Adleepower AM-60L User manual

ADLEEPOWER

INSTRUCTION MANUAL

THANK YOU VERY MUCH FOR YOUR PURCHASE

OF ADLEE PRODUCTS.

PLEASE READ THIS INSTRUCTION MANUAL

BEFORE INSTALLATION.

R

BRUSHLESS IPM

MOTOR & DRIVES

CONTENTS

1. PREFACE

2. NAMEPLATE

3. SPECIFICATION

4. DIMENSIONS

5. ENVIRONMENTAL REQUESTS

6. FUNCTION DESCRIPTION .

7. OPERATION AND CONNECTION

8. Motor T-N curve

9. APPLICATION

10. TROUBLE SHOOTING

11. REPAIRING AND MAINTENANCE

Appendix

1

5

6

8

11

13

21

63

64

65

67

70

1. Preface

This D305 drive and brushless servomotor made by ADLEE

Powertronic., Ltd.

Read this instruction manual throughly before operation.

This manual will be helpful in the installation, parameter setting

and troubleshooting of the BLDC motors and drives. To guarantee

safe operation of the equipment, read the following safety guide-

lines before connecting power to the drives. Keep this operating

manual handy and distribute to all users for reference.

Safety Precaution - Read These First

Indicates a potentially hazardous situation which, if against, may

result in personal injury, fire or damage to equipment.

DANGER

Do not install or operate motor or drive that are

damaged or has missing parts.

CAUTIION

Before installation, check specifications are

matched the equipment. Ex. voltage, power,

torque, RPM...

!

Receiving

!

!

Dangerous Electrical Shock

Danger and Caution

1

℃

2

Installation

!

!

!

℉

CAUTION

Impacts and shocks applied to the shaft end will

damage the rotary sensor and ball bearings. Pay

more attention when drive elements such as

pulleys, clutch disks, toothed wheels etc.

DANGER

Be sure to install the unit on flame-resistant material

such as a steel plate. Otherwise, there is the

danger of fire.

DANGER

Install units into a flowing air environment. See

inside manual requests. When mounting units in an

enclosure, install a cooling device to keep the

intake air temperature below 45 (115 ).

DANGEROUS ELECTRICAL VOLTAGE

Due to the permanent magnet excitatiion, the power

connector carries a hazardous high voltage if the

rotor is rotating and the motor is not electrically

connected. The unit must be completely

de-energized and halted before commencing any

connection or installation work.

CAUTION

Wiring should be performed only by qualified

personnal.

DANGER

For equipment protection, install a ground leakage

type breaker with a fast response circuit capable of

handling large currents.

Wiring

!

!

CAUTION

Hazardous terminals for any interconnection (motor,

contact breaker, filter, etc.) must be inaccessible in

the final installation.

DANGEROUS ELECTRICAL SHOCK

Be sure that the input voltage is matched the drive

specifications.

DANGEROUS ELECTRICAL SHOCK

Be sure not to connect an AC power supply to the

output terminals.

DANGEROUS ELECTRICAL SHOCK

Be sure to connect the grounding terminal to earth

ground. Ground resistance is less than 100 .

DANGEROUS ELECTRICAL SHOCK

Never remove connectors by pulling on its wire

leads. Otherwise, there is a danger of fire or injury

due to wire breakage.

CAUTION

Do not stop operation by switching of

electromagnetic contactors on the primary.

CAUTION

Tighten terminal screws.

CAUTION

When using D305 drives should match to

ADLEEPOWER®AM series motors. If using other

brand motors can cause the driver or motor dam-

age.

!

3

Ω

!

!

!

CAUTION

Danger of getting burnt! The surfaces of motors can

reach temperatures of up to approx. 100 (212 ).

A touch guard is to be provided where necessary.

DANGER

Danger of injury from shaft keys being slung out.

Motor may only be operated as installed.

CAUTION

Since it is easy to change operation direction or

speed from low to high speed. Verify the safe

working range of the equipment.

DANGEROUS ELECTRICAL SHOCK

To wait at least five minutes after turning off the

input power supply before performing maintenance

or an inspection. Otherwise, there is the danger of

electric shock.

DANGEROUS ELECTRICAL SHOCK

Never test the withstand voltage(HIPOT) on the

drive. It may cause components to be damaged.

DANGEROUS ELECTRICAL SHOCK

Never modify the unit. Otherwise, ther is danger of

electric shock and/ or injury.

℃

℉

Operation

Maintenance and Inspection

4

!

!

!

2. Nameplate

Motor

Drive

D305 ( B ) - 1

: With B : with magnet brake

: 1 : 110Vac : input source voltage 110Vac, output 220Vac

2 : 220Vac : input source voltage 220Vac, output 220Vac

j k

j

k

AM - XXX L (B)

: Rated power : example 370 represent 370W

: Rated speed : L : 2000RPM M : 3000RPM H : 6000RPM

: With B : with magnet brake

j k l

j

k

l

5

200~230V 50/60Hz

SINGLE PHASE 3.8A

AC-INPUT

Model:D305

ADLEE POWERTRONIC CO., LTD.

BLDC DRIVE

ADLEEPOWER

AC-OUTPUT

0~230V 3PHASE

180W 2.2A

DATE:

RManufacturing date

Rated Output power &

Output Voltage & PhaseInput Voltage & Frequency

Input phase & Max. Input

Model No.

Current Max. Current

ADLEEPOWER

Brushless DC Motor

ADLEE POWERTRONIC CO., LTD.

Model

Volts

AMP.S

AMB

Max. rpm

IP

Output

INS.

DRIVE

DATE

AM-180L

AC220V

0.55

45°C/113°F

2000

180W

40

B

R

Manufacturing date

Drive model

Implied protection

Rated powerModel No.

Input voltage

Rated current

Ambinent Temp

Max. rpm

Insulation grade

D305

3. Specification

6

Model No. AM-60

L/M AM-90

L/M/H AM-120

L/M/H AM-180

L/M/H AM-250

L/M/H AM-370

L/M/H

Input Voltage 100~130VAC / 1ψ OR 200~230VAC / 1ψ (TN system)

Input Frequency HZ 50 / 60

Input Rated Current A 0.7 1.1 1.5 2.1 2.9 3.6

Max. Input Current A

(For 220V input) 2.8 3.4 4.2 56.5 8.5

Max. Input Current A

(For 110V input) 5.6 6.2 7.3 10 11.6 15

Output Rated Current A 0.4 0.6 0.8 1.1 1.6 2.2

Max. Output Current A 1.8 22.4 3.2 4.1 4.9

Overload Current

Protection (A) 2.0/2.4 2.4/2.4/2 2.6/3.2/3.0 3.6/4.4/3.5 5.0/5.6/5.0 6.4/6.6/6.4

Motor Rated Current A 0.32/0.34 0.45/0.45/0.43 0.61/0.64/0.52 0.94/0.94/0.78 1.45/1.15/1 1.92/1.7/1.4

Motor Phase 3ψ

Rated Output W 60 90 120 180 250 370

Rated Torque Kg-cm

(in-lb) 2.9/2.0

(2.5/1.7) 4.4/2.9/1.5

(3.8/2.5/1.3) 5.8/3.9/2.0

(5.0/3.4/1.7) 8.8/5.8/2.9

(7.6/5.0/2.5) 12.0/8.1/4.0

(10.4/7.0/3.5) 18.0/12.0/6.0

(15.6/10.4/5.2)

Rated Speed RPM L:2000 / M:3000 / H:6000

Max. Efficiency % > 80 > 80 > 80 > 80 > 80 > 80

Max. Output W 180 220 280 330 450 600

Max. Torque Kg-cm

(in-lb) 12/6

(10.4/5.2) 15/9/5.5

(13.0/7.8/4.8) 18/12/8

(15.6/10.4/6.9) 27/18/10.5

(23.4/15.6/9.1) 36/24/13

(31.2/20.8/11.3) 54/36/20

(46.8/31.2/17.3)

Variable Speed Range RPM L:150~2000 / M:150~3000 / H:300~6000 / HX1:130~5000 / HX2:300~9999

Acc. Dec. Time Around 0.2 ~ 600 Sec / Max. 45dB (L Model)

The magnet brake torque is 25Kg-cm (21.65 in-lb).

The varnished copper wire is F class insulation.

110V/1 Max. input current is approximately double in above table.

※ ∮

※ ∮

※ ∮

ψ

7

Model No. AM-60

L/M AM-90

L/M/H AM-120

L/M/H AM-180

L/M/H AM-250

L/M/H AM-370

L/M/H

Speed

regulation

Load ±1% Below (0~Rated Torque at rated speed)

Voltage ±1% Below (Source voltage±10% at rated speed No Load)

Temperature ±1% Below (0~40℃ / 32~104℉ at rated speed No Load)

Motor Insulation/

Max. Working TEMP. ※ B Class ( 130℃/266℉ ) / Max. 100℃/212℉

Type of control Rectangular wave PWM

Speed command Built-in potentiometer / External Potentiometer ≧ 2 kΩ / RS-485

Operation

1. Remove control pannel : CW, CCW, STOP Key

2. Terminal : Type of input : Photocoupler, input impedance 2.2kΩ / CF, CW, CCW, SLOW DOWN

Common

3. Communication : RS-485

Output signal Open collect output, External use condition 5VDC、10mA below

SPEED OUT、ALARM OUT

Protection

Any phenomenons as below, motor will stop and output alarm signal.

●Over load:Motor working temperature is not over 120℃(248℉).

●Over heat:Power D305 model over heat 120℃(248℉) shut down itself. ※110℃(230℉) Reset.

●Lost phase:Motor signals are abnormal, due to motor cables was broken or discounector.

●Phase to phase short circuit.

Environmental Enclosure

Rating IP20

Protective Class I

Figure No. 1 1 2(L/M) 1 3(L/M) 2 45 4(M/H)

Motor Weight Kg

(lb) 2.1/2.1

(4.62/4.62) 2.4/2.4/2.4

(5.28/5.28/5.28) 2.6/2.5/2.5

(5.72/5.50/5.50) 2.9/2.7/2.7

(6.38/5.94/5.94) 4.0/3.8/3.7

(8.8/8.36/8.14) 4.5/4.5/4.0

(9.90/9.90/8.80)

D305 Driver Weight Kg

(lb) 0.75

(1.65) 0.75

(1.65) 0.75

(1.65) 0.75

(1.65) 0.8

(1.77) 0.8

(1.77)

4. Dimensions

4-1 Motor dimensions

Unit : mm

Lead cable length : 1M (3.28ft)

8

No. PM∮S∮N∮TLA LB L1 L2 AD AB1 B2 Output Shaft End

ED QED∮GA F

1

90 104 8.5 83 2.5 8

99.5 127.5 160.5

109.8 28.5 61 33

20 25 28 12 13.5 4

2114.5 146.5 179.5

25 29 32

3

14 16 54 169.5 201.5 234.5

5184.5 216.5 249.5

□

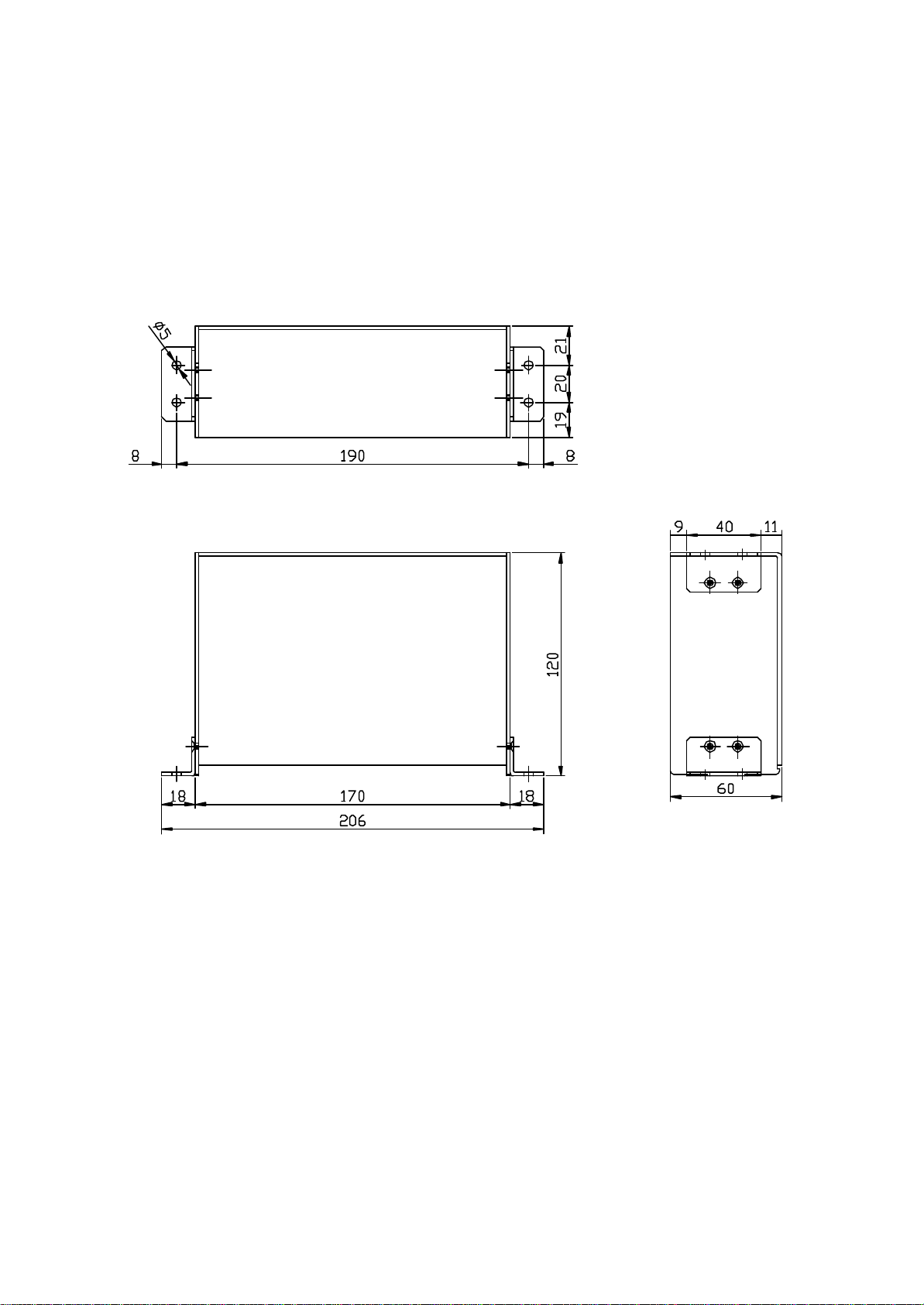

4-2 Drive dimensions

Unit : mm

9

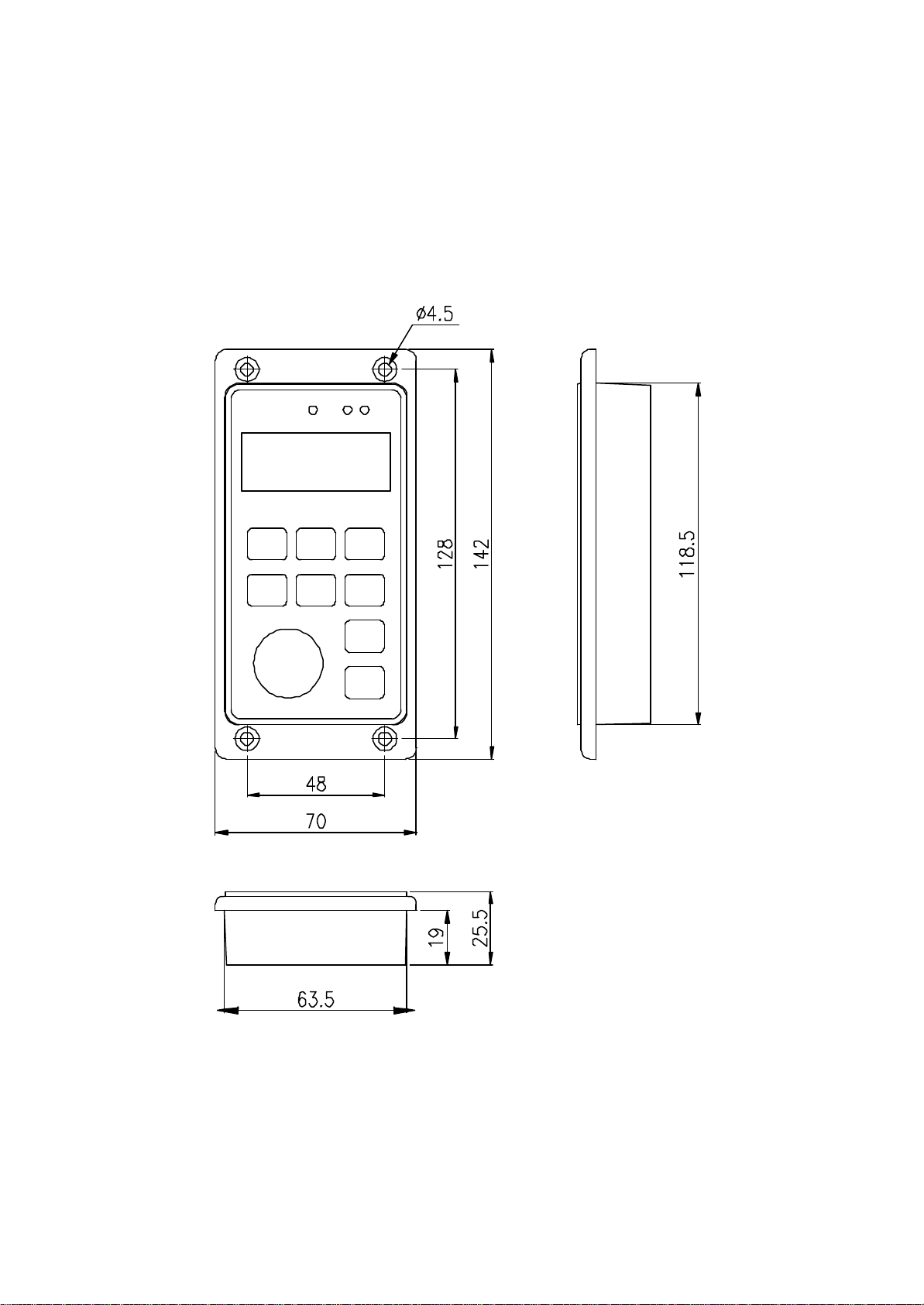

4-3 F306 dimensions

Unit : mm

10

5. Environmental requests

Operation

Storage

Transportation

Note :

a. Bad installation can reduce product service life.

b. Do not put motors and drives into worse environment. Such as

high temperature/humidity/vibration, corrosiveness gas, burst.

c. Keep enough cooling space for motors and drives.

Air temperature -20~60 (-4~140 )℃ ℉

Air pressure 86~106kPa

Humidity Less than 90%, no frosting

Air temperature -20~60 (-4~140 )℃ ℉

Air pressure 86~106kPa

Humidity Less than 90%, no frosting

Vibration Less than 20HZ : maximum 9.86m/s2

20~50HZ : maximum 5.88m/s2

11

Air temperature -10~45 (14~113 )℃ ℉

Air pressure 86~106kPa

Attitude Under 1000 meters

Vibration Less than 20HZ : maximum 9.86m/s2

20~50HZ : maximum 5.88m/s2

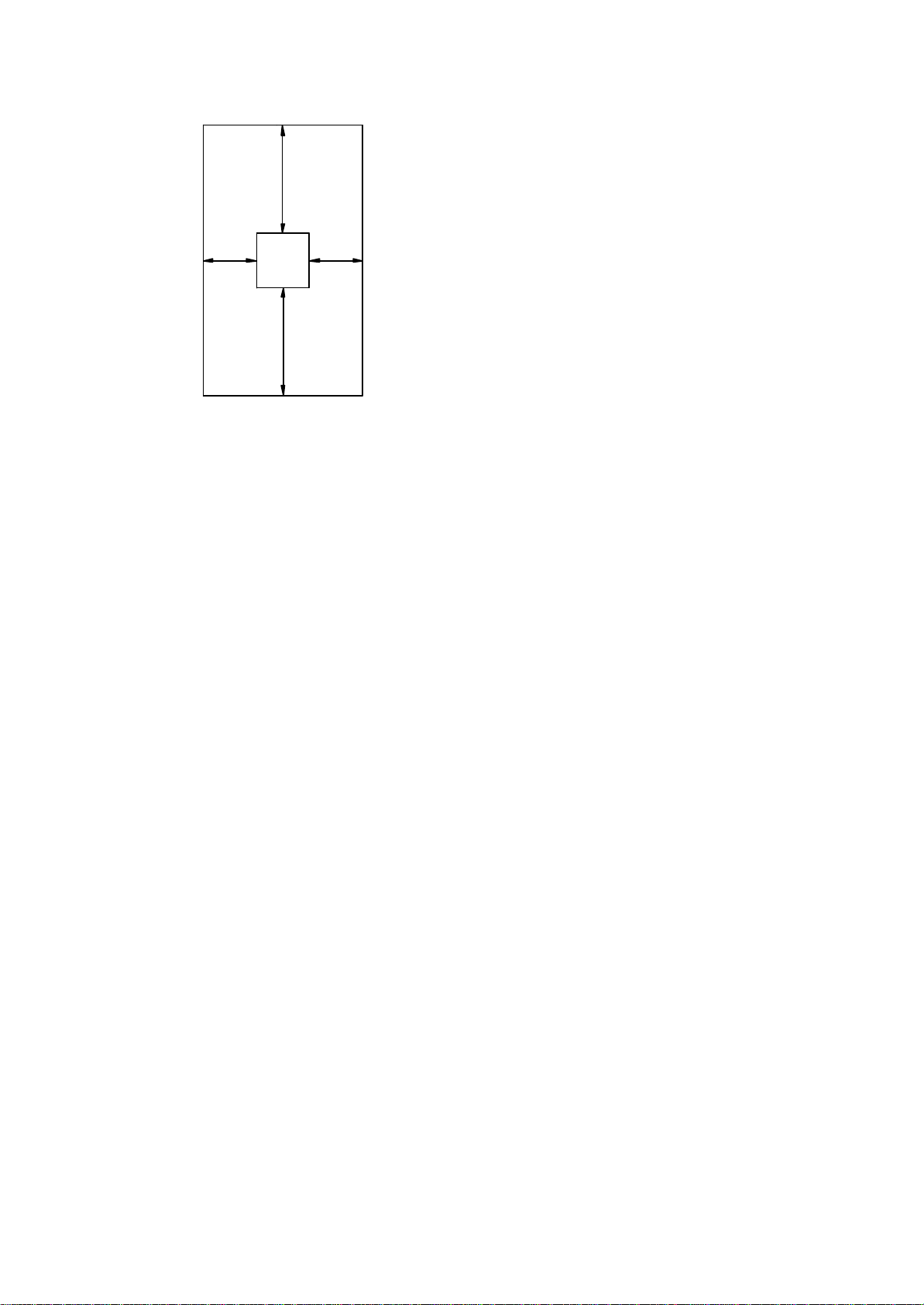

10cm 10cm

Motors

Drives

5cm 5cm

12

6. Function Description

6-1 Digital operation panel

FUNC

STOP

F306 FWD

CHARGE

REV

REMOTE CONTROL

FUNC

STOP

13

Keypad Function Description

Forward

run Commands forward run

Reverse

run Commands reverse run

Cursor

movement Select the digit

Down Decrease the parameter value 9~0

Up Increase the parameter value 0~9

Memory

storage Saves the setting parameter value

Function Press once to select function code and

press again to change its content

Stop Stop operation / Escape to standby mode

6-2 Terminals

14

BRUSHLESS IPM MOTOR

DRIVES

ADLEEPOWER R

Ground

Power input

Case ground

Power LED

Direction LED

Motor

Speed/error display

Fault LED

Internal speed setting

Magnet brake power

7

10

9

8

6

5

3

4

1

2

11

12

Relays, etc.

When using switches.

INT.

(Default value)

When using PLC etc.

EXT.

Command selection(Terminal, F306, RS485)

Communication port

Twist line

11 L

7 ALARM OUT

6 SPEED OUT

3

9 H

10 M 1

2

1 INPUT COM

5 SLOW DOWN

3 CW

4 CCW

2 CF

3

21

Slow down input

+24V external power input

12 GND Shielding line Speed knob (options)

C.C.W. input

C.W. input

Speed selector

ON

OFF

ON

OFF

ON

OFF

ON

OFF

EXG

EXG

EXG

Alarm output

Speed output

EXG

EXG

6-3 Main circuit terminals

15

Wire Wire type Torque

Input(L1,L2, ) 14AWG~16AWG

(2.0mm2~1.3mm2)Standard copper only

(300V/80 )℃8Kg-cm

(6.95lb-in)

External control

signal terminals 24AWG

(0.2mm2)Standard copper only

(300V/80 )℃5Kg-cm

(4.34lb-in)

FG screw (M4) 14AWG~16AWG

(2.0mm2~1.3mm2)Standard copper only

(300V/80 )℃8Kg-cm

(6.95lb-in)

6-4 Terminal description

Input source power line added 20A line fuse (or equivalent) is

recommanded for safety. Do not try to modify the wire between

motors and drives. The extension cable is available from factory.

Do not connect the shielding wires to any other component.

Make sure all plugs are tight enough with socket. Otherwise, it

may damaged the motors and drives.

: Case ground.

L, N : 100~130VAC or 200~230VAC, 50/60HZ, power input.

Power : Green LED light on when AC power input.

CW, CCW : Motors operation direction.

RPM : Static display for motor real speed (motor running).

Flash display for motor setting speed (motor stop).

Error codes, check the trouble shooting.

In “open loop control mode”, the RPM display is showing

“Duty”, not motor speed. The unit is 0.1%. Ex. 1000 is

100.0%, 999 is 99.9%.

Motor : Wires connect to motors.

There are extension cable for option as below

1M(3.28ft), 3M(9.84ft), 5M(16.4ft), 9M(29.52ft).

Motor cable should be no more than 10M(32.8ft) in

length.

Ground terminal : Wires by AWG18 (0.75mm2).

F306/RS-485 : F306 or RS-485 communication port.

JP : Control mode

F306 : Jumper on F306.

RS485 : Jumper on RS485.

Terminal : Jumper on both F306 and RS485.

Note : It needs to reset driver to effect the new JP setting.

!

█

█

█

█

█

█

█

█

█

16

Speed :

1. Close loop control mode (Default)

Motor stops operation if speed command is lower than minimum

speed.

L series : 150~2000 RPM

M series : 150~3000 RPM

H series : 300~6000 RPM

HX1 series : 130~5000RPM

HX2 series : 300~9999RPM

Default value : 0RPM

2. Open loop control mode

Motor speed is controlled by PWM duty. The duty is set by

analog signal.(0~100%) Motor speed is changed with loading.

3. Open / close loop control mode is set at CD02.

Alarm : Fault LED.

Red LED lighted when protect function effected. Please

check the error on display refer to trouble shooting.

EXT-INT : EXT : Using external control power 24VDC ±10%.

INT : Using internal control power.

Magnet brake : Connect to motors external brake, 24VDC Max.

15W.

External signal terminals :

The following terminals can be connected to a switch, relay,

TTL or Transistor for control purpose.

1. 24V in :

24VDC external control power input when using the circuit

control. The EXT-INT switch is set on EXT.

The EXT-INT switch is set at INT when using relays or

switch control.

█

█

█

█

█

●

17

●

2. CF :

Analog command mode (CD19=0)

OFF : Panel VR

ON : Terminal control (HML)

Digital command mode (CD19=1)

Close loop control

OFF : CD28 speed setting

ON : CD29 speed setting

Open loop control

OFF : CD34 speed setting

ON : CD35 speed setting

(Note : F306 does not relate to CF setting.)

3. CW : Forward operation (ON), stop(OFF).

4. CCW : Reserve operation (ON), stop(OFF).

5. S.D. : Set “ON”when using S.D. function (Dec. time)

Set “OFF”for immediately stop (without Dec.time)

6.Speed : Output motor speed

L, M, HX1 series : 12 pulse / per turn

H, HX2 series : 6 pulse / per turn

7. Alarm out : Output fault signal.

Drives output fault signal when protect function

take effect such as over load, over voltage,

overheat and so on.

Motors stop by free run.

Check detail information at trouble shooting.

8. EXG : Common terminal for external signal 2~7.

9. H : 5VDC output.

10. M : Speed voltage signal input.

11. L : Common terminal for H, M terminal.

12. GND : Connect to the shielding line for external speed

command signal.

18

█

●

█

█

█

█

█

█

█

█

●

█

█

Model Slow down signal

Start by Acc. time & stop by Dec. time ON

Start by Acc. time & stop by CD03 content OFF

This manual suits for next models

16

Table of contents

Other Adleepower DC Drive manuals

Popular DC Drive manuals by other brands

Toshiba

Toshiba G3 Plus Pack Operation manual addendum

SEW-Eurodrive

SEW-Eurodrive MAXO-RG-BMS operating manual

ABB

ABB DCS880 series Hardware manual

ABB

ABB PSTX30 Service instruction

ABB

ABB ACS880-14 Hardware manual

Cerus Industrial

Cerus Industrial Titan GS Series Installation, operation & maintenance manual