Ados T060E Operating manual

1569‐PT060EE1Rev.7Page1of62

ELECTRONIC WEIGHING TRANSMITTER

T060E

User and installation manual

1569‐PT060EE1Rev.7Page2of62

Tableofcontents

1.INTRODUCTION........................................................................................................................................ 4

1.1Overview...........................................................................................................................................................4

1.2Description........................................................................................................................................................4

1.2.1Options/ Versions .........................................................................................................................................4

1.3Use ....................................................................................................................................................................5

1.4Description of labels .........................................................................................................................................5

1.5Operating specifications....................................................................................................................................6

2.INSTRUMENT’S OPERATION .................................................................................................................. 7

2.1Turning on the instrument.................................................................................................................................7

2.2Transmitter’s functions .....................................................................................................................................8

2.2.1Management of the calibration .....................................................................................................................8

2.2.2Sum value function.......................................................................................................................................9

2.2.3Management of the zero................................................................................................................................9

2.2.4Signal filtering ............................................................................................................................................10

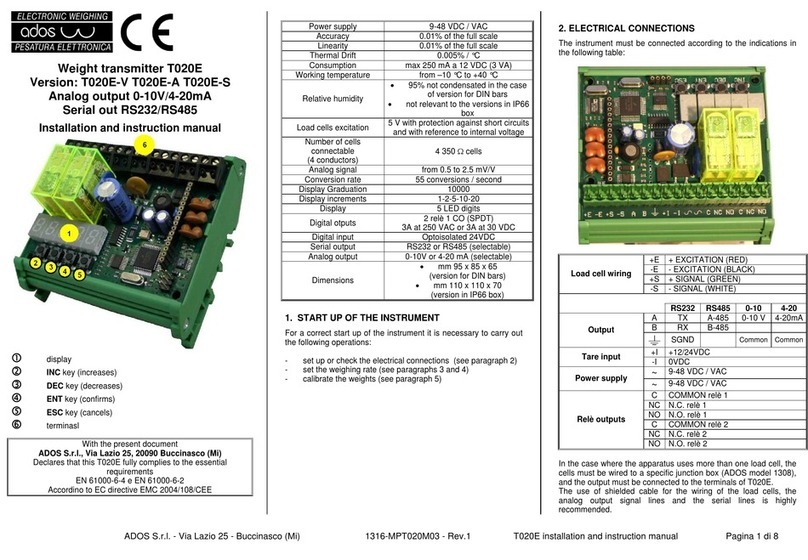

2.3Front panel ......................................................................................................................................................11

2.3.1Display........................................................................................................................................................11

2.3.2LED signals ................................................................................................................................................12

2.3.3Key functions..............................................................................................................................................12

2.4Self-troubleshooting........................................................................................................................................12

2.4.1Cell connection fault (FAIL) ......................................................................................................................12

2.5Management of relays.....................................................................................................................................13

3.INSTALLATION........................................................................................................................................ 14

3.1Receiving the material.....................................................................................................................................14

3.2Assembling the instrument..............................................................................................................................14

3.3Connections.....................................................................................................................................................15

3.4Rear panel .......................................................................................................................................................15

3.5Power supply tag.............................................................................................................................................15

3.6Connection to power supply (side B)..............................................................................................................16

3.6.1Version 110÷230V~ 24-48V~ ....................................................................................................................16

3.6.2Version 12÷24V ................................................................................................................................16

3.7Connection of load cells (side A)....................................................................................................................17

3.7.1Connection of load cells 1...........................................................................................................................17

3.7.2Connection of load cells 2 input .................................................................................................................19

3.7.3Wiring example (single weighing system)..................................................................................................20

3.7.4Wiring example (double weighing system) ................................................................................................21

3.8Connection of serial lines (side A)..................................................................................................................22

3.9Digital inputs (side B).....................................................................................................................................23

3.10Connection of relay outputs (side B)...............................................................................................................24

3.11Optional analogue output................................................................................................................................25

3.12PROFIBUS DP output (optional)....................................................................................................................26

4.MAINTENANCE ON THE INSTRUMENT................................................................................................ 27

4.1Preventive maintenance...................................................................................................................................27

4.2Corrective maintenance...................................................................................................................................27

5.MANAGEMENT OF THE INSTRUMENT................................................................................................. 28

5.1Introduction.....................................................................................................................................................28

5.2Operational sequence ......................................................................................................................................28

5.3Selection of the management functions...........................................................................................................28

5.3.1Time-Out function on the keys’ operation..................................................................................................28

5.4Configuration of operational parameters.........................................................................................................29

5.4.1Selection of operational parameters............................................................................................................29

5.4.2Editing of the value of operational parameters...........................................................................................30

5.4.3Setting the load cells’ signal.......................................................................................................................31

5.4.4Setting the weighing system capacity.........................................................................................................31

5.4.5Setting the system resolution......................................................................................................................31

5.4.6Average settings..........................................................................................................................................31

5.4.7Reference channe selection (only with instrument with double channel)...................................................32

5.4.8Scale factor selection ((only with instrument with double channel)...........................................................32

5.4.9Relay 1 function..........................................................................................................................................32

5.4.10Threshold value of relay 1......................................................................................................................33

5.4.11Hysteresis value of relay 1......................................................................................................................33

1569‐PT060EE1Rev.7Page3of62

5.4.12Minimum alarm time of relay 1..............................................................................................................33

5.4.13Minimum time to return to idle mode of relay 1 ....................................................................................33

5.4.14Enabling of FAIL function for channel 1...............................................................................................33

5.4.15Enabling of FAIL function for channel 2...............................................................................................33

5.4.16Function of serial port 1 .........................................................................................................................34

5.4.17Function of serial port 2 (excluded in case of PROFIBUS option)........................................................34

5.4.18Physical interface of serial port 1 ...........................................................................................................34

5.4.19Data transmitted on serial port 1 in continuous mode ............................................................................35

5.4.20Data transmitted on serial port 2 in continuous mode ............................................................................35

5.4.21Baud rate of serial port 1 ........................................................................................................................35

5.4.22Baud rate of serial port 2 (excluded in case of PROFIBUS option).......................................................36

5.4.23RS485 address of serial port 1................................................................................................................36

5.4.24RS485 address of serial port 2 (excluded in case of PROFIBUS option)...............................................36

5.4.25PROFIBUS address (only in case of PROFIBUS option)......................................................................37

5.4.26Analogue output .....................................................................................................................................37

5.4.27Definition of the type of analogue output...............................................................................................37

5.4.28Function of the analogue output.............................................................................................................37

5.4.29Full scale of the analogue output............................................................................................................38

5.4.30Digital filter setting.................................................................................................................................38

5.4.31Unbalanced load alarm setting ...............................................................................................................39

5.5Calibration.......................................................................................................................................................40

5.5.1Theoretical calibration procedure ...............................................................................................................40

5.5.2Permanent tare ............................................................................................................................................41

5.5.3Zero calibration...........................................................................................................................................42

5.5.4Span calibration ..........................................................................................................................................43

5.5.5Linearization...............................................................................................................................................44

5.5.6Analogue output adjustment.......................................................................................................................45

5.5.7Zero adjustment D/A ..................................................................................................................................46

5.5.8Full scale adjustment D/A...........................................................................................................................47

5.6Instrument test.................................................................................................................................................48

5.6.1Testing relay outputs and digital inputs......................................................................................................48

5.6.2Testing the analogue output........................................................................................................................49

5.6.3Testing load cell inputs...............................................................................................................................50

6.SERIAL PROTOCOL COMMUNICATION............................................................................................... 51

6.1Serial interface management...........................................................................................................................51

6.2String format in continuous mode...................................................................................................................52

6.2.1Calculation of the checksum.......................................................................................................................54

6.3String format in bi-directional mode...............................................................................................................54

6.3.1Weight request command ...........................................................................................................................54

6.4Bi-directional modality with MODBUS protocol...........................................................................................55

6.4.1T060E registers list.....................................................................................................................................56

6.4.2Status word coding......................................................................................................................................57

6.4.3List of Colis supported by T060E...............................................................................................................57

6.5PROFIBUS DP protocol .................................................................................................................................58

6.5.1Data from T060E weight transmitter ..........................................................................................................58

6.5.2Status word coding......................................................................................................................................58

6.5.3Command register.......................................................................................................................................58

6.5.4GDS file......................................................................................................................................................59

IMPORTANT

Theinstructionmanualmustbestoredproperlyandmadeavailabletoallauthorizedstaff.

Theinstructionmanualmustbepreserveduntiltheequipmentisputoutofservice.

AdditionalcopiescanberequestedtotheCompany’sassistancecentre.

Foranyclarificationsortechnicalinformation,pleasecontacttheCompany’sassistancecentre.

1569‐PT060EE1Rev.7Page4of62

1. INTRODUCTION

1.1 Overview

Thismanualdescribestheinstalling,programmingandtroubleshootingproceduresofweighttransmitter,mod.

T060E.Theinstructionmanualmustbestoredproperlyandmadeavailabletoallauthorisedstaff.

Theinstructionmanualmustbepreserveduntiltheequipmentisputoutofservice.Additionalcopiescanbe

requestedtotheCompany’sassistancecentre.

Foranyclarificationsortechnicalinformation,pleasecontacttheCompany’sassistancecentre.

Pleasenotethatanyinstrumentalterationswillvoidthewarranty,therefore,incaseofissues,contactexclusivelythe

Company’sassistancecentres.

Theuseroftheequipmentmustcomplywithallsafetystandardsapplicableinthecountrywherethedeviceisused,

andhemustalsoensurethattheequipmentisoperatedincompliancewithitsintendeduse,forhisownsafety.

1.2 Description

T060Eisaweighttransmitterdesignedforuseinweighingsystemsboastingstraingaugeloadcells.Themain

operatingcharacteristicsare:

Checkingof5basicthresholdsthatcanbeactivatedaccordingtoprogrammableoperatingparameters.

Managementof2inputsthatcanbeactivatedfortarefunction.

Interfacingtoexternalperipheralunitsthroughthemanagementofseriallines,withphysicalinterfaceRS232

orRS485.

Connectiontosupervisorysystemsthroughthemanagementofananalogueoutputundervoltageorcurrent.

1.2.1 Options/ Versions

T060Eoffersaseriesofoptions:

Inputforasecondweighingsystem

PROFIBUS‐DPinterface

T060EOP1OP2

D=DOUBLECHANNEL

P=PROFIBUSDP

1=110VAC

2=220VAC

3=24VAC

4=24VDC

Exampleofconfiguration:T060E1‐DPInstrumentintendedfor110VACpowersupply,featuringdoubleweighing

inputandPROFIBUS‐DPinterface.

1569‐PT060EE1Rev.7Page5of62

1.3 Use

THEFOLLOWINGISPROHIBITED:

Openandapplychangesand/oralterationstotheequipment.Ifthisclauseisnotrespected,the

warrantywillbevoided.

Wetand/orimmersetheinstrumentinanyliquid.

Exposeittostrongmagneticand/orelectricfields

Useinareassubjecttoexplosionhazard

Opentheequipment(itcanbeopenedexclusivelybyauthorisedpeople)

DANGER:

Cut‐offpowerbeforeperforminganyinterventionontheinstrument.

Inspectthepowersupplycableonaregularbasistocheckifthereareanydamages,andifso,

cut‐offpowerandreplaceit.

Themanufacturerdeclinesanyliabilityfordamagescausedtopeopleorobjectsderivedfroman

improperuseofthedevice.

1.4 Description of labels

ThelabelsaffixedonT060Econtain:

indicationofmanufacturer

identificationoftheinstrument'smodel

Instrument’sserialnumber

identificationoftheoperatingvoltage

CEmarking

Thelabelsmustnotberemoved;itisprohibitedtoaffixotherlabelstotheinstrumentwithoutthemanufacturer’s

authorisation.

Attheendofitsusefullife,the

productmustbedisposedofat

suitableseparatecollectioncentres.

Warning:pleaserefertothesupplied

documents

CEmarking

Warning:fulgurationhazard

Alternatingcurrent

1569‐PT060EE1Rev.7Page6of62

1.5 Operating specifications

Powersupply

From9÷24V ±10%(option)

110‐230~±10%

Absorbedpower10W

Operatingtemperaturefrom–10°Cto+40°C

Storagetemperaturefrom–20°Cto+50°C

Relativehumidity95%noncondensing

Maindisplay6digits,11mmLEDS

Statussignals85mmLEDS

Keyboard4mechanicalkeys

Loadcellinputpowersupply5V /114mA(max8cellsof350Ωinparallel)

Loadcellinput2inputpowersupply(optional)5V /114mA(max8cellsof350Ωinparallel)

Inputsensitivity0.02µV

Linearity

Temperaturedrift

Converter’sresolution24bit

Resolutionofdisplayedweight50000div.

Analoguesignal From–2mV/Vto+3mV/V

Conversionspeed100Hz

DigitalfilterSelectable

Serialports1RS232/RS485(fullduplex)opto‐isolated

Serialports1RS485(halfduplex)

Logicoutputs5SPSTrelayoutputs

Logicoutputs(optional)1SPSToutput(safetyoutput)

Logicinputs2digitalopto‐isolatedinputs

Opto‐isolatedanalogueoutput1selectable0÷10V/4÷20mA(activetype)

Resolution 16bit

Impedances Min.voltage10KΩ/Max.current500Ω

Linearity

Temperaturedrift

Sizes100x105x10mm

Assembly OnDINEN60715TH35bar.

ContainerABSRAL7035

FrontprotectiondegreeIP40/DINEN60529

1569‐PT060EE1Rev.7Page7of62

2. INSTRUMENT’S OPERATION

2.1 Turning on the instrument

Whentheinstrumentisturnedon,thefollowingsequenceofindicationsappearsontheprimarydisplay,approx.

everytwosecondsapart:

A D O S

T 0 6 0 E

R 1. 0 0 (Revisionoftheinstalledsoftware)

Whenreachingthisphase,theinstrumentbecomesimmediatelyoperativeandtheweightvalueappearsonthe

display.

1569‐PT060EE1Rev.7Page8of62

2.2 Transmitter’s functions

InstrumentT060Eisaweighttransmitterwithpotentialthresholdrelaymanagementfunction.

Therefore,itisnotatraditionalweighinginstrument,sinceGross,NetandTaremanagementfunctionsarenot

available.

OnlyZEROcorrectionscanbeexecuted(throughexternalinputs)withthepurposetorecoverzeroderivativesor

deviationsrelativetotheweighingsystem.

Theonboardrelaysaremanagedasalarmrelays,thereforetheyarealwayskeptenergizedandarede‐energizedin

caseofalarm.

2.2.1 Management of the calibration

T060Eforeseestheset‐upofatheoreticalcalibration.However,theoperatorcanexecutepotentialcorrectionsduring

thecalibrationphase.Theadvantageofthistypeofset‐upliesinthefactthatthesystemcarriesoutanautomatic

calibration,byknowingthecells’characteristics.

Thesystemisnotvalidincaseofloadcellsnotsupportingdirectlytheentireweightappliedtothesystem(e.g.incase

ofaweighingpinappliedtoaresultantofareturnsystem).Inthiscase,theoperatormustsettheweightvalueused

attheendofthemeasurementchain.

Forexample,incaseofaweighingpinappliedtothefixedcomponentofaliftingsystem,theoperatormustsetthe

valueactuallyliftedbythebridgecrane;forexample,incaseofpinweighing1tonandthecapacityofthebridge

craneconsistingof300tons.Inthiscase,thesignalwillbesetaccordingtothepin’sdatasheetandthecapacitywill

besetto300(correspondingto300tonsofthesystem'scapacity),whilethesensitivitywillbesetaccordingtothe

accuraciesidentifiedintheapplicationofthesystem(forexample,ifitweights200kg,thesensitivitymustbesetto

0.2).

Theresolution(divisionvalue)issettotheresultofthe60000divisions.Higherset‐upsarediscardedbythesystem.

Thesystem’sresolutionisgivenbytheratiobetweencapacityandresolution.

Asystemwitha100Kgcellandaresolutionof0.01isasystemconsistingof10000divisions.

SE G N 1

T060Eforeseesloadcellswithmaximumsignalof3.5mV/V.

PO R T 1

Thevaluesetinthisparameterconstitutesthefullscaleoftheweighingsystem.Itforeseesamaximumvalueof

100000divisions.

SE N S 1

Thevaluecanbeselectedwithintherangefrom50to0.001divisions.

Thechangeofbothsystemcapacityandloadcellsignal(mV/V)causetheclearanceofcalibrationdata

(linearizationsincluded)alreadycarriedout,ofsetpointsvaluesandtheanalogoutputdata.

1569‐PT060EE1Rev.7Page9of62

2.2.2 Sum value function

TheT060Ethedoublechannelweighingversion(Doption)foreseesthepossibilitytohandlethesumvalueofthetwo

channels.Thevaluecanbedisplayedbothpushingandinassociationwithoneormorethresholdrelays

alarms(seechapter2.5).Incaseofsystemswithcapacityordifferentunitmeasure,theoperatormusrealignthe

valuetothesameunitmeasure,decidingwhichofthetwochannelsmustbetakenasreferencechannel.

I.E.:

Channel1F.S.10.00tandchannel21000kfF.S.consideringchannel1asreferencechannel(parameterPRIOR),we

shouldreturnthechannel2toadisplayint.

InordertogetthistheT060EwithparameterMULTIPallowsdividingormultiplyingthechannelvalue.

Inourexampledividingby1000thechannel2valueisdisplayedasforchannel1int.

Accordingtodifferentsystemscapacities,multiplyingordividing,itispossibletosumvalueswiththesamemeasure

unit.

2.2.3 Management of the zero

Theexternalinputscanbeusedtoresetpotentialzeroderivativesordeviationsrelativetotheweighingsystem.The

AZMlimitisvalidinbothways,thereforetheactualfieldis‐100.0%.+100.0%.

Theinputisactiveontheclosingpanel.

Weightresettingiscarriedoutafterconversionandlinearizationoperationswhicharenotinfluenced,causinga

verticaltranslationofthetransmitter’sresponsecurve.

Zeroingaffectsalltransmitters’functions:display,serialtransmission,analogueoutputandthresholdmanagement

arealllinkedtothecorrectweightvalue.

Theresetvalueislostiftheequipmentisturnedoff.

Thenon‐resettotalweightvaluecanbecheckedlocallybypressingkeyDEC:bykeepingthiskeypressed,the

instrumentdisplaysthetotalweightvalue.

1569‐PT060EE1Rev.7Page10of62

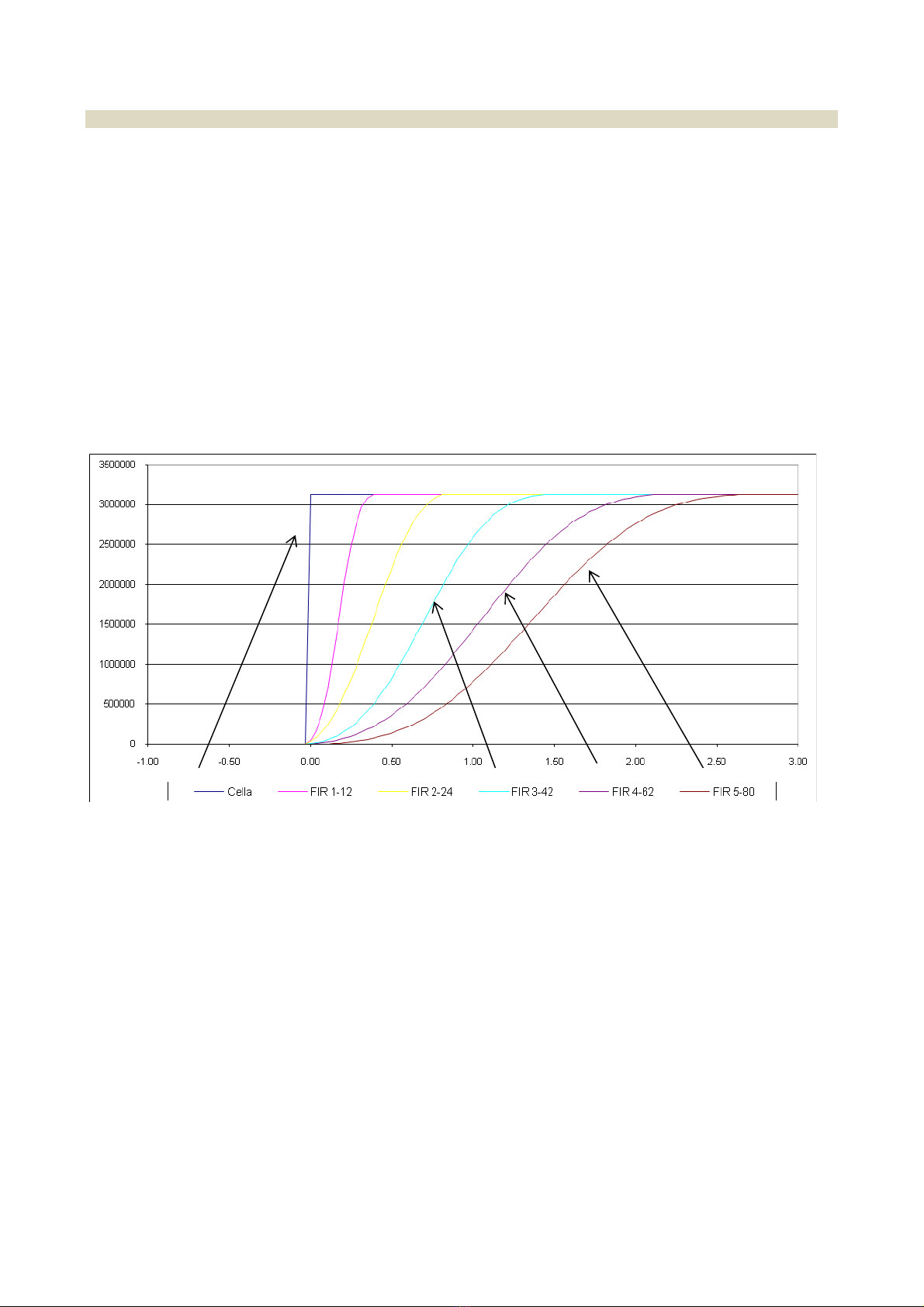

2.2.4 Signal filtering

Theinstrumentallowsintroducingfilteringmethodsofthesignalcomingfromloadcells(FIRfilters).Thismethodis

basedonDigitalSignalProcessing(DSP)modesandallowshandlingatbest,signalscontainingstrongharmonic

components(e.g.generatedbymixers).

Duringtheconfigurationphase,itispossibletoselectthreetypicalfilters(withmovingaverage)and5DSPfilters.

Theformerallowquickerresponsetimesbutarelesseffectivewithregardstointerferences,thereforetheymustbe

usedwhenextremelyquickweightvariationsmustbedetected.

Thelatterallowmitigatinginterferences(sincetheyboastahigherfilteringeffect)atthedisadvantageoftheresponse

timetoweightvariations.

Inbothcases,thehigheristhefilter’snumber,thegreateristhefilteringeffectandtheresponsetimetoaweight

variation.

Forexample,theresponsetoastepweightvariationisshowninthechartbelow,basedontheselectedfilter.

ThechartshowsthatfilterFIR1boastsaresponsetimeofapprox.0.2seconds,whilefilterFIR5boastsaresponse

timeofapprox.2.5seconds.

1569‐PT060EE1Rev.7Page11of62

2.3 Front panel

2.3.1 Display

Innormaloperatingconditions,thedisplayindicatestheweightvaluesaccordingtothefollowingcriteria:

theirrelevantinitialzerosarenotdisplayed

the“minus”sign(incaseofnegativeweightvalues)isdisplayedinthefirstleftdigit

Ifthenegativeweightvalueisofsixdigits(e.g.‐324210),thefirstleftdigitwillindicatethe“minus”signandthe

weightvalue,alternatively.

Ifthenegativeweightvalueisofsevendigits,thelesssignificantfivedigitsaredisplayedandthemessagestarts

flashinginordertoindicatethepresenceofanon‐visibleinitial“1”.Thefirstleftdigitwillindicatethe“minus”

signandtheweightvalue,alternatively.

Theweightindicationlimitsare:

Lowerlimit:‐20%offullscale

upperlimit:120%offullscale

Iftheweightislowerthanthelowerlimit,thefollowingindicationisdisplayed:

- - U L - -

Iftheweightisgreaterthantheupperlimit,thefollowingindicationisdisplayed:

- - O L - -

2 1 0 0 0 0

1569‐PT060EE1Rev.7Page12of62

2.3.2 LED signals

ThemeaningofthemessagesprovidedbythesignalLEDSlocatedontheinstrument’sfrontpanelisthefollowing:

RL1÷RL5TheLEDisonduetothetriggeringoftherelativethreshold

SRTheLEDisontonotifythetriggeringofthesafetysignal

TXTheLEDflashestosignalthetransmissionactivityofserialport1.

RXTheLEDflashestosignalthereceivingactivityofserialport1.

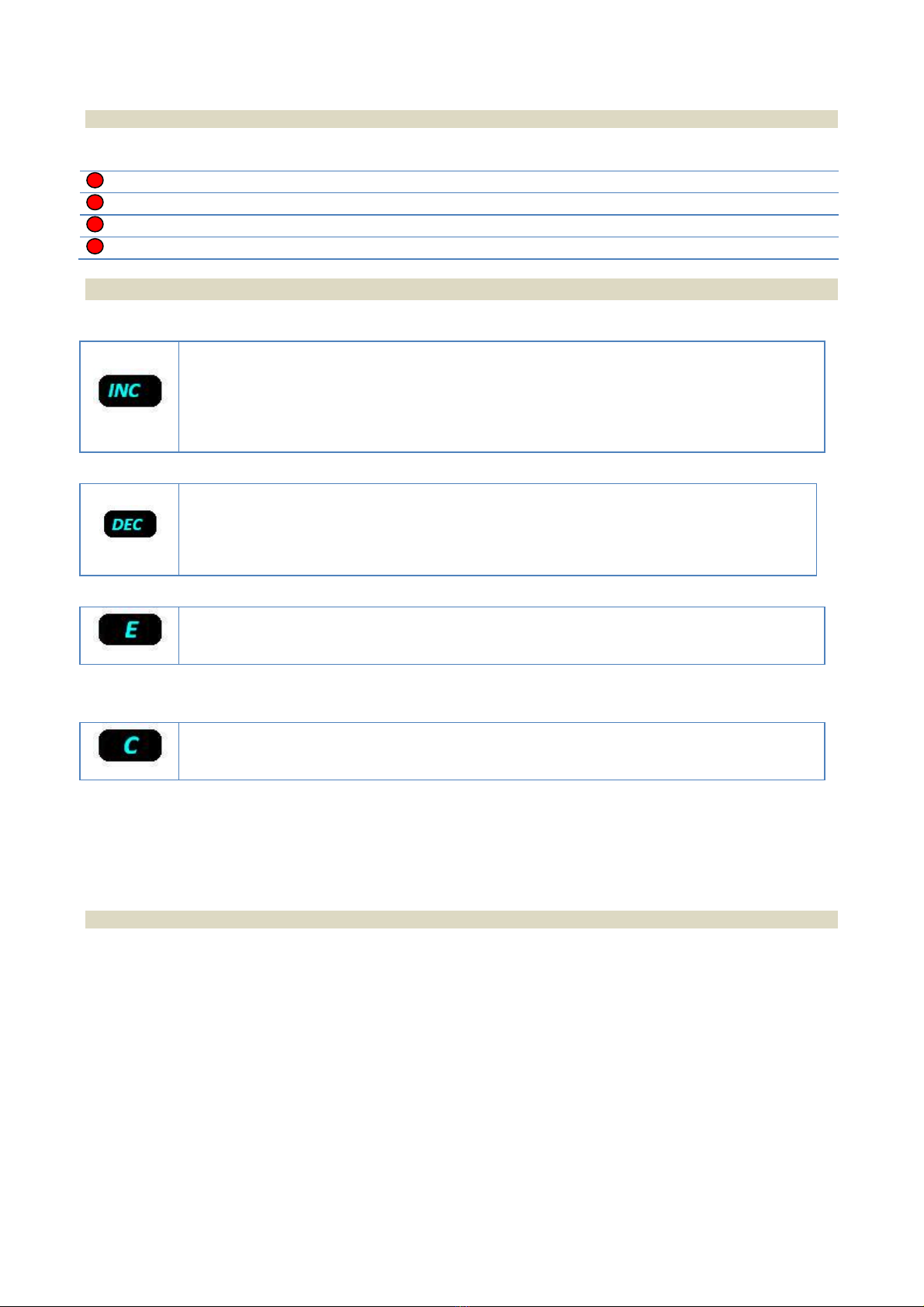

2.3.3 Key functions

Iftheinstrumentisinoperatingmode,itallowscommutingthereading(iftheinstrumentforesees

theoptionalsecondchannel)todisplaytheweightvalueofthesecondchannelortotalvalue

(channel1+channel2).

Iftheinstrumentisinconfigurationmode,itallowsbrowsingforwardthemenuitemsand

increasingtheparameters’value.

Iftheinstrumentisinoperatingmodeandtheweightwaszeroed,thedisplaywillindicatethe

valuebypressingthiskey(fortheselectedchannel).

Iftheinstrumentisinconfigurationmode,itallowsbrowsingbackwardthemenuitemsand

decreasingtheparameters’value.

Iftheinstrumentisinoperatingmode,itallowsenteringinconfigurationmode.

Iftheinstrumentisinconfigurationmode,thekeywillconfirmtheselectionsmade.

Iftheinstrumentisinoperatingmode,ithasnofunction.

Iftheinstrumentisinconfigurationmode,thiskeywillcanceltheselectionsmade.

2.4 Self-troubleshooting

2.4.1 Cell connection fault (FAIL)

Theinstrumentconstantlychecksthecorrectconnectionoftheloadcell(interruptionandshort‐circuitofthesignal

andpowersupplyconnections)and,incaseananomalyisdetected,aFAILinternalsignalisgenerated.

ByprogrammingoneormorerelaysasFAIL,inadditiontothemessageappearingonthedisplay,allchannel’srelays

areforcedinalarmstatus(theyarede‐energized).Forexample,byprogrammingFAIL1,allrelayssetwithalarm

thresholdsonchannel1and/orthetotal,areforcedinalarmstatus.

1569‐PT060EE1Rev.7Page13of62

2.5 Management of relays

Thebasicinstrumentisequippedwithfiverelaysthatcanbeconfiguredasrequired.

Agenerallyopencontact(NA)notundervoltageisavailableforeachrelay.

Therelays’operationislinkedtotheconditionsdefinedintheconfigurationphase.

Therelays’commutationtakesplacewhenthethresholdvaluesetintheconfigurationphase(SET#parameter)is

reachedandremainsinthisconditionforatimeframeequaltoorexceedingthealarmminimumtime(DAL#

parameter).Itisrestoredinnormalconditionswhentheweightvalueisdroppedbelowthevaluedeterminedbythe

sumofthethresholdvalueandtheconfiguredhysteresisvalue(DB#parameter)andremainsinthisconditionfora

timeframeequaltoorexceedingtheminimumnormaltime(DOH#parameter).

Thechangeoftherelayoperationcausetheclearanceofsetpointsvalues.

Eachrelaycanbeconfiguredtooperateinoneofthefollowingmodes:

F A I L 1 Loadcellconnectionfault(FAIL).Thealarmstatusistriggered

whentheFAILconditionispresent.

L O N 1 Minimumalarm(LON)

Thealarmstatusistriggeredwhentheweightvalueislower

thanorequaltothethresholdvalue.

H I N 1 Maximumalarm(HIN)

Thealarmstatusistriggeredwhentheweightvalueisgreater

thanorequaltothethresholdvalue.

L O G 1

Minimumalarm(LOG).Thealarmistriggered,regardlessof

theresetvalue.

Thealarmstatusistriggeredwhentheweightvalueislower

thanorequaltothethresholdvalue.

H I G 1

Maximumalarm(HIG).Thealarmistriggered,regardlessof

theresetvalue.

Thealarmstatusistriggeredwhentheweightvalueislower

thanorequaltothethresholdvalue.

T O T N Alarmonthetotalvalueofthetwochannels(TOTG).The

alarmstatusistriggeredwhentheweightvalueisgreater

thanorequaltothethresholdvalue.

T O T G

Alarmonthetotalvalueofthetwochannels(TOTG).The

alarmistriggered,regardlessoftheresetvalue.

Thealarmstatusistriggeredwhentheweightvalueisgreater

thanorequaltothethresholdvalue.

O N Therelayiskeptconstantlyenergized.

1569‐PT060EE1Rev.7Page14of62

3. INSTALLATION

3.1 Receiving the material

Beforesigningthetransportdocument,makesuretherearenodamagestotheequipmentcausedduringtransport

andifso,notifythecarrier.

Inadditiontotheinstrument,thefollowingmustbepresent:

1seriesoffemaleflyingterminalsforconnectingthepowersupplyandinputandoutputsignals

1copyoftheinstructionmanual

1copyoftheinstrument’stestingreport(checkthattheserialnumberappearingintherelativelabel

correspondstotheserialnumberindicatedonthetestingsheet).

INPUT100‐240V~

10W50/60Hz

MODELT060E1

S.N.20160234

Eachdevicefeaturestherequiredinformationforproperidentification:modelandserialnumber.

Thisdata,togetherwiththesoftwareversion,mustbeindicatedwhenrequestinginformation.

3.2 Assembling the instrument

WARNING

Makesurethatthesupplyvoltagefallswithintheinstrument’sallowedlimits.

Makesurethatitispossibletodisconnectpowerduringinstallationand/ormaintenancephases.

Performagroundconnectionifrequired.

Itisrecommendedtouseashieldedcableforcell’sinputsignals,analogueoutputsandseriallines.

Usetroughsforcell’sinputsignals,analogueoutputsandseriallines,whichareseparatefromthoseofpowersignals.

Connectthepanelonwhichtheinstrumentisinstalledtotheground.

Theinstrument’soutputrelaysmustbeusedtocontroltherelays’coils(whichnominalcurrentmustfallwithin

declaredlimitsandanyhow,usingsuitablearcsuppressiondevices),logicinputsorsignalLEDS;theymustnotcontrol

powersignals.

1569‐PT060EE1Rev.7Page15of62

3.3 Connections

Allinstrument’sconnectionsarecarriedoutonthesideoftheinstrument.

3.4 Rear panel

Alabelcontainingscreen‐printedindicationstofacilitatetheoperatorincarryingoutcablingoperationsisaffixedon

thesidesoftheinstrumentnearterminals.

SIDE B

SIDE A

3.5 Power supply tag

Beforeconnectingtheequipmenttoapowersource,makesurethattheselectedvalueonthelabelcorrespondsto

theforeseenvoltage.Iftheforeseenvaluesdiffersfromthevoltageindicatedonthetag,donotconnectthe

equipmentandcontactexclusivelyacompany’sassistancecentretochangetheversionifneeded.

1569‐PT060EE1Rev.7Page16of62

3.6 Connection to power supply (side B)

3.6.1 Version 110÷230V~ 24-48V~

INDICATIONFUNCTIONTERMINAL

NNeutral2

LLine1

EGround3

Connecttheinstrument’ssafetygroundterminaltothesystem’sgroundbarthroughflexiblecable.

3.6.2 Version 12÷24V

INDICATIONFUNCTIONTERMINAL

++12÷241

‐02

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

OUT 1

OUT 4

OUT 2

OUT 1

OUT 2

OUT 4

OUT 3

OUT 3

G SAFETY OUT

V SAFETY OUT

OUT 5

OUT 5

INP 2

INP 1

C INP

100-240VAC

124VAC 48VAC

LL

NN

EE

2

3

24VDC

-

+L

E

N

1569‐PT060EE1Rev.7Page17of62

3.7 Connection of load cells (side A)

Thecablecomingfromtheloadcellsorjunctionboxmustbeconnectedtotheterminalslocatedontherearofthe

instrumentandcalledLOADCELL1.

Connectionbetweentheloadcellandtheinstrumentmustbecarriedoutwithashieldedcable.Thecable’sshield

mustbeconnectedtotheground.

Connectionmusttakeplacerespectingthecolourcodeindicatedontheloadcells.

T060foreseesthestandardconnectionof6‐wireloadcells.Incaseofconnectionof4‐wireloadcells,connectthe

referencewirestotherelativepolaritiesofthepowersupplycables.

MAKESURETHECONNECTIONCABLEBETWEENLOADCELLSANDINSTRUMENTISDUCTEDINTROUGHSSEPARATE

FROMTHOSEOFPOWERLINES,INORDERTOAVOIDCOUPLINGTHATMAYPREJUDICETHEMEASUREMENT

ACCURACY.

3.7.1 Connection of load cells 1

LC1

INDICATIONFUNCTION TERMINAL

+A+Excitation 39

‐A‐Excitation 38

+S+Signal37

‐S‐Signal 36

+R+Reference 35

‐R‐Reference 34

3128 29 30

-S

+R

-R

3432 33

+S

3635 37

-A

+A

3938

-R

+R

-S

+S

-A

+A

LOAD CELL 2 LOAD CELL 1

232019 2221 2524 2726

SGND 3

IOUT+

VOUT+

SGND 2

-RS485

+RS485

SGND 1

-RS485/RX

+RS485/TX

SERIAL

OUT 1

SERIAL

OUT 2

ANALOG

OUTPUT

OPTO OPTO

1569‐PT060EE1Rev.7Page18of62

Incaseof4‐wireconnection,short‐circuittheterminals–Excitationwith‐Referenceand+Excitationwith+

Reference.

CONNECTIONWITH4‐WIRELOADCELLS

CONNECTIONWITH6‐WIRELOADCELLS

1569‐PT060EE1Rev.7Page19of62

3.7.2 Connection of load cells 2 input

T060Eforeseesanoptionalsecondloadcellsinput.Theconsiderationsmadeforthemainchannelalsoapplyforthe

optionalinputchannel.

LC2

INDICATIONFUNCTION TERMINAL

+A+Excitation 33

‐A‐Excitation 32

+S+Signal 31

‐S‐Signal 30

+R+Reference 29

‐R‐Reference 28

3128 29 30

-S

+R

-R

3432 33

+S

3635 37

-A

+A

3938

-R

+R

-S

+S

-A

+A

LOAD CELL 2 LOAD CELL 1

232019 2221 2524 2726

SGND 3

IOUT+

VOUT+

SGND 2

-RS485

+RS485

SGND 1

-RS485/RX

+RS485/TX

SERIAL

OUT 1

SERIAL

OUT 2

ANALOG

OUTPUT

OPTO OPTO

1569‐PT060EE1Rev.7Page20of62

3.7.3 Wiring example (single weighing system)

Inthecaseofplantconsistsofasingleweighingsystemwithoneormorecellsconnectedinparallelthewiringmust

bemadeonchannel1(seediagramasanexample)

Exampleofasystemconsistingofasingleweighingsystemwithonlytwoloadcellsinparallel

Table of contents

Other Ados Transmitter manuals

Popular Transmitter manuals by other brands

Electronic Broadcast Equipment

Electronic Broadcast Equipment SIRIO 2000T User and maintenance manual

NIVELCO

NIVELCO EasyTREK SP-300 Installation and programming manual

SMW

SMW LNB-LINK user guide

Moseley

Moseley DSP6000A user manual

Indexa

Indexa DF-100 operating instructions

YOKOGAWA

YOKOGAWA EJA210E user manual

NET-K

NET-K WT-1550-EM30 operating manual

Omega Engineering

Omega Engineering CYTX231 Series user guide

Ametek Drexelbrook

Ametek Drexelbrook Universal Lite 509-1 Series Installation and operating instructions

Toyo

Toyo SOT-EQ80 Series Operation manual

Hydac

Hydac HFT 2100 user manual

BSi

BSi Mini-Tx UHD product manual