4

3.Lifting

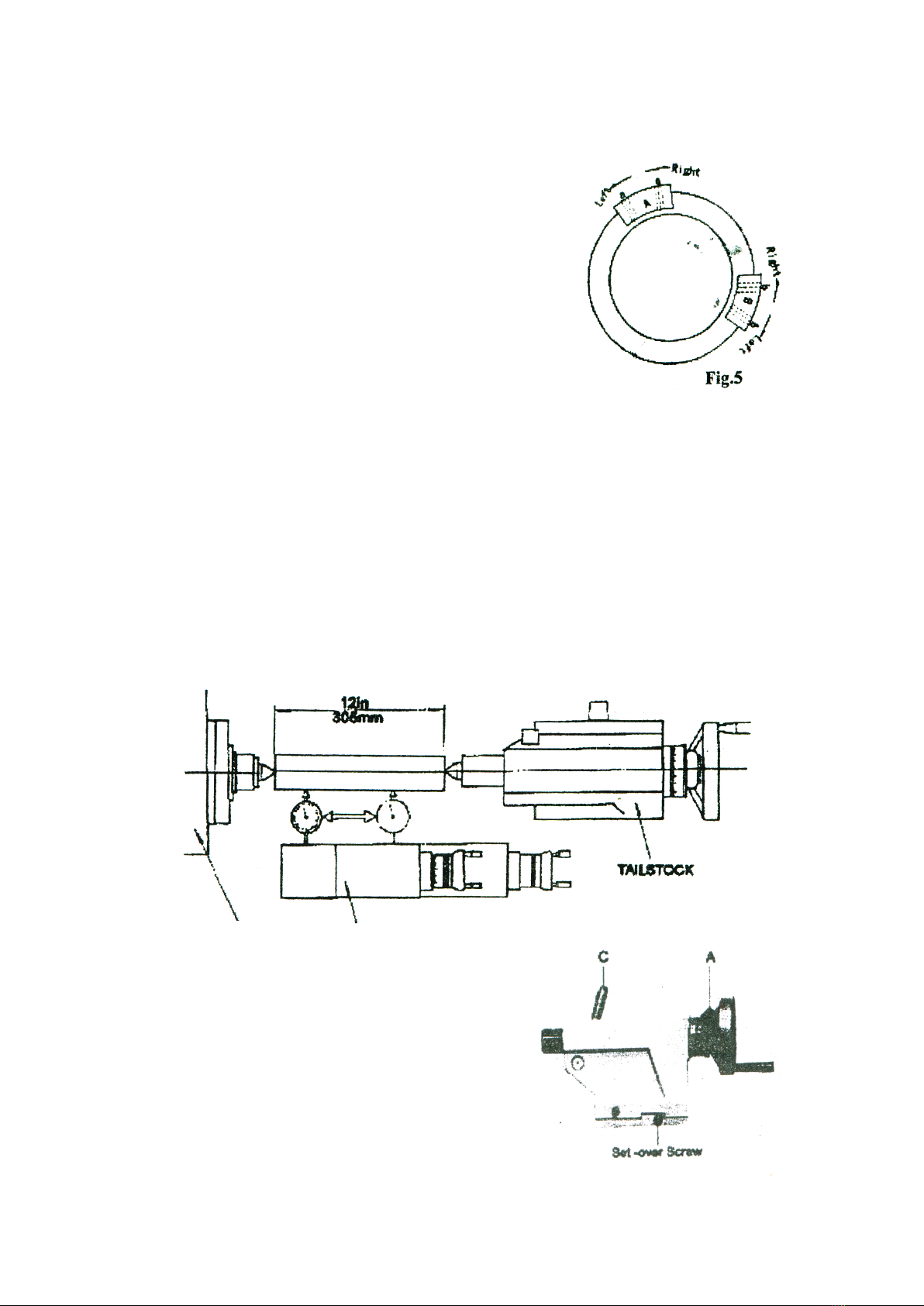

U se a sling-china to sling the lathe as in fig position the saddle and

tailstock along the bed to obtain balance.

I

I

I

I mportant:

mportant:

mportant:

mportant: the sling-chain should not touch the leadscrew or

feed-shaft to avoid damage.

U nloading of the machine. W hen the machine is unloaded form the

car or to the moved, please

proceed with following

steps.(fig.1)

1. preparing two round sticks

(long approx.800mm dia 35mm)

insert into the preserved holes on

lathe bed. T hen lift up with

applying wires on both end of

stick.

2. lifting the machine by a

crane.

3. before lifting adjust the

position of lathe apron and

tailstock to maintain the balance of machine.

4. when the machine was shifted to its destination, always handle

with care to put it down. Don

’

t let go of ot to hit the ground or it will

affect the accuracy of the machine

Note: machine weight can be seen in specification table

5. for the adjustment of electric control, keep the distance between

machines and wall not less than 600mm

4.cleaning

B efore operationg any controls remove the anticorrosion coating

from all slideways and the end gear train, using white spirit or kerosene.

Do not use dellulose solvents for cleaning, as they will damage the

paint finish.

O il all bright-machined surfaces immediately after cleaning using

machine oil or slide way lubricant; use heavy oil or grease on the end

gear.