ADFINIS SKYLOCK User manual

Page 1 of 9 False Car User Manual Version 10.20

ADFINIS PTY LTD

Rail Guided False Car Platform

And Wall Guided False Car Platform

User Manual

This User Manual has been prepared by Adfinis Pty Ltd to provide a general user overview of the Adfinis False Car Rail Guided work

platform, and the Adfinis False Car Wall Guided Platform.

Page 2 of 9 False Car User Manual Version 10.20

THE SAFE USE OF A FALSE CAR

Respect these rules at all times

•No unauthorized or untrained personnel to operate the False Car

•Never overload the False Car. The maximum carrying capacity

(SWL) must be adhered to

•The False Car is a mobile working platform and NOT a means of

transport for personnel or materials

•The Safety Gear must be released to move in the downwards

direction

•Winch must be driven upwards 50mm to release brake arm.

(False Car only)

•The Safety Gear must be fully engaged when the False Car is not

ascending or descending

•Do not drive False Car out of rails above guide wheels.

•Never disconnect the rope climber hoist from the False Car for

lifting other materials

•Carry out daily inspections on the False Car, its suspension and

Safety devices! (refer to False Car Daily Checklist located within

document holder)

•Report irregularities to your charge hand or supervisor without

delay

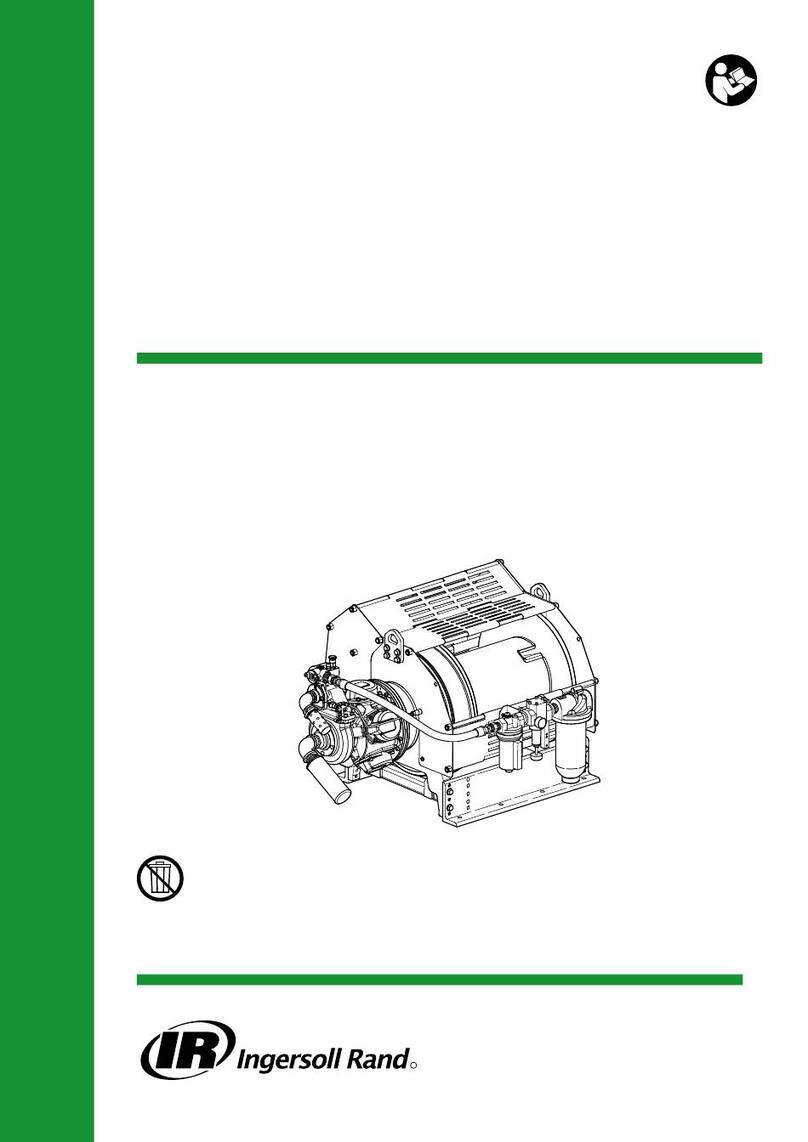

SKYLOCK

Instructions to release

Never attempt to reset SKYLOCK when under load

DRIVE WINCH UPWARDS 50mm

RESET HANDLE –MANUAL TRIP LEVER -

Pull handle clockwise Push LEVER anti-clockwise

to reset to trip SKYLOCK manually

Page 3 of 9 False Car User Manual Version 10.20

1. Safety Characteristics of the Adfinis False Car

•Brake mechanism (gripper wheel) fitted to False Car Frame (controlled by Spring Device) on a Rail Guided False Car.

•Suspended by 2 wire ropes for Rail Guided False Car.

•Brakes are removed from a Wall Guided False Car.

•Suspended by 3 wire ropes, utilizing 1 winch and 2 sky locks for Wall Guided False Car.

•Emergency Stop button available on Alpha Winch.

•Over speed Protection device (Sky lock) fitted.

2. The Alpha Hoist (what you should know)

•The winch operates with traction plates that effectively allow the winch to climb up or down the rope. The rope is not to be able to slip through the traction plates under

normal operation. If power is lost to the winch the service brake on the winch is engaged automatically. The service brake is an Electromagnet type unit and requires

power to disengage (override the spring pressure). Without power, the brake is always on.

•There is a “no power”emergency decent system activated by manual release of the service brake.

•The hoist can be lowered at a controlled speed without power supply.

•The emergency brake lever has limited movement. A light application will allow movement.

•A Heavy application will usually trip the overspeed device (Sky Lock) and may cause damage to the brake lever.

•Emergency Stop Button to be used if up/down switch or 240v motor malfunctions.

3. Winch Operation (best practice)

•Always have an operator standing next to the winch with their hand on the up/down switch when the platform is in motion.

•Never use grips or other means to hold the up/down switch in the up/down position.

•When commencing your down direction (if the False Car Gripper Wheels or Skylock have been engaged) always drive the car up enough (100 ~ 150mm) to enable the

release the brakes and/or Skylock.

•When traveling upwards practice driving beyond the required level and then lowering slowly to the required level. (Repeated upward flicking of the switch for small

upward movements puts added pressure on the electrical system and will reduce the life of capacitors causing loss of power).

Page 4 of 9 False Car User Manual Version 10.20

4. Safety Characteristics of the Skylock (over speed protection)

•The Over speed protection device (Skylock) will allow the wire rope to pass at a safe speed, activation of this device is referred to as “tripping” or “engaging”. The device

is utilised on all Adfinis False Car’s with the following purpose: -

•Failure of main winch rope

•Mechanical failure of the hoist creating an over-speed

•The Sky Lock is a fall arrest device and is engaged mechanically or automatically at a factory preset speed in excess of 25m/min.

•Skylock Operation –can trip manually by rotating the manual lever anti clockwise. The operator may do this if they wish to remove the winch or change winch

ropes.

•Before resetting the Skylock live load must be transferred to the main suspension primary rope by driving the hoist up approximately 50mm.

•Reset by rotating the reset lever clockwise which allows the Skylock to be released from the rope.

•To test pull the rope quickly from above and it should engage instantly.

5. Brake Operation of a Rail Guided False Car

•The brakes are engaged manually by releasing the handle on the spring device or automatically by the release of tension on the spring in the device if the frame ever

becomes detached from the winch.

•Brake Operation –The brake system functions through the movement of a hardened knurled roller (gripper) forced against the Lift Rail (compression)

•When the brake handle is moved to the UP position the brake arm releases the knurled grippers (away from the rail), against the tension of the springs. This moves

the gripper down and away from the rail to allow movement of the false car.

•When the handle is moved to the down position the tension of the springs pulls the roller up into the narrow section of the slot causing the gripper to engage and

prevent downward movement.

•Drive the false car up to disengage the grippers before moving the handle to the up position to release brakes. If the brake handle is forced while the grippers are

engaged the handle may malfunction.

•Do not tie off or prevent brake system from operating unless an additional safety device is fitted e.g. second Skylock on independent rope

•When at working position engage brakes and Skylock if required.

•Do not drive false car out of rails beyond the brake block.

•Do not exceed 250 kg on platform (Approximately 2 technicians & tools). Not to be used to transport people other than those working in the shaft or materials other

than tools i.e. not for trimmer beams or other heavy objects.

6. Electrical Safety

•Each False Car is fitted with a Work Light and a Non-Maintained Emergency Light. In case of power failure inside the lift shaft, the emergency light will become

illuminated and stay illuminated for approx 120 minutes.

•Power to all electrical items is supplied by the Power Control Unit, containing a RCD. The RCD should be manually tripped every morning before starting work.

•When tripping the RCD the emergency light should become illuminated.

Page 5 of 9 False Car User Manual Version 10.20

Trouble Shooting

•Grippers engaging without releasing handle - could be buildup of grease on grippers causing them to touch on rails and engage. Drive to lowest level and clean

with degreaser/mineral turps until gripper wheels, guide shoes etc are free from grease. Clean dirty rails if required.

•Split pins and brake arm mechanism can be damaged by loose bolts located on Lift Rail fixing “fish”plates. Liaise with Client (Project Supervisor) to ensure all

Rail fixings are tightened, allowing acceptable clearance between Brake Arm Mechanism & Lift Rail fixings.

•Gouging or scratching rails –false car may be too loose between rails and may need to be adjusted. Contact Adfinis.

•Winch power “tripping”: -

•RCD “Tripping”- possible electrical fault. Electrical Capacitors can cease without warning from poor power supply, overheating etc. Plugs loose. Brake

cable broken/damaged. Winch wet due to weather. Contact Adfinis.

•Winch Overload “Tripping”–Car overloaded, Low Supply Voltage. Check load on false car, check with site electrical contractor.

•Cement and cement dust can get into the winch mechanism and cause serious damage. Ensure that if concrete cutting occurs in the shaft that the winch and

Skylock are adequately covered or removed from the vicinity.

•Winch “driving”down but not up –Capacitor blown. False Car severely overloaded. Contact Adfinis.

•Winch “falls”when operating in either direction –Severely low supply voltage. Sky Lock will activate. Check with site electrical contractor.

Page 6 of 9 False Car User Manual Version 10.20

QUICK REFERENCE GUIDE

Emergency Decent Lever

Check the emergency Decent Activation handle (located on winch) is

undamaged

Emergency Decent Operation

Remove Winding arm from side of Winch

Note: - The “No Power” emergency bypass will be activated on removal

of Winding Arm

(see picture on right hand side)

Removal of Winding arm will ensure that Winch will not operate

automatically once power is restored

Remove Protection cap at top of Winch and attach winding arm or insert

through motor fan cowling at bottom of electrical motor.

NB. For long distances the Emergency drive through BRAKE is 3 times

faster than through MOTOR, but the motor drive dog is easier to access.

Page 7 of 9 False Car User Manual Version 10.20

Lift Emergency brake to enable manual operation of Winch

Anti-Clockwise winding will move winch up

Clockwise winding will move winch down

Manual operation of the winch is substantially slower than powered

operation which will ensure that the Skylock will not activate during this

process

Brake Control

Test the brake lever, Brakes are engaged if lever is down, rotate

clockwise to disengage

Sky lock Control

The Skylock (Over speed Protection Device) is disengaged by pulling the

handle up (figure 1)

Engage by rolling lower lever anti clockwise (figure 2)

Page 8 of 9 False Car User Manual Version 10.20

The following checks and inspections are to be carried out at the frequencies indicated and a record of the examination

is to be submitted. Use the Adfinis Check List accessed via the QR Code on this car.

If any repair work is to be done on the false car, a safety sling MUST always be placed around the rail/bracket/trimmer

and the false car structure.

1. Daily Pre-operational Checks

a) Visually check the lift shaft above and below the car to ensure it is clear of obstruction.

b) Visually check the Winch rope. Check for broken strands, surface wear, corrosion, wire or strand distortion,

diameter changes and the lengthening of the lay.

c) Visually inspect LMR / shaft hitch point i.e. slings / chains / shackles

d) Visually check the "sky lock" rope(s). Check for broken strands, surface wear, corrosion, wire or strand distortion,

diameter changes and the lengthening of the lay.

e) Visually check the operation of the brake lever and the safety gear operating line.

f) Visually inspect the power cable and plugs (including the intercom cable) connected to the false car.

g) Clean the platform floor.

h) Check the handrails and platform fixings.

i) Inspect the hoist, hitch-plate and sky lock(s) fixing bolts and nuts.

j) Check that the "load notice" and "operating instruction" signs are fixed to the platform handrail.

k) Check the emergency light function.

l) Ensure the toe gear is fitted correctly and secure.

m) Check the height limiting device striker plate is tight on the rope (if fitted).

2. Daily Operational Tests

After the above checks are completed the "work platform" may then be moved and the following items carried out:

a) Drive the platform UP and depress the emergency stop button to validate its function.

b) Drive the platform UP for about 200-mm releasing the safety gear with the brake lever, then stop. (Brakes are

now off).

c) Release the brake lever (brakes on) and drive the hoist in the down direction.

d) The platform should not move (safety gear operated) and the hoist rope should become slack above the car.

e) STOP THE HOIST and drive in the UP direction to take up slack.

f) Test the "sky lock" device (best performed at lowest level). Grasp the safety rope above the "sky lock" and pull it

quickly upwards. The sky lock will “trip”. Reset the "sky lock".

g) In the event of a safety gear engagement as the result of a false car fall, visually check the false car crosshead for

damage i.e. splitting, cracking etc.

h) Should any damage or irregularities be observed in the false car structure, or operation of either the safety gear

or the winch, the FALSE CAR MUST NOT BE OPERATED until it has been checked by a competent person.

i) Fill out the appropriate sections of the Powered Working Platform Daily Checklist.

Page 9 of 9 False Car User Manual Version 10.20

3. Monthly Examination.

After performing daily check, drive the platform to the lowest level to permit inspection of the safety gear.

a) Clean any debris / rubbish / grime / grease from the safety gear assembly.

b) Check the condition of the safety gear jaws (blocks) to ensure there is no excessive indenting on the ramp

surface

c) Check the safety gear roller for condition i.e. wear and or damage.

d) Check the adjustment of the brake lever release lines to ensure that the safety gear rollers are clear of the rails

when the release lever is operated.

e) When the lever is released the lines should be slack and the safety gear rollers in contact with the rails.

f) Check the RCD function.

g) Check for damage, splitting and cracking to timber platform (work deck), crosshead and bottom beam.

4. Commissioning & Six-Monthly Tests

4.1 Safety Gear Drop Test - Adfinis False Car (UNLOADED)

NOTE: This test should only be carried out by (or in the presence of) a qualified rigger.

1. Lower the platform to the lowest landing.

2. Place timber under the frame in the pit. Alternatively, place rail clamps on the rails. This must stop the false car if

drop test fails.

3. When false car frame is resting on stops release the brake lever.

4. Disconnect the Sky Lock. Alternatively pull 1 metre of rope through the Sky Lock and clamp off to stop rope

pulling back through the sky lock.

5. Disconnect the winch from the hitch device.

6. Install release device between winch and hitch device.

7. Drive false car up no more than 200mm.

8. Step off false car.

9. Pull release device lever to drop false car.

10. Brakes should come on and false car stop downward movement with 100mm of release point.

11. Check under car for damage.

12. Check frame and deck for damage.

13. Refit Sky Lock or remove rope clamp and allow slack to travel through Sky Lock.

14. Manually trip Sky Lock to hold the car.

15. Lower winch enough to allow reinstallation to hitch device.

16. Remove release device and reinstall winch.

17. Drive car up 300mm.

18. Set brake on and drive car down to rest car on brakes.

19. Check rails for damage from grippers locking on.

4.2 Sky lock rated load test

Sky Lock Test Procedure

After completing the Safety Gear Drop Test, carry out the Sky Lock Test.

1. Move the platform up and release the brake lever (brakes off).

2. Stop the winch and keep the brake lever released.

3. Drive the false car down with the brake lever released.

4. Trip the Sky Lock manually while travelling down. The false car should stop immediately via the Sky Lock and the

hoist rope will become slack. (Caution, the winch will lean over when the rope becomes slack).

5. Stop driving the winch.

6. Drive the winch in the up direction and take the load off the sky lock.

Popular Winch manuals by other brands

AL-KO

AL-KO 351 Instructions for use

Ingersoll-Rand

Ingersoll-Rand Force 5i Series Product Maintenance Information

Ingersoll-Rand

Ingersoll-Rand FORCE5i FA2i-MRA Product Maintenance Information

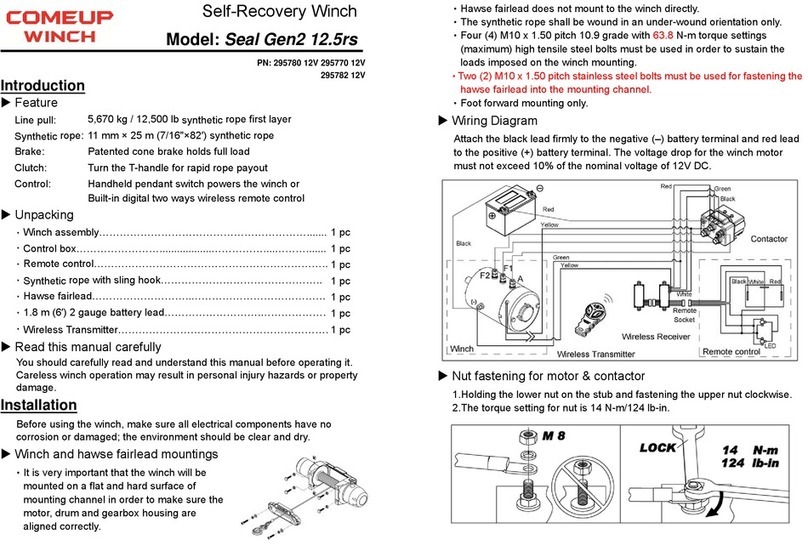

Comeup

Comeup DV-15 manual

Comeup

Comeup Seal Gen2 12.5rs quick start guide

Ramsey Electronics

Ramsey Electronics 2000 owner's manual

GEBUWIN

GEBUWIN WW250 D/Ex Series operating instructions

Harken

Harken 40.2 PT Installation and maintenance manual

Superwinch

Superwinch H14W Fitting instructions

Mile Marker

Mile Marker H9000 Installation & operator's manual

Harken

Harken Performa 50.2 STP Installation and maintenance manual

REMA

REMA WW Series owner's manual