55 to 60° C

-Extruder = 220 to 230 °C (best layer adhesion)

-No cooling, except for the tips (~20%)

7- H-75 –décomposition :

Part

Qtty

weight

(g)

Comment

STL name

factory file & G-code name

Fuselage A1 / A3

F1

1

H-75A1-1_12-F1

H-75A-1-1_12-F1

Battery hatch

1 + 1

H-75A1-1_12-hatch-front

H-75A1-1_12-hatch-rear

H-75A-1-1_12-Hatch

Fuselage A4 / A5

F1

1

H-75A4-1_12-F1

H-75A-4-1_12-F1

Battery hatch

1 + 1

H-75A4-1_12-hatch-front

H-75A4-1_12-hatch-rear

H-75A-4-1_12-Hatch

Fuselage common

fishplate F1 / F2

2

H-75-1_12-F1-F2-eclisse

../accessoires/H-75-1_12-

pieces-PLA

F2

1

H-75-1_12-F2

H-75-1_12-F2

F3

1

H-75-1_12-F3

H-75-1_12-F3

F4

1

H-75-1_12-F4

H-75-1_12-F4

Elevator cap

1

H-75-1_12-F4-stab-cover

Canopy

1

Can be printed

with clear PLA

H-75-1_12-canopy

H-75-1_12-canopy

lock

1

hatch-lock

../accessoires/H-75-1_12-

pieces-PLA

ADDIMP 3D

Une création originale ADDIMP 3D

Lock housing

1

H-75-1_12-lock-housing

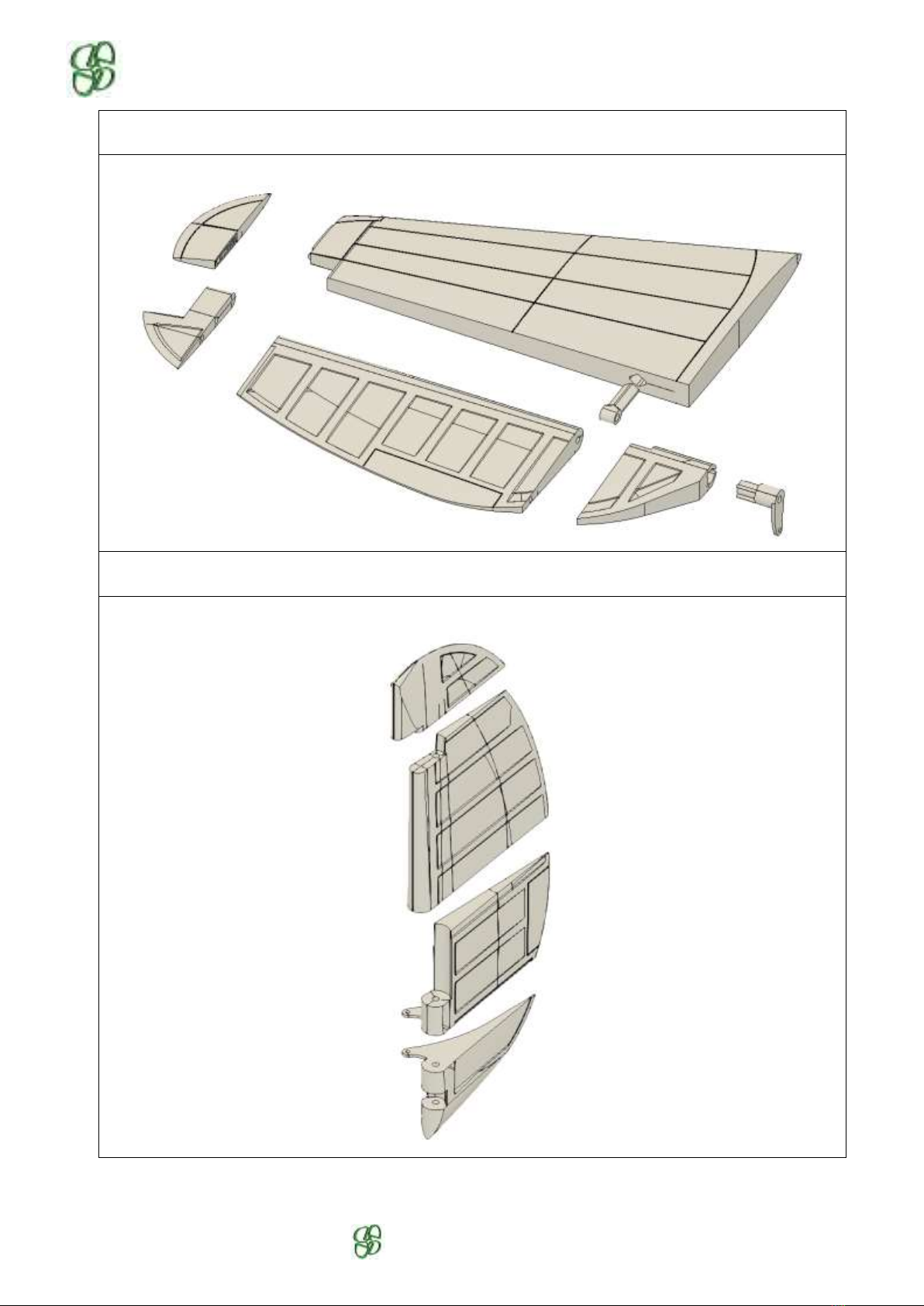

Wing

W1L / R

1

Symetrics,

H-75-1_12-W1L

H-75-1_12-W1R

H-75-1_12-W1L

H-75-1_12-W1R

W2L / R

1

Symetrics,

H-75-1_12-W2L

H-75-1_12-W2R

H-75-1_12-W2LR

W3L / R

1

Symetrics,

H-75-1_12-W3L

H-75-1_12-W3R

H-75-1_12-W3LR

W3L / R tip hinge

1

Symetrics,

H75-1_12-W3L-TE-hinge

H75-1_12-W3R-TE-hinge

Aileron L

1 + 1

H75-1_12-aileron-G-ext

H75-1_12-aileron-G-int-sans-tab

H75-1_12-ailerons

Aileron R

1 + 1

H75-1_12-aileron-D-ext

H75-1_12-aileron-D-int-avec-tab

Wing fairing

1 + 1

H-75-1_12-Belly-front

H-75-1_12-Belly-rear

Gear cover

1 + 1

Symetrics,

H75-1_12-W1L-bossage-train-Av

H75-1_12-W1L-bossage-train-Ar

H75-1_12-W1LR-bossages-

trains

Leading edges

1 + 1

3 versions, lisse, 1

ou 2 trous

H75-1_12-WR-BA-lisse

H75-1_12-WR-BA-1_gun

H75-1_12-WR-BA-2_guns

Tails

Horizontal tail

1 + 1

Symetrics

H-75-1_12-H-stab-D

H-75-1_12-H-stab-G

H-75-1_12-H-stab

Tip

1 + 1

Symetrics

H-75-1_12-h-stab-D-saumon

H-75-1_12-h-stab-G-saumon

elevator

1 + 1

Symetrics

H-75-1_12-H-volet-D-int

H-75-1_12-H-volet-D-mid

H-75-1_12-H-volet-D-ext

H-75-1_12-H-elevators

Elevator control horn

1 + 1

Symetrics

H-75-1_12-H-stab-D-raccord

H-75-1_12-H-stab-G-raccord

../accessoires/H-75-1_12-

pieces-PLA

Vertical fin

1

H-75-1_12-V-stab-fixe

H-75-1_12-V-stab

Rudder (2x)

4

H-75-1_12-Rudder-D1-2X

H-75-1_12-Rudder-D2-2X

H-75-1_12-Rudder-D3

H-75-1_12-Rudder-D4

H-75-1_12-Rudder-2x

Rudder (3x)

4

H-75-1_12-Rudder-D1-3X

H-75-1_12-Rudder-D2-3X

H-75-1_12-Rudder-D3

H-75-1_12-Rudder-D4

H-75-1_12-Rudder-3x

Accessories

../ motors-mounts

Supports

1_12-MM-« length of motor »-

« screw pattern »

1_12-MM-Template

ADDIMP 3D

Une création originale ADDIMP 3D

Hinges

elevator

2

hinge-court-D2x15x5

../accessoires/H-75-1_12-

pieces-PLA

Aileron

2

hinge-court-D2x15x6_4

rudder

2

hinge-long-D2x15x5

1

hinge-court-D2x15x5

Servo mount L / R

1 + 1

symetrics

support_D_servo-mini

couvercle-D-servo-aile

servo-mount_16g-LR

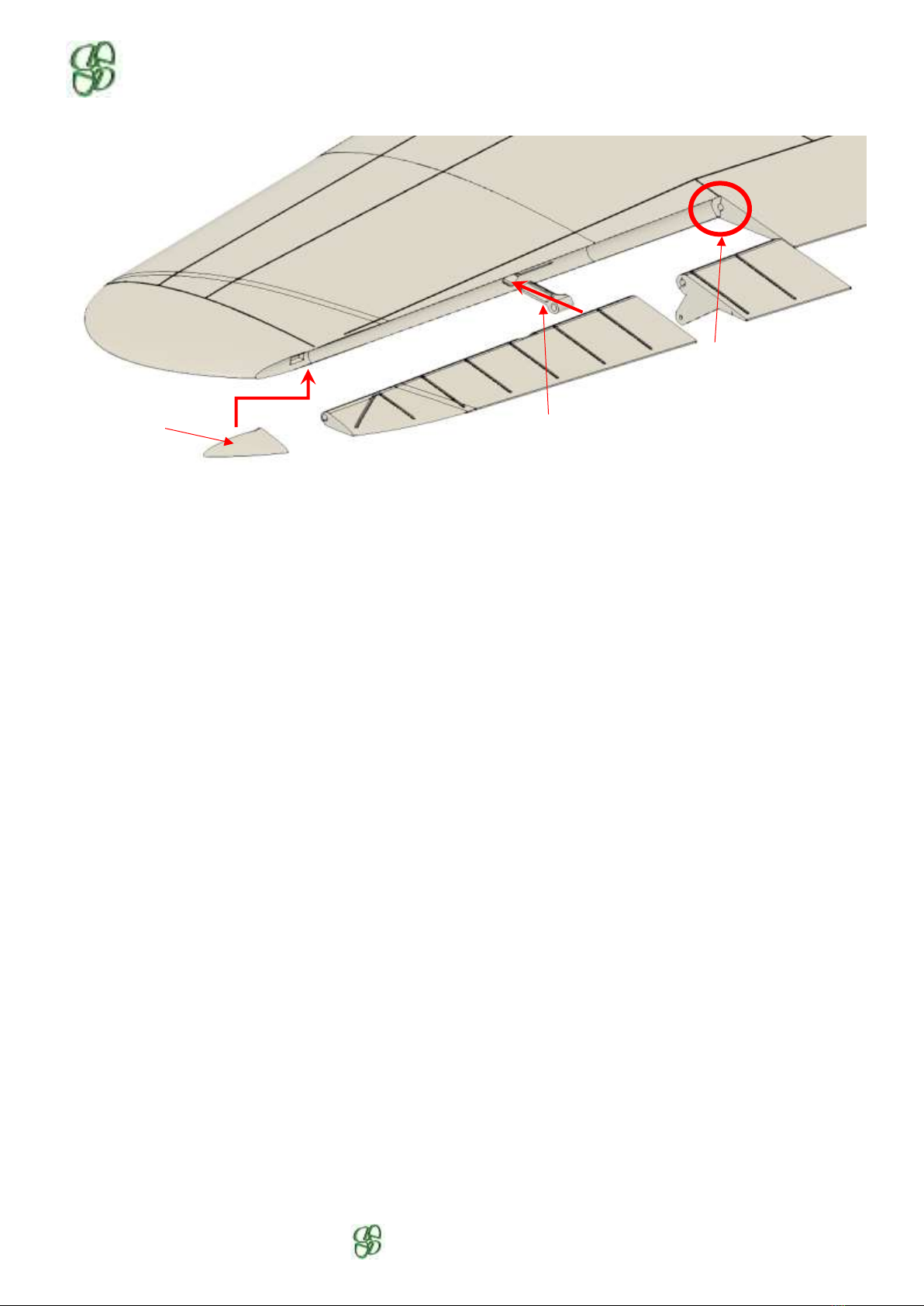

8- wings

8.1- Contrôler toutes les pièces

First, check all the parts, remove all the residual skirt, to sand if needed the parts. Check that all hinge

housings are clean and open.

Assemble all the parts without any glue, to check the well adjustment and alignement.

If you use the carbon tube option, check that it slides freely in its housing.

Then glue each section together, beginning by root section, L1 with L2, then L3. Same order for the right

wing.

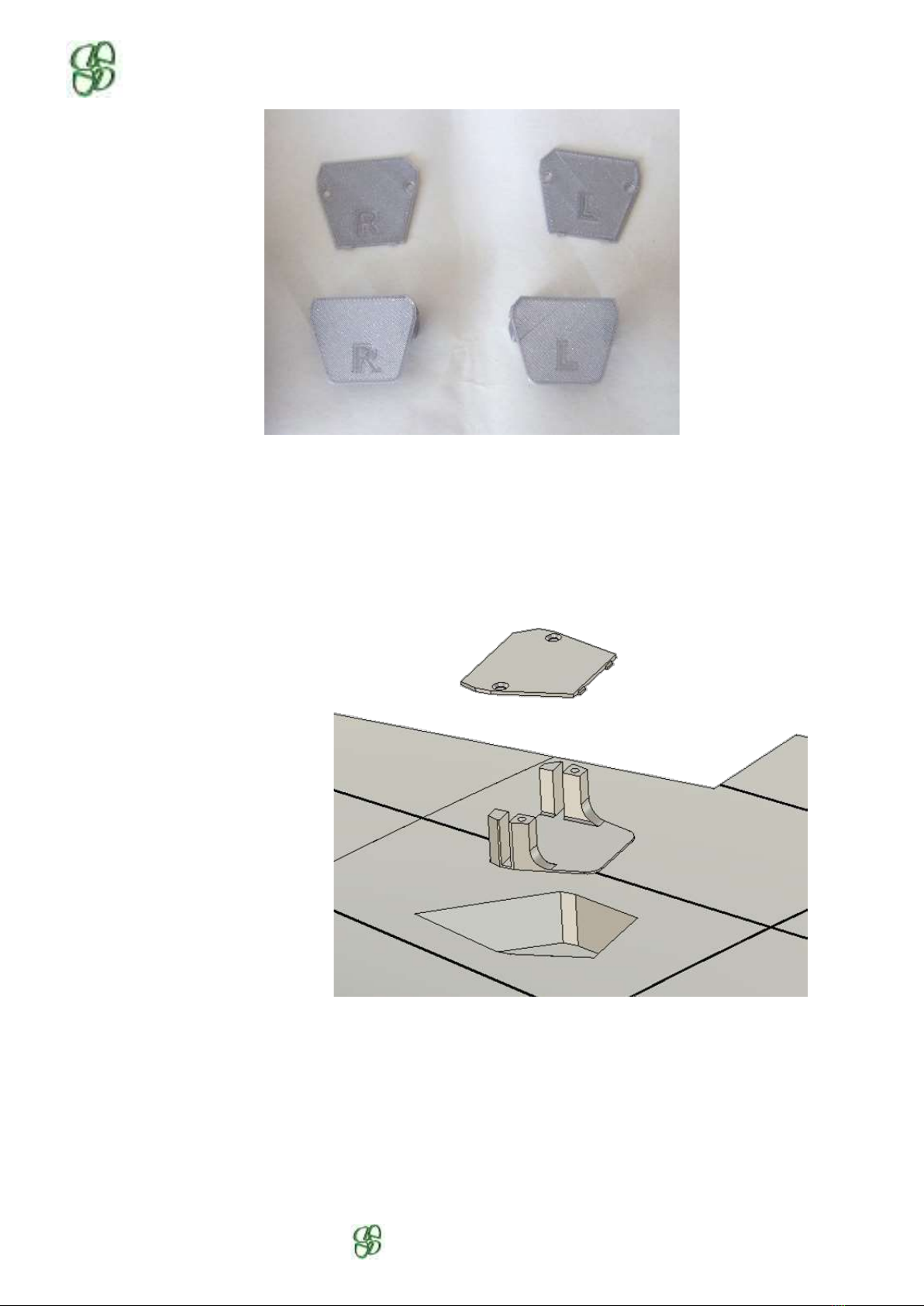

8.2- Support servo

To facilitate the mount and setup of the servo, it is used a special mount with cover. Each part is labelled

with « R » for right side and « L » for left side

W2

W1

W3

ADDIMP 3D

Une création originale ADDIMP 3D

First, glue the mount to the wing. Each one have a letter to indicate the side (L for the left wing, R for right

wing). You can use a servo to keep it straight.

Then fit the servo on the bay, adjust the linkage to the aileron easily, once finish, screw the cover to the

mount with 2 screws 2 x 10.

Install the aileron, check all the passage holes of the hinge pin, glue the 2 parts of the aileron together.

On the wing, there is 1 Ø2 x 15 x 6.4 hinge to present and adjust. Do not stick it.

Installation

W2L

W1L

ADDIMP 3D

Une création originale ADDIMP 3D

Present the aileron with its axis on the assembly, adjust the constant clearance between the wing and the

aileron, then glue the hinges to the wing.

Then assemble the two parts of the wing. Do not forget the Ø3mm carbon tube if necessary

(recommended for LW and PETG filaments).

Do not glue the lower wing fairings at this time.

Hole for the axis

Hinge width 6.4mm

Tip hinge

ADDIMP 3D

Une création originale ADDIMP 3D

9- Fuselage

Assembly diagram, for details, see following pages.

Check all the control passage ducts, a Ø2mm rod must slide freely.

F1

•check the two servo housings and the wire passages

•check the two fishplate housings

•install the velcro strap

F2 to F4

•check the two fishplate housings in F2

•check the nut seat in F3 (if used)

•check the correct fit of each section, then glue them together with F1, in the

order of the sections.

•possibility of adding 2 Ø1mm rods in F3 and F4 to stiffen the rear (LW filament)

Fin

•check all the hinge points, adjust if necessary

•glue the fixed fin part

H stab

•check all the shaft passages in the elevator and hinges (Ø2mm carbon rod)

•assemble the three parts of the elevator together

•install the elevator pushrod in the fuselage and connect it to the horn

•assemble the left stab then the right on the fuselage

Rudder

•glue the cap in F4 to hide the elevator horn

•check all the shaft passages in the rudder and the hinges (Ø2mm carbon rod)

•assemble the four parts of the rudder together

•install the rudder pushrod (if used) in the fuselage and connect it to the horn

•install the hinges in the rudder with the carbon axis

•glue the hinges into the fuselage

ADDIMP 3D

Une création originale ADDIMP 3D

Version A1 to A3

F1

Battery hatch

Version A4 & A5

F1

Battery hatch

ADDIMP 3D

Une création originale ADDIMP 3D

F2

F3

F4

Fin

ADDIMP 3D

Une création originale ADDIMP 3D

Horizontal Stabilizer

Rudder

ADDIMP 3D

Une création originale ADDIMP 3D

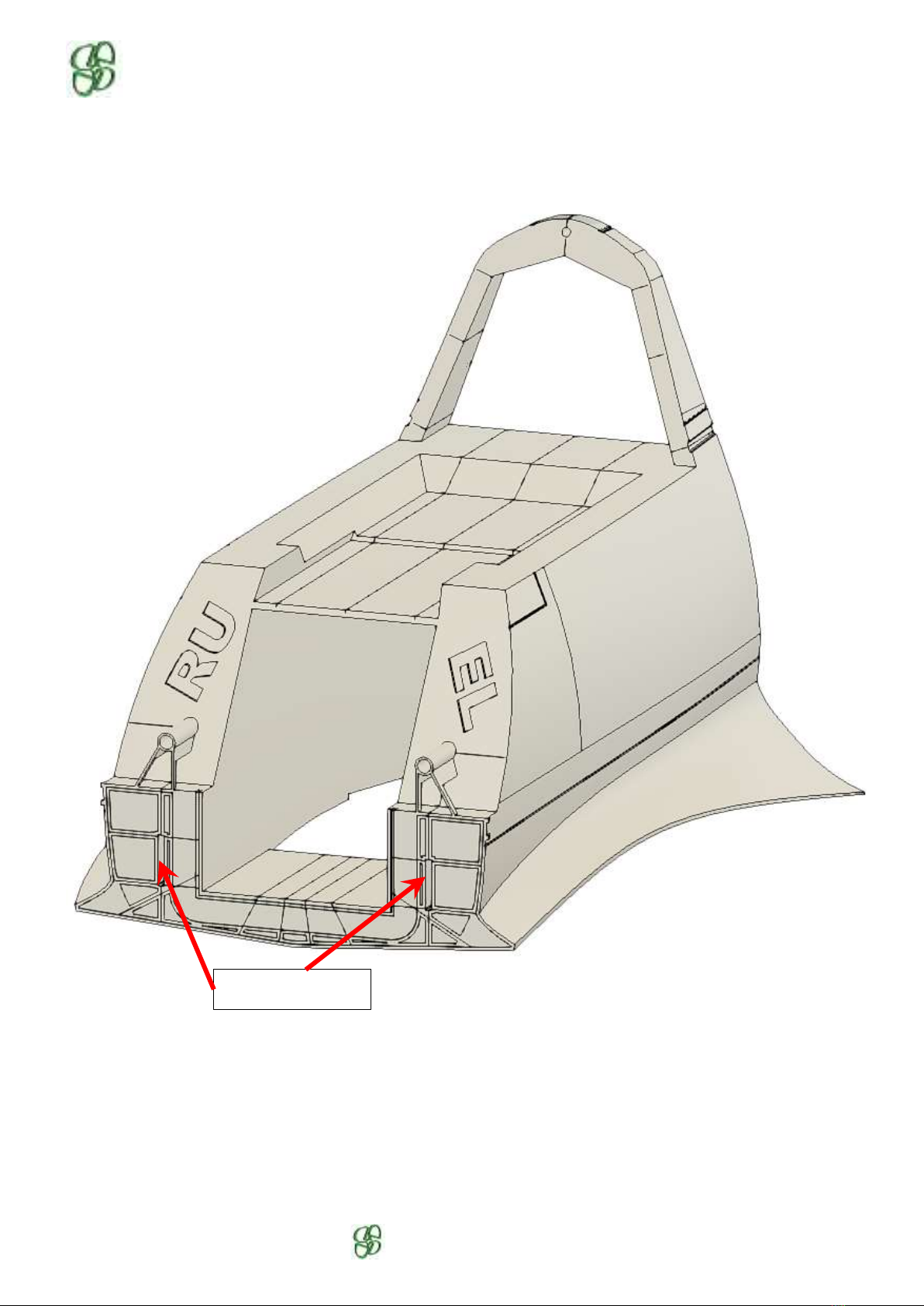

9.1- F1 Preparation

Check the two servo housings and the electrical wire passages.

Check the two fishplate housings.

Install the strap for the battery, provide hook-and-loop strips in the bottom of the battery compartment.

Battery strap

Fishplate housings

ADDIMP 3D

Une création originale ADDIMP 3D

9.2- F2 Preparation

Check the two fishplate housings.

Fishplates housings

ADDIMP 3D

Une création originale ADDIMP 3D

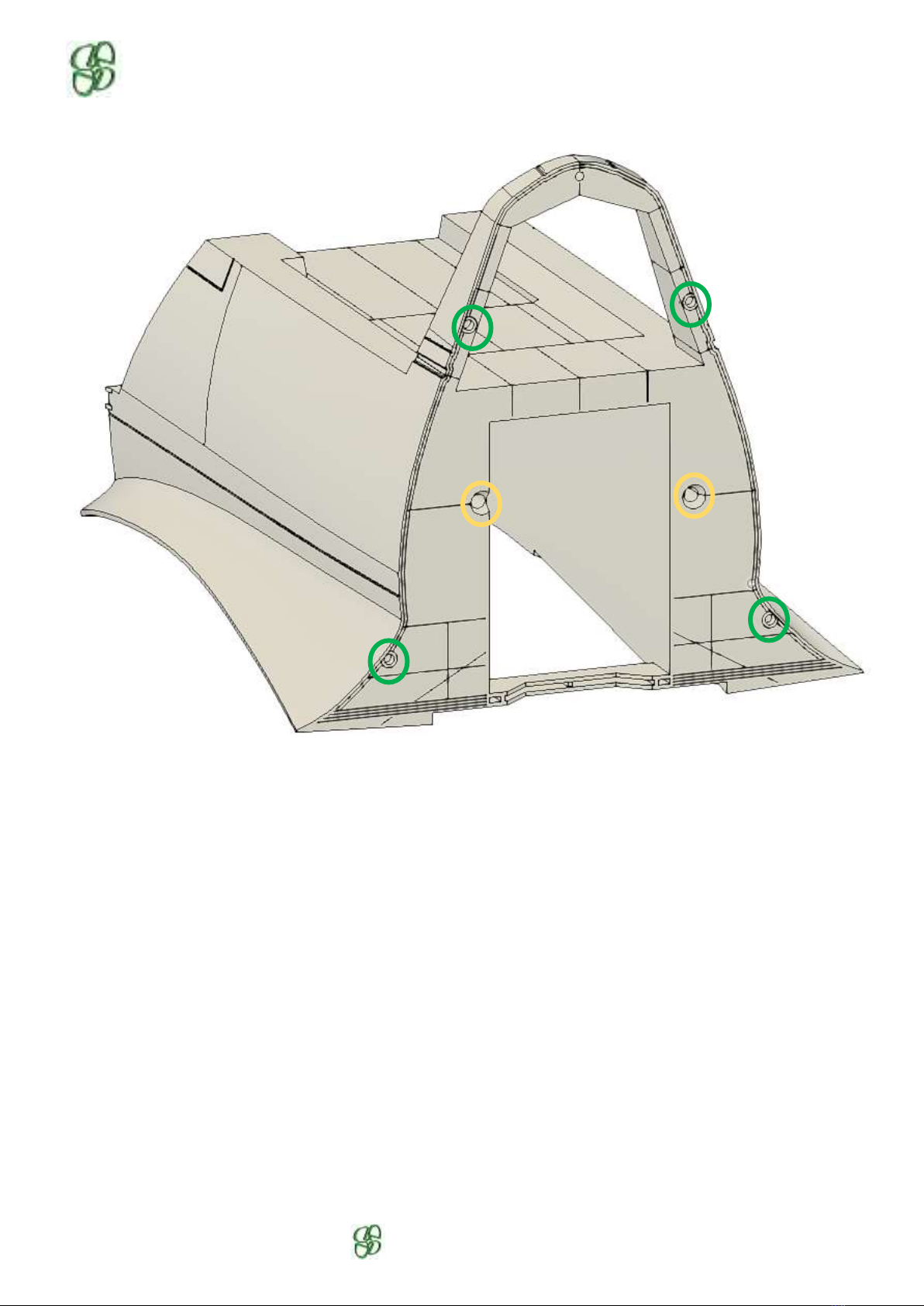

Check the pushrod passages (yellow circles) and the 4 holes for centering (green circles).

ADDIMP 3D

Une création originale ADDIMP 3D

9.3- Préparation de F3

Check the pushrod passages (yellow circles), the 4 holes for centering (green circles) and the 2 housings for

the Ø1mm carbon rod (blue circles).

The centering of the sections F3 and F4 is effected by peripheral ribs. Check that they are in good condition

when printed as well as that of the receptacle part in the adjacent section.

Open the lower area if using rubber bands, otherwise, drill a Ø7mm hole for

the screw to pass

Check the nut housing if used

ADDIMP 3D

Une création originale ADDIMP 3D

10-Horizontal Stabilizer

Use CA glue for assembly,

Check the passage of the Ø2 mm rod in all the hinge pin holes and the bearings / horn. The length of the

axle is 300mm

Hinge length 5mm

Passages d’axe carbone

Table of contents