FORK SEAL DRIVER

MODEL NO: MS016.V2

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions,

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

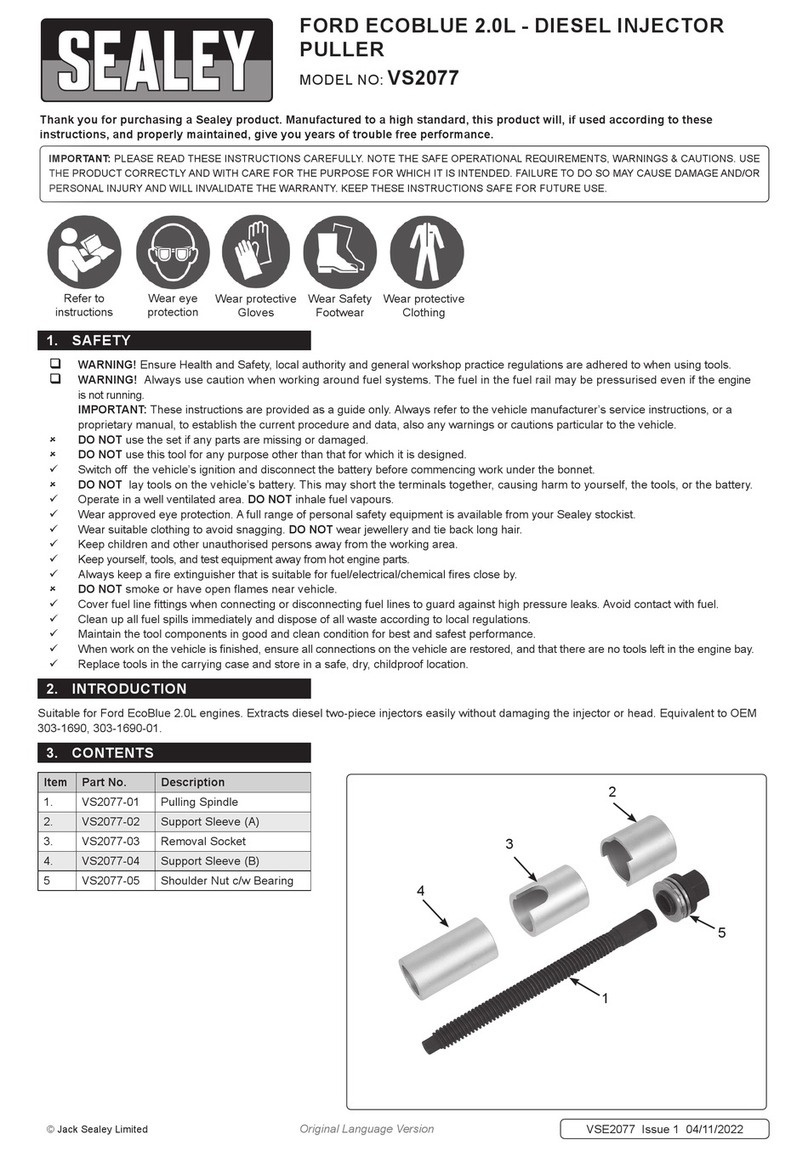

1. SAFETY

8DO NOT use the driver for a purpose it is not designed to perform.

8DO NOT use the driver if it is damaged, it could scratch the stanchion.

8DO NOT make any modifications to the driver.

9Maintain the driver in a good clean condition for the best and safest performance.

9When not in use, store in a dry location.

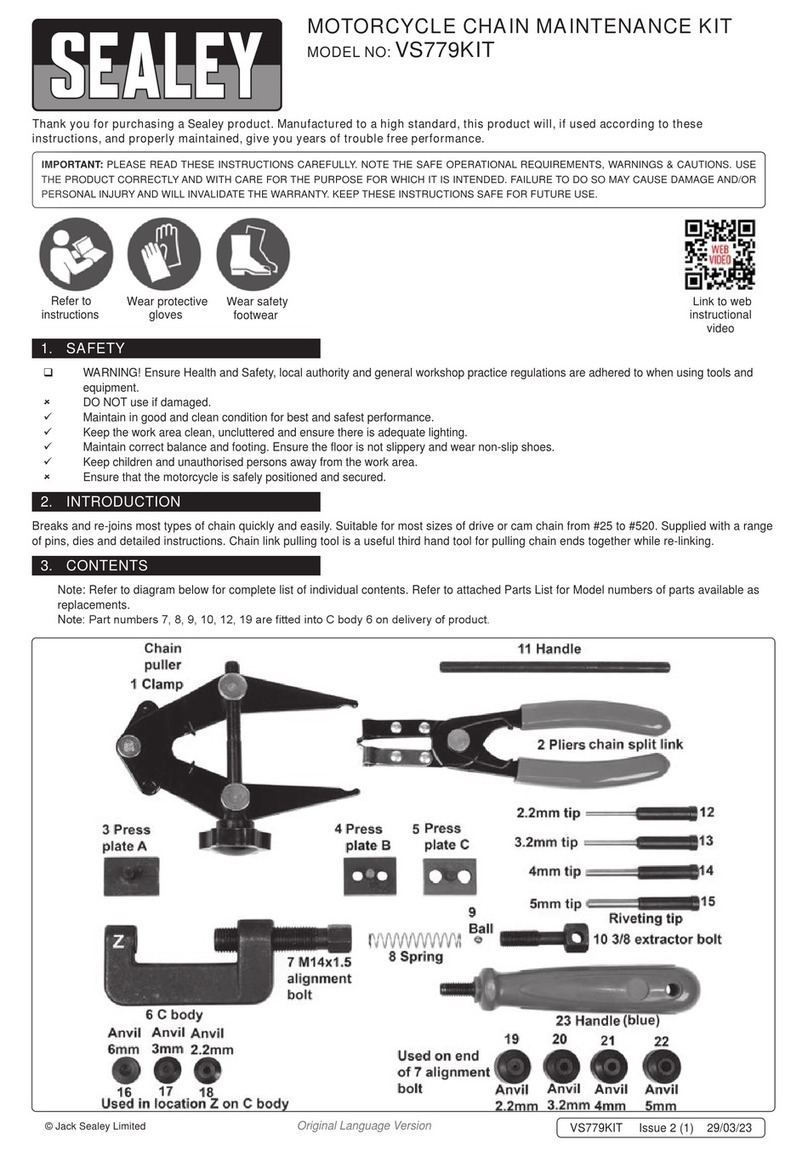

2. INTRODUCTION

Designed for easy installation of fork seals. Limits potential damage

caused by other installation methods to the forks.

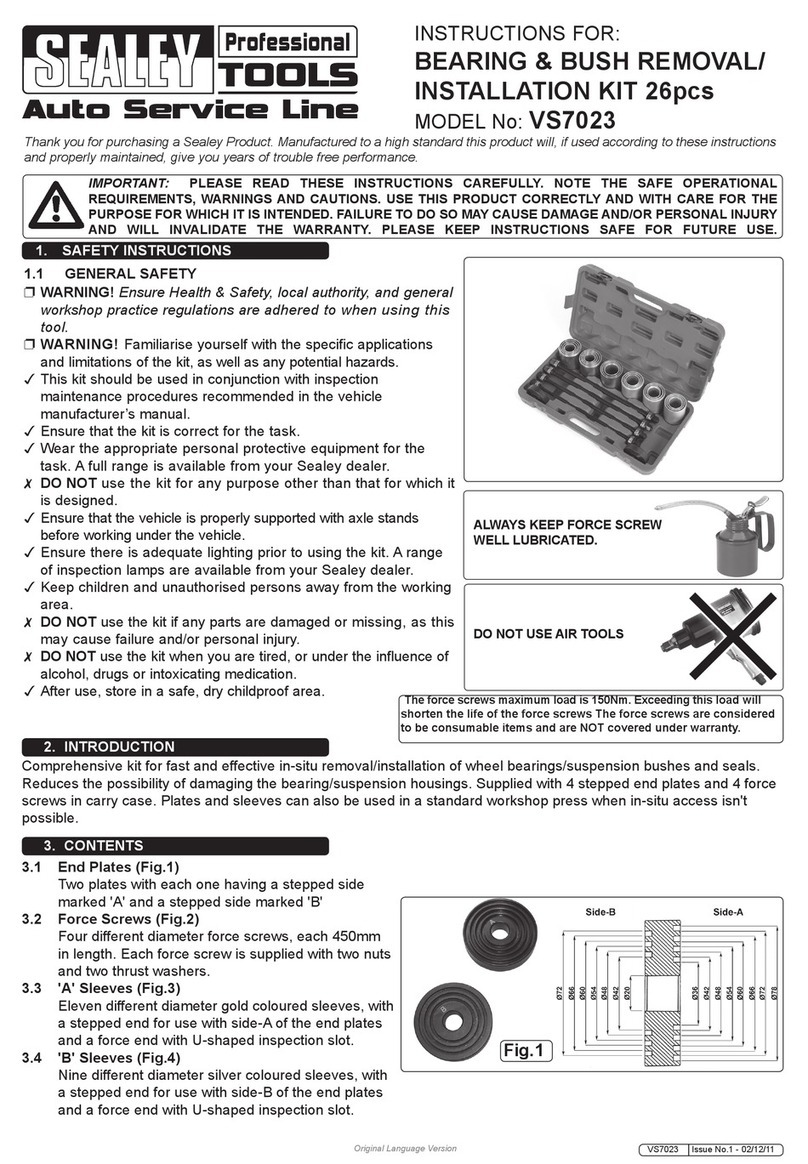

3. SPECIFICATION

Model No.: ........................................................... MS016.V2

Max. / Min. Fork diameter ...............................Ø35 - Ø47 mm

4. OPERATION

Always refer to the original manufacturer’s manual for

assembly/disassembly of the motorcycle fork seals.

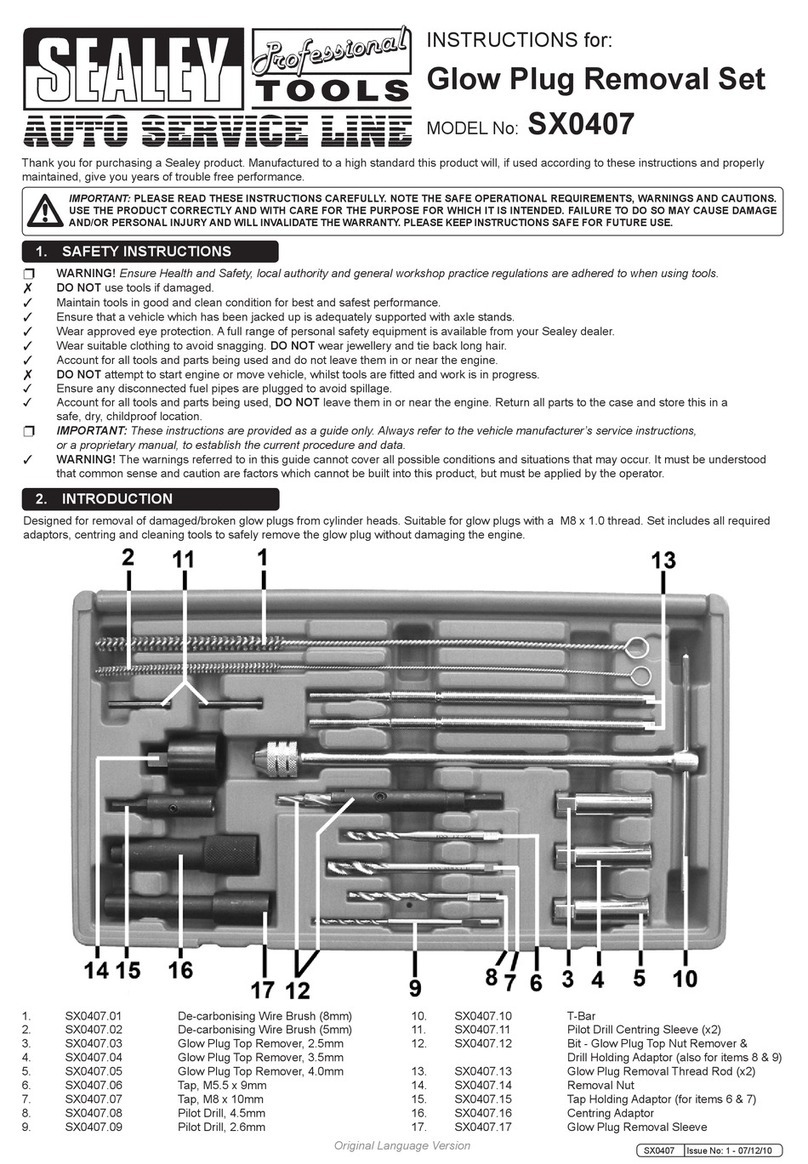

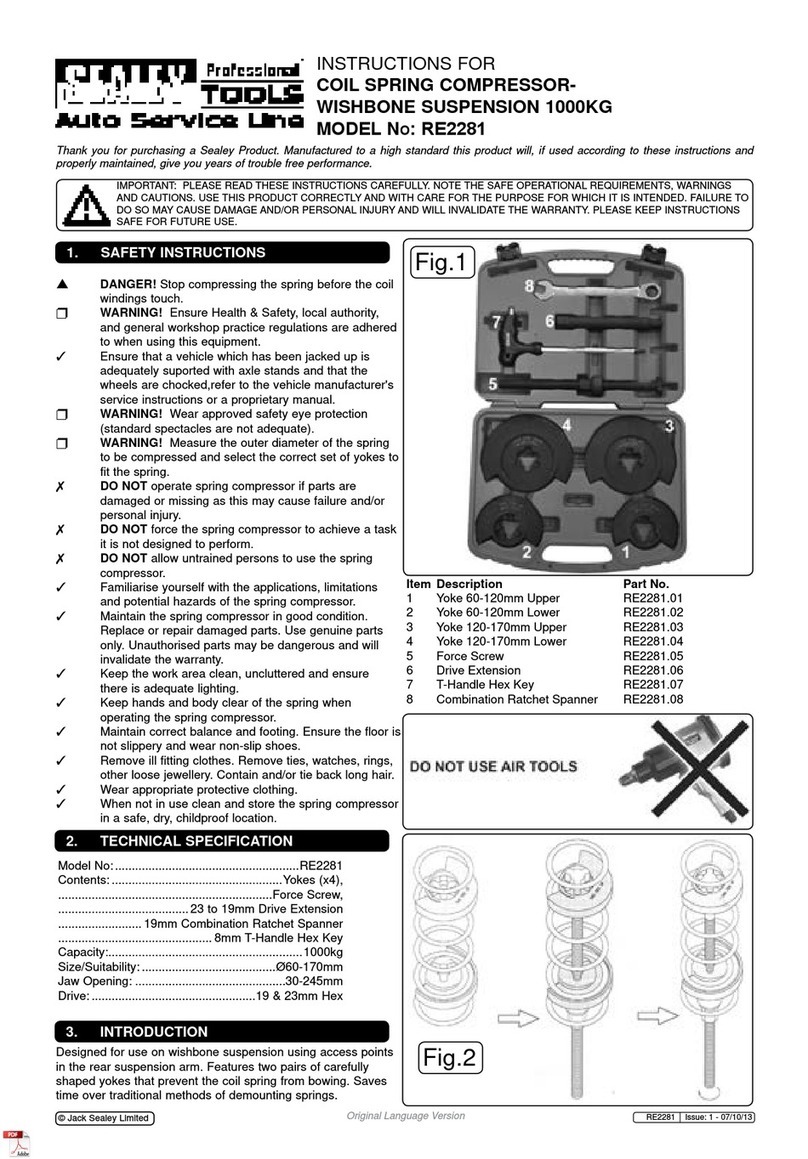

4.1. COLLET ORIENTATION (Refer to g.3, g.4).

4.1.1. Measure the stanchion diameter (Ø”A”) and the seal ring outer diameter. Determine the required engagement diameter of the collet

(Ø”B”)tothesealringandhenceitsorientationinordertoobtainfullsealringinsertion(g.3andg.4).Itisrecommendedthatthe

collet diameter (Ø”B”) is slightly less than the maximum seal ring diameter in order to allow for full seal ring insertion.

4.1.2. Lightly lubricate the stanchion, slip on the new seal ring and slide it down to the slider housing.

4.1.3. Fromsection4.1.1andgs.3and4,decideonthecorrectcolletsetup(e.g.colletorientation)andslideitontothestanchion.

4.2. SLIDE HAMMER

4.2.1. Ing.3andg.4thepinsintheslidehammerwillbeengagedwithopposingholesoftheotherhalfofthehammerhoweveritmaybe

suchthattheengagementbetweenthepinsandholeswillbelost(g.5).Inthesecircumstancesitwillbenecessarytoalignthetwo

halves of the slide hammer by eye in order to obtain even pressure and thus correctly aligned seal ring insertion.

4.2.2. Holding the slide hammer halves together press the seal into the slider housing. Replace seal retaining ring if required and repeat all

tasks with the other fork.

4.3.

4.4.

.

Refer to

instruction

manual

fig.1fig.2

Ø"A"

Ø"B"

Ø"B"

Ø"A" Ø"A"

Ø"B"

Slide

Hammer

Collet

Seal

Ring

fig.3fig.4fig.5

Original Language Version

© Jack Sealey Limited MS016.V2Issue129/10/19