3

SUMMARY

INTRODUCTORY COMMENT ............................................3

GENERAL RULES OF SAFETY ...........................................4

Transfer ...........................................................................................................4

Storage and disposal .................................................................................4

Correct use.....................................................................................................4

Maintenance .................................................................................................4

Transporting the machine.........................................................................4

General rules of the batteries..................................................................4

TECHNICAL DESCRIPTION.................................................5

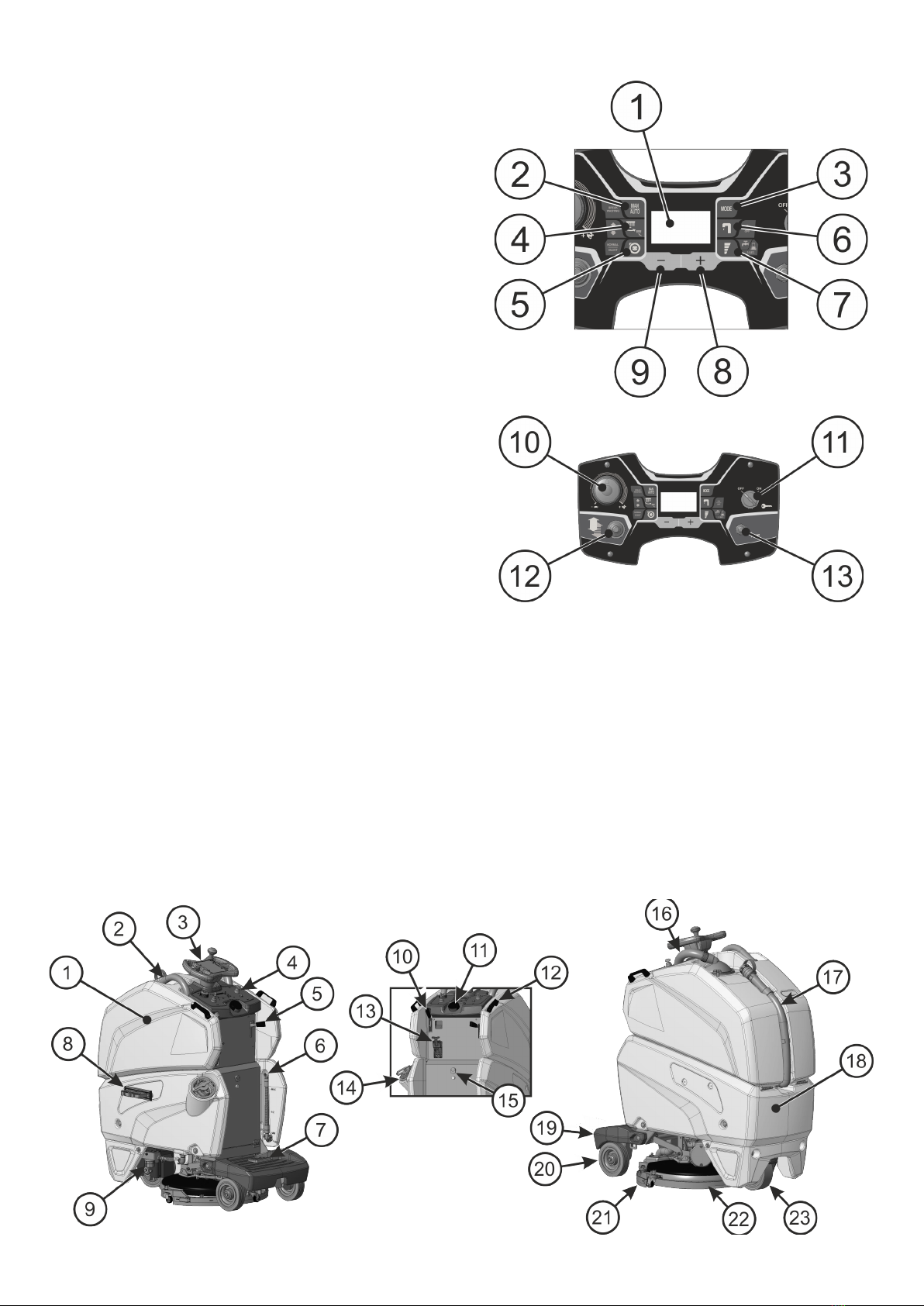

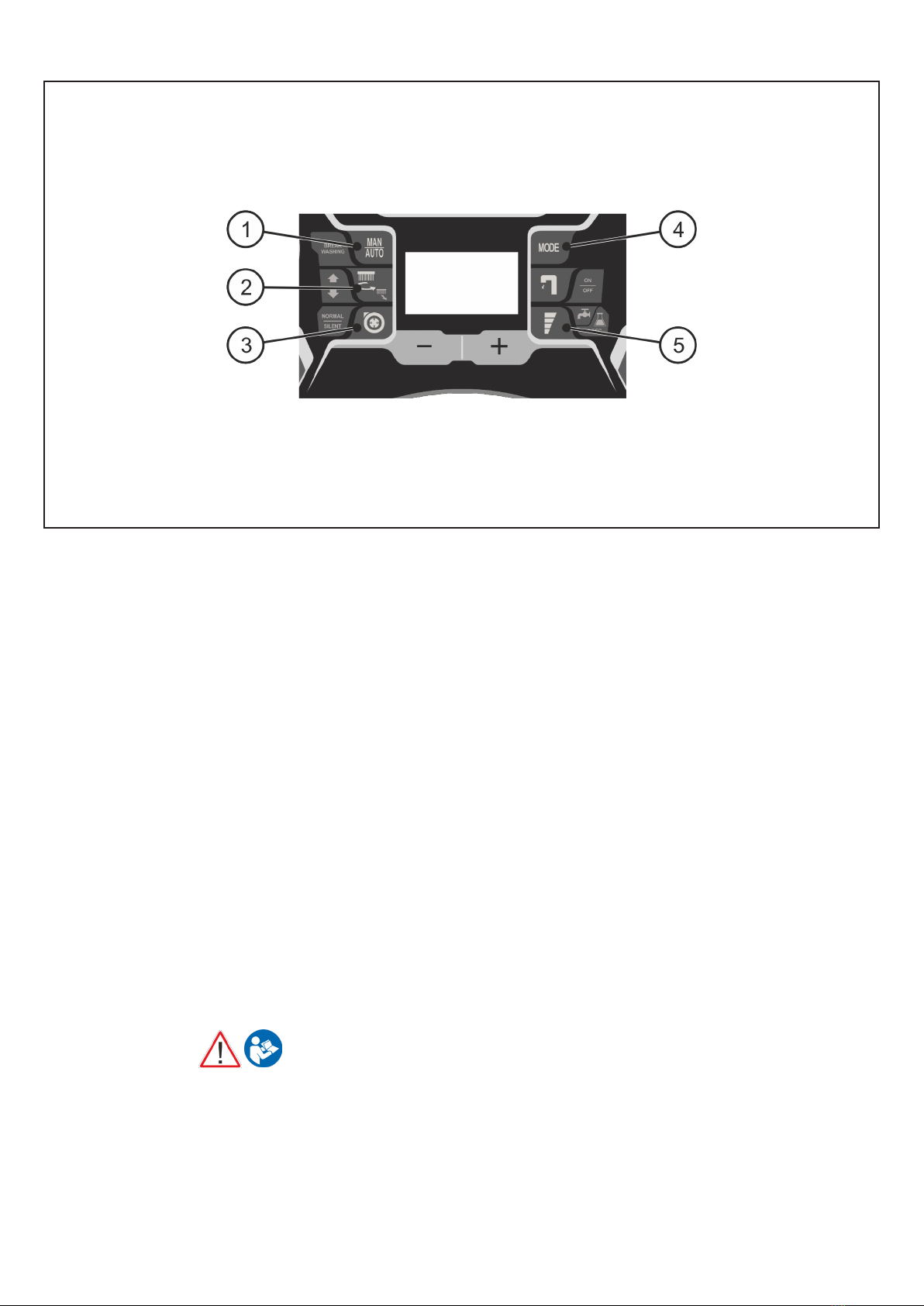

DISPLAY AND CONTROLS LEGEND.................................6

MACHINE LEGEND..............................................................6

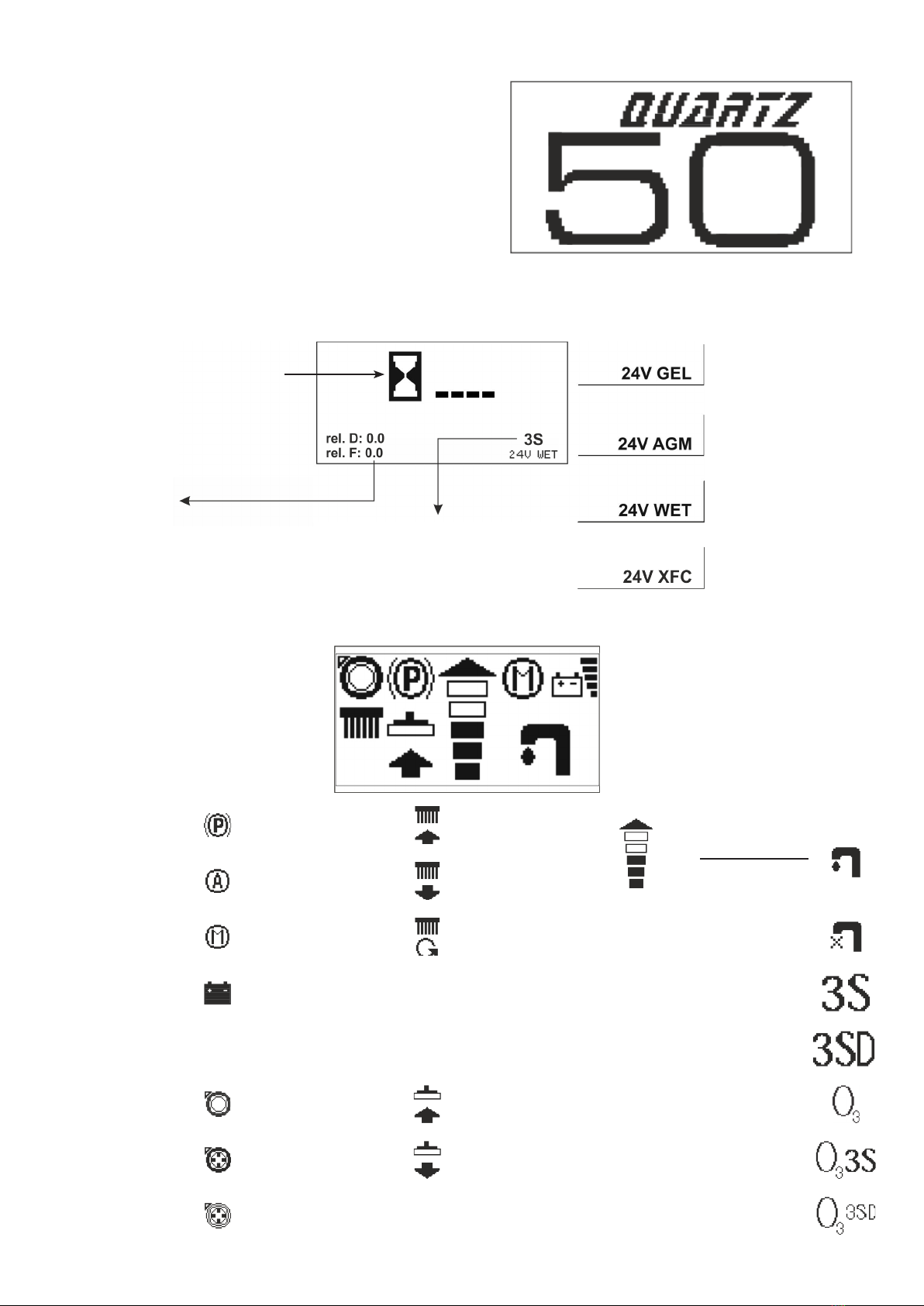

READING THE DISPLAY......................................................7

Display when switching on.......................................................................7

Software release...........................................................................................7

Controls display............................................................................................7

Hourmeter......................................................................................................7

Water system.................................................................................................7

Battery settings............................................................................................7

NAVIGATION CONTROLS...................................................8

General settings ...........................................................................................8

Select the display language .....................................................................8

Change the battery setting ......................................................................8

Change the water system..........................................................................8

Display tune .................................................................................................8

Display brightness........................................................................................8

MANUAL SYMBOLS............................................................9

OPTIONAL EQUIPMENTS...................................................9

BEFORE THE USE .................................................................10

Handling of the packed machine ...........................................................10

Unpacking and manually moving the machine.................................10

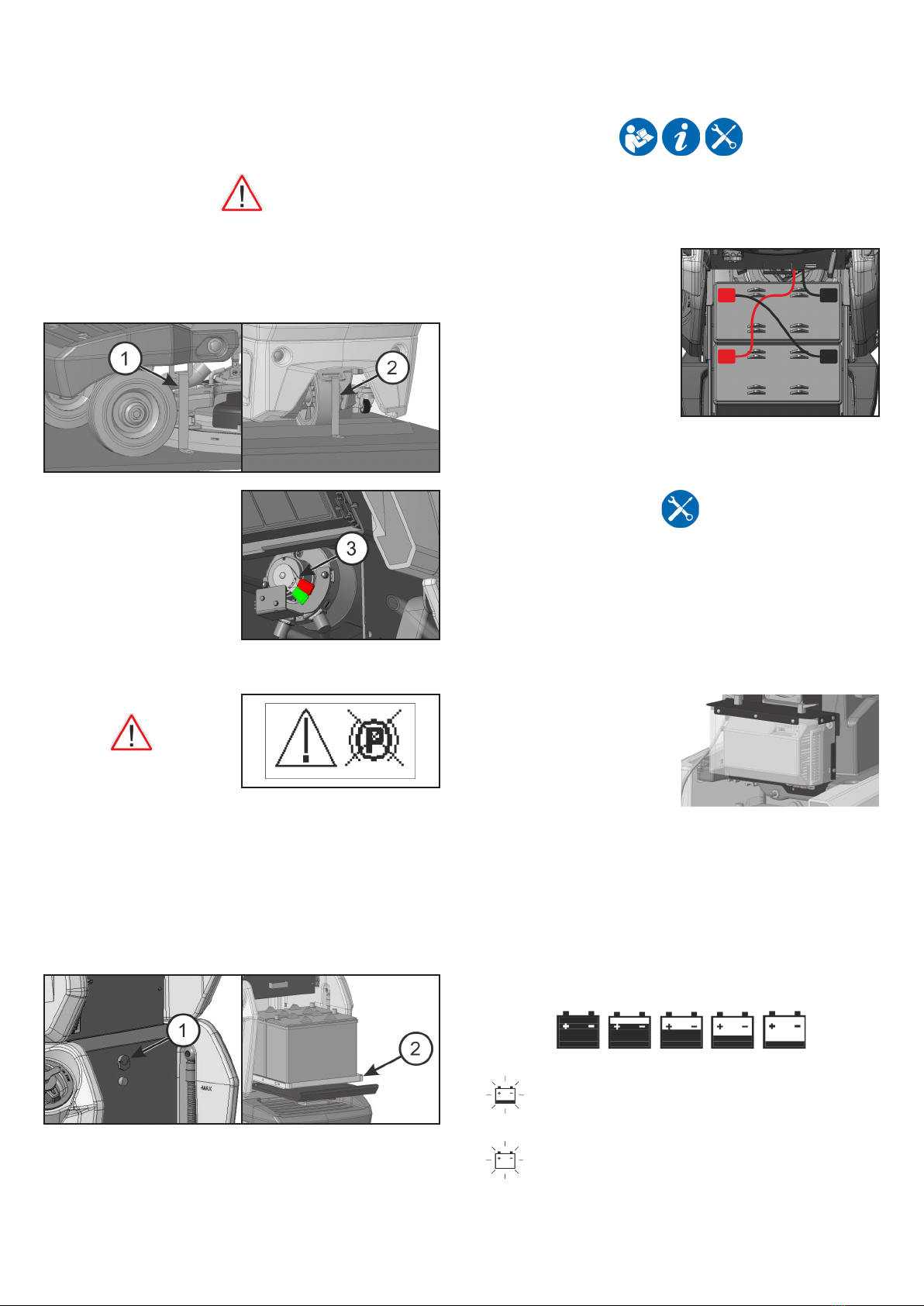

Access to the battery van .........................................................................10

Installing the batteries...............................................................................10

Battery charger.............................................................................................10

On-board battery charger (optional) ....................................................10

Battery charge level indicator.................................................................10

Lifting the recovery tank...........................................................................11

Battery charging ..........................................................................................11

Battery charging using the on-board charger (optional) ..............11

Assembling the brush.................................................................................11

Assembling and disassembling the splashguards ..............................11

FLOOR CLEANING ...............................................................12

Connecting the battery connector and switching on the machine ..... 12

Recovery tank ...............................................................................................12

Detergent solution tank ............................................................................12

3S “Solution Saving System” (optional) ...............................................12

3SD “Solution Saving System Dispenser” (optional) ........................12

Water carriage level selection – 3S and 3SD System.......................13

Detergent solution percentage selection – 3SD System.................13

WORK .....................................................................................13

Manual mode work.....................................................................................13

Speed adjustment, forward and backward..........................................14

Detergent solution flow adjustment .....................................................14

Automatic mode work ...............................................................................14

Silent mode suction motor.......................................................................14

Stand-by mode.............................................................................................14

Horn .................................................................................................................15

Parking brake ................................................................................................15

Brushes motor overload protection system ........................................15

Overflow system...........................................................................................15

MACHINE STOP AFTER CLEANING OPERATION .........16

Break washing mode...................................................................................16

DAILY MAINTENANCE........................................................16

Draining and cleaning the recovery tank.............................................16

Cleaning the suction filter........................................................................16

Automatic disassembling of the brush.................................................16

Draining and cleaning the detergent tank (3SD) ..............................16

Draining and cleaning the solution tank.............................................16

Cleaning the brush......................................................................................17

Cleaning the squeegee...............................................................................17

WEEKLY MAINTENANCE....................................................17

Rear squeegee rubber check ....................................................................17

Cleaning the squeegee hose.....................................................................17

Cleaning the outer filter and the solution tank ................................17

Squeegee height adjustment...................................................................17

Cleaning the filter (3S or 3SD version).................................................17

TWO-MONTHLY MAINTENANCE.....................................18

Front squeegee rubber check...................................................................18

SIX-MONTHLY MAINTENANCE........................................18

Splash guards rubber check .....................................................................18

TROUBLESHOOTING GUIDE..............................................18

The suction motor does not work ..........................................................18

The brush motor does not work..............................................................18

The traction motor does not work.........................................................18

The solution is not spilled on the brush...............................................18

The machine does not clean properly ..................................................19

The squeegee does not dry properly......................................................19

Excessive foam production.......................................................................19

PROGRAMMED MAINTENANCE .....................................19

Periodic ordinary maintenance chart....................................................19

INTRODUCTORY COMMENT

Thank you for having chosen our machine. This floor cleaning machine is used for the industrial and civil cleaning and is able to clean any type of floor.

During its advance movement, the combined action of the brushes and the detergent solution removes the dirt which is aspirated through the rear

suction assembly, giving a perfectly dry surface.

The machine must be used only for such purpose. It gives the best performance if it is used correctly and maintained in perfect efficiency. We therefore

ask you to read this instruction booklet carefully whenever difficulties arise in the course of the machine’s use. In case of need, we ask you to contact

our service department for all advice and servicing as may prove necessary.

CAUTION This machine is for indoor use only

CAUTION This machine shall be stored indoors only.