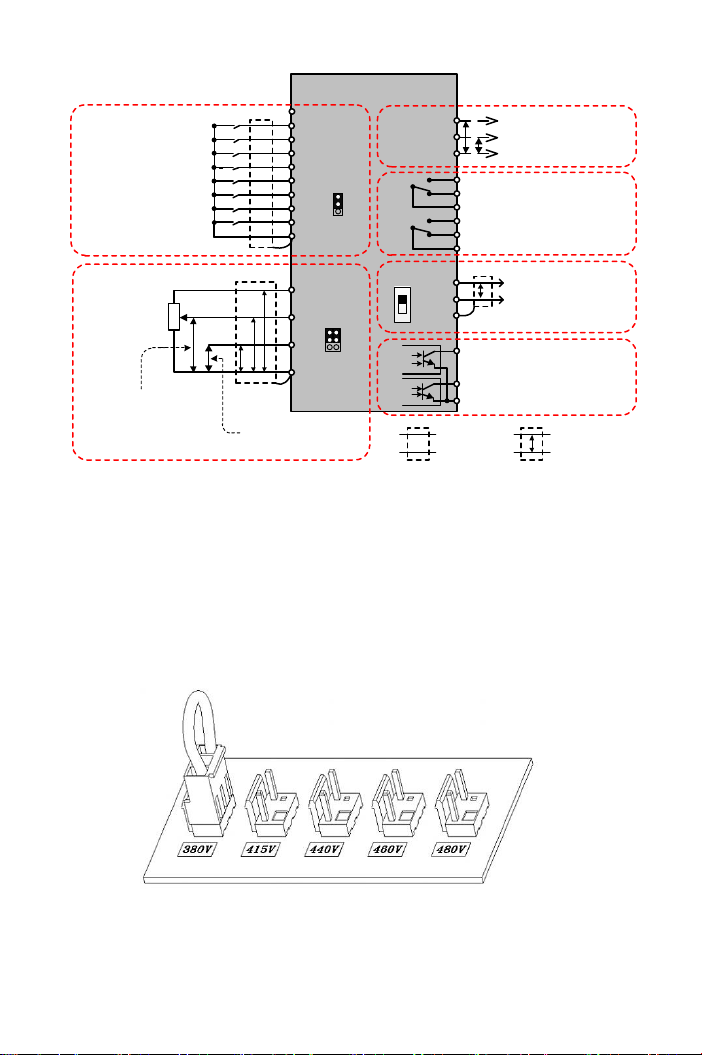

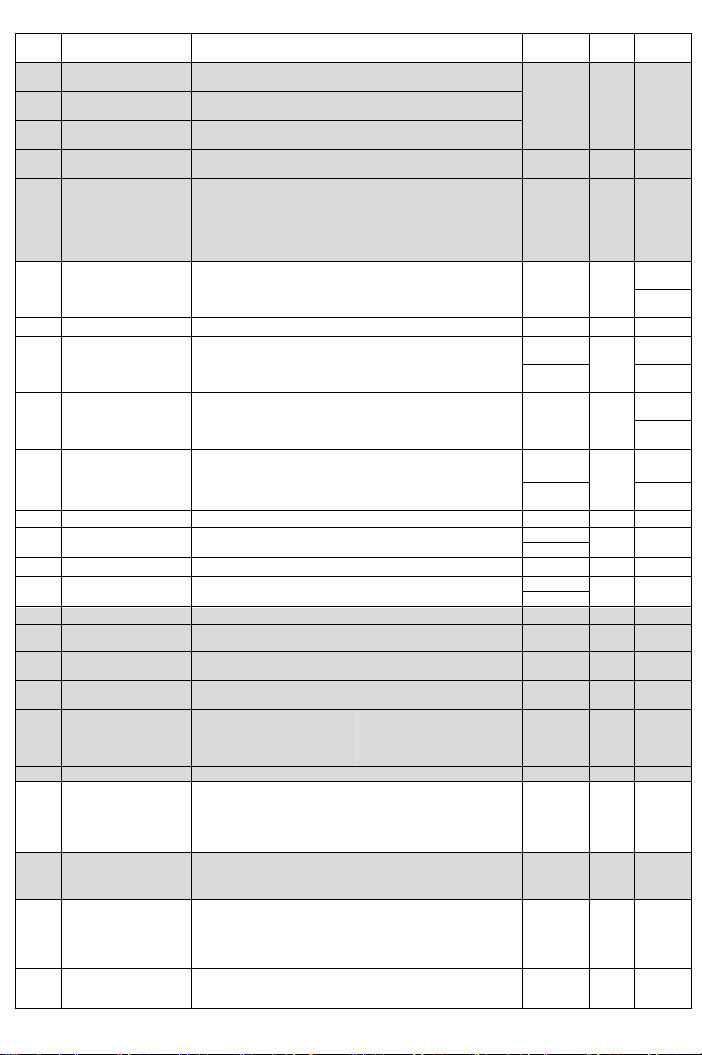

Power terminal;

Control device usage

Output DC+24V; Maximum supplied current is 50mA.

Output DC+12V; Maximum supplied current is 20mA.

Common of analog input

control terminals

Common terminal for control power (P12/12V,P24) and

analog input terminal (Vin, Iin).

Connect the FWD and COM terminals for forward

operation. (F_001=0,1,2)

Connect the REV and COM terminals for reverse operation.

(F_001=0,1,2)

Multi-function input

terminal 1

․The function is set by F_052.

․Default setting: Multi-speed level 1 command

Multi-function input

terminal 2

․The function is set by F_053.

․Default setting: Multi-speed level 2 command

Multi-function input

terminal 3

․The function is set by F_054.

․Default setting: Jog command

Multi-function input

terminal 4

․The function is set by F_055.

․Default setting: Secondary accel/decel time command

Multi-function input

terminal 5

․The function is set by F_056.

․Default setting: External fault command (thr)

Multi-function input

terminal 6

․The function is set by F_057.

․Default setting: Reset command

Common of digital input

control terminals

Common of digital input control signal terminals. (FWD,

REV and X1 ~ X6)

․Input signal selection

JP4: I position (current signal)

JP4: V position (voltage signal)

․Input range: DC 4~20mA (2~10V) or

DC 0~20mA (0~10V)

․The function is set by F_126.

․Voltage meter with 10V full scale spec.

(meter impedance: 10kΩ above)

․Maximum output current: 1mA

Common of

analog output terminals

Common of analog output terminals.

Multi-function

output terminals

(relay type)

․N.O (contact a); The function is set by F_060 .

․Default setting: Error detection

․Capacity: AC250V, 0.5A Max, cosθ=0.3

․N.C (contact b); The function is set by F_060

․Capacity: AC250V, 0.5A Max, cosθ=0.3

Common terminal for Ta1, Tb1.

․N.O (contact a); The function is set by F_131

․Default setting: Operation detection

․Capacity: AC250V, 0.5A Max, cosθ=0.3

․N.C (contact b); The function is set by F_131

․Capacity: AC250V, 0.5A Max, cosθ=0.3

Multi-function output

terminals

(open collector type)

․The function is set by F_058, F_059.

․Capacity: DC48V, 50mAMax

Common terminal of Y1, Y2.

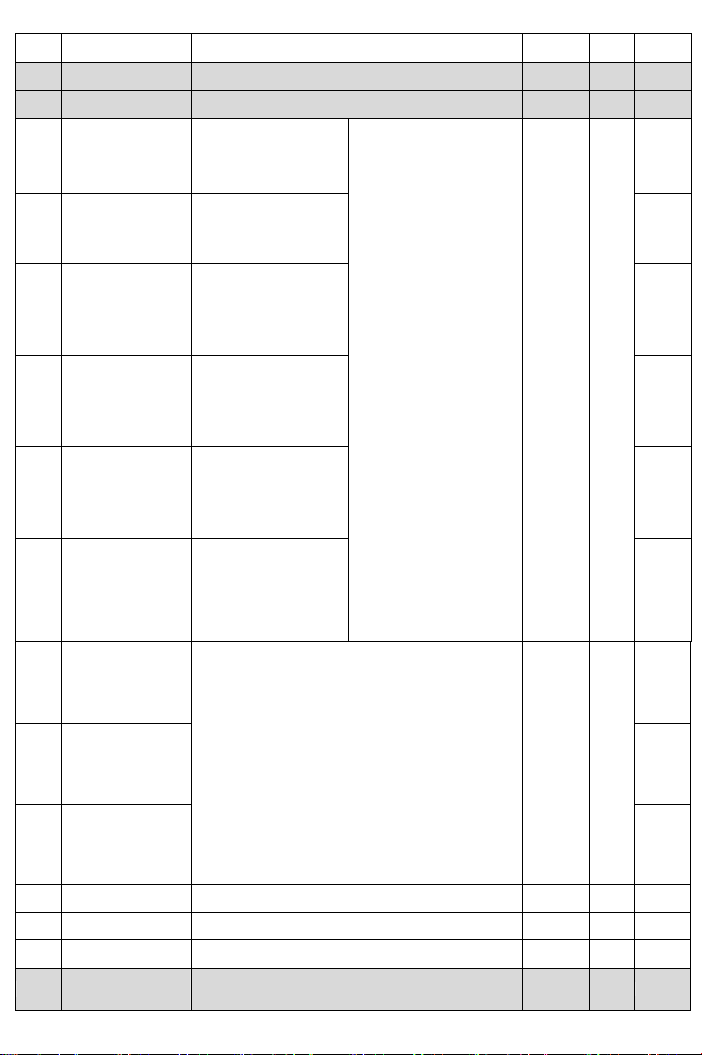

External

Communication

Terminal

Signal transmission

terminal(+)

․Connect the RM6 series drive by transmission cable,

when the drive is controlled by RS-485 communication

interface.

․Communication protocol: Modbus

Signal transmission

terminal(-)

Grounding terminal of

signal transmission

Grounding terminal of shielding wire.