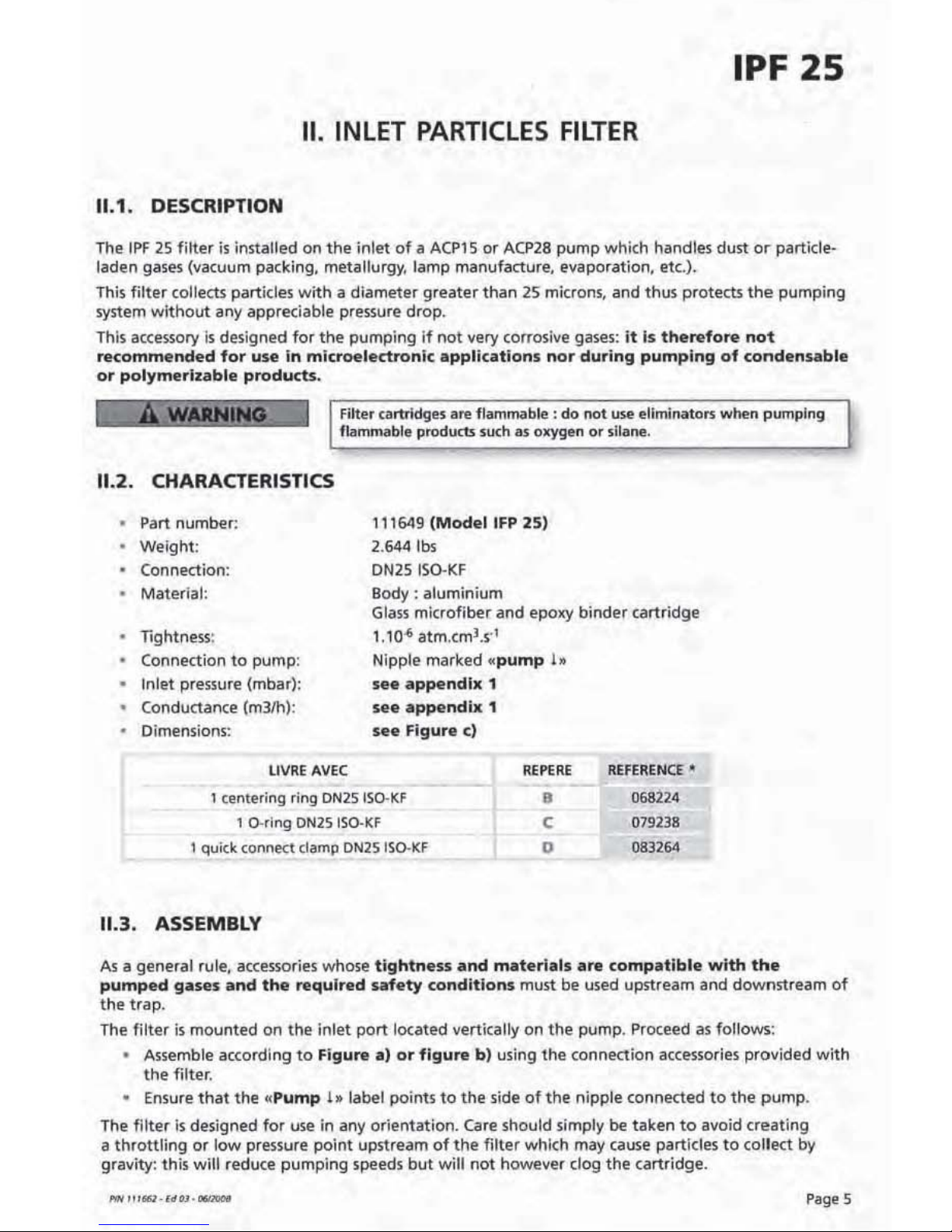

Adixen IPF 25 User manual

Popular Water Filtration System manuals by other brands

SeaLand

SeaLand BASIC HOLDING TANK SYSTEM owner's manual

HANKISON

HANKISON HF-12 instruction manual

A.J.Antunes

A.J.Antunes UF-224 Series owner's manual

Kongskilde

Kongskilde RVS 5000 S3 CR 50 Operator's manual

Omnifilter

Omnifilter OT32 Series A installation instructions

Trico

Trico 30035 Set up and operating instructions

Apec Water

Apec Water Ultimate Ro-Lite Commercial Series Installation instructions & owner's manual

Apec Water

Apec Water SOFTENER Series Installation instructions & owner's manual

Charger

Charger CONTRACTOR Series manual

REPLIGEN

REPLIGEN XCell ATF 2 user guide

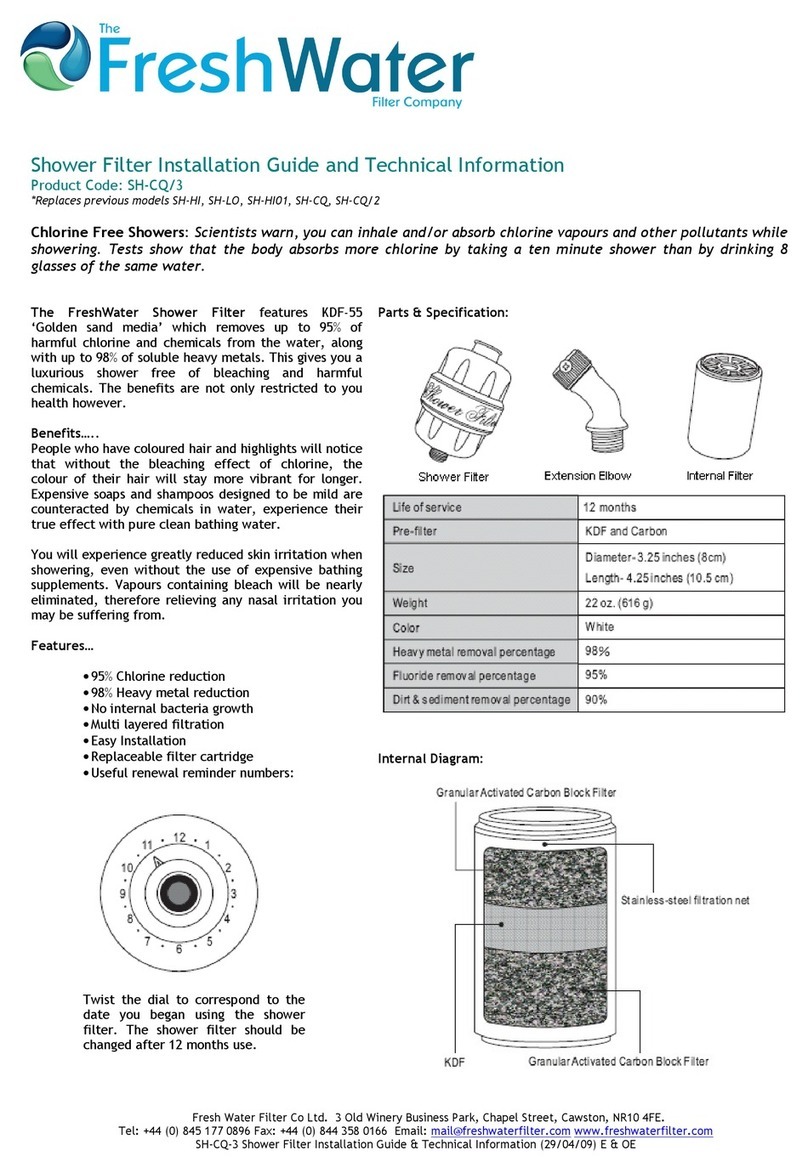

FreshWater

FreshWater SH-CQ/3 Installation guide & technical information

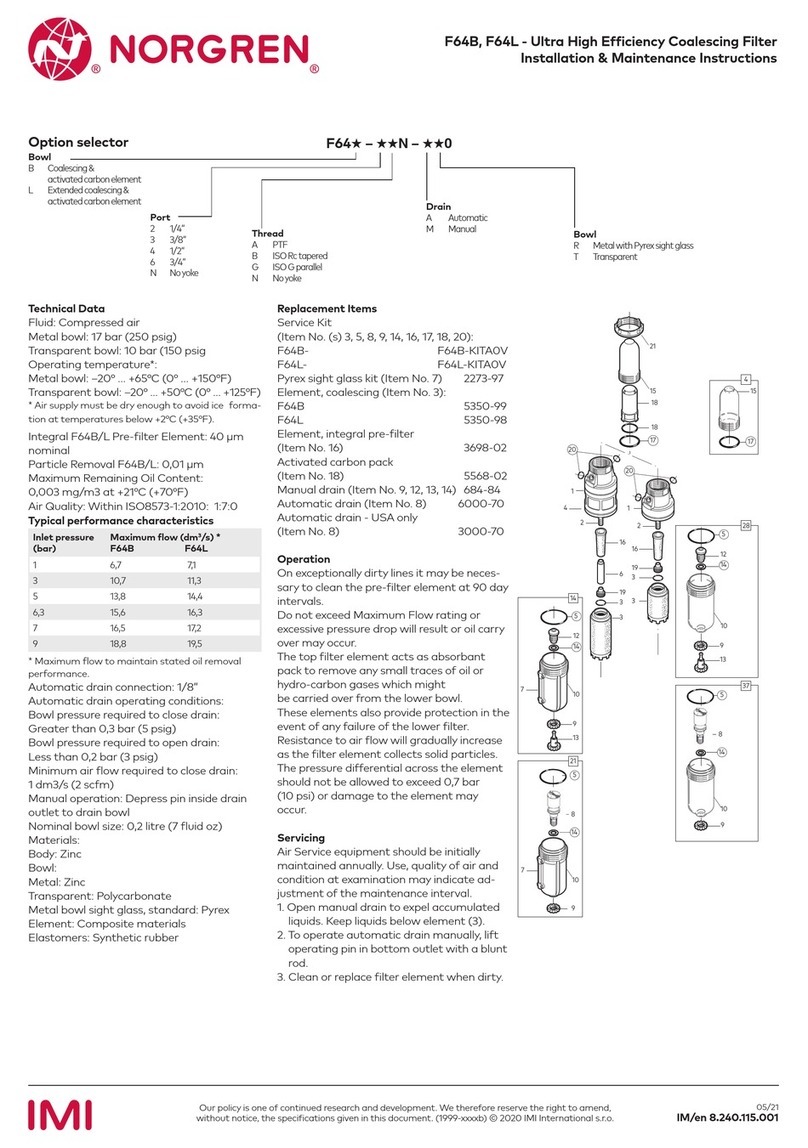

IMI

IMI NORGREN F64B Series Installation & maintenance instructions

Hydac

Hydac FluidAqua Mobil FAM 15 ATEX Operating and maintenance instructions

Bühler technologies

Bühler technologies AGF-PV-30 Installation and operation instruction

Premier

Premier RO-TFM-4SV/W50 Installation, operation and maintenance manual

DuPure

DuPure EcoPur S-Series user manual

Oase

Oase Filtoclear 3000 Warranty, safety and operating instructions

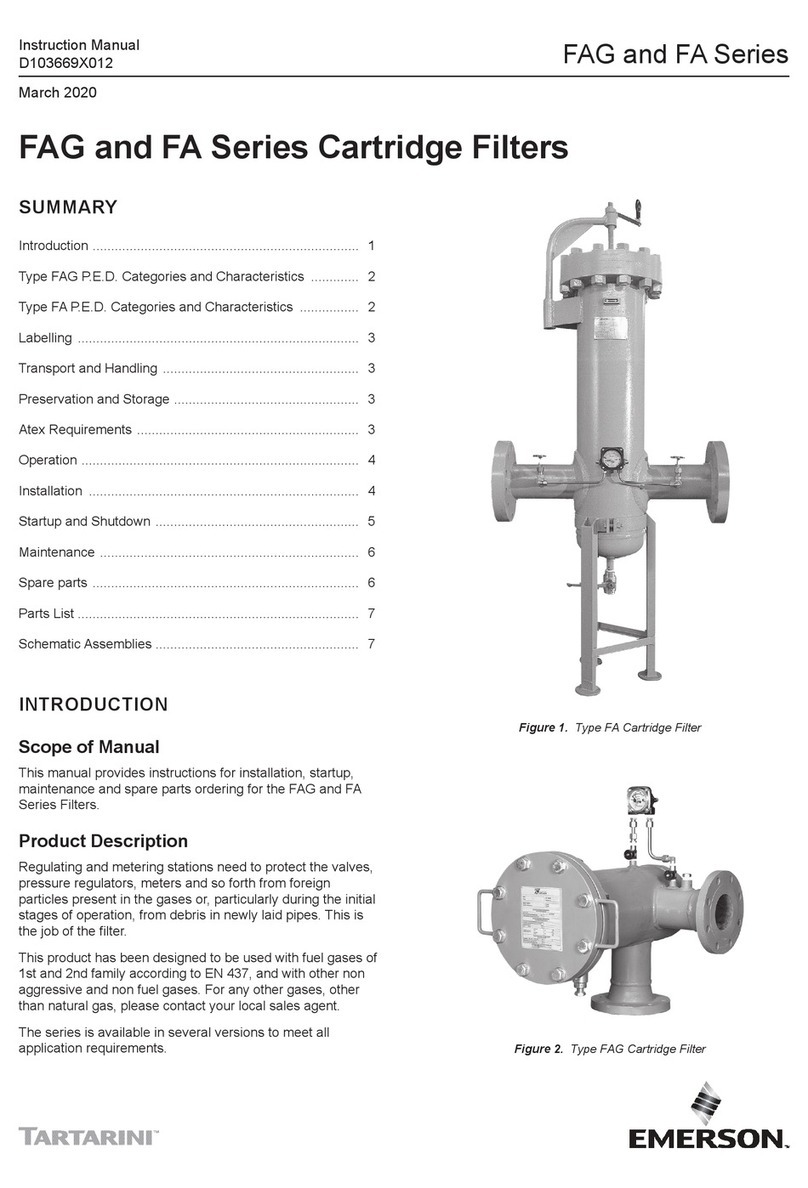

Emerson

Emerson TARTARINI FA Series instruction manual