2 3

KENNED

thoroughly recommends reading these instructions before using the

iming Light, even if you have used one before. Reading these instructions carefully

and understanding them fully will enable you to perform tasks correctly and will

prevent injury to yourself or someone else as well as prevent damage to the vehicle

and equipment. For detailed and concise instructions on using this product correctly,

refer to the manufacturer’s workshop manual or the appropriate Haynes service and

repair manual.

SAFET GUIDELINES

lIf any doubt, contact a qualified auto electrician.

lAlways wear safety goggles to protect your eyes from battery acid, petrol, dust

and dirt flying off moving engine parts.

lAlways wear protective gloves when working with engine components.

lAlways ensure that hands, hair, clothing or cables are well clear of any moving or

hot parts.

lAlways follow the vehicle manufacturer’s recommendation and procedures.

lAlways turn off the ignition of the vehicle before connecting the clamps to the

battery and disconnecting the timing light.

lAlways ensure that the hand brake is on and the vehicle transmission is in Neutral

(manual) or Park (automatic).

lAlways keep children and unauthorised persons away from the working area.

lAlways store the timing light in a safe, dry and child proof location when not in use.

lAlways run the engine in a well ventilated area.

lAlways remember that a flashing timing light “freezes” rotating components. Do not

be tempted to touch an apparently stationary component which is, in fact, rotating.

lNever use the timing lights if they are damaged in any way.

lNever smoke, create sparks or use a naked flame near batteries.

lNever rest tools or metallic items on top of the battery.

lNever touch any ignition components when the ignition is on as very high voltages

are present.

lNever pull the cables or clamps from the battery terminals.

lNever operate in the vicinity of flammable liquids or gases.

lNever place the timing light on the hot engine surface.

lNever modify the timing light in any way or use it for a task for which it is not

designed.

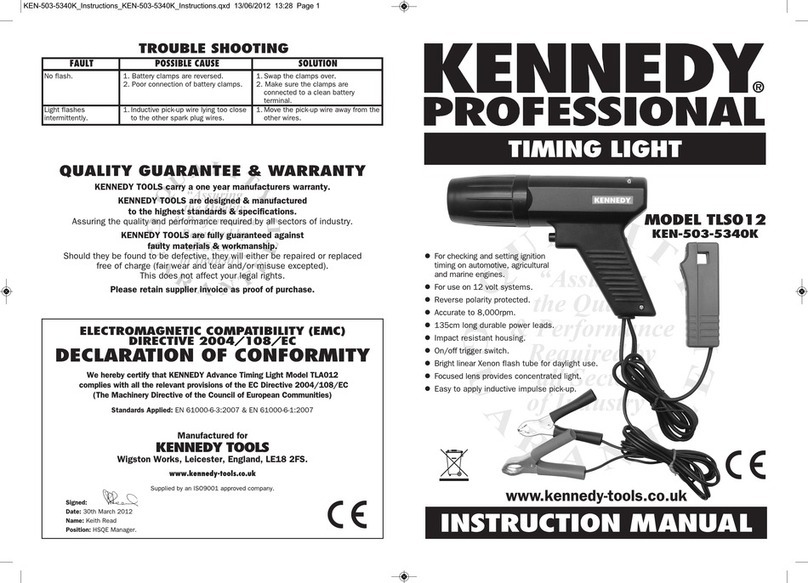

Timing is given in “linear measurement”

or “degrees” relative to the “Top Dead Centre” (TDC), of

the movement of the piston (see figure 1).

B. .D.C Before Top Dead Centre. When the timing is

“advanced”, the spark will occur before the piston

reaches the top of the engine cylinder ensuring that the

full power of the explosion is obtained.

.D.C Top Dead Centre. The piston is at its highest point

in the cylinder.

A. .D.C After Top Dead Centre. When the timing is

“retarded”, the spark occurs after the piston has started

to go down in the cylinder.

LEAD CONNEC IONS (see fig.2)

1. Clamp the inductive pick-up around the number one (1)

spark plug wire. Make sure the arrow on it is facing towards

the spark plug. Do not allow the inductive pick-up to touch

the exhaust manifold or surrounding parts as these areas

become extremely hot and will damage the inductive pick-up.

2. Connect the RED clamp to the positive (+) battery

terminal.

3. Connect the BLACK clamp to a secure engine ground

such as the alternator bracket or the engine block. For safety

reasons, do not use the negative (-) battery terminal or fuel

system components as a ground connection point.

N.B. When the trigger is pressed the check light should come

on if the timing light is connected properly.

S ANDARD IMING ADJUS MEN

PLEASE NO E: Before adjusting the timing, the “dwell

angle” or “gap” should be adjusted on vehicles

fitted with contact breaker points.

1. Check manufacturers specifications for correct timing for engine being serviced.

2. Loosen the distributor clamp bolt so that the distributor can be rotated in either direction.

3. Locate engine timing mark and use a rag to clean all grease and dirt from the mark and the pointer. It

may help to use chalk or white paint on the mark to make it more easily seen.

4. Start and run the engine until normal operating temperature is reached. Approximately 15 minutes and

then stop engine.

5. Start the engine and operate at normal idle speed, aiming the timing light towards the timing mark.

6. Set the advance dial to zero if you require to use the manufacturers timing marks on the pulley.

7. Trigger the timing light and observe the reading from the timing mark.

8. Compare the reading obtained with the manufacturers specifications. If the timing is not as specified, slowly

rotate the distributor slightly to obtain a correct reading.

9. Stop the engine.

10. Tighten the distributor clamp bolt.

11. Restart and check the timing.

12. If it is the correct reading, stop the engine and reconnect the vacuum hose.

INTRODUCTION

OPERATING INSTRUCTIONS

“Timing” is the precise moment a spark plug ignites an air and fuel mixture which results

in an explosion delivering maximum power to the engine piston. B. .D.C

Before top dead centre

.D.C

Top dead centre

A. .D.C

After top dead centre

PIST N

PULLEY

TIMING MARKS

T.D.C T.D.C T.D.C

P INTER

Fig. 1

Fig. 2

+

Engine

block or

chassis

Distributor

Battery

Black

Red

No.1

Spark plug

Inductive

pick-up

Inductive

pick-up

Advance dial

Trigger

Check light Clamps

_

ADVANCE IMING ADJUS MEN

The timing light is fitted with an advance dial. The dial allows you to put the degree of timing required

according to the manufacturers specifications into the timing light. This means you only have to find the

TDC timing mark on the engine pulley. It also allows the checking of advance timing when raising engine

revs. The dial can be turned until the mark on the belt aligns with the TDC mark on the engine pulley and

the dial setting gives you the timing degrees.