Adleepower AM Series User manual

ADLEEPOWER

INSTRUCTION MANUAL

THANK YOU VERY MUCH FOR YOUR PURCHASE

OF ADLEE PRODUCTS.

PLEASE READ THIS INSTRUCTION MANUAL

BEFORE INSTALLATION.

R

AM Brushless motors & BL drives

CONTENTS

1. PREFACE

2. RECEIVING

3. ENVIRONMENTAL REQUESTS

4. SPECIFICATION

5. DIMENSIONS

6. DIGITAL OPERATION PANEL .

7. TERMINALS AND WIRING

8. OPERATION AND CONNECTION

9. TROUBLE SHOOTING

Appendix

1

4

5

7

10

16

17

23

63

65

1. Preface

Thank you for purchasing ADLEEPOWER AM Brushless DC motor

and BL drives. Please read this manual thoroughly before installa-

tion and operation.

This manual should be stored by the user for maintenance refer-

ence and inspection.

Indicated a potentially hazardous situation which,

if not avoided, could result in death or serious

personnel injury.

Indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate

personnel injury and damage to equipment.

Danger

Caution

!

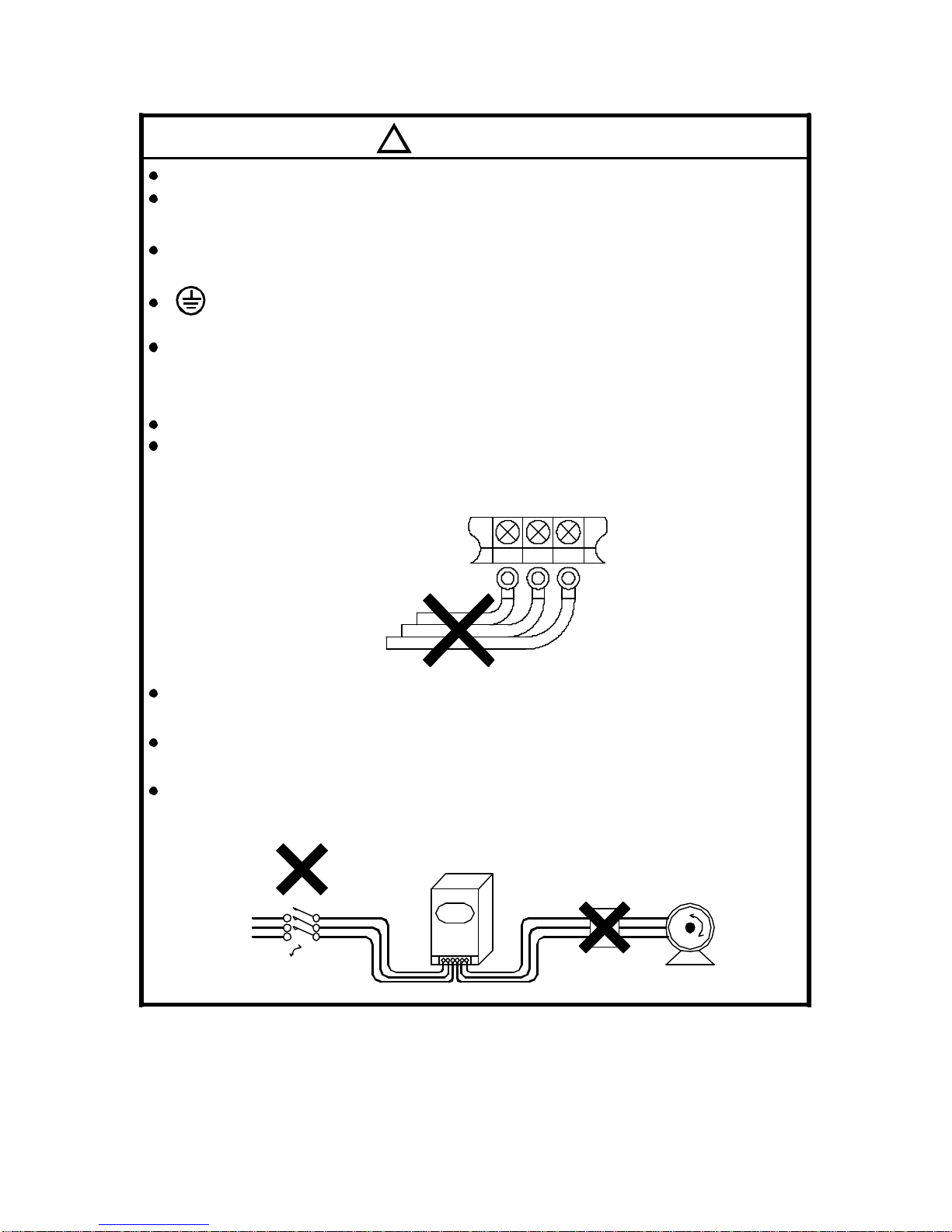

Danger

Only commence wiring after verifying that the power supply is turned

OFF.

Wiring should be performed only by qualified personnel.

Make sure to connect the ground terminal. Ground resistance 0.1

or less.

Do not measure any element signal during operation. Failure to observe

this caution can result in personal injury.

Perform maintenance or inspection only after verifying that the

CHARGE LED goes OFF 5 minute and after the main circuit power

source is turned OFF.

Never modify the product. Failure to observe this warning can result in

an electrical shock or personal injury and will invalidate the guarantee.

!

℃

Ω

1

Caution

Mount the driver on nonflammable material.(i.e. metal)

When mounting units in an enclosure, install a fan or other cooling

device to keep the intake air temperature below 45 .

Overheating may cause a fire or damage to the unit.

!

※

UVW

power input

2

Caution

Please confirm power source voltage to driver input rated voltage.

Please make sure the wiring is correct when driver adds a braking

resister.

Do not put the advance phase capacitor between the driver and motor.

is grounding symbols. Be sure ground both the driver and motor.

Check the power connecter is locked on the terminal of driver.

( Do not looseness, otherwise, connecter will be oxidized and over

heat.)

Check that the input power source voltage is correct.

Be sure to connect the power source to L1,L2(input terminals) and the

motor to U.V.W.(output terminals). (Wrong connection will damage the

driver.)

Do not make any replacement for electronic parts when troubles are

occurred.

Do not perform a withstand voltage test of the driver. It may cause

semiconductor parts or power switches to be damage.

Do not install relay between power source and driver for operating

start and stop.

Phase advancing

capacitor

ON - OFF

Motor

power

source

Motor

BL

!

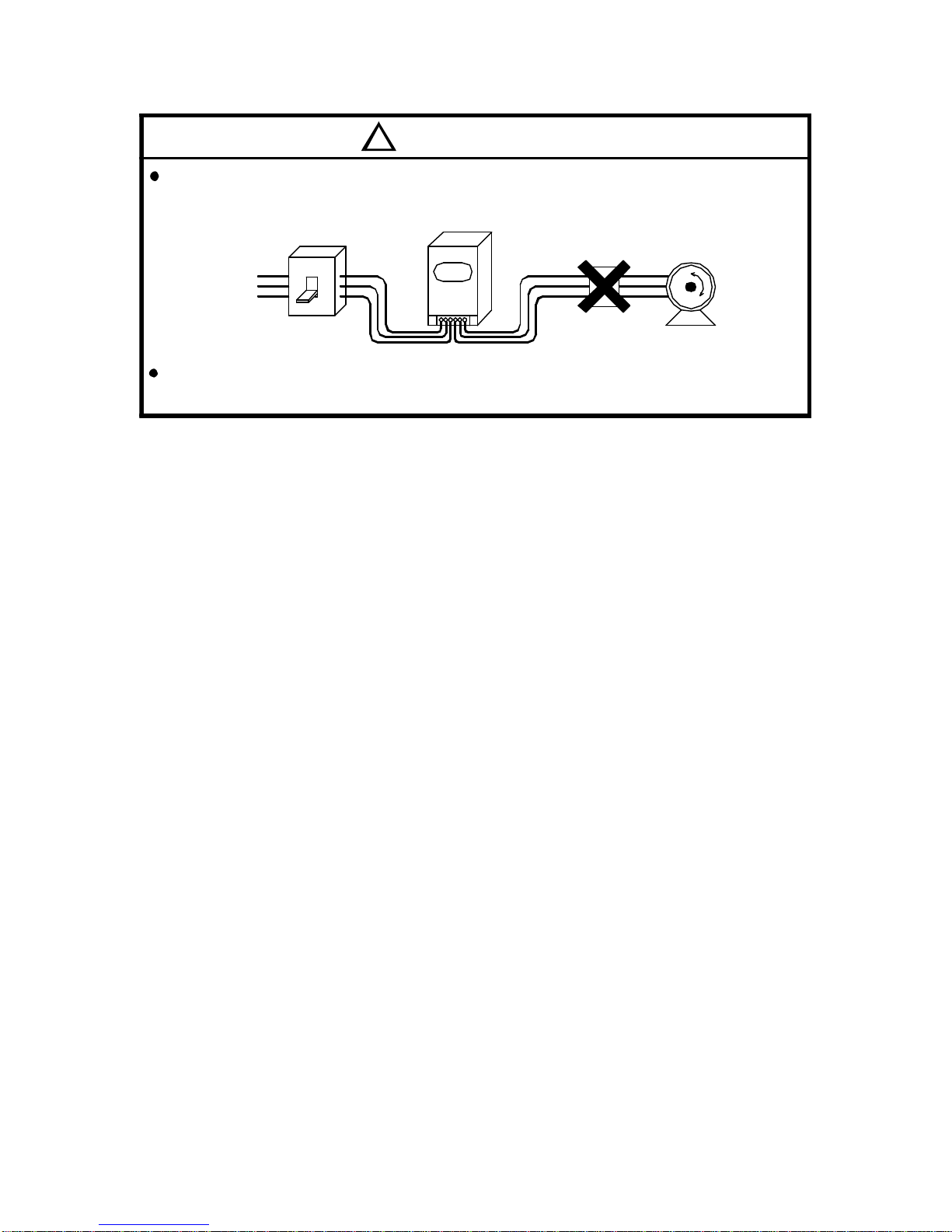

Caution

For operating motor "start" and "stop" should use keypad or terminal

to control these functions.

Do not install phase advancing capacitor between driver and motor

for operating motor.

3

ON - OFF

(NFB)

power

Motor

source

BL

4

Motor Drive

AM - XXX L (B) BL X - X XX X

: Rated power : example 370 represent 370W

: Rated speed : L : 2000RPM M : 3000RPM

H : 6000RPM HX : 9999RPM

: With B : with magnet brake

: Rated voltage : 2 : 220V 4 : 440V

: 1 : single phase input 3 : three phase input

: 01 : 0.1KW 02 : 0.2KW 04 : 0.4KW

07 : 0.75KW 15 : 1.5KW 22 : 2.2KW

Note : 60~370W motors and drives are with CSA approval.

j k l m n

j

k

l

m

o

n

o

2. Receiving

2-1 Acceptance Inspection and Precautions

During product manufacturing, packaging, and shipment

have been standardised. If any problem is discovered,

please contact your dealer or producer immediately.

Any damage with each product after shipping.

The instruction manual is contained in the package.

The product as same as an order (check the nameplate,

voltage and frequency).

All of terminals are locked and unusual substance.

The keyboard of remote control must be corrected.

Check the additional accessories.

2-2 Nameplate

Motor

Drive

k

MATCHSERVO MOTOR

ADLEE POWERTRONIC CO., LTD.

ADLEEPOWER

AMP.S

AMB.

R.P.M

MODEL

VOLTS

R

1.7A

3000

AM-370M

AC220V 370W

B

40

0~200Hz40 /104°C °F

DATE

IP

INS.

OUTPUT

Ambinent Temp

Rated current

Input voltage

Model No.

Rated rpm

Rated power

Implied protection

Insulation grade

Frequence grange

AC-INPUT

1 Rated 3.6A

200~230V 50/60Hz

ADLEE POWERTRONIC CO., LTD.

MATCHSERVO MTR DRIVES

ψ

AC-OUTPUT

370W Rated 1.70A

0~230V 3

BL2 - 104M

ψ

R

Output voltage & phase

Rated output power &

Input voltage & frequency

Model No.

Input phase & Rated current Rated current

3. Environmental requests

Operation

Storage

Transportation

Note :

a. Bad installation can reduce product service life.

b. Do not put motors and drives into worse environment. Such as

high temperature/humidity/vibration, corrosiveness gas, burst.

c. Keep enough cooling space for motors and drives.

Air temperature -20~60 (-4~140 )℃ ℉

Air pressure 86~106kPa

Humidity Less than 90%, no frosting

Air temperature -20~60 (-4~140 )℃ ℉

Air pressure 86~106kPa

Humidity Less than 90%, no frosting

Vibration Less than 20HZ : maximum 9.86m/s2

20~50HZ : maximum 5.88m/s2

5

Air temperature -10~45 (14~113 )℃ ℉

Air pressure 86~106kPa

Attitude Under 1000 meters

Vibration Less than 20HZ : maximum 9.86m/s2

20~50HZ : maximum 5.88m/s2

10cm 10cm

Motors

Drives

5cm 5cm

6

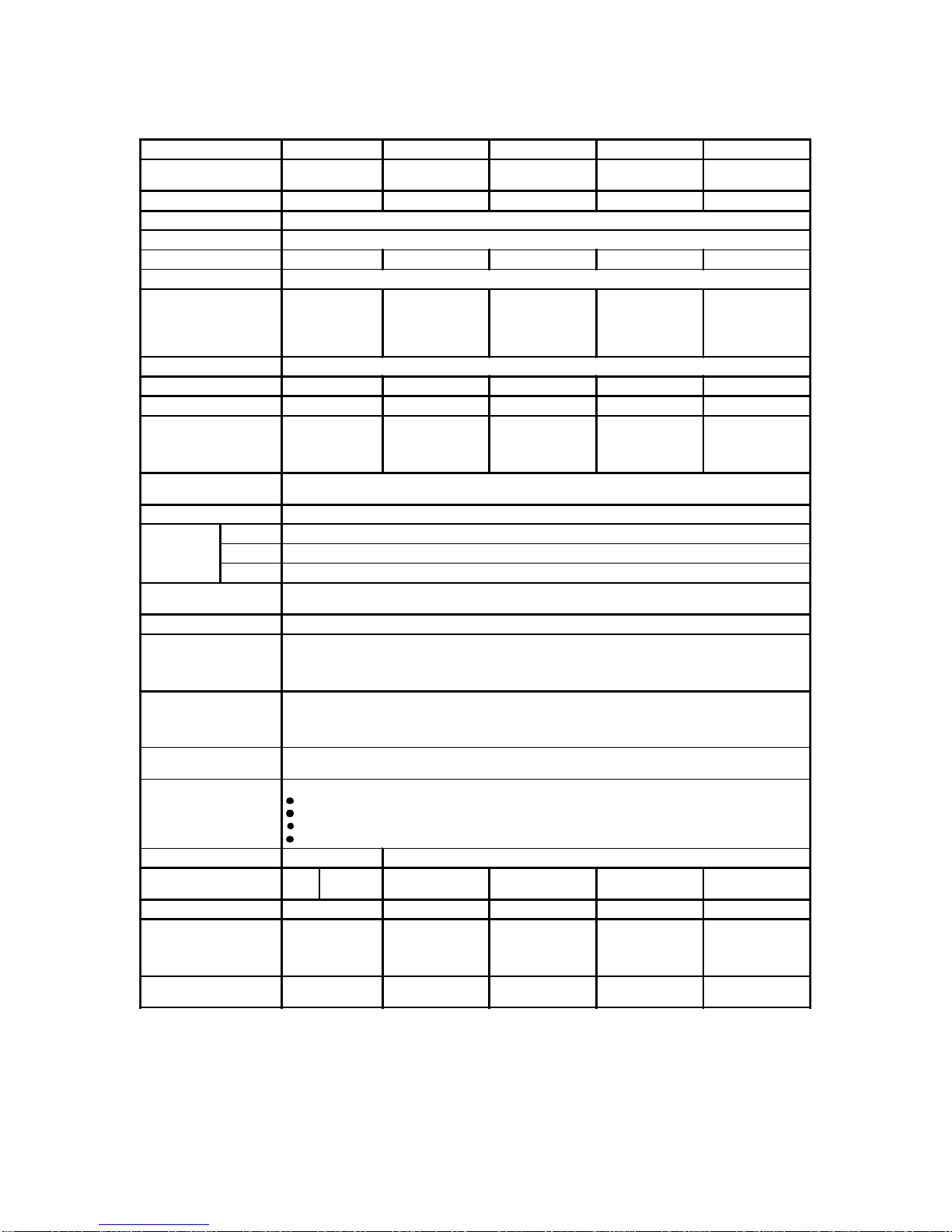

4. Specification

7

The varnished copper wire is F class insulation.

AM-60~370 motor has magnet brake option. The brake torque is 25Kg-cm

(21.6in-lb) and BL driver offers 24VDC to control it directly.

※ ∮

※ ∮

±

Ω

Ω

Rated Power W 60 90 120 180 250 370

Motor No. AM-60

L/M AM-90

L/M/H AM-120

L/M/H AM-180

L/M/H AM-250

L/M/H AM-370

L/M/H

Drive No. BL2-101 BL2-101 BL2-102 BL2-102 BL2-104 BL2-104

Input Voltage 220V 10% 1ψ

Input Frequency HZ 50 / 60

Rated input current 0.7 1.1 1.5 2.1 2.9 3.6

Motor Phase 3ψ

Rated Torque Kg-cm

(in-lb) 2.9/2.0

(2.5/1.7) 4.4/2.9/1.5

(3.8/2.5/1.3) 5.8/3.9/2.0

(5.0/3.4/1.7) 8.8/5.8/2.9

(7.6/5.0/2.5) 12.0/8.1/4.0

(10.4/7.0/3.5) 18.0/12.0/6.0

(15.6/10.4/5.2)

Rated Speed RPM L/M/H : 2000 / 3000 / 6000

Max. Efficiency % > 80 > 80 > 80 > 80 > 80 > 80

Max. Output W 180 220 280 330 450 600

Max. Torque Kg-cm

(in-lb) 12.0/6.0

(10.4/5.2) 15.0/9.0/5.5

(13.0/7.8/4.8)

18.0/12.0/8.0

(15.6/10.4/6.9)

27.0/18.0/10.5

(23.4/15.6/9.1)

36.0/24.0/13.0

(31.2/20.8/11.3)

54.0/36.0/20.0

(46.8/31.2/17.3)

Variable Speed Range

RPM L :150~2000 M :150~3000 H :300~6000

Acc. Dec. Time 0.1 ~ 600.0 Sec

Speed

regulation

Load ±1% Below (0~Rated Torque at rated speed)

Voltage ±1% Below (Source voltage±10% at rated speed No Load)

Temperature ±1%Below(-10~45 /14~113 atrated speed NoLoad)

℃ ℉

Motor Insulation/

Max. Working TEMP. BClass (130 /266 )/Max.100 /212

※ ℃ ℉ ℃ ℉

Type of control Rectangular wave PWM

Speed command

1. Built-in potentiometer

2.ExternalPotentiometer2k

≧

3. 0~5VDC, 0~10VDC, 4~20mA control

4.RS485

Operation

1. Pannel : CW、CCW、Key

2. Terminal : Type of input:Photocoupler, input impedance 2.2 k /

CW 、CCW、Common (4.5 ~ 5VDC)

3. Communication : RS485

Output signal Open collect output, External use condition DC48V、10mA below

SPEED OUT、Fault relay A/B

Protection

Any phenomenons as below will come to stop output alarm signal will be output and the

motor.

Over load:Motor over temperature protection.

Over heat:Power modular over heat shut down itself.

Lost phase:Motor signals are abnormal, due to motor cables was broken or

discounector.

Phase to phase short circuit.

Motor enclosure type IP40

Motor figure No. 1 1 2 3 4 5 4(M/H)

BL Driver figure No. 10 10 10 10 10 10

Motor Weight Kg

(lb) 2.1/2.1

(1.8/1.8) 2.4/2.4/2.4

(2.1/2.1/2.1) 2.6/2.5/2.5

(2.3/2.2/2.2) 2.9/2.7/2.7

(2.5/2.3/2.3) 4.0/3.8/3.7

(3.5/3.3/3.2) 4.5/4.0/4.0

(3.9/3.5/3.5)

BL Driver Weight Kg

(lb) 1.1

(1.0) 1.1

(1.0) 1.1

(1.0) 1.1

(1.0) 1.1

(1.0) 1.1

(1.0)

±

Ω

Ω

8

Rated Power W 750 1000 1500 2200

Motor No. AM-750M/H

CM-750L/M/HX AM-1000M/H AM-1500M/H

CM-1500L/M/HX AM-2200M/H

CM-2200L/M/HX

Drive No. BL2-107 BL2-115 BL2-115 BL2-122

Input Voltage 220V 10% 1ψ

Input Frequency HZ 50 / 60

Rated input current 7.55 10 13.4 18.6

Motor Phase 3ψ

Rated Torque Kg-cm

(in-lb)

AM:24.4/12.2

(21.1/10.6)

CM:36.6/24.4/9.1

(31.7/21.1/7.9)

AM:32.5/16.2

(28.2/14.0)

AM:48.8/24.4

(42.3/21.1)

CM:73.2/48.8/18.3

(63.4/42.3/15.9)

AM:73.2/36.6

(63.4/31.7)

CM:109.8/73.2/26.8

(95.1/63.4/23.2)

Rated Speed RPM L/M/H/HX:2000/3000/6000/9999

Max. Efficiency % > 85 > 85 > 85 > 85

Max. Output W 1600 2300 3000 4000

Max. Torque Kg-cm

(in-lb)

AM:48.8/24.4

(42.3/21.1)

CM:73.2/48.8/18.2

(63.4/42.3/15.8)

AM:65/32.4

(56.3/28.1)

AM:97.6/48.8

(84.6/42.3)

CM:146.4/97.6/36.6

(126.9/84.6/31.7)

AM:146.4/73.2

(126.9/63.4)

CM:210/146.4/53.6

(182/126.9/46.4)

Variable Speed Range

RPM L:150~2000 M:150~3000 H:300~6000 HX:300~9999

Acc. Dec. Time 0.1 ~ 600.0 Sec

Speed

regulation

Load ±1% Below (0~Rated Torque at rated speed)

Voltage ±1% Below (Source voltage±10% at rated speed No Load)

Temperature ±1%Below(-10~45 /14~113 atrated speed NoLoad)

℃ ℉

Motor Insulation/

Max. Working TEMP. BClass (130 /266 )/Max.100 /212

※ ℃ ℉ ℃ ℉

Type of control Rectangular wave PWM

Speed command

1. Built-in potentiometer

2.ExternalPotentiometer2k

≧

3. 0~5VDC, 0~10VDC, 4~20mA control

4. RS485

Operation

1. Pannel : CW、CCW、Key

2. Terminal : Type of input:Photocoupler, input impedance 2.2 k /

CW、CCW、Common (4.5 ~ 5VDC)

3. Communication : RS485

Output signal Open collect output, External use condition DC48V、10mA below

SPEED OUT、Fault relay A/B

Protection

Any phenomenons as below will come to stop output alarm signal will be output and

the motor.

Over load:Motor over temperature protection.

Over heat:Power modular over heat shut down itself.

Lost phase:Motor signals are abnormal, due to motor cables was broken or

discounector.

Phase to phase short circuit.

Motor enclosure type L:IP54 M/ H/HX:IP40

Motor figure No. AM:6

CM:A/A/D AM:7 AM:8

CM:B/B/E AM:9

CM:C/C/F

BL Driver figure No 10 11 11 11

Motor Weight Kg

(lb)

AM:8.0/7.8

(6.9/6.8)

CM:11.0/11.0/14.2

(9.5/9.5/12.3)

AM:9.4/8.7

(8.1/7.5)

AM:11.0/9.7

(9.5/8.4)

CM:14.0/14.0/15.3

(12.0/12.0/13.2)

AM:13.2/16.5

(11.4/14.3)

CM:15.6/15.6/16.5

(13.5/13.5/14.3)

BL Driver Weight Kg

(lb) 1.1

(1.0) 1.3

(1.1) 1.3

(1.1) 13

(1.1)

9

Ω

Ω

±

Rated Power W 370 750 1000 1500 2200

Motor No. AM-370L/M/H AM-750M/H

CM-750L/M/HX AM-1000M/H AM-1500M/H

CM-1500L/M/HX AM-2200M/H

CM-2200L/M/HX

Drive No. BL4-304 BL4-307 BL4-315 BL4-315 BL4-322

Input Voltage 380/440V 10% 3ψ

Input Frequency HZ 50 / 60

Rated input current 1.4 2.2 3.0 3.5 5.0

Motor Phase 3ψ

Rated Torque Kg-cm

(in-lb)

AM:18.0/12.0/6.0

(15.6/10.4/5.2)

AM:24.4/12.2

(21.1/10.6)

CM:36.6/24.4/9.1

(31.7/21.1/7.9)

AM:32.5/16.2

(28.2/14.0)

AM:48.8/24.4

(42.3/21.1)

CM:73.2/48.8/18.3

(63.4/42.3/15.9)

AM:73.2/36.5

(63.4/31.6)

CM:109.8/73.2/26.8

(95.2/63.4/23.2)

Rated Speed RPM L/M/H/HX:2000/3000/6000/9999

Max. Efficiency % > 85 > 85 > 85 > 85 > 85

Max. Output W 600 1600 2300 3000 4000

Max. Torque Kg-cm

(in-lb) AM:54/36/20

(46.8/31.2/17.3)

AM:48.8/24.4

(42.3/21.1)

CM:73.2/48.8/18.2

(63.4/42.3/15.8)

AM:65/32.4

(56.3/28.1)

AM:97.6/48.8

(84.6/42.3)

CM:146.4/97.6/36.6

(126.9/84.6/31.7)

AM:146.4/73.2

(126.9/63.4)

CM:210/146.4/53.6

(182/126.9/46.4)

Variable Speed Range

RPM L:150~2000 M:150~3000 H:300~6000 HX:300~9999

Acc. Dec. Time 0.1 ~ 600.0 Sec

Speed

regulation

Load ±1% Below (0~Rated Torque at rated speed)

Voltage ±1% Below (Source voltage±10% at rated speed No Load)

Temperature ±1%Below(-10~45 /14~113 atrated speed NoLoad)

℃ ℉

Motor Insulation/

Max. Working TEMP. BClass (130 /266 )/Max.100 /212

※ ℃ ℉ ℃ ℉

Type of control Rectangular wave PWM

Speed command

1. Built-in potentiometer

2.ExternalPotentiometer2k

≧

3. 0~5VDC, 0~10VDC, 4~20mA control

4. RS485

Operation

1. Pannel : CW

、

CCW

、

Key

2. Terminal : Type of input

:

Photocoupler, input impedance 2.2 k /

CW

、

CCW

、

Common (4.5 ~ 5VDC)

3. Communication : RS485

Output signal Open collect output, External use condition DC48V

、

10mA below

SPEED OUT

、

Fault relay A/B

Protection

Any phenomenons as below will come to stop output alarm signal will be output and the motor.

Over load

:

Motor over temperature protection.

Over heat

:

Power modular over heat shut down itself.

Lost phase

:

Motor signals are abnormal, due to motor cables was broken or discounector.

Phase to phase short circuit.

Motor enclosure type L/M/H:IP40 L:IP54 M/H/HX:IP40

Motor figure No. 5 4(M/H) AM:6

CM:A/A/D AM:7 AM:8

CM:B/B/E AM:9

CM:C/C/F

BL Driver figure No 10 11 11 11 11

Motor Weight Kg

(lb) AM:4.5/4.5/4.0

(3.9/3.9/3.5)

AM:8.0/7.8

(6.9/6.8)

M:11/11/14.2

(9.5/9.5/12.3)

AM:9.4/8.7

(8.1/7.5)

AM:11/9.7

(9.5/8.4)

CM:14/14/15.3

(12.1/12.1/13.3)

AM:13.2/16.5

(11.4/14.3)

CM:15.6/15.6/16.5

(13.5/13.5/14.3)

BL Driver Weight Kg

(lb) 1.1

(1.0) 1.3

(1.1) 1.3

(1.1) 1.3

(1.1) 1.3

(1.1)

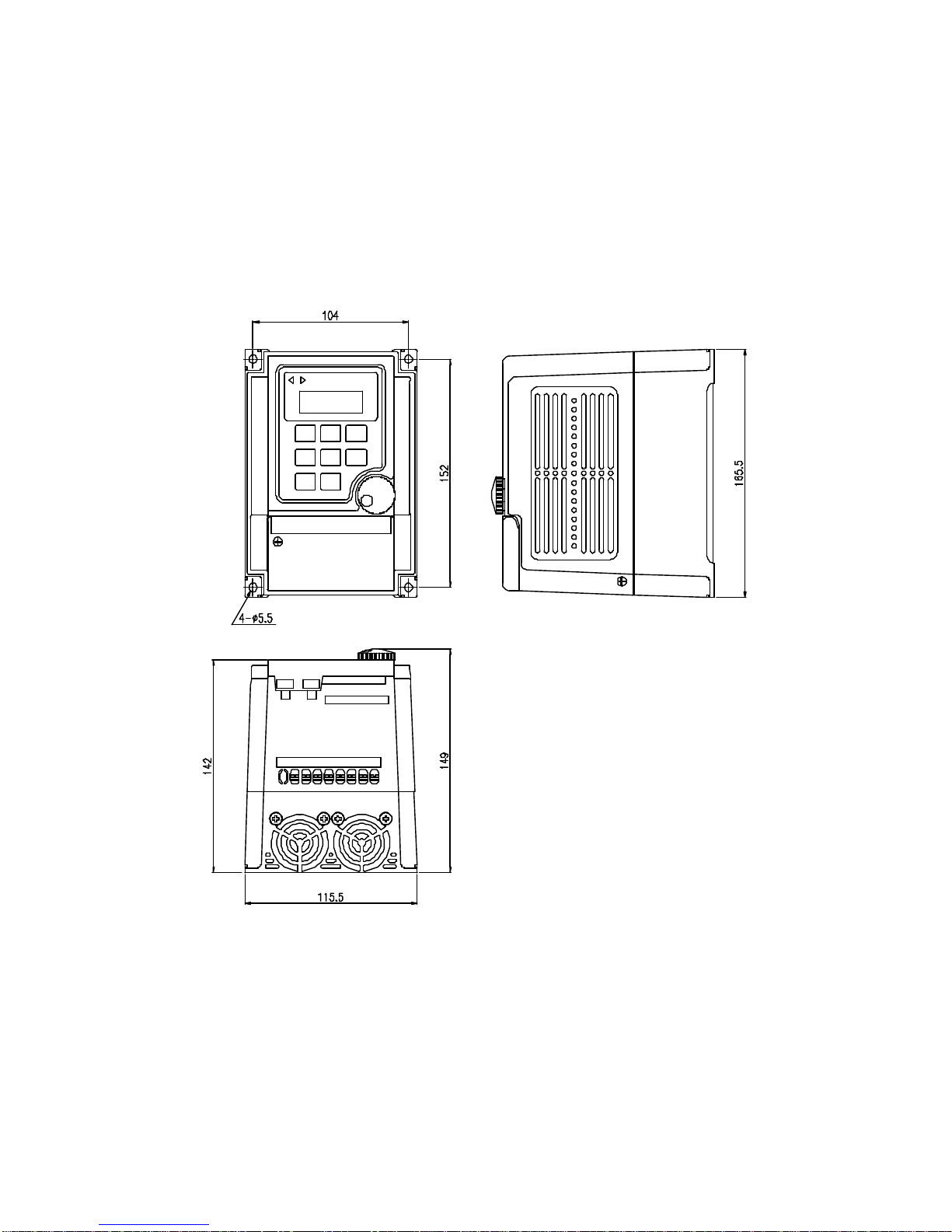

5. Dimensions

5-1 Drive dimensions

BL2-101~107,BL4-304 Unit : mm

10

BL2-115~BL2-122,BL4-307~BL4-322 Unit : mm

11

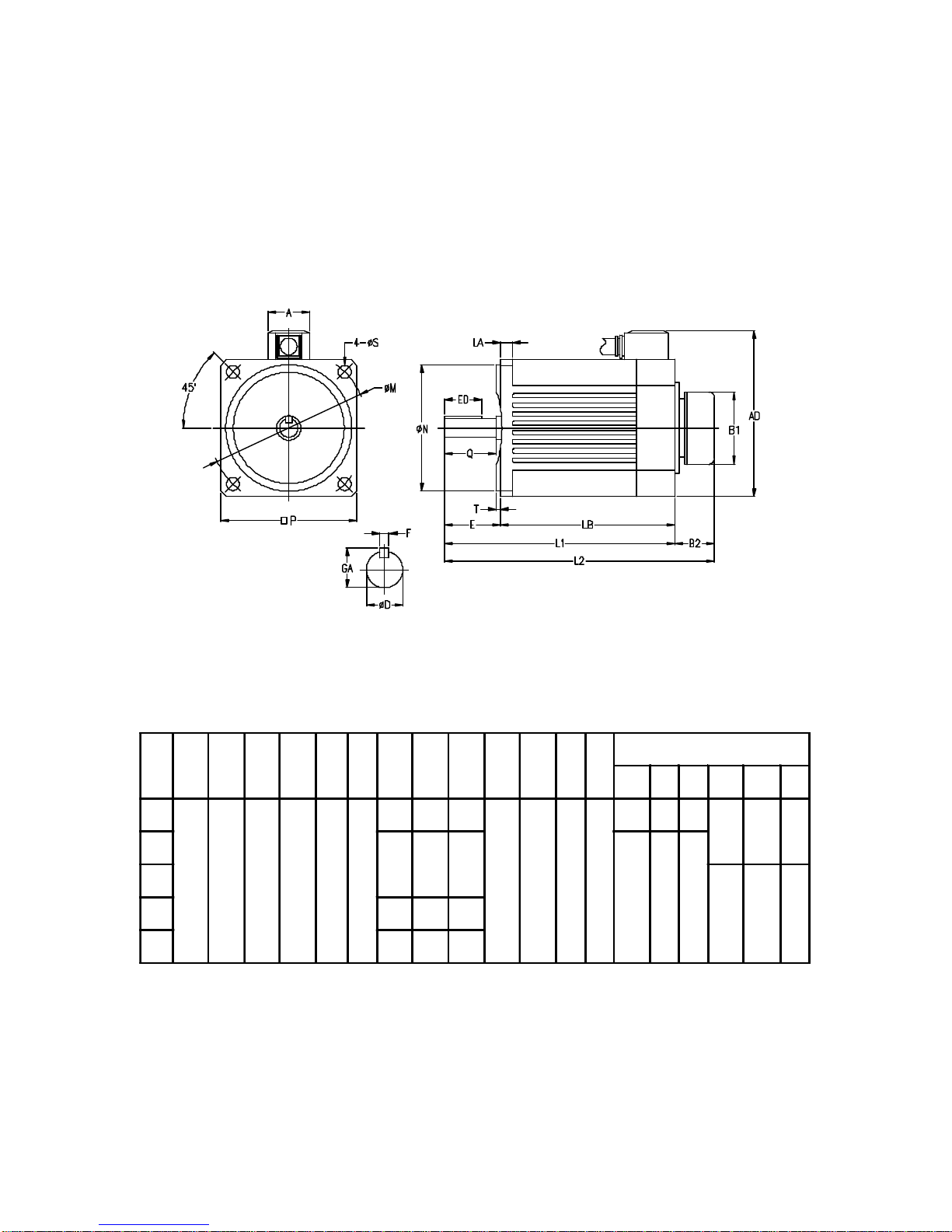

5-2 Motor dimensions

AM-60~370 Unit : mm

12

Wires colors : U(red), V(white), W(black).

No. P M∮S∮N∮TLA LB L1 L2 AD AB1 B2 OUTPUT SHAFT END

ED QED∮GA F

1

90 104 8.5 83 2.5 8

100 128 161

109 27 61 33

20 25 28 12 13.5 4

2115 147 180

25 29 32

3

14 16 54 170 202 235

5 185 217 250

□

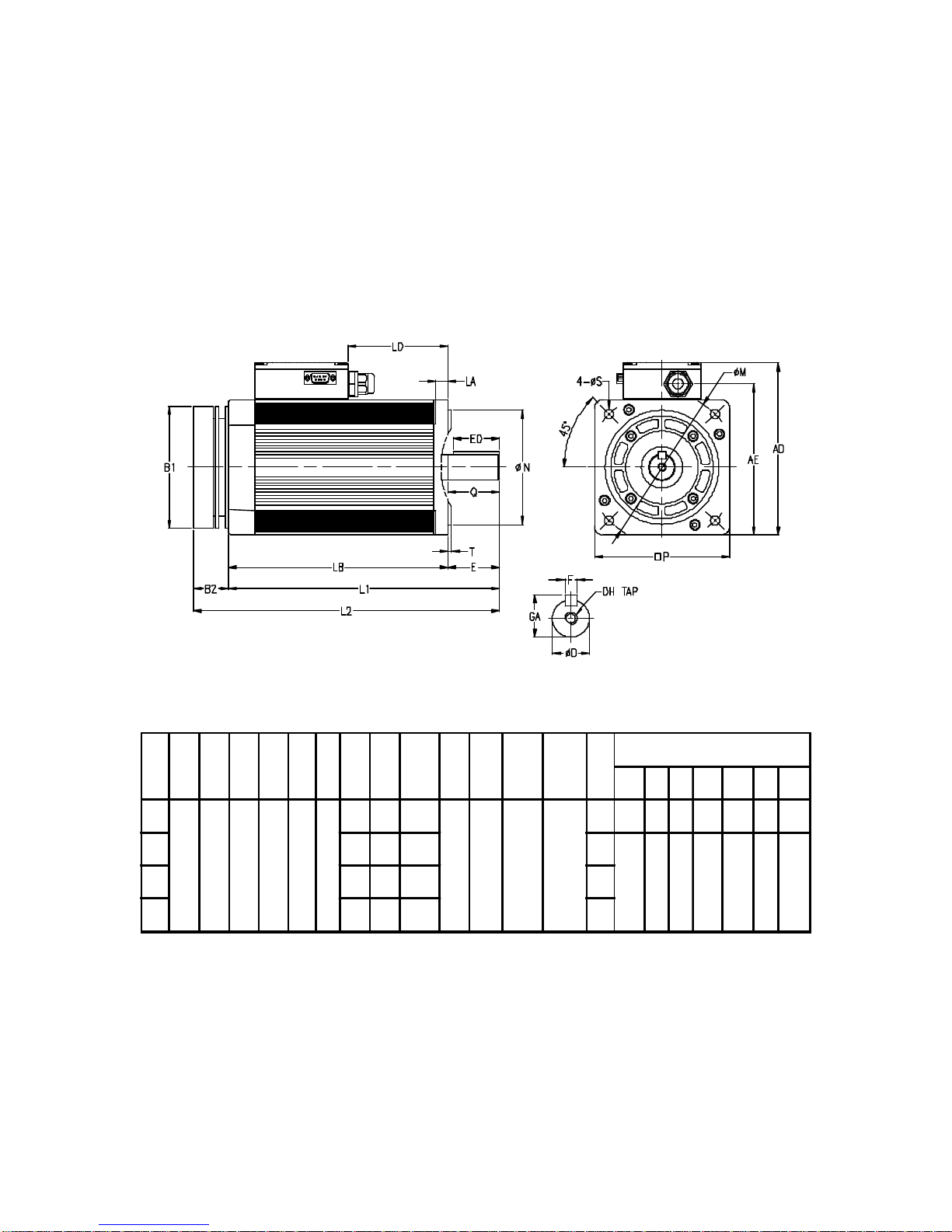

AM-750~AM-2200 Unit : mm

13

No. P M∮S∮N∮TLA LB L1 L2 B1 B2 AD AE LD OUTPUT SHAFT END

ED QED∮GA FDH

6

130 145 9 110 3.5 12

178 218 252.3

117 34.3 165.5 146

63 35 40 40 19 21.5 6M6

7 195 245 279.3 80

45 50 50 24 27 8 M88 212 262 296.3 97

9 232 282 316.3 117

□

CM-750~CM-2200 Unit : mm

14

No. P M∮S∮N∮TLA LB LAC AD AE LD OUTPUT SHAFT END

ED QED∮GA FDH

A

175 165 12 130 3.5 13

205 245

142

186 166

67 35 40 40 19 21.5 6M6

B239 289 101 45 50 50 24 27 8 M8

C259 309 121

D287 327

144 67 35 40 40 19 21.5 6M6

E337 45 50 50 24 27 8 M8

F296 346 76

□

5-2 F306 dimensions

Unit : mm

15

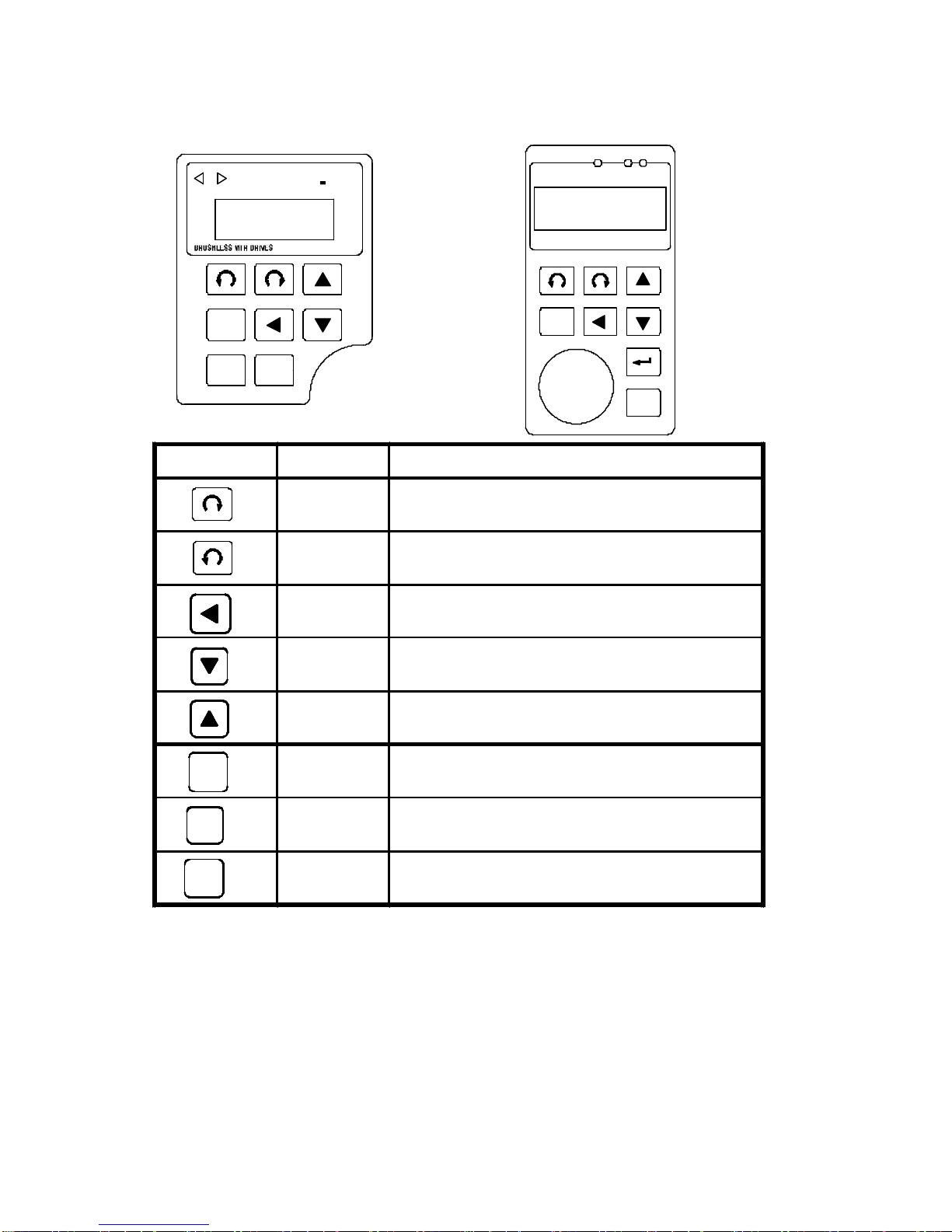

6. Digital operation panel

REV FWD

FUNC

STOPPROG

BL2 IPM

FUNC

STOP

F306 FWD

CHARGE

REV

REMOTE CONTROL

PROG

FUNC

STOP

16

Keypad Function Description

Forward

run Commands forward run

Reverse

run Commands reverse run

Cursor

movement Select the digit

Down Decrease the parameter value 9~0

Up Increase the parameter value 0~9

Memory

storage Saves the setting parameter value

Function Press once to select function code and

press again to change its content

Stop Stop operation / Escape to standby mode

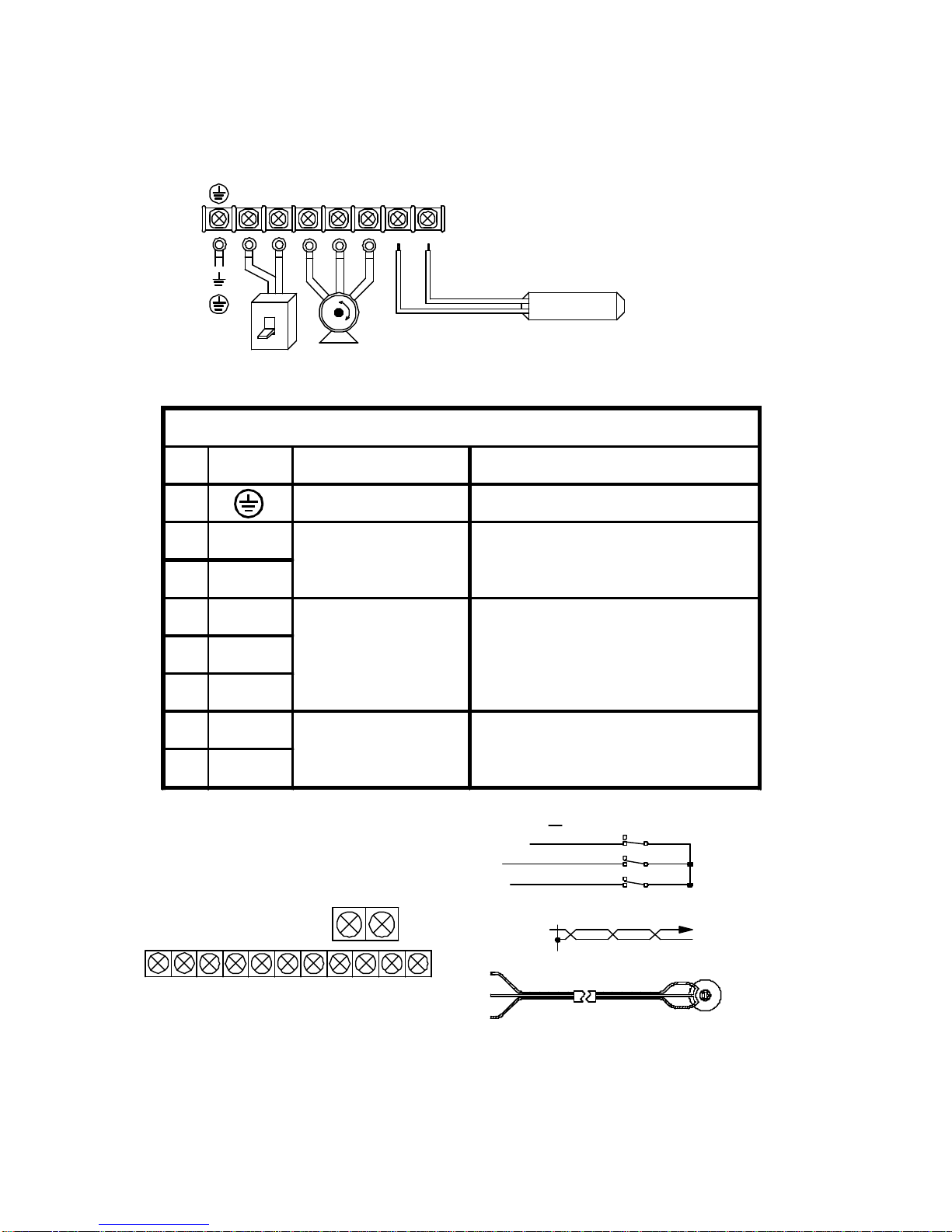

7. Terminals and wiring

7-1 Main power circuit terminals

7-2 Control terminals

17

L1 L2 UVWPRP

Motor

Power

Ground External braking resistor

Refer to the appendix

Source

OUT

SPEED

HMA/BLCCW

CF CCW EXG24V

MB+

MB-

+24 EXTERNAL POWER INPUT

SPEED SELECTION

CW. Input

CCW. Input

SPEED OUTPUT

OFF

ON

ON

OFF

OFF

ON

11 INPUT COM

6 CF

7 CW

8 CCW

4 A/B

9 SPEED OUT

5 C

1 H

2 M

3 L

EXG

3

2

1 3

21

SPEED KNOB(OPTIONS)

EXG

EXG

Main circuit terminal

No. Symbol Terminal name Description

1Ground Ground (Earth) Terminal

2 L1 Connect power

supply (L1, L2) Single Phase

3 L2

4U

Driver output

Terminal connecting to motor

U(red), V(white), W(black)

wrong UVW connection can

damage motor driver

5V

6W

7PDynamic brake

resistor See appendix for braking

resistor selection

8PR

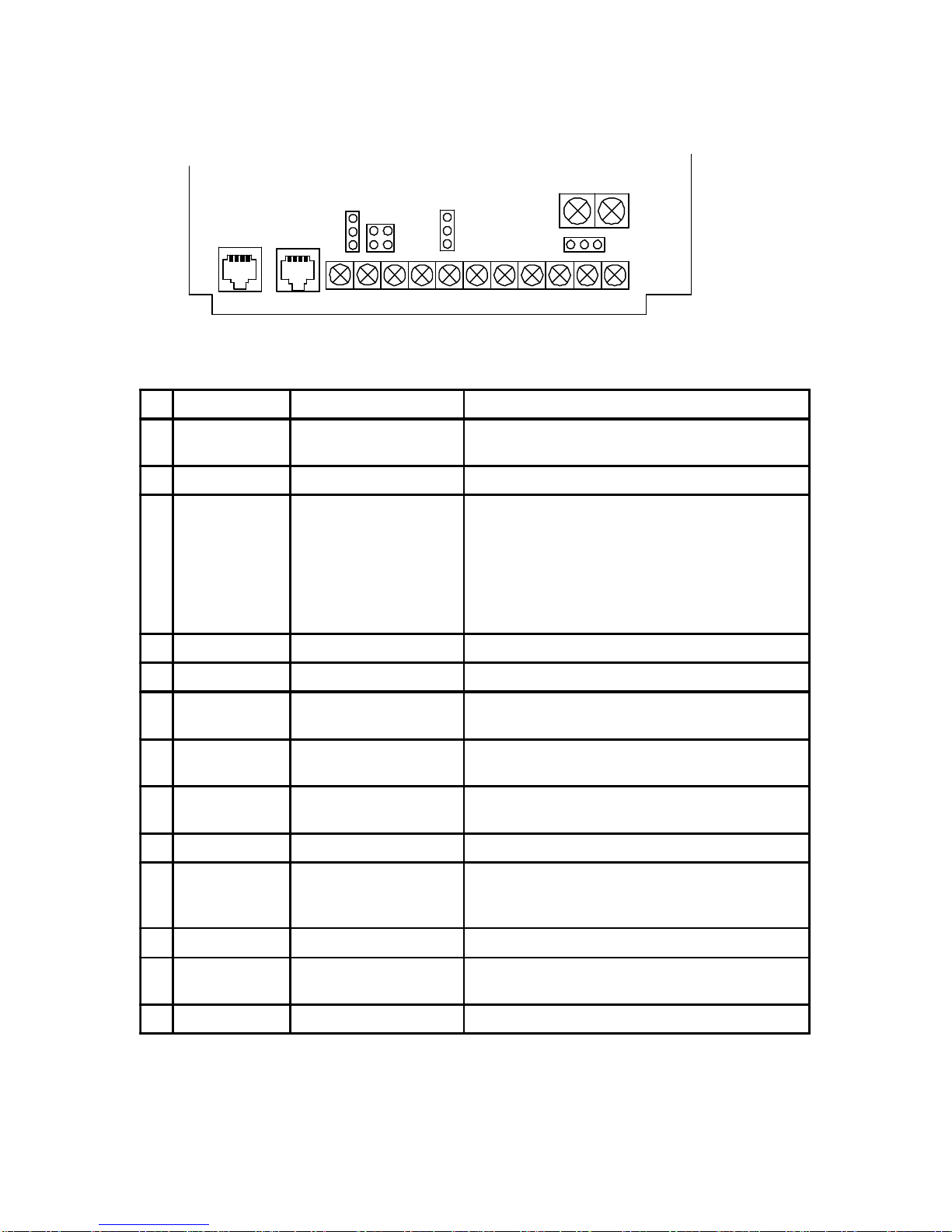

7-3 Control terminals descriptions

All terminal can connect to switch, relay, TTL or Transistor. Refer

to 8-3 for detail.

18

SPEED

A/BLCCW CCW OUT

HMCF EXG 24V

J4

J5

S161

J6

MB+

MB-

HallRS485 sensor

No Symbol Terminal name Description

1A/B Alarm output Fault alarm contact. Set J4 jumper for A

(normal open) or B (normal close).

2CAlarm output common Fault alarm contact C.

3CF Analog and digital

speed input selection

CF/EXG open : Analog speed input is from

panel VR or F306 VR. Digital speed input is

CD28 or CD34 setting. Set J5 jumper for panel

VR or F306 VR selection.

CF/EXG short : Analog speed input is from

external VR by H M L terminals. Digital speed

input is CD29 or CD35 setting.

4CW Forward operation Forward operation / stop terminal.

5CCW Reverse operation Reverse operation / stop terminal.

6SPEED OUT Speed signal output L, M model : 12 pulses/turn

H, HX model : 6 pulses/turn

7EXG Common terminal Common for terminal 3~6 or for external

24VDC(20mA)

824V External 24VDC input +24VDC external power input. Set S161

jumper to select internal or external power.

9H+10 VDC External VR reference voltage.

10 MAnalog command input External analog speed command input. Set J6

jumper for voltage 0~5VDC, 0~10VDC or

4~20mA.

11 LH and M common

MB- Motor brake - 24VDC, 15W, connect to magnet brake for

60~370W motor only

MB+ Motor brake +

This manual suits for next models

45

Table of contents

Other Adleepower DC Drive manuals

Popular DC Drive manuals by other brands

Aumuller

Aumuller KS2 Twin Assembly and commissioning instructions

Rowan Elettronica

Rowan Elettronica 390S.B instruction manual

SEW-Eurodrive

SEW-Eurodrive MGF-DSM Series Addendum to the operating instructions

Rockwell Automation

Rockwell Automation Allen-Bradley 1336 PLUS II instructions

Lenze

Lenze L-force 8400 Series Mounting instructions

Siemens

Siemens SINAMICS G120 installation manual