Ados T020E Series Quick guide

ADOS S.r.l. - Via Lazio 25 - Buccinasco (Mi) 1316-MPT020M03 - Rev.1 T020E installation and instruction manual Pagina 1 di 8

Weight transmitter T020E

Version: T020E-V T020E-A T020E-S

Analog output 0-10V/4-20mA

Serial out RS232/RS485

Installation and instruction manual

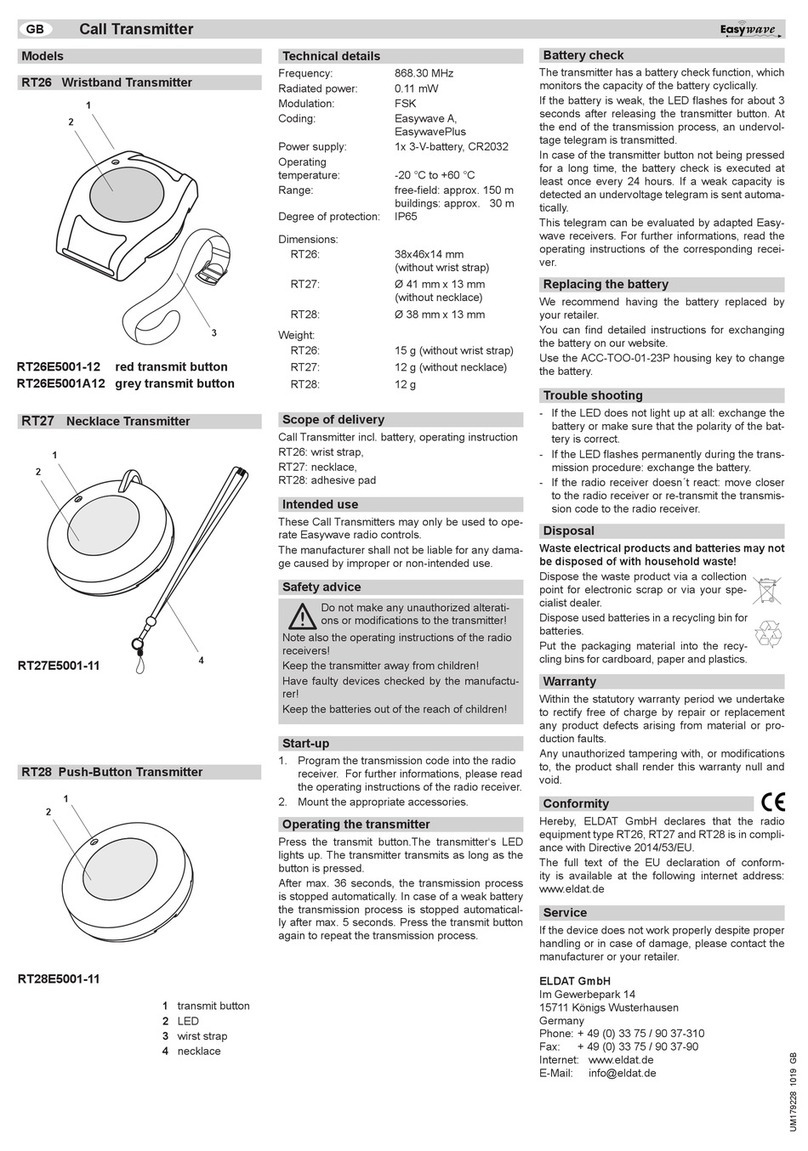

display

INC key (increases)

DEC key (decreases)

ENT key (confirms)

ESC key (cancels)

terminasl

With the present document

ADOS S.r.l., Via Lazio 25, 20090 Buccinasco (Mi)

Declares that this T020E fully complies to the essential

requirements

EN 61000-6-4 e EN 61000-6-2

Accordino to EC directive EMC 2004/108/CEE

Power supply 9-48 VDC / VAC

Accuracy 0.01% of the full scale

Linearity 0.01% of the full scale

Thermal Drift 0.005% / °C

Consumption max 250 mA a 12 VDC (3 VA)

Working temperature from –10 °C to +40 °C

Relative humidity

95% not condensated in the case

of version for DIN bars

not relevant to the versions in IP66

box

Load cells excitation 5 V with protection against short circuits

and with reference to internal voltage

Number of cells

connectable

(4 conductors) 4 350 cells

Analog signal from 0.5 to 2.5 mV/V

Conversion rate 55 conversions / second

Display Graduation 10000

Display increments 1-2-5-10-20

Display 5 LED digits

Digital otputs 2 relè 1 CO (SPDT)

3A at 250 VAC or 3A at 30 VDC

Digital input Optoisolated 24VDC

Serial output RS232 or RS485 (selectable)

Analog output 0-10V or 4-20 mA (selectable)

Dimensions

mm 95 x 85 x 65

(version for DIN bars)

mm 110 x 110 x 70

(version in IP66 box)

1. START UP OF THE INSTRUMENT

For a correct start up of the instrument it is necessary to carry out

the following operations:

- set up or check the electrical connections (see paragraph 2)

- set the weighing rate (see paragraphs 3 and 4)

- calibrate the weights (see paragraph 5)

2. ELECTRICAL CONNECTIONS

The instrument must be connected according to the indications in

the following table:

+E + EXCITATION (RED)

-E - EXCITATION (BLACK)

+S + SIGNAL (GREEN)

Load cell wiring

-S - SIGNAL (WHITE)

RS232 RS485 0-10 4-20

A TX A-485 0-10 V 4-20mA

B RX B-485

Output SGND

Common Common

+I +12/24VDC

Tare input -I 0VDC

~9-48 VDC / VAC

Power supply ~9-48 VDC / VAC

C COMMON relè 1

NC N.C. relè 1

NO N.O. relè 1

C COMMON relè 2

NC N.C. relè 2

Relè outputs

NO N.O. relè 2

In the case where the apparatus uses more than one load cell, the

cells must be wired to a specific junction box (ADOS model 1308),

and the output must be connected to the terminals of T020E.

The use of shielded cable for the wiring of the load cells, the

analog output signal lines and the serial lines is highly

recommended.

ADOS S.r.l. - Via Lazio 25 - Buccinasco (Mi) 1316-MPT020M03 - Rev.1 T020E installation and instruction manual Pagina 2 di 8

The load cell colour code in the above tabel is that used on

standard ADOS cells. Check carefully that the conductors function

correctly in the case where special ADOS cells or other brands of

cells are used. ATTENTION

-the incorrect connection of the wires or the inversion of poles

on the power supply may damage the apparatus

-the connection wires must not be connected to dangerous

power supplies

3.SETTING OF WEIGHING SCALE

The numeric value of the weight on the display consists of the

multiplication of two parameters: DIVIS AND SENSI, with the

possibility to set the number of DECIMALS required.

The number of divisions represents the number of steps that the

weighing rate is divided into; the more divisions set the easier it will

be possible to recognise small variations in weight.

The accuracy value represents the value associated with each

step of the weighing rate, and it should be chosen in order to reach

the required weighing rate.

The decimal values are needed to set the position of the point on

the weight display, in order to read the weight value in the correct

measure unit.

EXAMPLE: in order to obtain a weigh rate from 0 to 20000 units, it

is necessary to set a value of 10000 divisions with an accuracy of

2 units per division (10000 x 2 = 20000). In this way the weight will

be visualised in increments of 2. Another solution, though less

efficient, is that of setting a value of 2000 divisions with an

accuracy of 10 units per division: this however means that the

recognisable minimal variation in weight would be inferior.

In the case where the full scale weight is 20000 kg, if the decimals

are set at 0.0, the value displayed would go from 0.0 to 2000.0 with

increments of 0.2 kg.

DIVISIS SENSI’ DECIM

1000 1 0

2000 2 0.0

3000 5 0.00

4000 10 0.000

5000 20 0.0000

10000 50

The values available are:

N.B.: if it is not possible to obtain the desired weighing rate with the

combination of values available relating to divisions and accuracy,

the value should be rounded up: for example, in the case of a

weighing rate from 0 to 7000 the nearest obtainable would be 8000

4. CONFIGURATION OF PARAMETERS

to access configuration press ENT

press ENT again to access the configuration parameters

or press ESC to cancel

the name of the first parameter available will appear on

the display (for example the number of divisions)

use the INC and DEC keys to proceed to the next or

previous parameter

once the required parameter has been identified,

modifications can be made by pressing ENT

the parameter value will appear on the display and the

name of the parameter will flash intermittently.

use the INC and DEC keys to change the parameter

values (press the key for more than 3 seconds to

activate the automatic repetition option)

press ENT to confirm the set value or press ESC to

cancel

The configuration parameters available are as follows::

DIVIS number of divisions

(1000 - 2000 - 3000 – 4000 – 5000 - 10000)

SENSI accuracy values

(1 - 2 - 5 - 10 - 20 - 50)

DECIM number of decimals on the display

(0 - 0.0 - 0.00 - 0.000 - 0.0000)

MEDIE Number of data used for the dynamic average

(OFF - 2 - 4 - 8 - 16 – 32 - 64)

FUNR1 Relay number 1 functions

(ON - FAIL – POS G – NEG G – POS N – NEG N )

SETR1 Setpoint value of relay number 1

(from 0 to the full scale value)

FUNR2 Relay number 2 functions

(ON - FAIL – POS G – NEG G – POS N – NEG N )

SETR2 Setpoint value of relay number 2

(from 0 to the full scale value)

SERIA Setting of the serial port

(OFF - CONT - BIDIR)

LINE Selection of serial line type

(RS232 – RS485)

BAUD baudrate of the serial port

(1200 - 2400 - 4800 - 9600 - 19200)

ID485 Address for RS-485

(da 0 a 32)

The meaning of the DIVIS, SENSI, and DECIM

parameters is explained in paragraph 3.

MEDIE

This parameter is used for the digital filtering of the weight signal,

in order to reduce to a minimum the undesired effects due to for

example mechanical vibrations which affect the weighing system.

The higher the parameter value, the higher the capacity to filter the

undesired fluctuation, even if this causes an increase in the delay

of visualising the variations in the weight signal.

Pressing the OFF key excludes the filter option.

FUNR1 – FUNR2

ON: the relay is continuously excited; this option may be used to

check that the instrument is being powered

(excitation of the relay only stops due to the lack of power)

FAIL: excitation of the relay is interrupted when there is an

electrical fault in the +/- signal wires of the load cells.

NEG G: the relay is deenergized only if the weight value is lower or

equal to the preset value (see SETR1 and SETR2 parameters)

The set reacts independently from the zeroed value (by tare input).

POS G: the relay is deenergized only if the weight value is higher

or equal to the preset value (see SETR1 and SETR2 parameters).

The set reacts independently from the zeroed value (by tare input).

NEG N: the relay is deenergized only if the weight value is lower

or equal to the preset value (see SETR1 and SETR2 parameters)

POS N: the relay is deenergized only if the weight value is higher

or equal to the preset value (see SETR1 and SETR2 parameters).

SETR1– SETR2

This value represents the threshold used for the POS and NEG

options of the relay. The preset value ranges from zero to the full

scale.

X :

ADOS S.r.l. - Via Lazio 25 - Buccinasco (Mi) 1316-MPT020M03 - Rev.1 T020E installation and instruction manual Pagina 3 di 8

SERIA

This parameter is used to set the serial port modes.

OFF: the serial port is not used

CONT: continuous serial transmission is enabled by the ASCII

ADOS protocol string

BIDIR: transmission is enabled by serial request of the ASCII

ADOS protocol string

LINE

This parameter is used to set the physical interface mode: RS485

or RS232.

ID485

This parameter is used to set the address required for the

identification of the instrument on a multipoint line RS-485.

BAUD

This parameter is used to set the communication speed on the

serial line.

The transmission parameters of the line are:

8 data bit i – NO parity – 1stop bit

5. CALIBRATION OF WEIGHTS

After setting the desired weight range it is necessary to carry out

the two apparatus calibration phases:

zero calibration (see paragraph 5.1)

full scale calibration (see paragraph 5.2)

5.1 Zero Calibration

check that there is no weight loaded on the weighing

system (zero kg)

press ENT and then INC until the following word appears

on the display

to continue with the calibration press ENT, to cancel

press ESC

press the INC key or the DEC key until the display shows

the following word

to carry out the zero calibration press ENT (and wait), to

cancel press ESC

if this word appears

it means that the zero calibration has been successful; if

this word appears

it means that the calibration was not successful

(for example due to an error in installation or connection

of the load cells)

ATTENTION

Only if the zero calibration has been successfully terminated is it

possible to continue with the full scale calibration

5.2 Full scale calibration

load the weighing system with a sample weight of which

the exact weight is known, the same or as close as

possible to the preset full scale value

press ENT and then INC until the following word appears

to procede with the calibration option press ENT, to

cancel press ESC

press INC or DEC until the following word appears

to carry out the full scale calibration option press ENT, to

cancel press ESC

at this point a casual absolute value is visualised (1234

in the example), which must be replaced with the value

of the sample weight which was loaded onto the

weighing system.

using the INC and DEC keys change the value until it

corresponds to the value of the sample weight

to procede with the full scale calibration press ENT, to

cancel the operation press ESC

if this word appears

it means that the full scale calibration has been

successful; if this appears

it means that the calibration was not successful

(for example due to an error in installation or connection

of the load cells)

ATTENTION

The weighing system may only be used if both calibration options

have been concluded successfully

CHECK THE PROBLEM AND

REPEAT THE CALIBRATION

CHECK THE PROBLEM AND

REPEAT THE CALIBRATION

ADOS S.r.l. - Via Lazio 25 - Buccinasco (Mi) 1316-MPT020M03 - Rev.1 T020E installation and instruction manual Pagina 4 di 8

6. SYSTEM INITIALIZATION

This option resets the default factory settings and the calibration

values .

press the ENT key and then the INC key until the

following word appears on the display

to proceed with the initiating of the instrument press

ENT, to cancel press ESC

confirm the operation by pressing ENT again, or cancel

by pressing ESC

at this point the instrument has been initialised and the

display shows a blinking value.

After system initialization the display blinks as indicate

the not calibration status.

7. TEST

press the ENT key and then the INC key until the

following word appears on the display

to proceed with the instrument test option ENT, to cancel

press ESC

to start the test procedure press ENT, to cancel press

ESC

at this point the instrument will activate relays number 1

and 2 alternately, whilst on the analog output a “saw

tooth” ramp ranging from the minimum value to the

maximum value

to exit the test option press ESC

8. SERIAL OUTPUT (HW selection)

The serial line is available in both the RS232 and RS485 mode.

Serial board insertion mode

RS485

ADOS S.r.l. - Via Lazio 25 - Buccinasco (Mi) 1316-MPT020M03 - Rev.1 T020E installation and instruction manual Pagina 5 di 8

RS232

8.1 SERIAL PROTOCOL ASCII ADOS

The T020E instrument handles the serial communications in two

different ways:

BIDIRECTIONAL SLAVE

The instrument sends the ASCII data string only after

receiving the request from a device connected on the line

acting as the master

The master may interrogate individually the various slaves

connected to the line each identified by a different ID 485

(only RS-485), or a single slave on the line (both RS-232 and

RS-485).

CONTINUOUS TRANSMISSION

The instrument continuously transmits the ACII data string

without request to a single instrument (RS-232) or to one or

more instruments (RS-485).

8.2 Weight Request String Format

The ASCII string for the weight request differs in length according

to the ID485 parameter values as seen in the following cases:

ID485 = 0 (5 characters in length)

1° character [STX] (Hex 02) fixed

2° character [WEIGHT] <P> (Hex 50) fixed

3° character [CHK 1] from <0> (Hex 30) to <9> (Hex 39)

or from <A> (Hex 41) to <F> (Hex

46) to indicate the higher part of the

checksum (see paragraph 6.3)

4° character [CHK 2] from <0> (Hex 30) to <9> (Hex 39)

or from <A> (Hex 41) to <F> (Hex

46) to indicate the lower part

5° character <CR> (Hex 0D) fixed

ID485 > 0 (7 characters in length)

1° character [STX] (Hex 02) fixed

2° character [ID485 D] from <0> (Hex 30) to <9> (Hex 39)

to indicate the tens of the set ID485

value

3° character [ID485 U] from <0> (Hex 30) to <9> (Hex 39)

to indicate the units of the set ID485

value

4° character [WEIGHT] <P> (Hex 50) fixed

5° character [CHK 1] from <0> (Hex 30) to <9> (Hex 39)

or from <A> (Hex 41) to <F> (Hex

46) to indicate the higher part of the

checksum (see paragraph 6.3)

6° character [CHK 2] from <0> (Hex 30) to <9> (Hex 39)

or from <A> (Hex 41) to <F> (Hex

46) to indicate the lower part

7° character <CR> (Hex 0D) fixed

8.3 Format of the string transmitted by T020E

The ACII string transmitted by the instrument is the same for both

bidirectional and continuous transmission.

The length of the sting differs according to the ID485 parameter

value, as seen in the following cases:

ID485 = 0 (16 characters in length)

1° character <STX> (Hex 02) fixed

2° character [SIGNAL] <SPACE> (Hex 20) if the weight

value is positive

<-> (Hex 2D) if the weight value is

negative

3° character [WEIGHT 1] from <0> (Hex 30) to <9> (Hex 39)

to indicate the numeric weight value

with an eventual decimal point

<.> (Hex 2E) or

<SPACE> (Hex 20) to cancel the

insignificant zeros in front of the

number

4° character [WEIGHT 2] as above

5° character [WEIGHT 3] as above

6° character [WEIGHT 4] as above

7° character [WEIGHT 5] as above

8° character [WEIGHT 6] as above

9° character [WEIGHT 7] as above

10° character <SPACE> (Hex 20) fixed

11° character <SPACE> (Hex 20) fixed

12° character [STATUS] <SPACE> (Hex 20) if the instrument

is in a normal operative status

<F> (Hex 43) if the instrument is in

FAIL status

<S> (Hex 53) if the instrument is in

configuration phase

13° character [CHK 1] from <0> (Hex 30) to <9> (Hex 39)

or from <A> (Hex 41) to <F> (Hex

46) to indicate the higher part of the

checksum (for the calculation of the

checksum see paragraph 6.3)

14° character [CHK 2] from <0> (Hex 30) to <9> (Hex 39)

or from <A> (Hex 41) to <F> (Hex

46) to indicate the lower part of the

checksum

15° character <CR> (Hex 0D) fixed

16° character <LF> (Hex 0A) fixed

ADOS S.r.l. - Via Lazio 25 - Buccinasco (Mi) 1316-MPT020M03 - Rev.1 T020E installation and instruction manual Pagina 6 di 8

ID485 > 0 (18 characters in length)

1° character [STX] (Hex 02) fixed

2° character [ID485 D] from <0> (Hex 30) to <9> (Hex 39)

to indicate the tens of the set ID485

value

3° character [ID485 U] from <0> (Hex 30) to <9> (Hex 39)

to indicate the units of the set ID485

value

4° character [SIGNAL] <SPACE> (Hex 20) if the weight

value is positive

<-> (Hex 2D) if the weight value is

negative

5° character [WEIGHT 1] from <0> (Hex 30) to <9> (Hex 39)

to indicate the numeric weight value

with an eventual decimal point

<.> (Hex 2E) or

<SPACE> (Hex 20) to cancel the

insignificant zeros in front of the

number

6° character [WEIGHT 2] as above

7° character [WEIGHT 3] as above

8° character [WEIGHT 4] as above

9° character [WEIGHT 5] as above

10° character [WEIGHT 6] as above

11° character [WEIGHT 7] as above

12° character <SPACE> (Hex 20) fixed

13° character <SPACE> (Hex 20) fixed

14° character [STATUS] <SPACE> (Hex 20) if the instrument

is in a normal operative status

<F> (Hex 43) if the instrument is in

FAIL status

<S> (Hex 53) if the instrument is in

configuration phase

15° character [CHK 1] from <0> (Hex 30) to <9> (Hex 39)

or from <A> (Hex 41) to <F> (Hex

46) to indicate the higher area of the

checksum (for the calculation of the

checksum see paragraph 6.3)

16° character [CHK 2] from <0> (Hex 30) to <9> (Hex 39)

or from <A> (Hex 41) to <F> (Hex

46) to indicate the lower area of the

checksum

17° character <CR> (Hex 0D) fixed

18° character <LF> (Hex 0A) fixed

8.4 Calculation of the checksum

The two ASCII characters which identify the checksum must be

calculated in the following way:

1. Calcolate the XOPR binary of all the characters from the

1° to the 12° included in the case of strings of 16

characters (ID485 = 0) or to the 14° included in the case

of strings of 18 characters (ID485 > 0).

2. Separate the XOR values obtained into a high area (first

4 bit) and a low area (last 4 bit)

3. Code the high area according to the ASCII hex table,

which will become the character written in position [CHK

1] (13° character in the case of a string of 16 characters,

15° in the case of a string of 18 characters).

For example the binary value 5 (0101) will become

character <5> (Hex 35), or the binary value B (1011) will

become character capital <B> (Hex 42).

4. Code the lower area according to the ASCII hex table,

which will become the character written in position [CHK

2] (14° character in the case of a string of 16 characters,

16° in the case of a string of 18 characters).

(see previous example)

9. ANALOG OUTPUT (HW selection)

The analog output is available in both the 0-10Vand 4-20 mA

mode.

Analog board insertion mode

0-1 0V

ADOS S.r.l. - Via Lazio 25 - Buccinasco (Mi) 1316-MPT020M03 - Rev.1 T020E installation and instruction manual Pagina 7 di 8

4-20 mA

9.1 Analog output compensation

The analog output compensation options are identical for output at

0-10 V voltage and at 4-20 mA current.

The compensation of the analog output foresees 3 phases:

1. setting of the analog range (see paragraph 9.2)

2. zero compensation (see paragraph 9.3)

3. full scale compensation (see paragraph 9.4)

The first phase defines the weight value which shall correspond to

the maximum value of the analog output.

For example the full scale weight could be 5000, but the maximum

value of the analog output (10 V and 20 mA) may be set at 3000.

In this way for weight values from 0 to 3000 the analog output will

move from 0 to 10 V (or from 4 to 20 mA); for higher values the

output will remain set at maximum. In the same way, for negative

weight values the analog output will remain set at minimum.

The second phase is used to adjust the analog output so that that

the zero (minimum possible value) is exactly at 0 V or 4 mA.

The third phase is used to adjust the analog output so that the

span (maximum possible value) is exactly at 10 V or 20 mA.

9.2 Setting of the analog range

press ENT and then press INC until the following word

appears

to proceed with the setting of the analog range option

press ENT, to cancel press ESC

press INC or press DEC until the following writing

appears

to proceed with the setting of the analog range option

press ENT, to cancel press ESC

at this point the full scale weight value is visualised (5000

in the example), which must be replaced with the setting

of the weight value which corresponds to the maximum

analog output.

using the INC and DEC keys change the values until the

desired values are visualised

to confirm the visualised value press ENT, to cancel

press ESC

9.3 Zero analog compensation

press the ENT key and then the INC key until the

following word appears on the display

to proceed with the zero compensation of the analog

output press ENT, to cancel press ESC

press the INC key or the DEC key until the display shows

the following word

to proceed with the zero compensation of the analog

output press ENT, to cancel press ESC

at this point a numeric value is visualised, proportional to

the voltage or current output value read on the tester

use the INC and DEC keys to change the value until the

tester displays exactly 0 V or 4 mA

to confirm the displayed value press ENT, to cancel

press ESC

9.4 Full scale analog compensation

press the ENT key and then the INC key until the

following word appears on the display

to proceed with the full scale compensation of the analog

output press ENT, to cancel press ESC

press the INC key or the DEC key until the display shows

the following word

to proceed with the full scale compensation of the analog

output press ENT, to cancel press ESC

at this point a numeric value is visualised, proportional to

the voltage or current output value read on the tester

use the INC and DEC keys to change the value until the

tester displays exactly 10 V or 20 mA

to confirm the displayed value press ENT, to cancel

press ESC

To proceed it is necessary to connect a tester to the

analog output terminals of the instrument, making sure

they are connected correctly.

Preset the tester to measure the voltage and current

according to the type of T020E output

To proceed it is necessary to connect a tester to the

analog output terminals of the instrument, making sure

they are connected correctly.

Preset the tester to measure the voltage and current

according to the type of T020E output

ADOS S.r.l. - Via Lazio 25 - Buccinasco (Mi) 1316-MPT020M03 - Rev.1 T020E installation and instruction manual Pagina 8 di 8

10. INGRESSO DI AZZERAMENTO

The T020E is equipped with tare input.

The function is activated when the input goes from open to close

position. To allow the function use a voltage from 12 to 24 VDC to

close the input.

The tare function has effect on the serial output and on the relay

thresholds (except for POS G - NEG G setting).

The value of total zeroed load can be checked locally on

the transmitter by pressing the key INC: while the key is pressed

the zeroed load value is showed on display.

The zeroed value will lose in case of power off.

IMPORTANT

Keep this instruction manual for

consultation by all personnel authorised

to operate the instrument for as long as

the instrument remains in service.

Additional copies may be ordered from

ADOS service centres.

If additional technical information or

clarification is required, contact an ADOS

service centre.

Revisions = Text underlined & corsive

This manual suits for next models

3

Other Ados Transmitter manuals

Popular Transmitter manuals by other brands

schildknecht

schildknecht DATAEAGLE 3713 Installation and commissioning manual

Audiovox

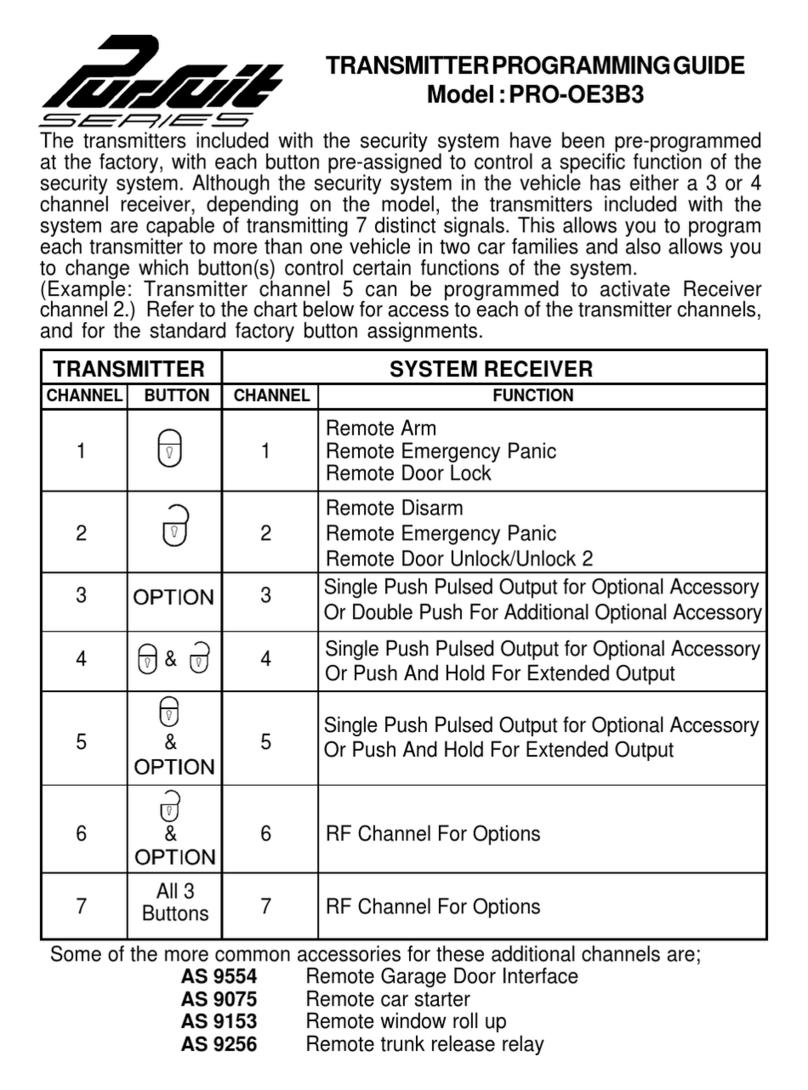

Audiovox PRO-OE3B370 Programming guide

Atal

Atal TR485-103D-150 instruction manual

Endress+Hauser

Endress+Hauser HART iTEMP TMT182B operating instructions

KROHNE

KROHNE OPTIFLEX 1300 C Supplementary instructions

Altinex

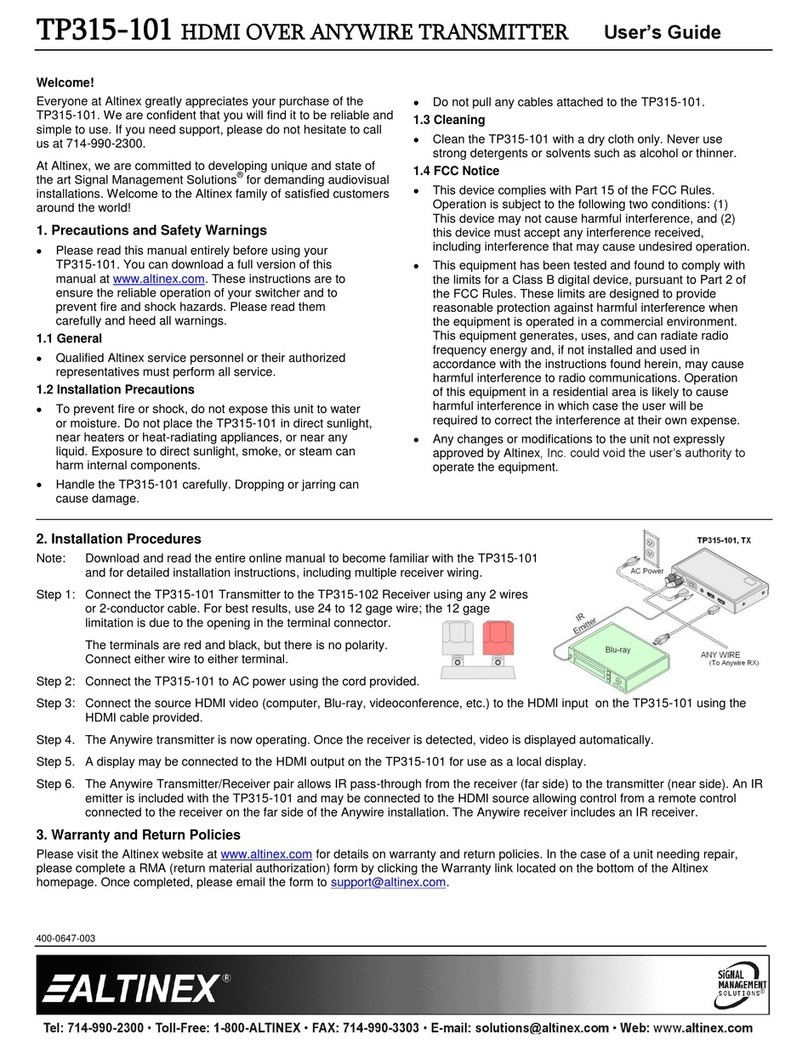

Altinex TP315-106 user guide

MuxLab

MuxLab 500777-TX Quick installation guide

Siemens

Siemens SITRANS L Series operating instructions

Easy wave

Easy wave RT26 quick start guide

Cadi

Cadi SmartSense SmartTAG STG-821W user manual

Keller-druck

Keller-druck 41 X Ei Series manual

National Semiconductor

National Semiconductor VAB100T user manual