Trico 30035 Installation manual

1235 Hickory Street | Pewaukee, WI 53072

For Customer Support: 800-558-7008

61433

Drum Pump Filtration Unit

Part #30035

Patent Pending

Setup and Operating Instructions

Rev C, October 2020

1235 Hickory Street | Pewaukee, WI 53072

For Customer Support: 800-558-7008

INTRODUCTION

The Low Viscosity (LV) Drum Pump filtration system has been designed to handle lubricants that

have a viscosity of 1250 cSt (5500 SUS) and below, directly filtering and dispensing lubricant

from a standard 55-gallon drum. Exceeding the viscosity limits of this system can cause

damage to the motor. All parts are made from high quality stainless steel and aluminum.

Before purchasing this unit, the customer should be aware of any specific requirements and/or

hazards of their lubricant and ensure that the fluid being filtered and dispensed is compatible

with the filter media and hose material.

REQUIRED ITEMS

Drum Pump motor – A motor is required to drive the pump shaft which attaches to the drive

coupler. It is interchangeable with different Trico Drum Pump designs. Only one motor is

needed and can be interchanged with multiple drum pumps.

30018 – Drum Pump Electric Motor, 1.1Hp, 110-120V, 50/60 Hz

30021 – Drum Pump Electric Motor, 1.1Hp, 220-230V, 50/60 Hz

30019 – Drum Pump Pneumatic Motor, 3/4 HP

INCLUDED COMPONENTS

Remove the Drum Pump components from the shipping container and inspect components for

any signs of damage.

Included Components:

•(1) LV Drum pump assembly

•(1) Hose Assembly

•(1) Hand Wheel

•(1) 3” Retaining ring

•(1) Motor Drive Coupler

•(1) Filter w/ gasket

•(1) 2” MNPT Drum adapter

Tools required for assembly:

•Large flat headed screwdriver

•(2) x 2.5” adjustable wrenches

•Filter Wrench/ Strap Wrench

If items are damaged contact the shipper. Trico Corporation provides a manufacturing

warrantee against product defects and workmanship up to 1 year of purchase, proof of

purchase required. It does not cover damage due to mishandling by shipper or customer nor

damages caused by misuse.

INSTALLATION AND OPERATION VIDEO

Scan this QR Code to see a series of videos on installing and operating the Drum

Pump Filtration System.

1235 Hickory Street | Pewaukee, WI 53072

For Customer Support: 800-558-7008

WARNING

•The use of 30018 and/or 30021 Trico Drum Pump Electric Motor is prohibited with

flammable or combustible materials which could cause serious injury or death if used.

•When filtering higher viscosity oils, such as ISO 460 and ISO 680 gear oils, the use of a drum

heating blanket is required to reduce the viscosity to under 1250 cSt (5500 SUS).

•The minimum allowable micron level for higher viscosity oil is 10 microns. Hydraulic oils

may be filtered down to 3 microns at room temperature.

CAUTION

Bonding and ground safety procedures must be used when operating in hazardous duty

environments or when there is a danger of static discharge. See national Fire Protection Code

77 for proper grounding and bonding procedures. It is the responsibility of the operator to

properly inspect and ground equipment before use.

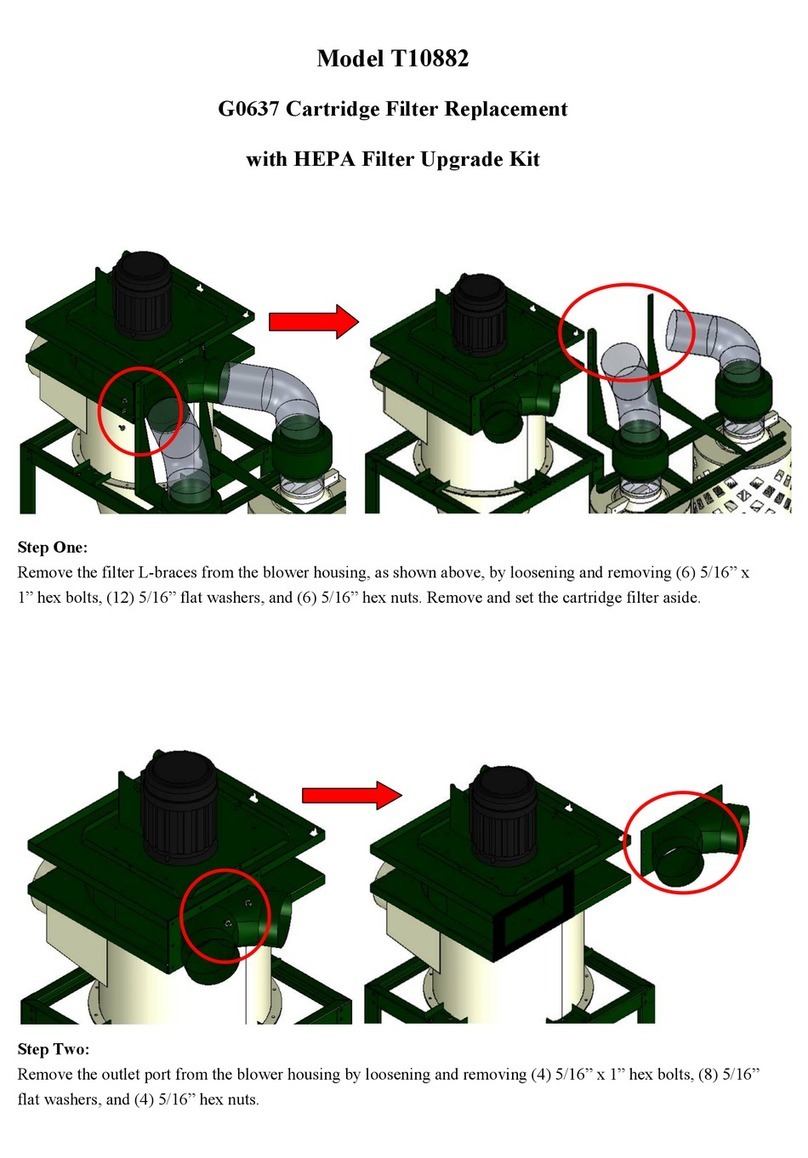

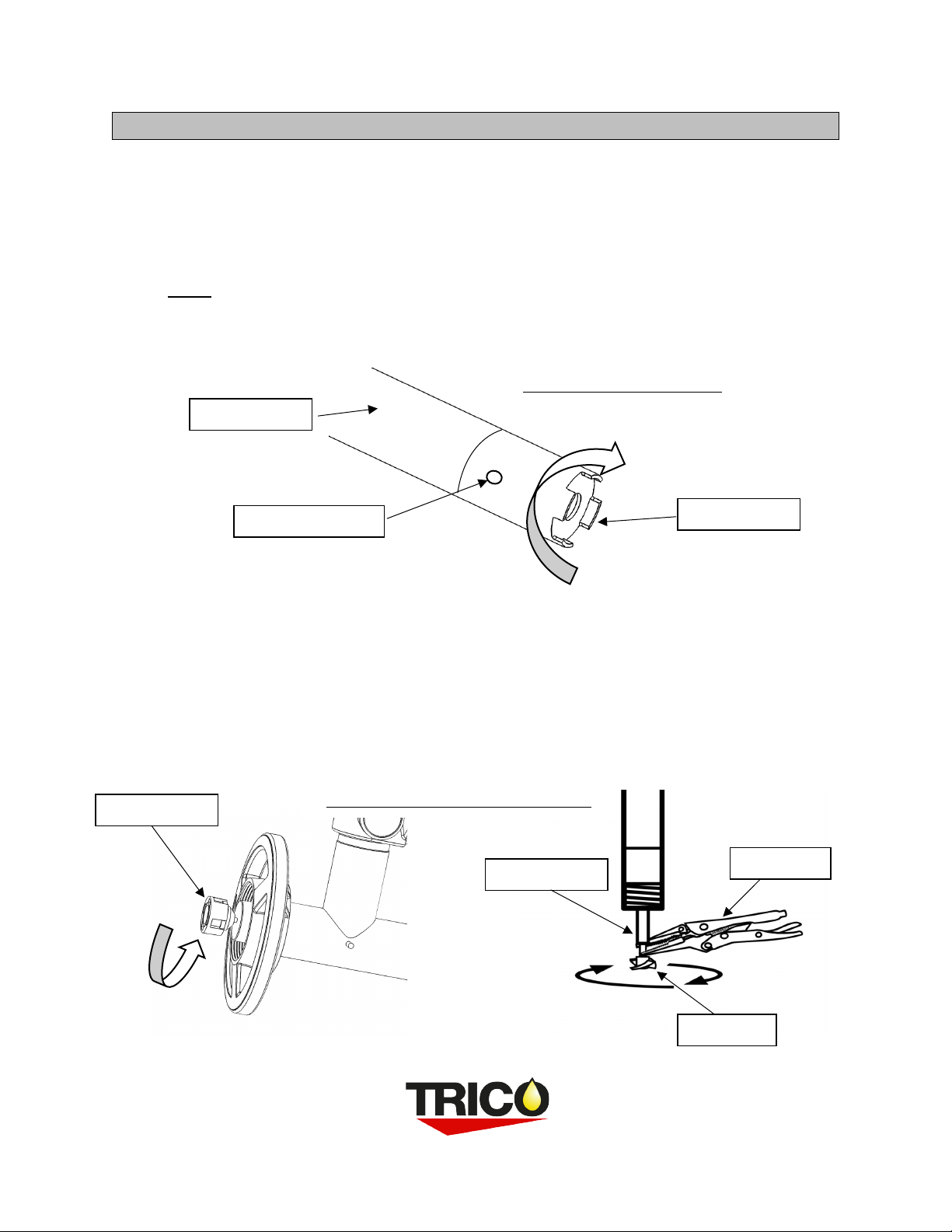

DRUM PUMP ASSEMBLY

1. Place LV drum pump assembly on a worktable long enough to support the entire unit.

2. Thread the Motor Drive Coupler onto the shaft and hand tighten.

3. Place 3” Retaining Clip over the top of the LV drum pump assembly and slide over the

pump head to the top of tube filter connection.

4. Place Hand Wheel on drum pump assembly with retaining ring groove facing down

toward pump foot.

5. While holding the Hand Wheel onto the pump head, slide one end of the retaining ring

into the groove on the Hand Wheel.

6. Use a flat headed screw driver to push the rest of the retaining ring into the groove.

7. Test the Hand Wheel operation by turning it in either direction making sure it moves

freely.

Hand Wheel

Retaining Clip

Drum Pump

Figure 1: Hand Wheel

Motor Drive Coupler

1235 Hickory Street | Pewaukee, WI 53072

For Customer Support: 800-558-7008

8. Attach the 2” MNPT Drum adapter onto the drum.

9. Place some lubricant on the foot of the Drum Pump to help slide it past the O-ring when

inserting into the Drum adapter on the drum.

10. Lift the unit and slide the pump foot into the drum adapter, guiding it until the foot

contacts the bottom of the drum.

11. Using thread sealant, thread the hose onto the elbow connector and tighten (Figure 2)

12. Place the filter gasket onto the groove on the filter head.

13. Thread the filter onto the head and hand tighten.

14. Use a strap wrench, place it at the top of the filter and tighten the filter ¼ turn to seat

the gasket

15. Assemble the short grounding lead with clamp to the Drum pump side ensuring the

fastener is securely tightened.

16. Use the additional supplied leads to bond the consecutive drums together; making sure

that one lead is connected to a grounded source. See NFPA 77.

Hose

Grounding Screw

Elbow Connector

Figure 2: Pump Assembly

Filter

Filter Head

1235 Hickory Street | Pewaukee, WI 53072

For Customer Support: 800-558-7008

OPERATION

1. Ensure the filter and all connections have been tightened before operation.

2. Place the motor onto the drive coupling on the top of the pump and secure it by

threading the handwheel onto the motor.

3. Ensure that the smaller drum plug has been removed or that the drum is fitted with a

breather to prevent the drum from collapsing during operation

4. Before connecting the pump motor to the power or air supply, be sure the switch is in

the off position “0” or that the regulated air supply is not above 100 psi.

5. Plug the motor into the correct power outlet as specified on the motor tag and or

connect an airline to the pneumatic motor.

6. Remove the dust cap from the end of the fill nozzle.

7. Turn the electrical switch to the on position indicated on the handle of the motor or

squeeze the trigger of the pneumatic motor to begin pumping.

8. Place the nozzle into the container or equipment in which you desire to fill.

9. Squeeze the hand trigger on the nozzle to allow lubricant to flow out of the tip.

10. While in operation, check around the filter gasket for leaks. If the filter is leaking stop

the unit and tighten an additional ¼ turn.

11. To stop the flow, release the nozzle hand trigger and then turn the motor off.

WHEN TO CHANGE THE FILTER AND PROCEDURE

The filter head is outfitted with two pressure gauges. The first gauge nearest to the pump

indicates the pressure being produced by the pump. The second gauge near the hose indicates

the pressure after the filter element. To determine when the filter element is at its maximum

holding capacity, calculate the differential pressure by subtracting the higher pressure from the

lower pressure to get the total differential pressure. Differential pressure is a more accurate

means of determining filter usage. The filter should be changed at 40 psi differential.

Example:

P1 (Pressure Produced by Pump)= 43 psi P2 (After Filter)= 35 psi

Differential Pressure= P1-P2 = 43psi -35psi = 8psi (filter still has remaining life)

To change the filter:

1. Remove motor from the top of the drum pump by unthreading the handwheel and

lifting the motor upwards off the coupler.

2. Place an oil catch pan beneath the filter to catch remaining oil in the filter and head that

will come out during the filter change.

3. Using a strap wrench at the top of the filter, turn the filter counter clockwise and

unthread the filter from the head.

1235 Hickory Street | Pewaukee, WI 53072

For Customer Support: 800-558-7008

4. Dispose of remaining oil in the filter and the used filter in accordance to local

environmental laws and practices.

5. Remove the old gasket from the filter head and wipe excess oil residue from the head.

6. Remove the new filter from its packaging and insert the new gasket provided with the

filer into the gasket groove of the head.

7. Thread the new filter onto the head turning it counterclockwise and hand tighten.

8. Using the strap wrench, place the strap near the top of the filter to prevent collapsing

and turn the filter ¼ turn to tighten.

9. Place the motor back on the pump and turn on.

10. Dispense fluid from the nozzle and observe the filter gasket checking for leaks.

11. If the leaking is noticed around the filer gasket, tighten the filter another ¼ turn with the

strap wrench and repeat the procedure.

Replacement Part

Part Number

Particulate Filter - 3 Micron Microglass Spin On Beta > 200 Absolute

36972

Particulate Filter - 10 Micron Microglass Spin On Beta > 200 Absolute

36973

Particulate Filter - 20 Micron Microglass Spin On Beta > 200 Absolute

36974

Water Filter - 10 Micron Nominal Spin On

36975

Water Filter - 25 Micron Microglass Spin On Beta > 200 Absolute

36995

1235 Hickory Street | Pewaukee, WI 53072

For Customer Support: 800-558-7008

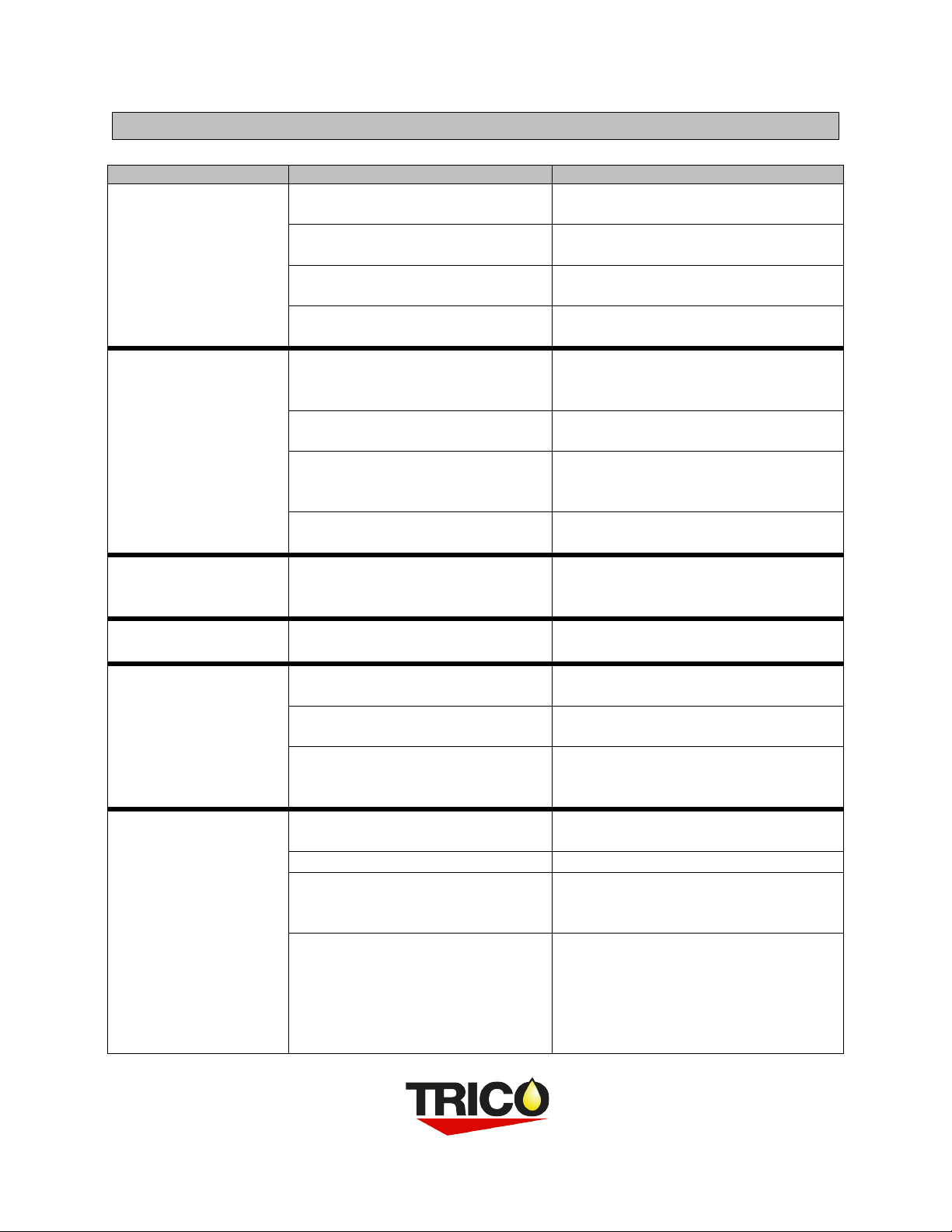

REPLACING THE DRIVE COUPLER

The motor drive coupler is designed to break if foreign material is accidently ingested into the

drum pump foot, preventing damage to the impeller, shaft and motor. If the drive coupler

breaks, follow this procedure to remove and install a new motor drive coupler.

1. Remove the drum pump from the drum and place it onto a table large enough to

support the unit

Note: Handling the unit may be easier if the hose is removed at the elbow connection.

2. Remove the pump foot to expose the impeller and shaft by placing the shaft of a long

screwdriver between the tangs on the foot bottom and turning the foot clockwise to

remove it from the pump tube. (Note: Foot threads are left-handed threads)

3. Place vise grips on the drive shaft above the impeller to hold the shaft while removing

the motor drive coupler.

4. Use a plyers on the motor coupler and turn clockwise to remove from drive shaft.

5. Thread the new coupler (P/N 10412) onto the shaft and hand tighten.

6. Remove the vise grips and thread the foot back onto the pump tube turning

counterclockwise to tighten.

7. Place a screwdriver into the discharge hole on the side of the outer tube and tighten the

foot using the shaft of a long screwdriver placed between the tangs on the foot bottom.

Figure 3: Pump Foot Removal

Figure 4: Motor Drive Coupler Removal

Pump Foot

Discharge hole

Outer Tube

Drive Coupler

Drive Shaft

Vise Grips

Impeller

1235 Hickory Street | Pewaukee, WI 53072

For Customer Support: 800-558-7008

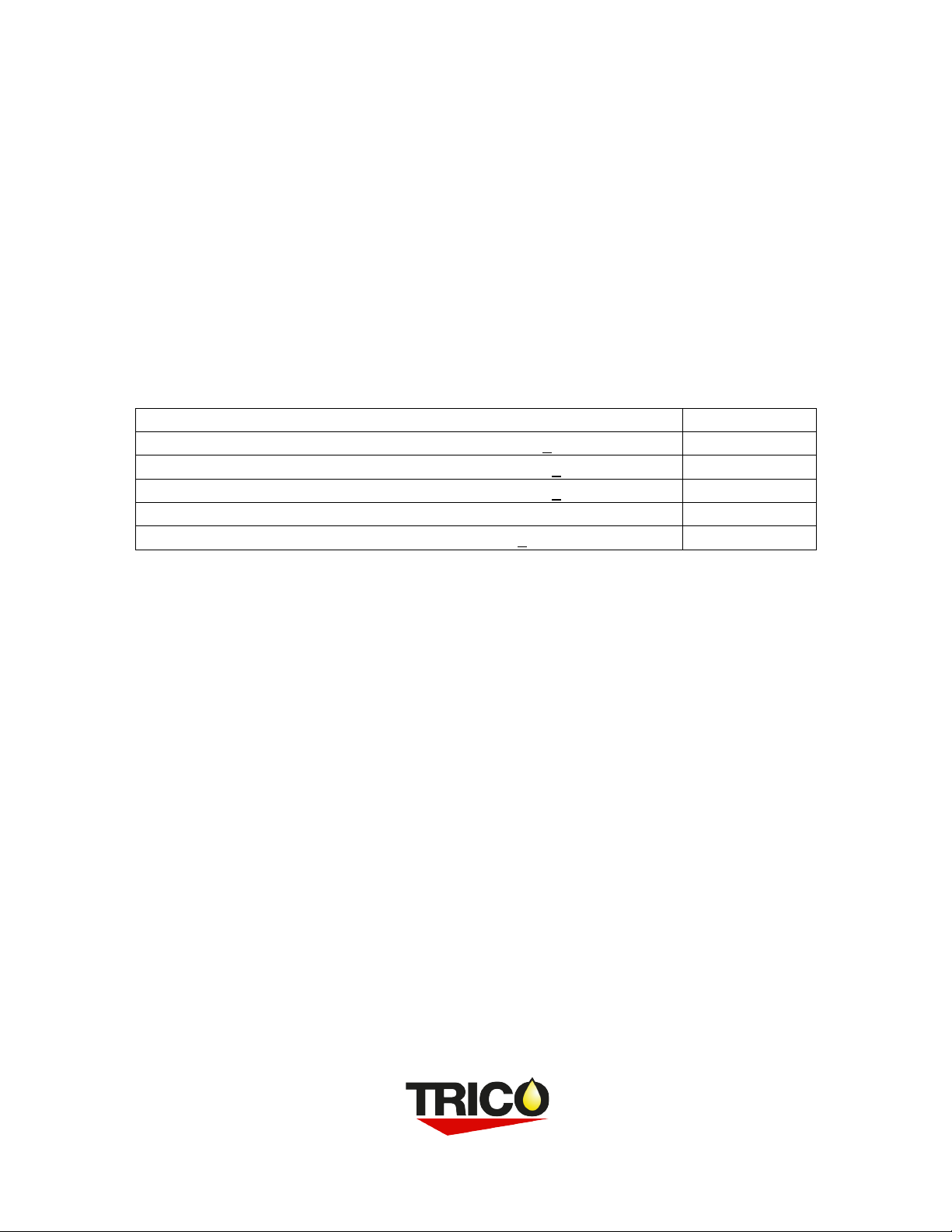

DRUM PUMP SPECIFICATIONS

When filtering higher viscosity oils that exceed 1250 cSt (5500 SUS),such as gear oils, the use of

a drum heating blanket is required to reduce the viscosity by heating the contents to 100°F

(40°C) or below 1250 cSt (5500 SUS). The minimum allowable micron level for higher viscosity

oil is 10 microns. Hydraulic oils may be filtered down to 3 microns at room temperature.

• Viscosity range = 0 – 1,250 cSt (0-5,500 SUS)

• Max Flow rate (181 cSt, ISO 68 @70F)= 7.25 GPM

• Max Viscosity = 1,250 cSt (5,500 SUS)

• Min Flow rate @ 1,250 cSt = 1.75 GPM

Average flow rates at room temp, 70°F (21.1°C), with 10 micron particle filter:

ISO 68 (188 cSt)

ISO 100 (302 cSt)

ISO 220 (797 cSt)

ISO 320 (1250 cSt)

Electric Pump #30018

7.25 GPM

5.75 GPM

2.25 GPM

1.75 GPM

Pneumatic Pump #30019

6.0 GPM

5.25 GPM

1.75 GPM

0.91 GPM

MOTORS:

PN

Voltage

Amps

Watts

HP

Phase

Hz

ENC

Haz. Duty

Wt. Lbs(Kg)

30018

110V

8.5

825

1

1

50-60

TEFC (IP54)

NO

12.7 (5.7)

30021

220V

5

825

1

1

50-60

TEFC (IP54)

NO

12.7 (5.7

PN

HP

Max Press.

Min Hose

Max dBA

Airline

Air Consumption

Wt. Lbs(Kg)

30019

3/4

100 psi

3/8”

87

¼ NPT

28 CFM

3.4 (1.5)

0

1

2

3

4

5

6

7

8

9

10

0 100 200 300 400 500 600 700 800 900 1000 1100 1200 1300

Flow Rate (GPM)

Viscosity (cSt)

Flow Rate Data with 10 Micron Filter and Electric Pump #30018

1235 Hickory Street | Pewaukee, WI 53072

For Customer Support: 800-558-7008

WARNING

The Electric Drum Pump motor 30018 and 30021 are totally enclosed fan cooled motors (TEFC)

with a thermal overload switch. Do not use these motors in conjunction with flammable

materials or in hazardous duty areas. Do not submerge motors or let motors contact liquids. If

motor stops running, turn the power switch to the off position “0” and allow at least 10

minutes for the motor to cool. Check the viscosity of lubricant being pumped to remain within

limitations and resume operations. Electric motors cannot be operated continuously and should

not be operated for more than 30 minutes without cooldown.

CAUTION

The Pneumatic Drum Pump motor 30019 has a recommended operating pressure of 90

psi @ 28 CFM. Do not exceed an inlet pressure of 100 psi. Always use a Filter Lubricator

Regulator (FLR) to remove water from the air supply and to lubricate the necessary

components, use SAE 10 weight oil.

1235 Hickory Street | Pewaukee, WI 53072

For Customer Support: 800-558-7008

ISO CLEANLINESS RATING

Lubricating oils stored in bulk containers may contain contaminates. Ordinarily it has been

thought lubricants stored in drums prior to use were contaminant-free; however, it is beneficial

to filter lubricants even prior to its use as the original container may impart impurities to the

lubricants prior to its first use. Most rotating equipment is manufactured to a class 2 or class 3

fit typical of most industrial operations. Hydraulic components and rotary screw compressors

tend to have tighter tolerances in the sliding and rotating elements. Clearances in components

are used to establish cleanliness requirements. The best source for cleanliness requirements is

from the equipment manufacturer. In general, as the viscosity of the oil increases the

cleanliness level decreases. Below is a general guideline for cleanliness levels.

ISO Oil Grade Classification

Cleanliness Code (R4/R6/R14)

32

16/14/11

46

16/14/11

68

17/14/12

100

18/15/13

150

18/15/13

220

19/16/14

320

19/16/14

460

19/16/14

680

20/18/14

Determining the ISO Cleanliness level of equipment requires analysis of the running lubricating

oil. Trico’s oil analysis laboratories can provide an accurate indication of the ISO Cleanliness

level of lubricating oil before and after filtration. Each number in the ISO code represents the

micron range of particulate in which the count lies within (R4microns/ R6microns/ R14 microns).

Example: 19/16/14, the 19 code shows that count of 4 micron particle lies between 5,000 and

2,500 per ml of fluid.

ISO Number

Particle Count per ml of fluid

25

160,000

to

320,000

24

80,000

to

160,000

23

40,000

to

80,000

22

20,000

to

40,000

21

10,000

to

20,000

20

5,000

to

10,000

19

2,500

to

5,000

18

1,300

to

2,500

17

640

to

1,300

16

320

to

640

15

160

to

320

14

80

to

160

13

40

to

80

12

20

to

40

11

10

to

20

10

5

to

10

9

2.5

to

5

8

1.3

to

2.5

ISO 320

19/16/14

1235 Hickory Street | Pewaukee, WI 53072

For Customer Support: 800-558-7008

GROUNDING AND BINDING

The Drum Pump Filtration System is not rated for a hazardous duty environment due to

possible static discharge, use proper bonding and grounding per NFPA 77. A Bonding system

connects various pieces of conductive equipment together to keep them at the same potential.

Static sparking cannot take place between objects that are the same potential. Grounding is a

special form of bonding in which conductive equipment is connected to an earthing electrode,

or to the building grounding system, to prevent sparking between conductive equipment and

grounded structures.

Grounding is an electrical connection between a metal vessel, pump, motor and a constant

ground; i.e. a metal rod driven into the earth. Failure to bond and ground properly can cause a

discharge of static electricity resulting in fire, injury or death. If in doubt, do not start the pump!

Be sure bonding and grounding wires are secure before starting operation. (Ground and bond

wires must have less than one-ohm resistance for safe usage. Check continuity before starting.)

Always check with a safety engineer when any question arises and periodically check safety

procedures with a safety engineer.

.

1235 Hickory Street | Pewaukee, WI 53072

For Customer Support: 800-558-7008

TROUBLE SHOOTING

Symptom

Possible Cause(s)

Corrective Action

Pump system does not

prime

Suction tube is above liquid

Ensure open end of suction tube remains

completely below surface of liquid

Clogged suction tube/ discharge line

and/or filter

Clean suction tube/ discharge line and/or

replace filter

Damaged/worn pump impeller

Remove pump foot and inspect impeller,

replace if damaged

Motor adapter worn, damaged or

detached

Inspect adapter for wear and/or damage,

replace if necessary

Insufficient flow

Clogged filter

Check differential pressure between

gages, if 40 psi or greater, change filter

element

Clogged/ kinked discharge line or

nozzle

Remove and flush discharge line and

nozzle, inspect for damage

Fluid viscosity exceeds

recommended viscosity for motor

Check viscosity of fluid at temperature. If

viscosity exceeds 1250 cSt (5500 SUS),

fluid must be warmed to reduce viscosity

Air supply for Pneumatic motor low

Check air supply and ensure inlet

pressure is 90 psi

Fluid Leaking from filter

area Loose filter and or connections

Check tightness of filter element to

ensure proper seal, check hose

connections

Fluid Leaking from Top

of pump

TFE Seal worn

Remove motor adapter, hand Wheel and

bearing assembly and replace TFE seal

Pneumatic motor turns

slowly or does not

function

Air supply low

Check air supply and ensure pressure is

90 psi

Pneumatic motor improperly

lubricated and or corroded

Ensure a FLR is installed in line of air

supply, use SAE 10 weight oil

Fluid viscosity exceeds

recommended viscosity for

Pneumatic motor

Check viscosity of fluid at temperature. If

viscosity exceeds 1250 cSt (5500 SUS),

fluid must be warmed to reduce viscosity

Electric motor does not

function or stops

working while filtering

Power On/Off switch not fully

switched

Check On/Off switch

No power to receptacle

Check outlet for power and breaker

Unit has overheated tripping internal

overload breaker

Turn unit power to the off position, allow

motor to cool, turn back to “on” position

and resume filtering

Unit generates excessive heat

>140°F

Fluid viscosity exceeds maximum

recommended viscosity. When filtering

ISO 460 and ISO 680 gear oils, use a 55-

gallon drum heating blanket to heat the

oil to reduce viscosity to under 1250 cSt

(5500 SUS)

1235 Hickory Street | Pewaukee, WI 53072

For Customer Support: 800-558-7008

TRICO DRUM PUMP FILTRATION SYSTEM CONFIGURATION

Table of contents