Ados T060E PN Series Operating manual

1710‐PT060PNERev.0Page1of57

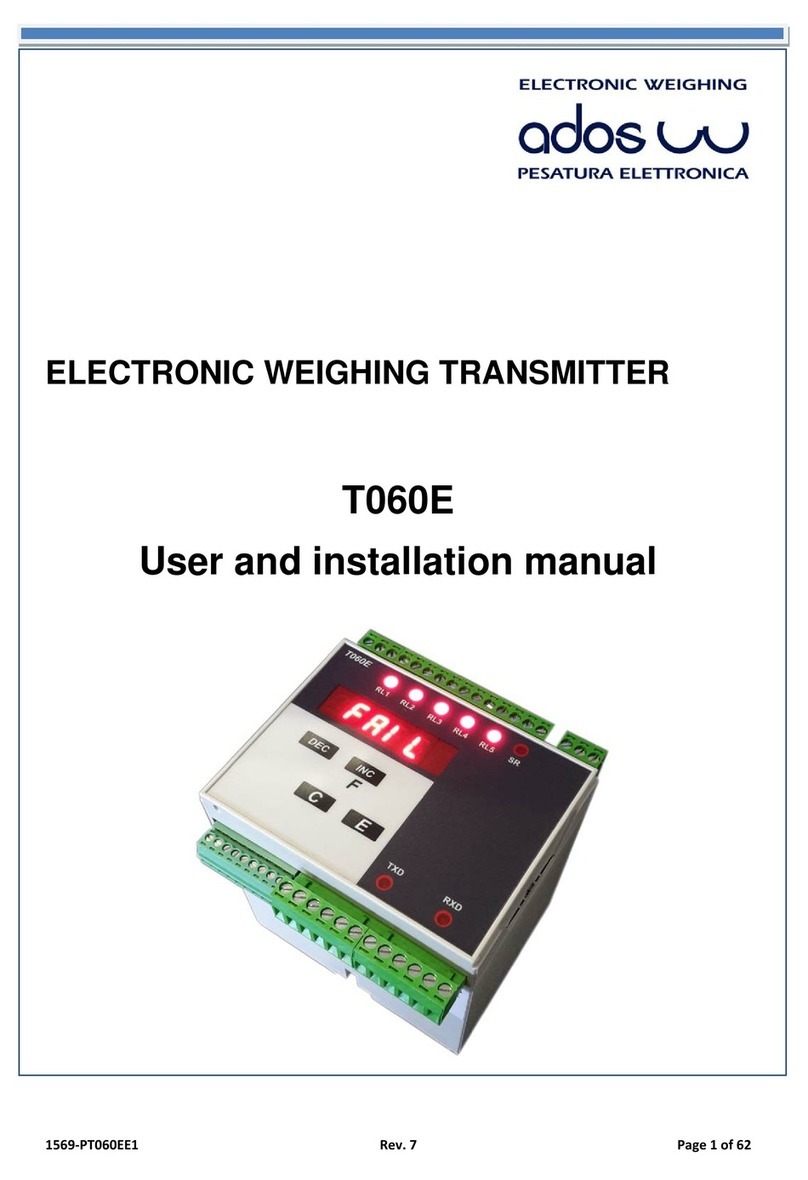

ELECTRONIC WEIGHING TRANSMITTER

(PROFINET VERSION)

T060Ex-PN

User and installation manual

1710‐PT060PNERev.0Page2of57

Tableofcontents

1.INTRODUCTION........................................................................................................................................ 4

1.1Overview...........................................................................................................................................................4

1.2Description........................................................................................................................................................4

1.2.1Options/ Versions .........................................................................................................................................4

1.3Use ....................................................................................................................................................................5

1.4Description of labels .........................................................................................................................................5

1.5Operating specifications....................................................................................................................................6

2.INSTRUMENT’S OPERATION .................................................................................................................. 7

2.1Turning on the instrument.................................................................................................................................7

2.2Transmitter’s functions .....................................................................................................................................8

2.2.1Management of the calibration .....................................................................................................................8

2.2.2Sum value function.......................................................................................................................................9

2.2.3Management of the zero................................................................................................................................9

2.2.4Signal filtering ............................................................................................................................................10

2.3Front panel ......................................................................................................................................................11

2.3.1Display........................................................................................................................................................11

2.3.2LED signals ................................................................................................................................................12

2.3.3Key functions..............................................................................................................................................12

2.4Self-troubleshooting........................................................................................................................................12

2.4.1Cell connection fault (FAIL) ......................................................................................................................12

2.5Management of relays.....................................................................................................................................13

3.INSTALLATION........................................................................................................................................ 14

3.1Receiving the material.....................................................................................................................................14

3.2Assembling the instrument..............................................................................................................................14

3.3Connections.....................................................................................................................................................15

3.4Rear panel .......................................................................................................................................................15

3.5Power supply tag.............................................................................................................................................15

3.6Connection to power supply (side B)..............................................................................................................16

3.6.1Version 110÷230V~ 24-48V~ ....................................................................................................................16

3.6.2Version 12÷24V ................................................................................................................................16

3.7Connection of load cells (side A)....................................................................................................................17

3.7.1Connection of load cells 1...........................................................................................................................17

3.7.2Connection of load cells 2 input .................................................................................................................19

3.7.3Wiring example (single weighing system)..................................................................................................20

3.7.4Wiring example (double weighing system) ................................................................................................21

3.8Connection of serial lines (side A)..................................................................................................................22

3.9Digital inputs (side B).....................................................................................................................................23

3.10Connection of relay outputs (side B)...............................................................................................................24

3.11Optional analogue output................................................................................................................................25

3.12PROFINET output ..........................................................................................................................................26

4.MAINTENANCE ON THE INSTRUMENT................................................................................................ 27

4.1Preventive maintenance...................................................................................................................................27

4.2Corrective maintenance...................................................................................................................................27

5.MANAGEMENT OF THE INSTRUMENT................................................................................................. 28

5.1Introduction.....................................................................................................................................................28

5.2Operational sequence ......................................................................................................................................28

5.3Selection of the management functions...........................................................................................................28

5.3.1Time-Out function on the keys’ operation..................................................................................................28

5.4Configuration of operational parameters.........................................................................................................29

5.4.1Selection of operational parameters............................................................................................................29

5.4.2Editing of the value of operational parameters...........................................................................................30

5.4.3Setting the load cells’ signal.......................................................................................................................31

5.4.4Setting the weighing system capacity.........................................................................................................31

5.4.5Setting the system resolution......................................................................................................................31

5.4.6Average settings..........................................................................................................................................31

5.4.7Reference channe selection (only with instrument with double channel)...................................................32

5.4.8Scale factor selection ((only with instrument with double channel)...........................................................32

5.4.9Relay 1 function..........................................................................................................................................32

5.4.10Threshold value of relay 1......................................................................................................................33

5.4.11Hysteresis value of relay 1......................................................................................................................33

1710‐PT060PNERev.0Page3of57

5.4.12Minimum alarm time of relay 1..............................................................................................................33

5.4.13Minimum time to return to idle mode of relay 1 ....................................................................................33

5.4.14Enabling of FAIL function for channel 1...............................................................................................33

5.4.15Enabling of FAIL function for channel 2...............................................................................................33

5.4.16Function of serial port 1 .........................................................................................................................34

5.4.17Physical interface of serial port 1 ...........................................................................................................34

5.4.18Data transmitted on serial port 1 in continuous mode............................................................................35

5.4.19Baud rate of serial port 1 ........................................................................................................................35

5.4.20RS485 address of serial port 1................................................................................................................35

5.4.21Analogue output .....................................................................................................................................36

5.4.22Definition of the type of analogue output...............................................................................................36

5.4.23Function of the analogue output.............................................................................................................36

5.4.24Full scale of the analogue output............................................................................................................37

5.5Calibration.......................................................................................................................................................38

5.5.1Theoretical calibration procedure ...............................................................................................................38

5.5.2Permanent tare ............................................................................................................................................39

5.5.3Zero calibration...........................................................................................................................................40

5.5.4Span calibration ..........................................................................................................................................41

5.5.5Linearization...............................................................................................................................................42

5.5.6Analogue output adjustment.......................................................................................................................43

5.5.7Zero adjustment D/A ..................................................................................................................................44

5.5.8Full scale adjustment D/A...........................................................................................................................45

5.6Instrument test.................................................................................................................................................46

5.6.1Testing relay outputs and digital inputs......................................................................................................46

5.6.2Testing the analogue output........................................................................................................................47

5.6.3Testing load cell inputs...............................................................................................................................48

6.SERIAL PROTOCOL COMMUNICATION............................................................................................... 49

6.1Serial interface management...........................................................................................................................49

6.2String format in continuous mode...................................................................................................................50

6.2.1Calculation of the checksum.......................................................................................................................52

6.3String format in bi-directional mode...............................................................................................................52

6.3.1Weight request command ...........................................................................................................................52

6.4Bi-directional modality with MODBUS protocol...........................................................................................53

6.4.1T060E registers list.....................................................................................................................................54

6.4.2Status word coding......................................................................................................................................55

6.4.3List of Colis supported by T060E...............................................................................................................55

6.5PROFINET protocol .......................................................................................................................................56

6.5.1Data from T060E weight transmitter ..........................................................................................................56

6.5.2Status word coding......................................................................................................................................56

6.5.3Command register.......................................................................................................................................56

IMPORTANT

The instruction manual must be stored properly and made available to all authorized staff.

The instruction manual must be preserved until the equipment is put out of service.

Additional copies can be requested to the Company’s assistance centre.

For any clarifications or technical information, please contact the Company’s assistance centre.

1710‐PT060PNERev.0Page4of57

1. INTRODUCTION

1.1 Overview

Thismanualdescribestheinstalling,programmingandtroubleshootingproceduresofweighttransmitter,mod.

T060E.Theinstructionmanualmustbestoredproperlyandmadeavailabletoallauthorisedstaff.

Theinstructionmanualmustbepreserveduntiltheequipmentisputoutofservice.Additionalcopiescanbe

requestedtotheCompany’sassistancecentre.

Foranyclarificationsortechnicalinformation,pleasecontacttheCompany’sassistancecentre.

Pleasenotethatanyinstrumentalterationswillvoidthewarranty,therefore,incaseofissues,contactexclusivelythe

Company’sassistancecentres.

Theuseroftheequipmentmustcomplywithallsafetystandardsapplicableinthecountrywherethedeviceisused,

andhemustalsoensurethattheequipmentisoperatedincompliancewithitsintendeduse,forhisownsafety.

1.2 Description

T060Eisaweighttransmitterdesignedforuseinweighingsystemsboastingstraingaugeloadcells.Themain

operatingcharacteristicsare:

Checkingof5basicthresholdsthatcanbeactivatedaccordingtoprogrammableoperatingparameters.

Managementof2inputsthatcanbeactivatedfortarefunction.

Interfacingtoexternalperipheralunitsthroughthemanagementofseriallines,withphysicalinterfaceRS232

orRS485.

Connectiontosupervisorysystemsthroughthemanagementofananalogueoutputundervoltageorcurrent.

1.2.1 Options/ Versions

T060Eoffersaseriesofoptions:

Inputforasecondweighingsystem

PROFIBUS‐DPinterface

PROFINETexternalinterface

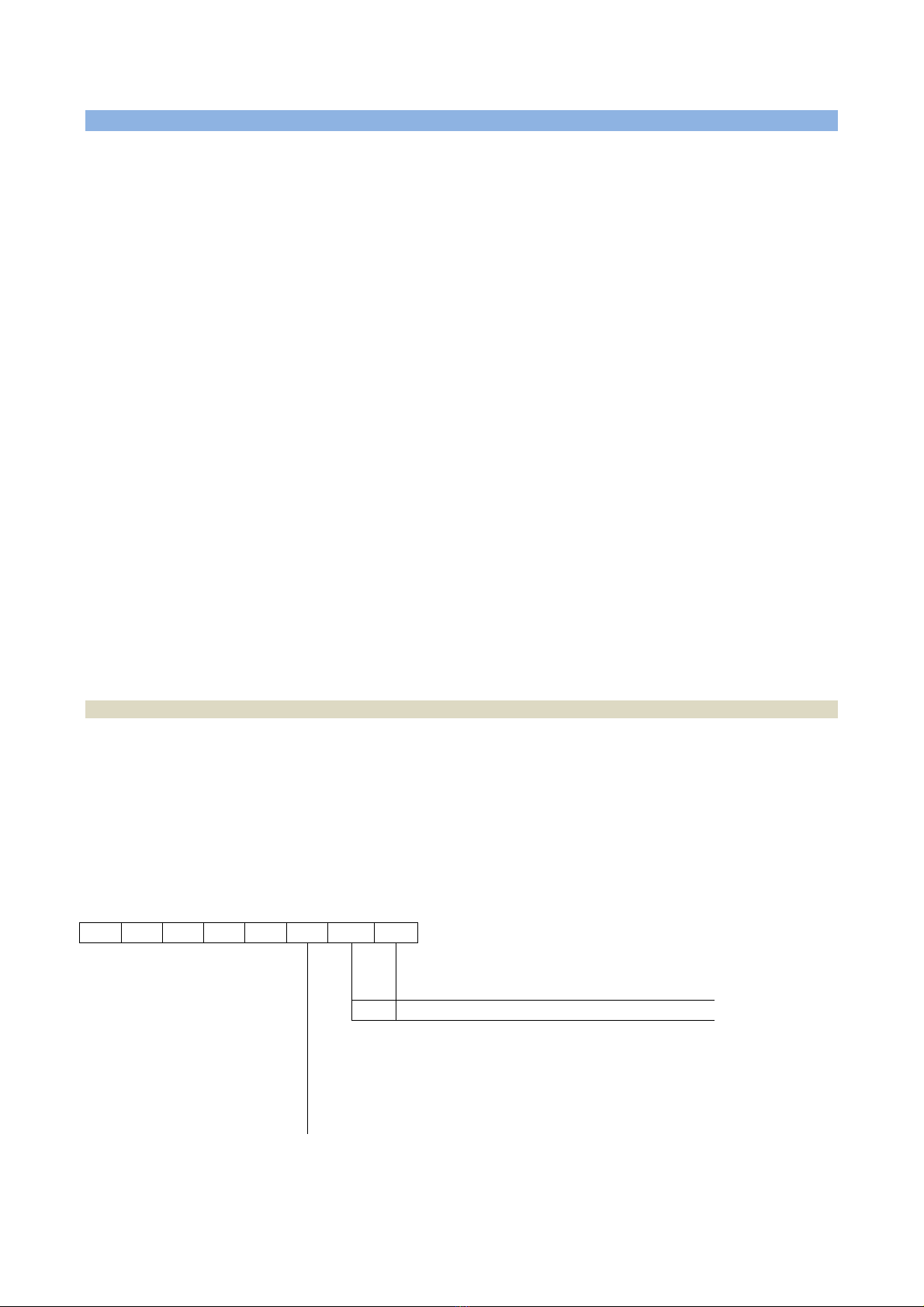

T060EOP1OP2

D=DOUBLECHANNEL

P=PROFIBUSDP

PN =PROFINET

1=110VAC

2=220VAC

3=24VAC

4=24VDC

Exampleofconfiguration:T060E1‐DPInstrumentintendedfor110VACpowersupply,featuringdoubleweighing

inputandPROFIBUS‐DPinterface.

1710‐PT060PNERev.0Page5of57

1.3 Use

THEFOLLOWINGISPROHIBITED:

Openandapplychangesand/oralterationstotheequipment.Ifthisclauseisnotrespected,the

warrantywillbevoided.

Wetand/orimmersetheinstrumentinanyliquid.

Exposeittostrongmagneticand/orelectricfields

Useinareassubjecttoexplosionhazard

Opentheequipment(itcanbeopenedexclusivelybyauthorisedpeople)

DANGER:

Cut‐offpowerbeforeperforminganyinterventionontheinstrument.

Inspectthepowersupplycableonaregularbasistocheckifthereareanydamages,andifso,

cut‐offpowerandreplaceit.

Themanufacturerdeclinesanyliabilityfordamagescausedtopeopleorobjectsderivedfroman

improperuseofthedevice.

1.4 Description of labels

ThelabelsaffixedonT060Econtain:

indicationofmanufacturer

identificationoftheinstrument'smodel

Instrument’sserialnumber

identificationoftheoperatingvoltage

CEmarking

Thelabelsmustnotberemoved;itisprohibitedtoaffixotherlabelstotheinstrumentwithoutthemanufacturer’s

authorisation.

Attheendofitsusefullife,the

productmustbedisposedofat

suitableseparatecollectioncentres.

Warning:pleaserefertothesupplied

documents

CEmarking

Warning:fulgurationhazard

Alternatingcurrent

1710‐PT060PNERev.0Page6of57

1.5 Operating specifications

Powersupply

From9÷24V ±10%(option)

110‐230~±10%

Absorbedpower10W

Operatingtemperaturefrom–10°Cto+40°C

Storagetemperaturefrom–20°Cto+50°C

Relativehumidity95%noncondensing

Maindisplay6digits,11mmLEDS

Statussignals85mmLEDS

Keyboard4mechanicalkeys

Loadcellinputpowersupply5V /114mA(max8cellsof350Ωinparallel)

Loadcellinput2inputpowersupply(optional)5V /114mA(max8cellsof350Ωinparallel)

Inputsensitivity0.02µV

Linearity

Temperaturedrift

Converter’sresolution24bit

Resolutionofdisplayedweight50000div.

Analoguesignal From–2mV/Vto+3mV/V

Conversionspeed100Hz

DigitalfilterSelectable

Serialports1RS232/RS485(fullduplex)opto‐isolated

Serialports1RS485(halfduplex)

Logicoutputs5SPSTrelayoutputs

Logicoutputs(optional)1SPSToutput(safetyoutput)

Logicinputs2digitalopto‐isolatedinputs

Opto‐isolatedanalogueoutput1selectable0÷10V/4÷20mA(activetype)

Resolution 16bit

Impedances Min.voltage10KΩ/Max.current500Ω

Linearity

Temperaturedrift

Sizes100x105x10mm

Assembly OnDINEN60715TH35bar.

ContainerABSRAL7035

FrontprotectiondegreeIP40/DINEN60529

1710‐PT060PNERev.0Page7of57

2. INSTRUMENT’S OPERATION

2.1 Turning on the instrument

Whentheinstrumentisturnedon,thefollowingsequenceofindicationsappearsontheprimarydisplay,approx.

everytwosecondsapart:

A D O S

T 0 6 0 E

R 1. 0 5 (Revisionoftheinstalledsoftware)

Whenreachingthisphase,theinstrumentbecomesimmediatelyoperativeandtheweightvalueappearsonthe

display.

1710‐PT060PNERev.0Page8of57

2.2 Transmitter’s functions

InstrumentT060Eisaweighttransmitterwithpotentialthresholdrelaymanagementfunction.

Therefore,itisnotatraditionalweighinginstrument,sinceGross,NetandTaremanagementfunctionsarenot

available.

OnlyZEROcorrectionscanbeexecuted(throughexternalinputs)withthepurposetorecoverzeroderivativesor

deviationsrelativetotheweighingsystem.

Theonboardrelaysaremanagedasalarmrelays,thereforetheyarealwayskeptenergizedandarede‐energizedin

caseofalarm.

2.2.1 Management of the calibration

T060Eforeseestheset‐upofatheoreticalcalibration.However,theoperatorcanexecutepotentialcorrectionsduring

thecalibrationphase.Theadvantageofthistypeofset‐upliesinthefactthatthesystemcarriesoutanautomatic

calibration,byknowingthecells’characteristics.

Thesystemisnotvalidincaseofloadcellsnotsupportingdirectlytheentireweightappliedtothesystem(e.g.incase

ofaweighingpinappliedtoaresultantofareturnsystem).Inthiscase,theoperatormustsettheweightvalueused

attheendofthemeasurementchain.

Forexample,incaseofaweighingpinappliedtothefixedcomponentofaliftingsystem,theoperatormustsetthe

valueactuallyliftedbythebridgecrane;forexample,incaseofpinweighing1tonandthecapacityofthebridge

craneconsistingof300tons.Inthiscase,thesignalwillbesetaccordingtothepin’sdatasheetandthecapacitywill

besetto300(correspondingto300tonsofthesystem'scapacity),whilethesensitivitywillbesetaccordingtothe

accuraciesidentifiedintheapplicationofthesystem(forexample,ifitweights200kg,thesensitivitymustbesetto

0.2).

Theresolution(divisionvalue)issettotheresultofthe60000divisions.Higherset‐upsarediscardedbythesystem.

Thesystem’sresolutionisgivenbytheratiobetweencapacityandresolution.

Asystemwitha100Kgcellandaresolutionof0.01isasystemconsistingof10000divisions.

SE G N 1

T060Eforeseesloadcellswithmaximumsignalof3.5mV/V.

PO R T 1

Thevaluesetinthisparameterconstitutesthefullscaleoftheweighingsystem.Itforeseesamaximumvalueof

100000divisions.

SE N S 1

Thevaluecanbeselectedwithintherangefrom50to0.001divisions.

Thechangeofbothsystemcapacityandloadcellsignal(mV/V)causetheclearanceofcalibrationdata

(linearizationsincluded)alreadycarriedout,ofsetpointsvaluesandtheanalogoutputdata.

1710‐PT060PNERev.0Page9of57

2.2.2 Sum value function

TheT060Eithedoublechannelweighingversion(Doption)foreseesthepossibilitytohandlethesumvalueofthetwo

channels.Thevaluecanbedisplayedbothpushingandinassociationwithoneormorethresholdrelays

alarms(seechapter2.5).Incaseofsystemswithcapacityordifferentunitmeasure,theoperatormusrealignthe

valuetothesameunitmeasure,decidingwhichofthetwochannelsmustbetakenasreferencechannel.

I.E.:

Channel1F.S.10.00tandchannel21000kfF.S.consideringchannel1asreferencechannel(parameterPRIOR),we

shouldreturnthechannel2toadisplayint.

InordertogetthistheT060EwithparameterMULTIPallowsdividingormultiplyingthechannelvalue.

Inourexampledividingby1000thechannel2valueisdisplayedasforchannel1int.

Accordingtodifferentsystemscapacities,multiplyingordividing,itispossibletosumvalueswiththesamemeasure

unit.

2.2.3 Management of the zero

Theexternalinputscanbeusedtoresetpotentialzeroderivativesordeviationsrelativetotheweighingsystem.The

AZMlimitisvalidinbothways,thereforetheactualfieldis‐100.0%.+100.0%.

Theinputisactiveontheclosingpanel.

Weightresettingiscarriedoutafterconversionandlinearizationoperationswhicharenotinfluenced,causinga

verticaltranslationofthetransmitter’sresponsecurve.

Zeroingaffectsalltransmitters’functions:display,serialtransmission,analogueoutputandthresholdmanagement

arealllinkedtothecorrectweightvalue.

Theresetvalueislostiftheequipmentisturnedoff.

Thenon‐resettotalweightvaluecanbecheckedlocallybypressingkeyDEC:bykeepingthiskeypressed,the

instrumentdisplaysthetotalweightvalue.

1710‐PT060PNERev.0Page10of57

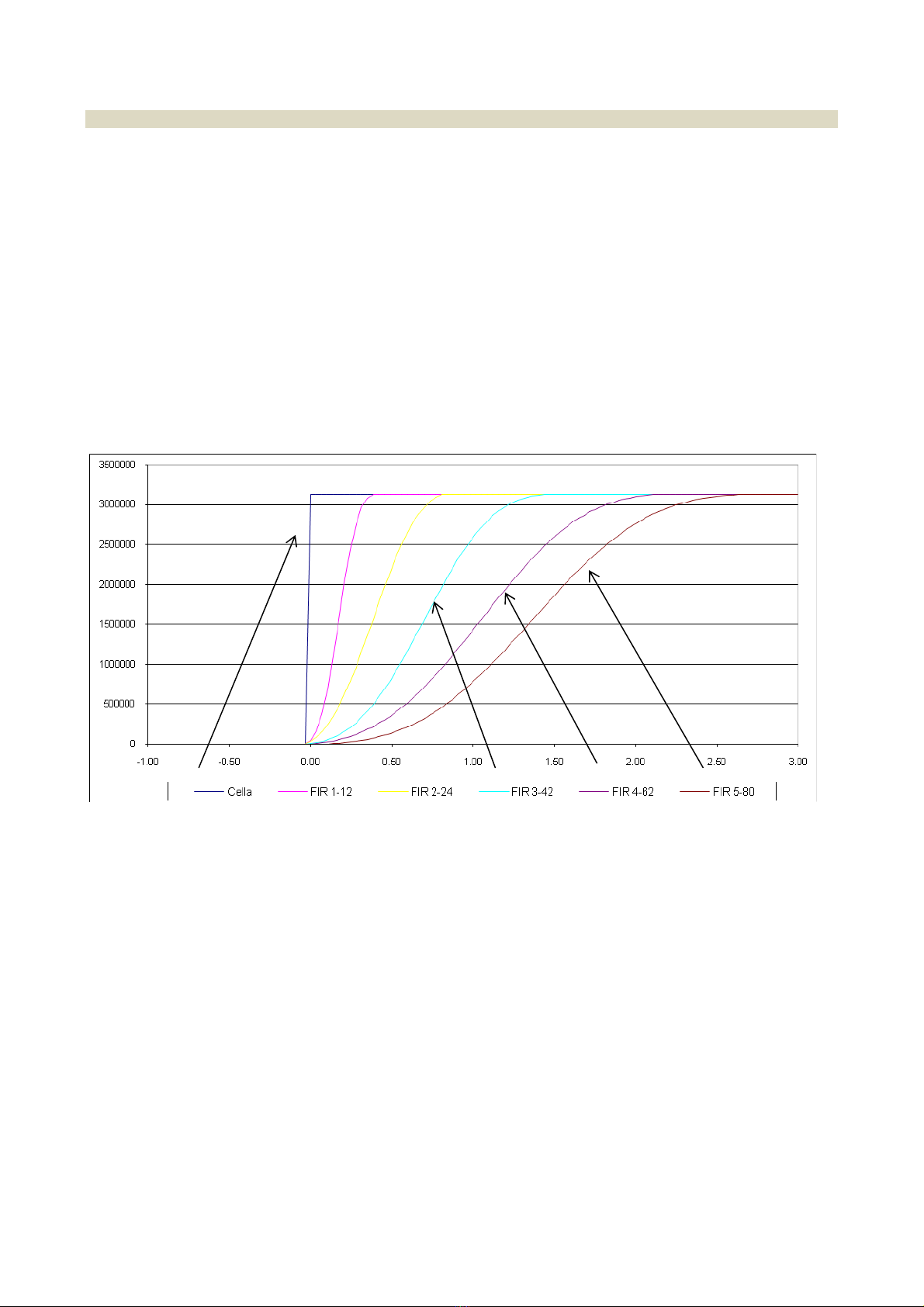

2.2.4 Signal filtering

Theinstrumentallowsintroducingfilteringmethodsofthesignalcomingfromloadcells(FIRfilters).Thismethodis

basedonDigitalSignalProcessing(DSP)modesandallowshandlingatbest,signalscontainingstrongharmonic

components(e.g.generatedbymixers).

Duringtheconfigurationphase,itispossibletoselectthreetypicalfilters(withmovingaverage)and5DSPfilters.

Theformerallowquickerresponsetimesbutarelesseffectivewithregardstointerferences,thereforetheymustbe

usedwhenextremelyquickweightvariationsmustbedetected.

Thelatterallowmitigatinginterferences(sincetheyboastahigherfilteringeffect)atthedisadvantageoftheresponse

timetoweightvariations.

Inbothcases,thehigheristhefilter’snumber,thegreateristhefilteringeffectandtheresponsetimetoaweight

variation.

Forexample,theresponsetoastepweightvariationisshowninthechartbelow,basedontheselectedfilter.

ThechartshowsthatfilterFIR1boastsaresponsetimeofapprox.0.2seconds,whilefilterFIR5boastsaresponse

timeofapprox.2.5seconds.

1710‐PT060PNERev.0Page11of57

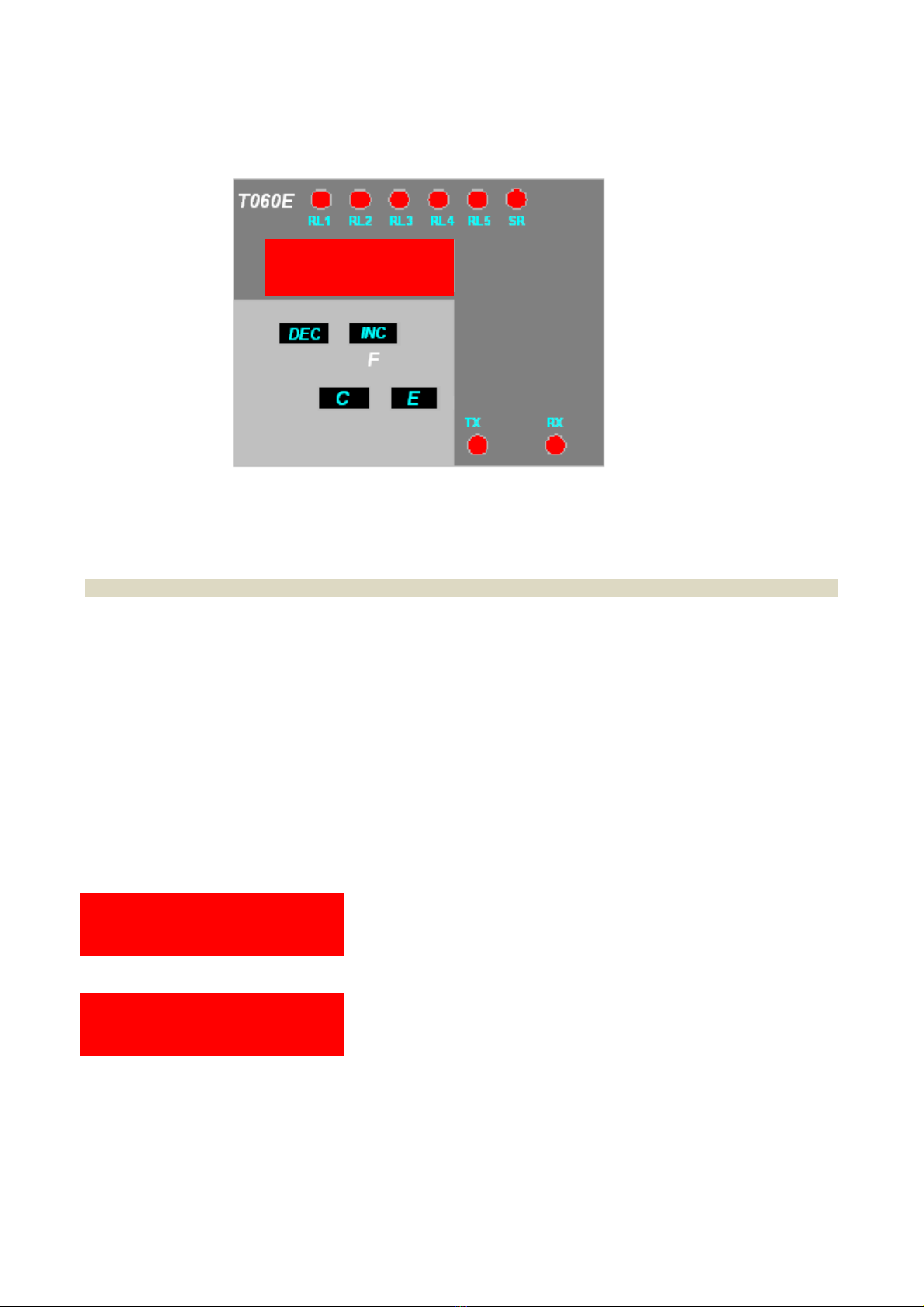

2.3 Front panel

2.3.1 Display

Innormaloperatingconditions,thedisplayindicatestheweightvaluesaccordingtothefollowingcriteria:

theirrelevantinitialzerosarenotdisplayed

the“minus”sign(incaseofnegativeweightvalues)isdisplayedinthefirstleftdigit

Ifthenegativeweightvalueisofsixdigits(e.g.‐324210),thefirstleftdigitwillindicatethe“minus”signandthe

weightvalue,alternatively.

Ifthenegativeweightvalueisofsevendigits,thelesssignificantfivedigitsaredisplayedandthemessagestarts

flashinginordertoindicatethepresenceofanon‐visibleinitial“1”.Thefirstleftdigitwillindicatethe“minus”

signandtheweightvalue,alternatively.

Theweightindicationlimitsare:

Lowerlimit:‐20%offullscale

upperlimit:120%offullscale

Iftheweightislowerthanthelowerlimit,thefollowingindicationisdisplayed:

- - U L - -

Iftheweightisgreaterthantheupperlimit,thefollowingindicationisdisplayed:

- - O L - -

2 1 0 0 0 0

1710‐PT060PNERev.0Page12of57

2.3.2 LED signals

ThemeaningofthemessagesprovidedbythesignalLEDSlocatedontheinstrument’sfrontpanelisthefollowing:

RL1÷RL5TheLEDisonduetothetriggeringoftherelativethreshold

SRTheLEDisontonotifythetriggeringofthesafetysignal

TXTheLEDflashestosignalthetransmissionactivityofserialport1.

RXTheLEDflashestosignalthereceivingactivityofserialport1.

2.3.3 Key functions

Iftheinstrumentisinoperatingmode,itallowscommutingthereading(iftheinstrumentforesees

theoptionalsecondchannel)todisplaytheweightvalueofthesecondchannelortotalvalue

(channel1+channel2).

Iftheinstrumentisinconfigurationmode,itallowsbrowsingforwardthemenuitemsand

increasingtheparameters’value.

Iftheinstrumentisinoperatingmodeandtheweightwaszeroed,thedisplaywillindicatethe

valuebypressingthiskey(fortheselectedchannel).

Iftheinstrumentisinconfigurationmode,itallowsbrowsingbackwardthemenuitemsand

decreasingtheparameters’value.

Iftheinstrumentisinoperatingmode,itallowsenteringinconfigurationmode.

Iftheinstrumentisinconfigurationmode,thekeywillconfirmtheselectionsmade.

Iftheinstrumentisinoperatingmode,ithasnofunction.

Iftheinstrumentisinconfigurationmode,thiskeywillcanceltheselectionsmade.

2.4 Self-troubleshooting

2.4.1 Cell connection fault (FAIL)

Theinstrumentconstantlychecksthecorrectconnectionoftheloadcell(interruptionandshort‐circuitofthesignal

andpowersupplyconnections)and,incaseananomalyisdetected,aFAILinternalsignalisgenerated.

ByprogrammingoneormorerelaysasFAIL,inadditiontothemessageappearingonthedisplay,allchannel’srelays

areforcedinalarmstatus(theyarede‐energized).Forexample,byprogrammingFAIL1,allrelayssetwithalarm

thresholdsonchannel1and/orthetotal,areforcedinalarmstatus.

1710‐PT060PNERev.0Page13of57

2.5 Management of relays

Thebasicinstrumentisequippedwithfiverelaysthatcanbeconfiguredasrequired.

Agenerallyopencontact(NA)notundervoltageisavailableforeachrelay.

Therelays’operationislinkedtotheconditionsdefinedintheconfigurationphase.

Therelays’commutationtakesplacewhenthethresholdvaluesetintheconfigurationphase(SET#parameter)is

reachedandremainsinthisconditionforatimeframeequaltoorexceedingthealarmminimumtime(DAL#

parameter).Itisrestoredinnormalconditionswhentheweightvalueisdroppedbelowthevaluedeterminedbythe

sumofthethresholdvalueandtheconfiguredhysteresisvalue(DB#parameter)andremainsinthisconditionfora

timeframeequaltoorexceedingtheminimumnormaltime(DOH#parameter).

Thechangeoftherelayoperationcausetheclearanceofsetpointsvalues.

Eachrelaycanbeconfiguredtooperateinoneofthefollowingmodes:

F A I L 1 Loadcellconnectionfault(FAIL).Thealarmstatusistriggered

whentheFAILconditionispresent.

L O N 1 Minimumalarm(LON)

Thealarmstatusistriggeredwhentheweightvalueislower

thanorequaltothethresholdvalue.

H I N 1 Maximumalarm(HIN)

Thealarmstatusistriggeredwhentheweightvalueisgreater

thanorequaltothethresholdvalue.

L O G 1

Minimumalarm(LOG).Thealarmistriggered,regardlessof

theresetvalue.

Thealarmstatusistriggeredwhentheweightvalueislower

thanorequaltothethresholdvalue.

H I G 1

Maximumalarm(HIG).Thealarmistriggered,regardlessof

theresetvalue.

Thealarmstatusistriggeredwhentheweightvalueislower

thanorequaltothethresholdvalue.

T O T N Alarmonthetotalvalueofthetwochannels(TOTG).The

alarmstatusistriggeredwhentheweightvalueisgreater

thanorequaltothethresholdvalue.

T O T G

Alarmonthetotalvalueofthetwochannels(TOTG).The

alarmistriggered,regardlessoftheresetvalue.

Thealarmstatusistriggeredwhentheweightvalueisgreater

thanorequaltothethresholdvalue.

O N Therelayiskeptconstantlyenergized.

1710‐PT060PNERev.0Page14of57

3. INSTALLATION

3.1 Receiving the material

Beforesigningthetransportdocument,makesuretherearenodamagestotheequipmentcausedduringtransport

andifso,notifythecarrier.

Inadditiontotheinstrument,thefollowingmustbepresent:

1seriesoffemaleflyingterminalsforconnectingthepowersupplyandinputandoutputsignals

1copyoftheinstructionmanual

1copyoftheinstrument’stestingreport(checkthattheserialnumberappearingintherelativelabel

correspondstotheserialnumberindicatedonthetestingsheet).

INPUT100‐240V~

10W50/60Hz

MODELT060E1

S.N.20160234

Eachdevicefeaturestherequiredinformationforproperidentification:modelandserialnumber.

Thisdata,togetherwiththesoftwareversion,mustbeindicatedwhenrequestinginformation.

3.2 Assembling the instrument

WARNING

Makesurethatthesupplyvoltagefallswithintheinstrument’sallowedlimits.

Makesurethatitispossibletodisconnectpowerduringinstallationand/ormaintenancephases.

Performagroundconnectionifrequired.

Itisrecommendedtouseashieldedcableforcell’sinputsignals,analogueoutputsandseriallines.

Usetroughsforcell’sinputsignals,analogueoutputsandseriallines,whichareseparatefromthoseofpowersignals.

Connectthepanelonwhichtheinstrumentisinstalledtotheground.

Theinstrument’soutputrelaysmustbeusedtocontroltherelays’coils(whichnominalcurrentmustfallwithin

declaredlimitsandanyhow,usingsuitablearcsuppressiondevices),logicinputsorsignalLEDS;theymustnotcontrol

powersignals.

1710‐PT060PNERev.0Page15of57

3.3 Connections

Allinstrument’sconnectionsarecarriedoutonthesideoftheinstrument.

3.4 Rear panel

Alabelcontainingscreen‐printedindicationstofacilitatetheoperatorincarryingoutcablingoperationsisaffixedon

thesidesoftheinstrumentnearterminals.

SIDE B

SIDE A

3.5 Power supply tag

Beforeconnectingtheequipmenttoapowersource,makesurethattheselectedvalueonthelabelcorrespondsto

theforeseenvoltage.Iftheforeseenvaluesdiffersfromthevoltageindicatedonthetag,donotconnectthe

equipmentandcontactexclusivelyacompany’sassistancecentretochangetheversionifneeded.

1710‐PT060PNERev.0Page16of57

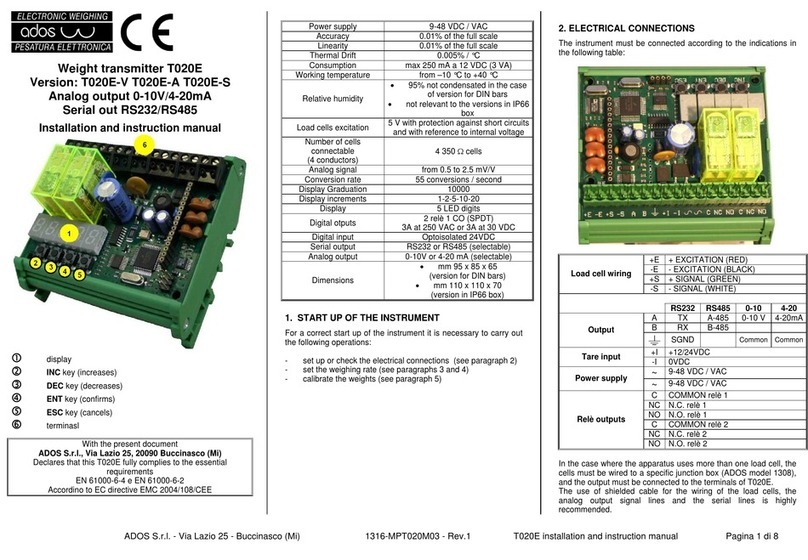

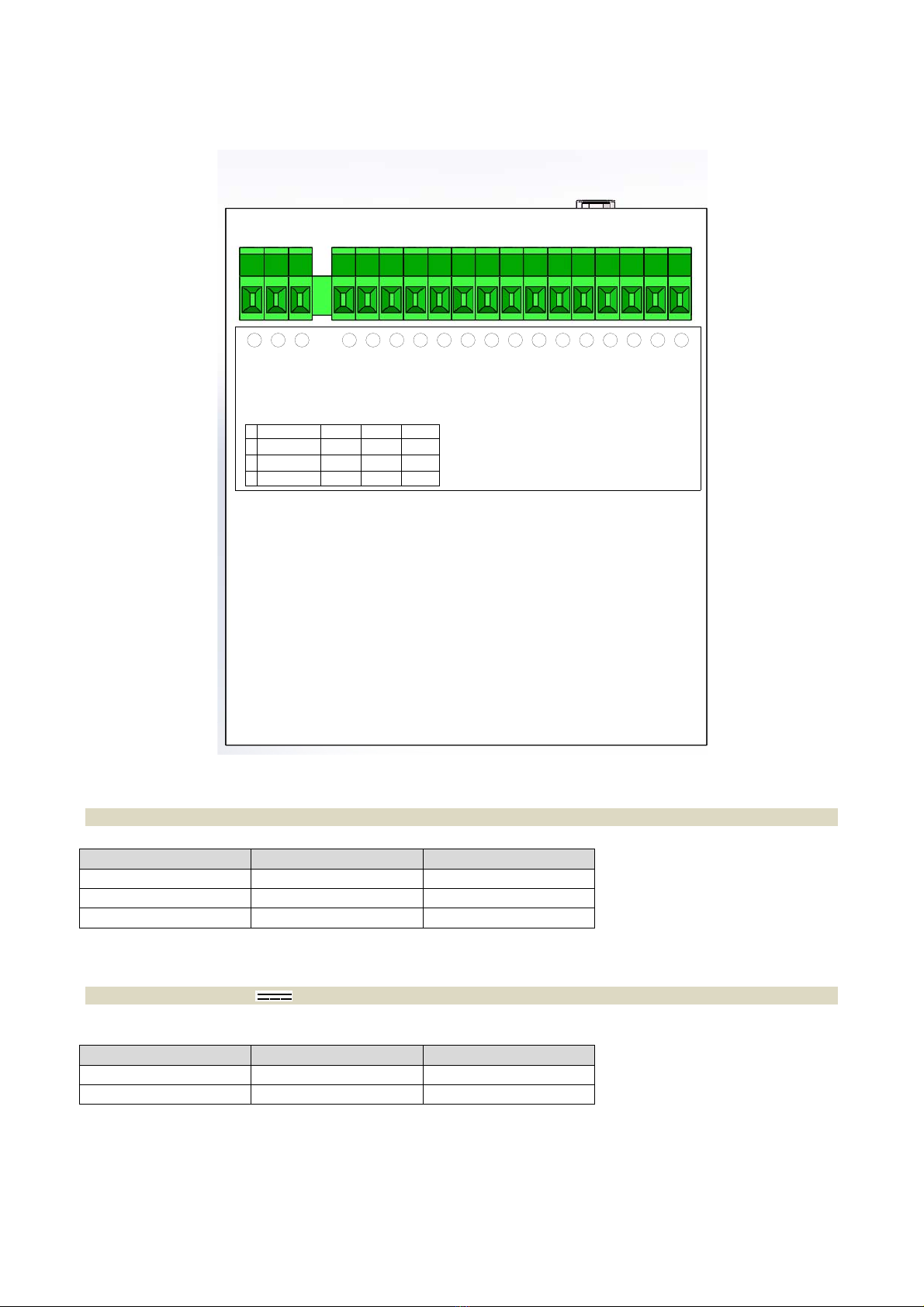

3.6 Connection to power supply (side B)

3.6.1 Version 110÷230V~ 24-48V~

INDICATIONFUNCTIONTERMINAL

NNeutral2

LLine1

EGround3

Connecttheinstrument’ssafetygroundterminaltothesystem’sgroundbarthroughflexiblecable.

3.6.2 Version 12÷24V

INDICATIONFUNCTIONTERMINAL

++12÷241

‐02

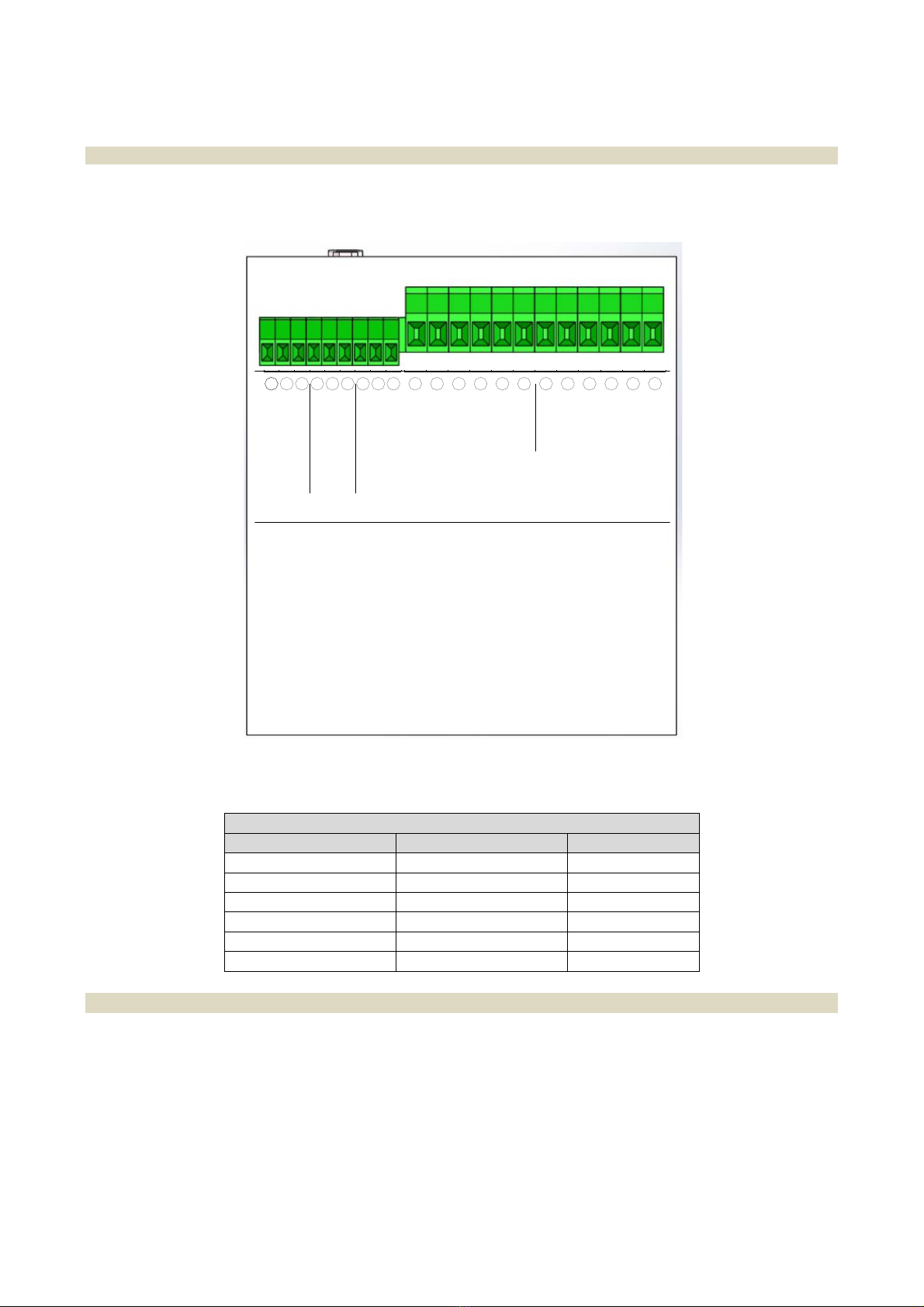

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

OUT 1

OUT 4

OUT 2

OUT 1

OUT 2

OUT 4

OUT 3

OUT 3

G SAFETY OUT

V SAFETY OUT

OUT 5

OUT 5

INP 2

INP 1

C INP

100-240VAC

124VAC 48VAC

LL

NN

EE

2

3

24VDC

-

+L

E

N

1710‐PT060PNERev.0Page17of57

3.7 Connection of load cells (side A)

Thecablecomingfromtheloadcellsorjunctionboxmustbeconnectedtotheterminalslocatedontherearofthe

instrumentandcalledLOADCELL1.

Connectionbetweentheloadcellandtheinstrumentmustbecarriedoutwithashieldedcable.Thecable’sshield

mustbeconnectedtotheground.

Connectionmusttakeplacerespectingthecolourcodeindicatedontheloadcells.

T060foreseesthestandardconnectionof6‐wireloadcells.Incaseofconnectionof4‐wireloadcells,connectthe

referencewirestotherelativepolaritiesofthepowersupplycables.

MAKESURETHECONNECTIONCABLEBETWEENLOADCELLSANDINSTRUMENTISDUCTEDINTROUGHSSEPARATE

FROMTHOSEOFPOWERLINES,INORDERTOAVOIDCOUPLINGTHATMAYPREJUDICETHEMEASUREMENT

ACCURACY.

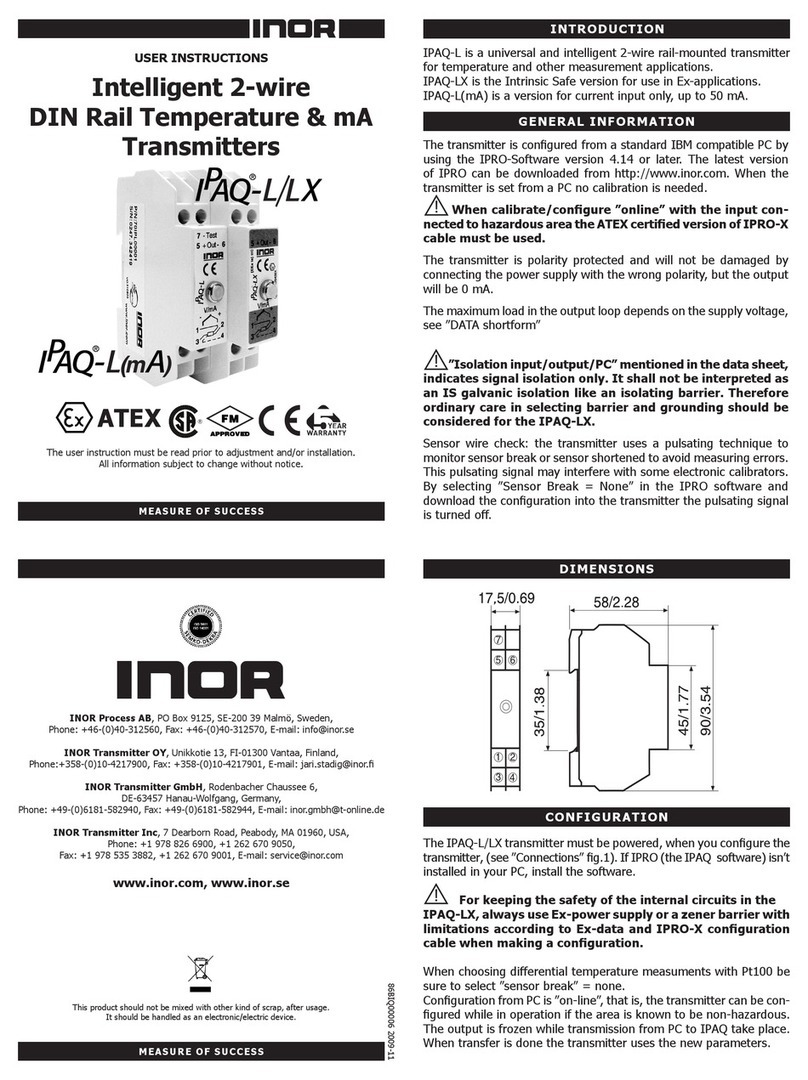

3.7.1 Connection of load cells 1

LC1

INDICATIONFUNCTION TERMINAL

+A+Excitation 39

‐A‐Excitation 38

+S+Signal37

‐S‐Signal 36

+R+Reference 35

‐R‐Reference 34

3128 29 30

-S

+R

-R

3432 33

+S

3635 37

-A

+A

3938

-R

+R

-S

+S

-A

+A

LOAD CELL 2 LOAD CELL 1

232019 2221 2524 2726

SGND 3

IOUT+

VOUT+

SGND 2

-RS485

+RS485

SGND 1

-RS485/RX

+RS485/TX

SERIAL

OUT 1

SERIAL

OUT 2

ANALOG

OUTPUT

OPTO OPTO

1710‐PT060PNERev.0Page18of57

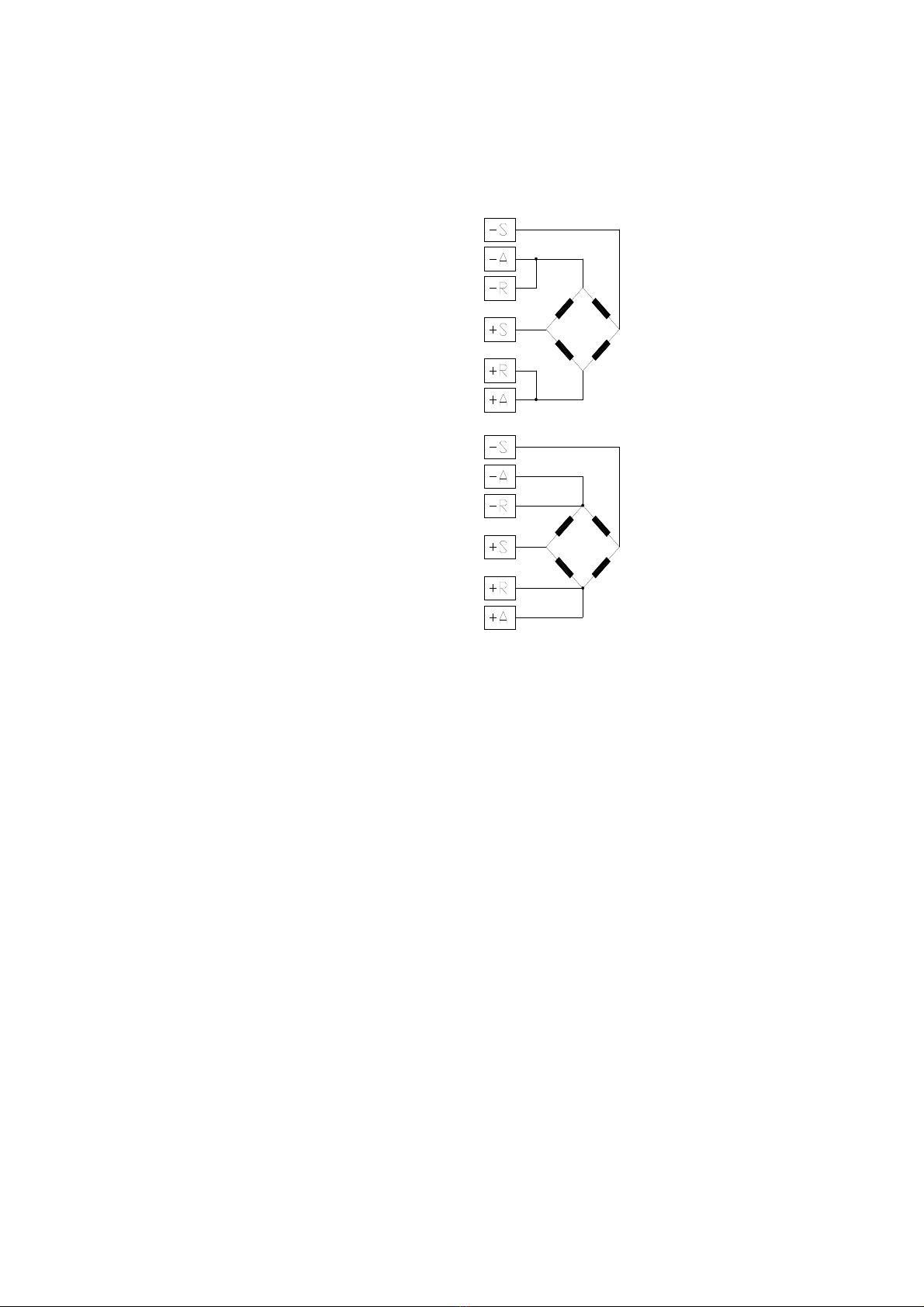

Incaseof4‐wireconnection,short‐circuittheterminals–Excitationwith‐Referenceand+Excitationwith+

Reference.

CONNECTIONWITH4‐WIRELOADCELLS

CONNECTIONWITH6‐WIRELOADCELLS

1710‐PT060PNERev.0Page19of57

3.7.2 Connection of load cells 2 input

T060Eforeseesanoptionalsecondloadcellsinput.Theconsiderationsmadeforthemainchannelalsoapplyforthe

optionalinputchannel.

LC2

INDICATIONFUNCTION TERMINAL

+A+Excitation 33

‐A‐Excitation 32

+S+Signal 31

‐S‐Signal 30

+R+Reference 29

‐R‐Reference 28

3128 29 30

-S

+R

-R

3432 33

+S

3635 37

-A

+A

3938

-R

+R

-S

+S

-A

+A

LOAD CELL 2 LOAD CELL 1

232019 2221 2524 2726

SGND 3

IOUT+

VOUT+

SGND 2

-RS485

+RS485

SGND 1

-RS485/RX

+RS485/TX

SERIAL

OUT 1

SERIAL

OUT 2

ANALOG

OUTPUT

OPTO OPTO

1710‐PT060PNERev.0Page20of57

3.7.3 Wiring example (single weighing system)

Inthecaseofplantconsistsofasingleweighingsystemwithoneormorecellsconnectedinparallelthewiringmust

bemadeonchannel1(seediagramasanexample)

Exampleofasystemconsistingofasingleweighingsystemwithonlytwoloadcellsinparallel

Table of contents

Other Ados Transmitter manuals

Popular Transmitter manuals by other brands

Dwyer Instruments

Dwyer Instruments Series CDTV Specifications-installation and operating instructions

diagral

diagral TT385 Installation and user guide

ASCOM

ASCOM TELECARE WP - BROCHURE 1 brochure

Dwyer Instruments

Dwyer Instruments 629 Series Installation and operating instructions

Acromag

Acromag TT339-0700 user manual

Erone

Erone 028A S2TR2681E2 manual

Worldcast Systems

Worldcast Systems ECRESO FM 750W quick start guide

Sony

Sony WRT-808A Service manual

Honeywell

Honeywell Satellite XT Guide to operations

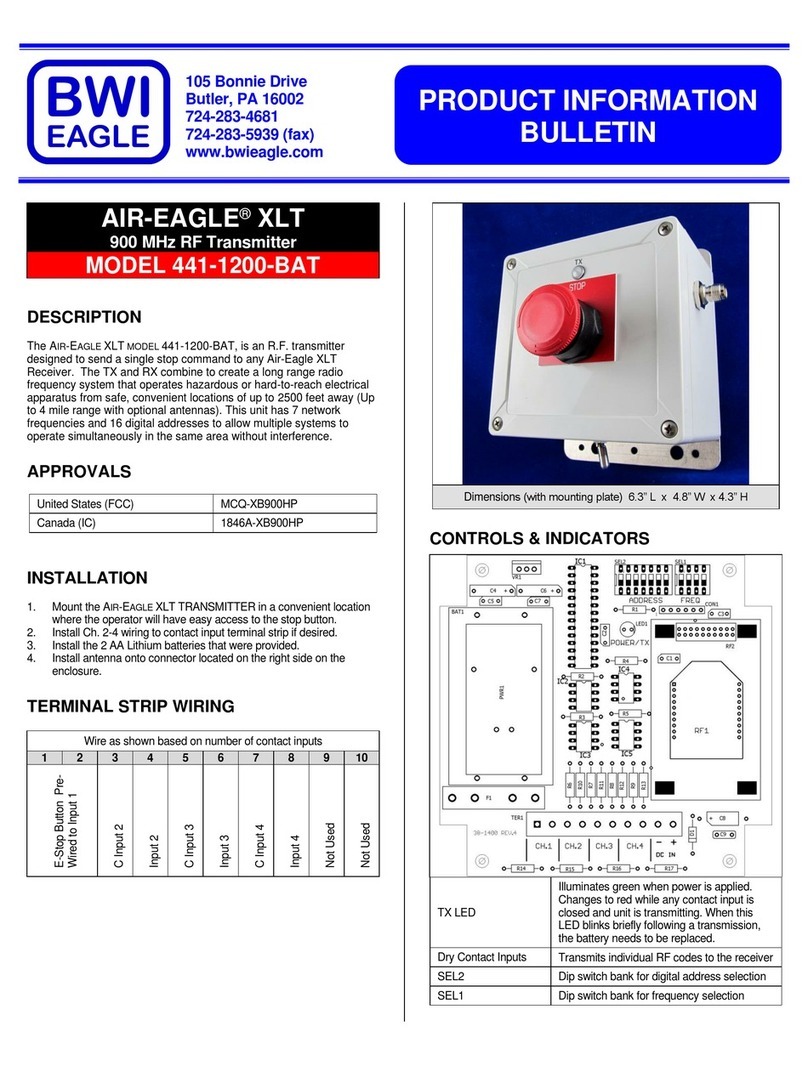

BWI Eagle

BWI Eagle AIR-EAGLE XLT manual

Ascon tecnologic

Ascon tecnologic ATT1 Engineering manual

BWI Eagle

BWI Eagle AIR-EAGLE XLT Product information bulletin