AdirPro N User manual

Concrete

USER GUIDE

ADI709-01

Impact

Hammer

PRO QUALITY FOR THE

PROFESSIONAL.

AdirPro is known for its quality products in the construction industry, all

manufactured to the highest standards. We strive to help you complete

your project in the most reliable, safe, and cost-effective manner. We

deliver everything with accuracy you can count on so your team can

count on you.

Thank you

for your

purchase.

Table of Contents

1 Important Safety information

3 Measuring

18 Maintenance

24 Data

25 Limited Warranty

27 Disclaimer

28 Notes

1

Important Safety Information

GENERAL INFORMATION

Basic information

The concrete test hammer is designed according to state-of-

the-art technology and recognized safety regulations. Please

read through these operating instructions carefully upon initial

startup. They contain important information about safety, use

and maintenance of the concrete test hammer.

Designated Use

The concrete test hammer is a mechanical device used for

performing rapid, nondestructive quality testing on materials in

accordance with the customer’s specications; in most cases,

however, the material involved is concrete. The device is to be

used exclusively on the surfaces to be

tested and on the testing anvil.

Liability

Our “General Terms and Conditions of Sale and Delivery” apply

in all cases. Warranty and liability claims arising from personal

injury and damage to property cannot be upheld if they are due

to one or more of the following causes:

• Failure to use the concrete test hammer in accordance

with its designated use

• Incorrect performance check, operation and maintenance

of the concrete test hammer

• Failure to adhere to the sections of the operating

instructions dealing with the performance check,

operation and maintenance of the concrete test hammer

• Unauthorized structural modications to the concrete test

hammer

• Serious damage resulting form the effects of foreign

bodies, accidents, vandalism and acts of God.

2

Important Safety Information

SAFETY REGULATIONS

General Information

• Perform the prescribed maintenance work on schedule.

• Carry out a performance check once the maintenance

work has been completed.

• Handle and dispose of lubricants and cleaning agents

responsibly.

Unauthorized Operators

The concrete test hammer is not allowed to be operated by

children and anyone under the inuence of alcohol, drugs or

pharmaceutical prescriptions. Anyone who is not familiar with

the operating instructions must be supervised when using

the concrete test hammer.

Safety Icons

The following icons are used in conjunction with all important

safety notes in these operating instructions.

Standards and Regulations Applied

DANGER WARNING

This note indicates a risk of

serious or fatal injury should

certain rules of behavior be

disregarded.

This note warns you about the

risk of material damage, nancial

lossand legal penalties (e.g. loss of

warranty rights, liability cases, etc.)

• ISO/DIS 8045 International

• EN 12 504-2 Europe

• ENV 206 Europe

• BS 1881, part 202 Great Britain

• DIN 1048, part 2 Germany

• ASTM C 805 USA

• NFP 18-417 France

• B 15-225 Belgium

• JGJ/ T 23-2001 China

• JJG 817-1993 China

3

Measuring

MEASURING PRINCIPLE

The device measures the rebound value R. There is a Specic

relationship between this value and the hardness and strength

of the concrete.

The following factors must be taken into account when

ascertaining rebound values R:

• Impacting direction: horizontal, vertically upwards or

downwards

• Age of the concrete

• Size and shape of the comparison sample (cube, cylinder)

Models N and NR can be used for testing:

• Concrete items 100 mm or more in thickness

• Concrete with a maximum particle size ≤ 32mm

Models L and LR can be used for testing:

• Items with small dimensions (e.g. thin- walled items with a

thickness from 50 to 100mm)

IMPORTANT: If necessary, clamp the items to be tested prior

to measurement in order to prevent the material deecting.

• Items made from articial stone which are sensitive to

impacts.

IMPORTANT: Preferably perform measurements at

temperatures between 50ºF and 122ºF only.

MEASURING PROCEDURE

The items in (brackets) are illustrated in Figure4, on page 5.

Perform a few test impacts with the concrete test hammer on a

smooth, hard surface before taking any measurements which

you are going to evaluate.

4

• Use a grindstone to

smoothen the test surface.

(Figure 1)

Preparing the test surface

• Position the concrete test

hammer perpendicular to

the test surface.

• Deploy the impact plunger

(1) by pushing the concrete

test hammer towards the

test surface until the

push button springs out.

(Figure 2) Deploying the impact plunger (1) (model NR)

IMPORTANT: Each test surface should be tested with at least

10 impacts. The individual impact points must be spaced at

least 20mm apart.

Measuring

The device measures the rebound value R. There is a Specific relationship between this

value and the hardness and strength of the concrete.

The following factors must be taken into account when ascertaining rebound values R:

- Impacting direction: horizontal, vertically upwards or downwards

- Age of the concrete

- Size and shape of the comparison sample (cube, cylinder)

Models N and NR can be used for testing:

- Concrete items 100 mm or more in thickness

- Concrete with a maximum particle size

Models L and LR can be used for testing:

- Items with small dimensions (e.g. thin- walle

If necessary, clamp the items to be tested prior to measurement in order to

prevent the material deflecting.

- Items made from artificial stone which are sensitive to impacts.

!gninraW

The impact plunger (1) generates a recoil when it deploys. Always hold the

concrete test hammer in both hands!

The device measures the rebound value R. There is a Specific relationship between this

value and the hardness and strength of the concrete.

The following factors must be taken into account when ascertaining rebound values R:

- Impacting direction: horizontal, vertically upwards or downwards

- Age of the concrete

- Size and shape of the comparison sample (cube, cylinder)

Models N and NR can be used for testing:

- Concrete items 100 mm or more in thickness

- Concrete with a maximum particle size

Models L and LR can be used for testing:

- Items with small dimensions (e.g. thin- walle

If necessary, clamp the items to be tested prior to measurement in order to

prevent the material deflecting.

- Items made from artificial stone which are sensitive to impacts.

Danger!

Always hold the concrete test hammer in

to the test surface, before u trigger the impact!

Each test surface should be tested with at least 10 impacts. The individual

impact points must be spaced at least 20 mm apart.

WARNING

The impact plunger (1) generates a recoil when it deploys. Always

hold the concrete test hammer in both hands!

DANGER

Always hold the concrete test hammer in both hands, perpendicular

to the test surface, before you trigger the impact!

5

• Position the concrete test

hammer perpendicular to

and against the test surface.

Push the concrete test

hammer against the test

surface at moderate speed

until the impact is triggered

(a high beep acknowledges

registration).

• Repeat this procedure for the whole measurement series.

(Figure 3) Performing the test (illustration shows model NR)

• If you are using models N and L, press the pushbutton (6) to

lock the impact plunger (1) after every impact. Then read off

and note down the rebound value R indicated by the pointer

(4) on the scale (19).

• If you are using models NR and LR, the rebound value R

is automatically printed on the recording paper. It is only

necessary to lock the impact plunger (1) using the push

button (6) after the last impact.

(Figure 4) Reading the test result from the scale (19) on models

N and L

Measuring

The device measures the rebound value R. There is a Specific relationship between this

value and the hardness and strength of the concrete.

The following factors must be taken into account when ascertaining rebound values R:

- Impacting direction: horizontal, vertically upwards or downwards

- Age of the concrete

- Size and shape of the comparison sample (cube, cylinder)

Models N and NR can be used for testing:

- Concrete items 100 mm or more in thickness

- Concrete with a maximum particle size

Models L and LR can be used for testing:

- Items with small dimensions (e.g. thin- walle

If necessary, clamp the items to be tested prior to measurement in order to

prevent the material deflecting.

- Items made from artificial stone which are sensitive to impacts.

If you are using models N and L, press the pushbutton (6) to lock the impact plunger (1)

after every impact. Then read off and note down the rebound value R indicated by the

pointer (4) on the scale (19).

If you are using models NR and LR, the rebound value R is automatically printed on the

recording paper. It is only necessary to lock the impact plunger (1) using the push button

(6) after the last impact.

Impact Plunger

Rider with

Guide Rod

Plexiglass

Window

Push Button

(Complete)

6

OUTPUTTING AND EVALUATING DATA

Output

Models N and L:

After every impact, the rebound value R is displayed by the

pointer (4) on the scale of the device.

Models NR and LR:

The rebound value R is automatically registered on the

recording paper.

It is possible to record about 4000 test impacts on each roll.

Evaluation

Take the average of the 8 – 10 rebound values R which you

have measured.

IMPORTANT: Do not include values which are too high or too

low (the lowest and highest values) in your calculation of the

average value.

• Determine which conversion curve is appropriate for the

selected body shape (see Figure 5 to Figure 10, on pages

8-13)Then, using the average rebound value Rm and the

selected conversion curve, read off the average compressive

strength.

IMPORTANT: Note the impact direction!

The average compressive strength is subject to a dispersion (±

4.5 N/mm² to ±8 N/mm²).

Measuring

7

CONVERSION CURVES

Derivation of the conversion Curves

The conversion curves (Figure 5, to Figure 10) for the concrete

test hammer are based on measurements taken on very many

sample cubes. The rebound values R of the sample cubes

were measured using the concrete test hammer. Then the

compressive strength was ascertained on a pressure testing

machine. In each test, at least 10 test hammer impacts were

performed on one side of the test cube which was lightly

clamped on the press.

Validity of the Conversion Curves

• Standard concrete made from Portland or bleat furnace slag

cement with sand gravel (maximum particle size dia. ≤ 32 mm)

• Smooth, dry surface

• Age: 14 – 56 days

Empirical values:

The conversion curve is practically independent of the:

• Cement content of the concrete

• Particle graduation,

• Diameter of the largest particle in the ne gravel mixture,

providing the diameter of the maximum

• Water/cement ratio

Measuring

8

Conversion Curves, Concrete Test Hammer Model N/NR

Concrete pressure resistance of a cylinder after 14 – 56 days

(Figure 5) Model N/NR: Conversion curves based on the

average compressive strength of a cylinder and the rebound

value of R

fckcyl.m: Average pressure resistance of a cylinder (probable

value)

IMPORTANT: The concrete test hammers shown in Figure 5

and Figure 6 indicates the impact direction.

Measuring

9

Conversion Curves, Concrete Test Hammer Model L/LR

Concrete pressure resistance of a cylinder after 14 – 56 days

(Figure 6) Model L/LR: Conversion based on the average

pressure resistance of a cylinder and the rebound value R

Limits of Dispersion

fckcyl: The max. and min. values are set so 80% of all test

results are included.

Measuring

10

Conversion Curves, Concrete Test Hammer Model N/NR

Concrete pressure resistance of a cube after 14 – 56 days

(Figure 7) Model N/NR: Conversion curves based on the

average compressive strength of a cube and the rebound

value of R

fckcube.m: Average pressure resistance of a cube (probable

value)

IMPORTANT: The concrete test hammers shown in Figure 7

and Figure 8 indicates the impact direction.

Measuring

11

Conversion Curves, Concrete Test Hammer Model L/LR

Concrete pressure resistance of a cube after 14 – 56 days

(Figure 8) Model L/LR: Conversion based on the average com-

pressive strength of a cube and the rebound value R

Limits of Dispersion

fckcube: The max. and min. values are set so 80% of all test

results are included.

Measuring

12

Conversion Curves, Concrete Test Hammer Model N/NR

Concrete pressure resistance of a cylinder after 14 – 56 days

(Figure 9) Model N/NR: Conversion curves based on the

average compressive strength of a cylinder and the rebound

value of R

fckcyl.m: Average pressure resistance of a cylinder (probable

value).

IMPORTANT: The concrete test hammers shown in Figure 9

and Figure 10 indicates the impact direction.

Measuring

13

Conversion Curves, Concrete Test Hammer Model L/LR

Concrete pressure resistance of a cylinder after 14 – 56 days

(Figure 10) Model L/LR: Conversion based on the average

compressive strength of a cylinder and the rebound value R

Limits of Dispersion

fckcyl: The max. and min. values are set so 80% of all test

results are included.

Measuring

14

Measuring

FACTORS AFFECTING THE VALUES

Direction of impact

The measured rebound value R is dependent on the impact

direction.

Shape coefcient

The compressive strength measured in a pressure Testing ma-

chine depends on the shape and size of the sample.

IMPORTANT: The samples prescribed for use in the Particular

country must be taken into account when converting the re-

bound value R into Compressive strength.

In the conversion curves on page 8 to page 17, the Values for

compressive strength are specied for cylinders (Ø 150 × 300

mm or Ø 6” × 12”) and for cubes (length of side 15cm). The

following shape coefcients are familiar from the literature:

Cube 150mm 200mm 300mm

Shape

coefcient

1.00

1.25

0.95

1.19

0.85

1.06

Cylinder Ø150×300mm

Ø6”×12”

Ø100×200mm Ø100×200mm

Shape

coefcient

0.80

1.00

0.85

1.06

0.95

1.19

Drill core Ø50×56mm Ø100×100mm Ø150×150mm

Shape

coefcient

1.04

1.30

1.02

1.28

1.00

1.25

15

Measuring

Example: A cube with a length of side of 200 mm is used for the

determination of the compressive strength with the pressure

testing machine. In this case the strength values shown in the

conversion curves in Figure 9 and Figure 10 on pages 12-13 (for

cylinders Ø 6”×12”) must be multiplied by the shape coefcient

of 1.19.

Time coefcient

The age of the concrete and its carbonate penetration depth

can signicantly increase the measured rebound values R.

It is possible to obtain accurate values for the effective strength

by removing the hard, carbonate-impregnated surface layer

using a manual grinding machine over a surface area of

about Ø 120 mm and performing the measurement on the

non-carbonate-impregnated concrete. The time coefcient,

i.e. the amount of the increased rebound values R, can be

obtained by taking additional measurements on the

carbonate-impregnated surface.

Rm carb.: Average rebound value R, measured on carbonate-

impregnated concrete surface.

Rm n.c.: Average rebound value R, measured on non-

carbonate-impregnated concrete surface (Factor on the base of

the Chinese standard JGJ/T23-2001, see our special info leaet).

Time coeff. Zf= Rm n.c =

Rm carb Rm carb

Rm n.c Zf

16

Measuring

Special Cases

Experience has shown that deviations from the normal

conversion curves occur under the following circumstances:

• Articial stone products with an unusual concrete

composition and small dimensions. It is recommended that a

separate series of tests should be performed for each product

in order to determine the relationship between the rebound

value R and the compressive strength.

• Aggregates made from low strength, lightweight or cleavable

stone (e.g. pumice, brick rubble, gneiss) result in a strength

value lower than shown on the conversion curve.

• Gravel with extremely smooth, polished surfaces and a

spherical shape results in values for compressive strength

which are lower than those ascertained by the rebound

measurements.

• A strong, dry mixed concrete (i.e. with low sand content) which

has not been placed adequately processed may contain

lumps of gravel which are not visible from the surface. These

affect the strength of the concrete without however inuencing

the rebound values R.

• The concrete test hammer gives inadequate rebound values

R on concrete from which the form has just been removed,

which is wet or which has hardened under water. The concrete

must be dried before the test.

• Very high values for compressive strength (> 70 N/mm²) can

be achieved by adding pulverized fuel ash or silica fume.

However, these strengths cannot reliably be ascertained using

the rebound value R measured by the concrete teat hammer.

17

Measuring

Conversion Curves for Special Cases

The recommended course in special cases is to prepare a

separate conversion curve.

• Clamp the sample in a pressure testing machine and apply a

preload of about 40kN vertically to the direction in which the

concrete had been poured in.

• Measure the rebound hardness by applying as many test

impacts as possible to the sides.

The only way to achieve a meaningful result is to measure

the rebound values R and the compressive Strength of several

samples.

IMPORTANT: Concrete is a very inhomogeneous material.

Sample made from the same batch of concrete and stored

together can reveal discrepancies of ±15% when tested in the

pressure testing machine.

• Discard the lowest and highest values and calculate the

average Rm.

• Determine the compressive strength of the sample using

the pressure testing machine and ascertain the average value

fckm. The pair of values Rm/ fckm applies to a certain range

of the measured rebound value R.

It is necessary to test samples of differing qualities and/or ages

in order to prepare a new conversion curve for the entire range

of rebound values from R=20 to R=55.

• Determine the curve with the pairs of values Rm/ fckm

(e.g. EXCEL in the RGP function).

This manual suits for next models

7

Table of contents

Popular Tools manuals by other brands

BEA

BEA SK 355-212E Spare parts list/service instructions

REED

REED PES1IPS operating instructions

Cirrus

Cirrus SR20 2010 Maintenance manual

Parkside

Parkside PSS 65 C1 Translation of the original instruction

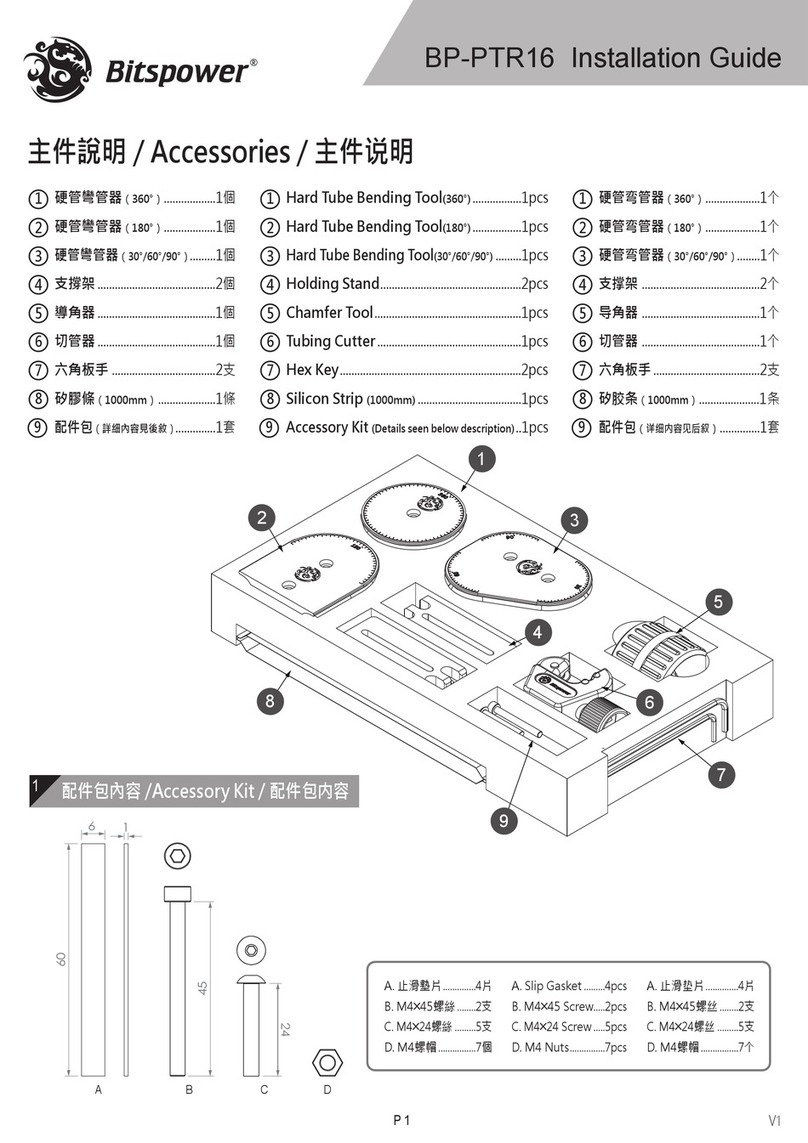

Bitspower

Bitspower BP-PTR16 installation guide

Harbor Freight Tools

Harbor Freight Tools CEN-TECH 2458 Assembly and operating instructions