A-3Section 61246045L1-5, Issue 261246045L1-5B

The unit can detect the loopback activation or

deactivation code sequence only if an error rate of

E-03 or better is present.

NOTE:

In all control code sequences presented, the

in-band codes are shown leftmost bit

transmitted first, and the ESF data link

codes with rightmost bit transmitted first.

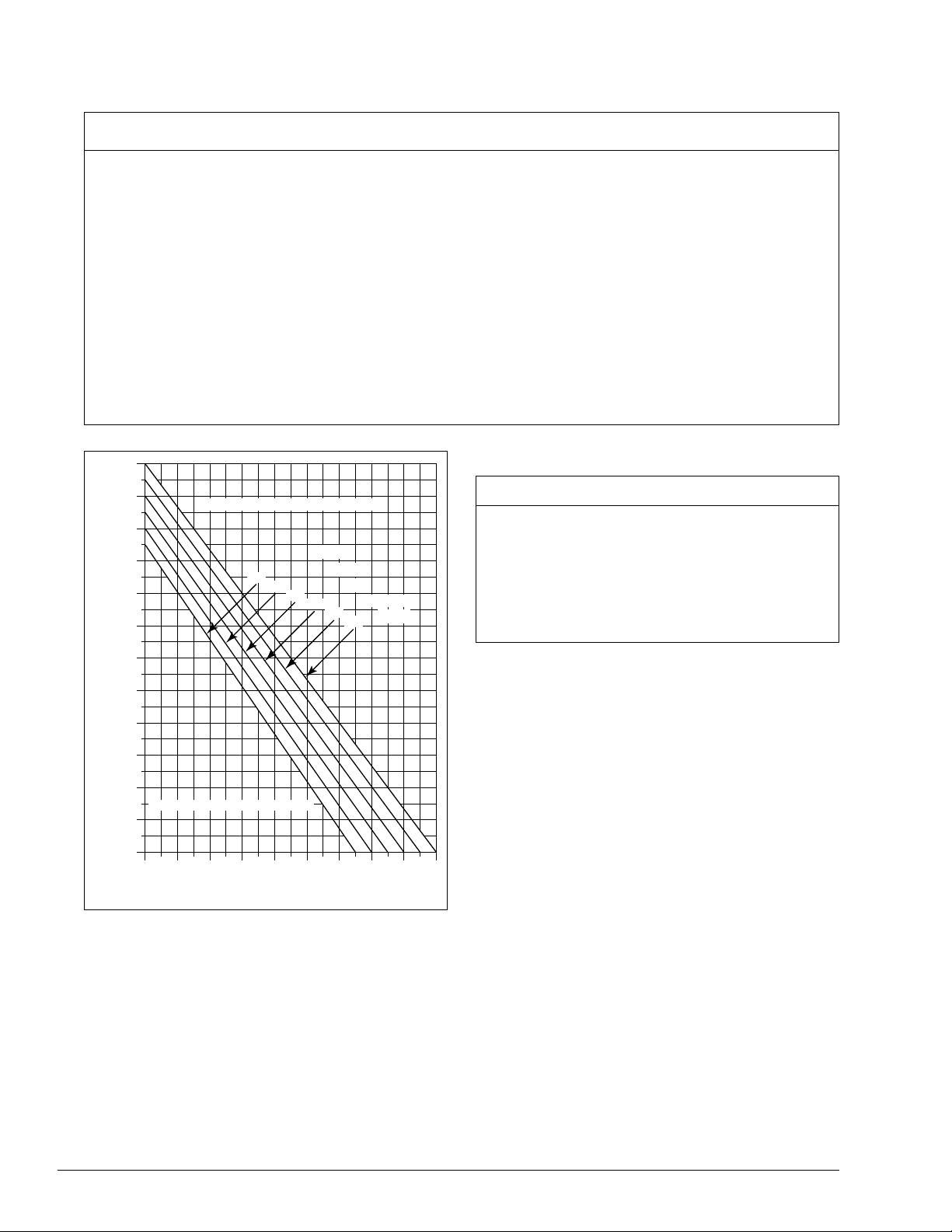

Disarmed State

The disarmed state is the normal mode of operation.

Each HDSL element is transparent to the data flow.

However, the in-band data flow and the ESF data

link are monitored for the arming sequence.

The in-band control code sequence used to

simultaneously arm the loopback capability of all

HDSL elements is the standard 5-bit in-band

sequence used for NIU Smartjack loop-up. Each

HDSL element arms after receiving the following

code for five seconds:

Arm Sequence

11000

The arming process ensures unambiguous race-free

operation of HDSL element arming and Smartjack

loop-up. The HDSL unit can detect the sequence

without interfering with the detection by the

Smartjack. Presently, the Smartjack loop-up

response requires a duration of at least five seconds.

The objective of the HDSL detection scheme is to

arm the HDSL elements without interfering with the

Smartjack loop-up.

The requirement imposed on the arm sequence is

that the Smartjack should loop-up and all HDSL

elements make a transition from the disarmed state

into the armed state. All other control code

sequences are ignored in the disarmed state.

The ESF data link sequence used to simultaneously

arm the loopback capability of all HDSL elements is

the standard 6-bit ESF data link sequence used for

NIU Smartjack loop-up.

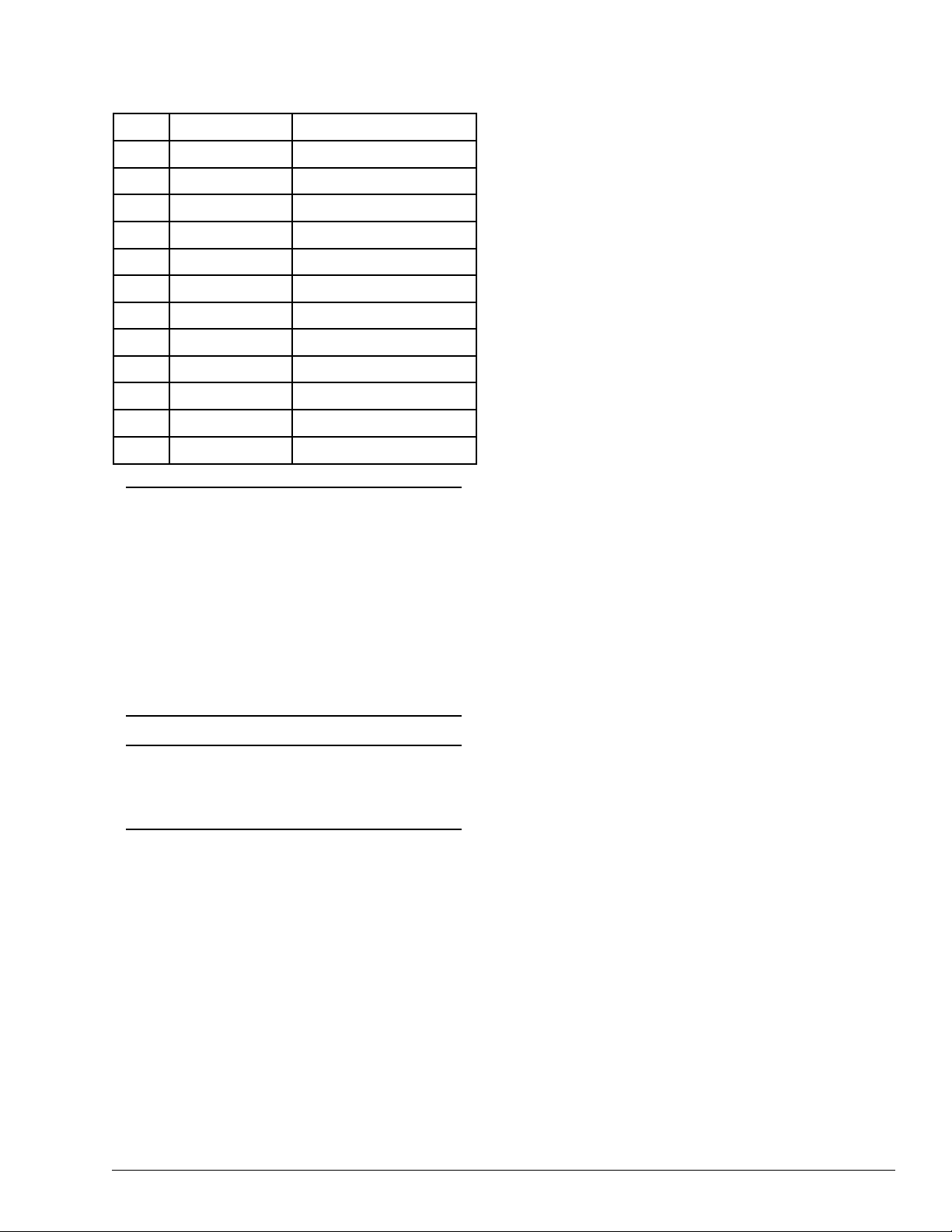

Table A-1. HDSL Standard Loopback Control Codes

Name

Arming (In-band) ...............................

Arming (ESF) .....................................

Activation (HTU-C) ..........................

Activation (HRE # ) ..........................

Activation (HRE #2) ..........................

Activation (HTU-R) ...........................

Deactivation (all HDSL elements) ....

Disarming (In-band) ..........................

Disarming (ESF) ................................

Arming Timeout .................................

Loop-up Timeout ...............................

Dete tion Time

5 Seconds

4 Repetitions

> 4 Seconds

> 4 Seconds

> 4 Seconds

> 4 Seconds

>5 Seconds

5 Seconds

4 Repetitions

2 Hours

Programmable from HTU-C:

None, 20, 60, or 20 minutes

Code

000 ...............................

000 00 0 .....

0 00 0 00 .....

00 0 0 00 000 .....

00 0 0 0 0 00

00 0 0 00 00 0 .....

00 00 00 00 .....

00 ...............................

00 0 0 00 .....

N/A ..................................

N/A ..................................

Comments

Signal sent in-band or over ESF

data link. HDSL elements in

disarmed state make transition to

armed state. Detection of either

code results in Smartjack loop-up,

if NIU loopback is enabled.

Signal sent in-band. HDSL

elements in armed state make

transition to loop-up state.

Loop-up state timeout is

programmable from the HTU-C.

Signal sent in-band. HDSL

element in loop-up state makes

transition to armed state.

Signal sent in-band or over ESF

data link. HDSL elements in any

state make transition.

HDSL elements in armed state

make transition to disarmed state.

HDSL element in loop-up makes

transition to armed state.