ADVANCE Easy Moving VACU MATIC FREE Quick setup guide

12

ASSEMBLY, USE AND

MAINTENANCE MANUAL

Fuel extraction system

VACU MATIC FREE

3

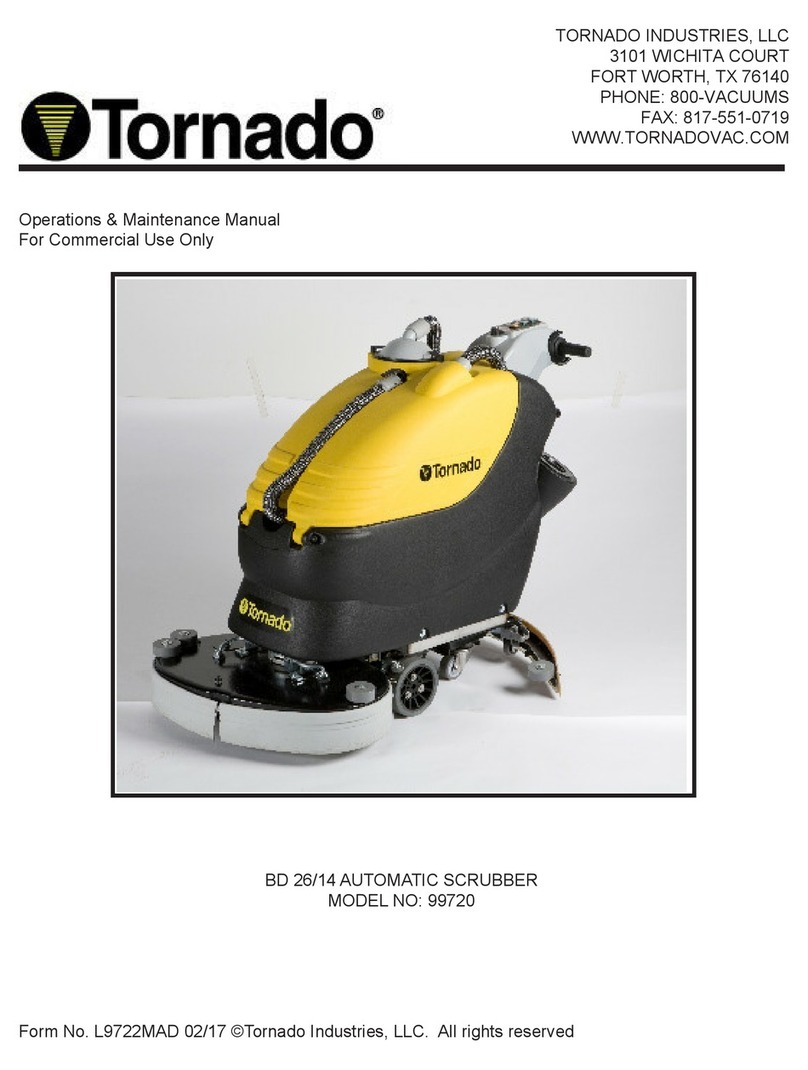

• Type: fuel extraction system

• Model: Vacu Matic Free

• Revision 1.0.5

FUEL

EXTRACTION SYSTEM

INSTRUCTION MANUAL

18/07/22 Rev:1.0.5

1 INTRODUCTION 4

1.1 Use of this manual 4

2 WARNINGS 4

3 TECHNICAL DATA, EXPLODED VIEW DRAWINGS AND DIMENSIONS 5

3.1 Identification plate 6

3.2 Safety symbols 6

4 PACKAGING CONTENT 7

5 PROPER USE OF THE PRODUCT 7

5.1 Caratteristiche del magazzino di stoccaggio 8

6 INSTALLATION 8

6.1 Instruction for the installation of systems 8

6.2 Positioning 9

6.3 Connection to the piping network 10

6.4 Electrical connection 11

7 START UP 12

7.1 Switching on and use 12

8 MAINTENANCE AND END-OF-LIFE 13

8.1 Spare parts 13

8.2 End-of-life 13

9 SAFETY REQUIREMENTS FOR FUEL STORAGE TANKS 14

10 WARRANTY 15

11 CERTIFICATION 16

INDEX

Suction case with motorized nozzle

4

18/07/22 Rev:1.0.5

1 INTRODUCTION

Dear customer,

the manufacturer would firstly like to thank you for the choice you made in buying an product, whose

technical features will certainly meet Your needs.

Our products have been designed and manufactured in total compliance with the current regulations, by

choosing the best materials to obtain durability and ease of use of the product.

We ask you, therefore, to read this manual carefully and completely, following strictly the instructions

contained herein.

1.1 Use of this manual

The instruction manual is a document drawn up by the manufacturer and is part of the product: it

integrates the specific rules of application and general rules for people, animals and objects safety. In the

event that the product is resold, handed over, rented or sold to others, it must always be accompanied

by this manual; therefore, it is recommended to use and keep it with care for the entire operative life of

the product.

The main objective of this manual is to make known the proper and safe way to use the equipment.

No part of this manual may be reproduced, copied, or shared in any way, without the written permission

of the manufacturer.

The manufacturer reserves the right to make improvements or modifications to this manual

and to the equipment at any time, without obligation to advise third parties.

2 WARNINGS

• Do not use the machine for any improper use.

• Do not let children near the machine.

• This unit must not be used by people (including children) with reduced physical, sensory or mental

capabilities, or with lack of experience and knowledge, unless they are supervised or instructed in the

use of the unit by a person responsible for their safety.

• Use only original spare parts.

• Do not put parts of the body into contact with the machine before having removed the electrical power.

• Disconnect the power supply when a long period of inactivity is expected.

The manufacturer declines any liability or guarantee, if the buyer or anyone

makes changes or even minor modifications to the purchased product.

5

English

18/07/22 Rev:1.0.5

3 TECHNICAL DATA, EXPLODED VIEW DRAWNGS AND DIMENSIONS

Article

AP3400.00.09

IP ProtecƟon degree IP 40

OperaƟng temperature min/max

°C 0 ÷ 40

Degree of humidity min/max % 30 ÷ 95

Power supply V ac 230

Frequency Hz 50

Motor power W 15

Max absorpƟon A 0,14

Fuse 5x20 T2A

InsulaƟon class 1

RevoluƟons per minute rpm 12

Rated torque Nm 5

Weight

Kg 3,1

Measurement A mm 185

Measurement B mm 108

Measurement C mm 235

Measurement D mm 226

Measurement E mm 261

Measurement F mm 125

Measurement H mm 245

Measurement L mm 80

Measurement R Ømm 6

Measurement S Ømm 50 M

Gearmotor

Frame

Flow regulator

Electronic board

Crankcase

Rod-crank

mechanism

6

5

1

3

2

4

A

B

C

D

E

S

F

H

L

R

F

Suction case with motorized nozzle

6

18/07/22 Rev:1.0.5

....................................

.........................................................................

Model:

P/N: S/N:

Type of equipment Manufacturer identification

CE Mark of

conformity

Technical data of the equipment

Serial number

Item number

3.1 Identification plate

Do not remove or damage the identification plate.

It is recommended to pay full attention to pictograms and warnings of danger and prohibition in the

present different parts of the equipment: if not respected, hazardous situations may occur.

DANGER OF VOLTAGE OR ELECTRICAL CURRENT

Danger of serious personal injuries.

During maintenance operations, always disconnect the power supply and make sure

that it cannot be restored.

DANGER OF CUTTING

Danger of serious personal injuries.

During maintenance operations, always disconnect the power supply and make sure

that it cannot be restored.

DANGER OF AUTOMATIC STARTING

Danger of serious personal injuries.

During maintenance operations, always disconnect the power supply and make sure

that it cannot be restored.

DANGER FOR THE HAND WHEN THE SCREW CONVEYOR IS IN OPERATION

Danger of serious personal injuries.

During maintenance operations, always disconnect the power supply and make sure

that it cannot be restored.

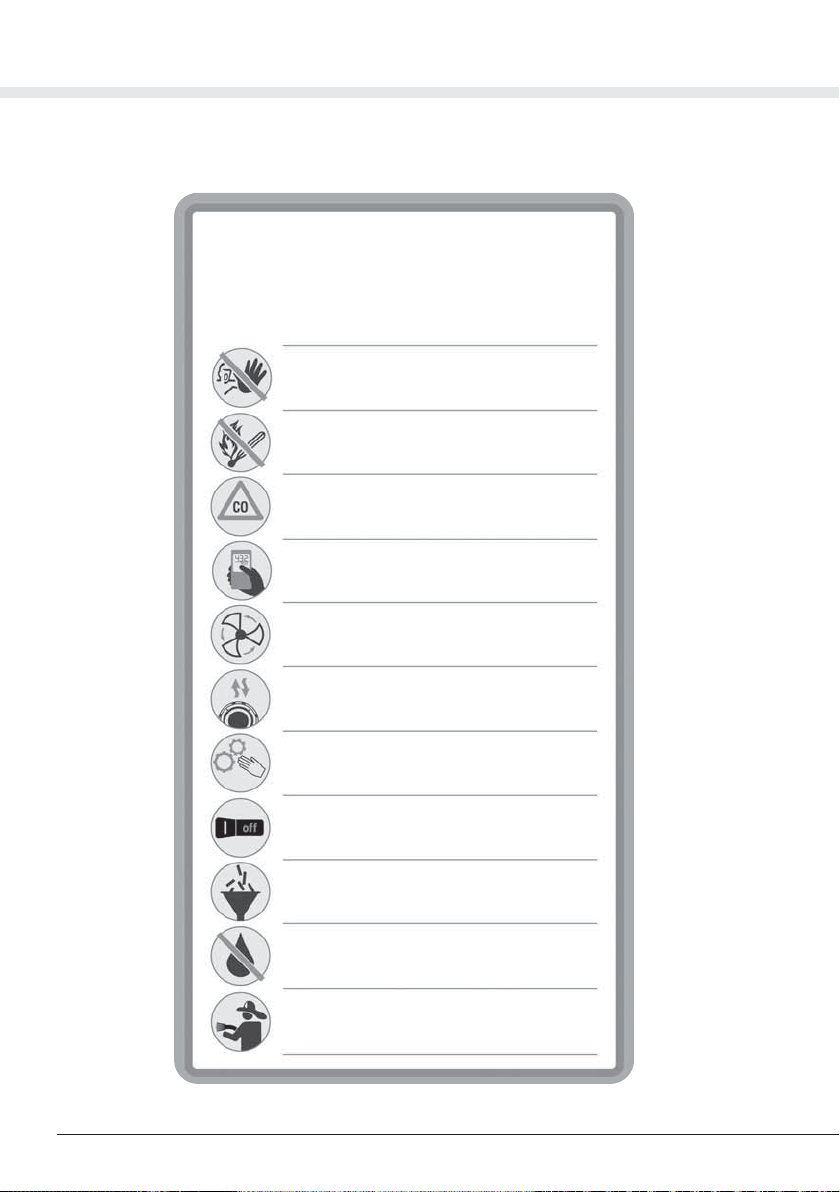

3.2 Safety symbols

7

English

18/07/22 Rev:1.0.5

Check that the product corresponds to the one ordered and that no transportation damage is

evident.

Should this not be the case, please contact immediately the seller.

5 PROPER USE OF THE PRODUCT

The suction caser has been designed to be installed for the pneumatic transport of pellets or other

biomass fuels with a medium-fine size;

it has the task of extracting the fuel from the bottom of any hopper tank.

This product is suitable for the extraction of biomass fuel such as pellets, olive pomace,

wood chips, crushed shells of dried fruit, corn, but it cannot work with fuels having a very

fine size, or having excessive dimensions and, in any case, having lengths over 40 mm or

diameter greater than 15 mm.

It is recommended to use only ENplus A1 certified pellet.

To provide the job for which it was designed, the suction case must be connected to a control

panelcalledthatcontrolstheoperationoftheentirepneumatictransportsystemortoanintegrated

central vacuum unit called.

Once installed and connected, the suction case extracts the fuel until the tank is completely

empty; by the movement of the rod-crank mechanism positioned in front of the suction inlet, a

possible blockage or clogging of the inlet itself because of slag or irregular dimensions fuel is

avoided.

4 PACKAGING CONTENT

After opening the packaging, verify that the material contained in it conforms to the following list:

1) Extraction system

2) Assembly, use and maintenance manual

3) Flow regulator

4) gum sleeves + 2 hose clamps

5) Warranty form

2

3

4

Manuale Tecnico

1

5

Suction case with motorized nozzle

8

18/07/22 Rev:1.0.5

5.1 Characteristics of the storage tank

The application of the suction case must be made at the lowest point of the hopper part of the tank.

Tanks can be constructed in any form, size, and material.

The hopper walls must be all connected at the point where the case is installed, so the warehouse will

be able to be completely empty.

Please remember that for a good sliding of solid fuels, the hopper walls of the tank must have a tilt of

about 45°.

It is always necessary to place a shutter between the tank and the suction case which, when closed,

separates the fuel in the tank from the suction case in order to facilitate inspections, maintenance and

repairs on internal movements.

The suction case can also be installed in small collection tanks that receive fuel from large tanks

already equipped with automatic emptying screw conveyors: in this case the suction case can work in

conjunction with them.

6 INSTALLATION

It is the installer’s responsibility to verify the presence of any risk of danger in the installation

area and to determine the suitability in accordance with both the applicable laws and the product

characteristics described in this manual.

The installer must also comply with the requirements of this manual as well as inform the user of the

operation and maintenance of the installed products and report any dangers related to their use.

It is necessary to leave a free space of adequate size all around the product, in order to permit any

repair, maintenance or inspection operation.

The product should not be exposed to atmospheric agents and should not be installed in areas subject

to high humidity, possible flooding, high temperatures and dust presence.

6.1 Instructions for the installation of systems

Consider that in pneumatic fuel transport systems there are two different types of pipe features:

A sections of pipes where only air and eventually dust pass through

B- sections of pipes where both air and fuel pass through

Mandatory all sections of piping through which the fuel passes must be made with PU or steel pipe and they

must be connected to be antistatic.

We remind you that the lengths of the various pipe sections described in our manuals and catalogs are purely

indicative: when we speak of “available length” we mean the total development of the various sections.

It is always advisable to make mainly straight and horizontal piping sections and, in any case, with the least

number of changes of direction and vertical paths.

For all the sections where fuel passes, it is recommended to follow these simple rules:

the maximum length allowed for the various sections of piping depends on the components chosen for your

system:

1- the maximum permissible length of the various pipe sections is always bound by the components chosen

for your system, the characteristics and technical data provided for each component must always be evalua-

ted in advance so that the system works at its best and has the required characteristics.

2- in two-pipe systems (fuel suction and air return to the silo) the limits on the lengths are generally much

lower and never exceed 10 meters. With some products pipe lenght cannot be more than 3 meters.

3- in single-pipe systems, the maximum length allowed for the various sections of pipe, despite being limited

9

English

18/07/22 Rev:1.0.5

6.2 Positioning

The suction case should be fastened to the wall of the tank with easily removable screws, through

the holes already available on the frame, taking care to ensure that the protection is positioned above

the rod-crank mechanism.

It is necessary to leave a free space of adequate size all around the machine, in order to permit any

repair, maintenance or inspection operation.

Remember that to remove the protection crankcase it is necessary to remove the suction case from

its seat. Therefore, in order to avoid the outgo of the fuel from the tank, a shutter that can be closed

from the outside of the tank must be installed.

For this purpose our shutter module can be useful.

by the components chosen for your system, is more generous, but even in these cases it is neces-

sary to evaluate in advance the characteristics and technical data provided for each component

installed.

4- paths with many curves or with very close curves should always be avoided.

5- the minimum radius of the curves must be equal to or greater than 0.5 meters.

6- sections of pipes that include both positive and negative siphons must be avoided.

7- the sections of horizontal pipes must be kept perfectly leveled.

8- vertical pipe sections longer than 3.5 meters must always be avoided and at the bases of these

the minimum radius of the bends must be equal to or greater than 1 meter

9- the sections of piping where fuel passes must be well fixed at least every 1.5 meters.

10- the pipe sections may be built-in or installed under flooring, but only for very short linear traces

and only by inserting them into an additional casing pipe of properly larger diameter.

It is recommended to use only pipes, fittings and accessories present in our catalog, as they have

been designed, tested and built specifically for these systems.

Before installation and start-up of the system, it is essential to carefully read the instructions sup-

plied with the various components and in case of doubts it is advisable to contact specialized

personnel.

The realization of the systems and the installation of the components must always meet the

safety standards corresponding to the type of rooms in which they are positioned.

Suction case with motorized nozzle

10

18/07/22 Rev:1.0.5

6.3 Connection to the piping network

CAUTION

To transport fuel, use only antistatic pipes that are correctly connected to a grounding point, in order

to avoid dangerous accumulation of static electricity.

To connect the suction case extraction system to the installation, use always a section of antistatic flexible

hose; do not glue the system pipes directly to the suction case outlet.

Mount the flow regulator (fluidifier) between the vacuum case outlet and the flexible hose of the fuel transport

system (see fig. 1)

Fix the fluidifier on the vacuum case using the joint sleeve 1 and two metal clamps, keeping the ventilation

cuts facing upwards.

On the other side, position the flexible hose of the fuel transport system and fix it with an additional clamp.

Switch on the system and adjust the amount of fuel transported, so that it is not such as to cause blockages

in the system.

To procede with this adjustment, close or open the ventilation cuts by forward or backward the regulation

sleeve (see fig. 2). By closing the cuts the amount of fuel transported will increase; vice versa keeping them

more open the quantity will decrease.

An excessive amount of fuel sucked in a unit of time will reduce transport times, but could lead to blockages

and obstructions in specific points of the system; vice versa, reducing the fuel transported in the unit of time

could bring to an unnecessary prolungation of the time required to transport the fuel.

For example, systems with a long pipes extension or with a high number of elbows, will involve less fuel

transported for the same amount of time.

It may be necessary, after the first start settings, a new adjustment in the case, for example, in which the

temperature, relative humidity or the physical characteristics of the transported fuel (type, specific weight,

dimensions, etc ...) change

Fig. 2

1 - Junction sleeve

3 - System piping

2 - Flow regulator

4 - Hose clamps

Fig. 1

11

English

18/07/22 Rev:1.0.5

3

1

0

OFF

OFF

ON

6.4 Electrical Connection

Before making the electrical connection, check that the supply voltage corresponds to

the one required and that the electrical system to which the product is connected is

done in compliance with current regulations.

Connect the two wires of the activation line called AUX to the correspondingAUX cable of the

integrated vacuum unit (if present) or to the corresponding terminals called AUX located inside

the control panel (if present).

Connect the power cord to a 230 V ac power outlet.

In the event of a protection circuit breaker intervention during the operation of the suction case,

the polarity of the plug must be inverted (invert phase with neutral).

F0030683

ALARM MICRO

OUT AUX

REED

MICRO

IN TIMER VALVE

SENSOR A SENSOR B

- + PNP NPN - + PNP NPN

POT

RELAY

SWITCHING

AC/DC

FUSE

RELAY

RELAY

L

N

F0030683

ALARM MICRO

OUT AUX

REED

MICRO

IN TIMER VALVE

SENSOR A SENSOR B

- + PNP NPN - + PNP NPN

POT

RELAY

SWITCHING

AC/DC

FUSE

RELAY

RELAY

L

N

F0030683

ALARM MICRO

OUT AUX

REED

MICRO

IN

VALV E

SENSOR A SENSOR B

- + PNP NPN - + PNP NPN

L

N

REED

MICRO

IN

SENSOR A SENSOR B

- + PNP NPN - + PNP NPN

L

N

F003068

3

ALAR

M

MICR

O

OU

T

AU

X

VA

LV

E

AUX

AUX

AUX

Connection to the control panel Connection to

integrated vacuum unit

230 V ac

23

0

V

230 V

2

3

0

V

230 V

Suction case with motorized nozzle

12

18/07/22 Rev:1.0.5

7 START UP

The operation of the suction case is managed by the fuel transport control system, which can be found in

the integrated vacuum units or in the control panels; it usually happens with a delay of about 3 seconds

from the start of the system: this to allow the emptying of any remaining fuel traces in the pipes.

Thanks to the rotating system of the rod-crank mechanism, the suction case avoids block formations in

front of the fuel suction inlet, so the fuel can be continuously aspirated.

7.1 Switching on and use

Before putting the suction case into service and filling the storage tank make sure that:

-the tubes are correctly and securely fixed

-electrical connections have been carried out according to law, as well as the electrical system to which it

is connected

-the rod-crank system operates regularly

-there are no foreign bodies in the storage tank.

For the first time, just place a small amount of fuel in the storage tank and test the system.

Place the flexible hose on the flow regulator so that it covers about half of the aeration cuts, during the phas-

es of operation will then be necessary to evaluate and adjust consequently the amount of fuel transported,

changing the position of the flexible hose going to cover more or less the aeration cuts of the flow regulator.

The more uncovered the aeration cuts, the less fuel will be transported and vice versa. The quantity of fuel

transported must be such as to prevent it from accumulating excessively in the transport hose and its fittings.

After reading also the manuals of all the components of the system, you can start using the fuel transport

system by following the adjustment steps described in integrated vacuum units or control panel manual.

Drive Nova 3

13

English

18/07/22 Rev:1.0.5

8 MAINTENANCE AND END-OF-LIFE

Before carrying out any maintenance operation, it is obligatory to disconnect the power

supply cable from the main socket and to aerate the premises in which it is installed for

at least 15 minutes. Complex or long maintenance operations must be done out of fuel

storage and heating unit premises.

Any maintenance and repair operation must be carried out by experienced personnel

and authorized by the manufacturer.

On the front of the crankcase there is the housing of the electrical parts protection fuse: to

replace it, unscrew the cap and remove the old fuse replacing it with a mod. 5x20 T2A

In the absence of a specific maintenance plan, a complete product inspection is recommended

for each filling of the storage tank or at least yearly .

The checks to be carried out at least yearly are:

- Check the antistatic pipe grounding conditions and the electrical system conditions

- Check the electrical wiring condition

- Verify the flow regulator conditions

- check that the rod-crank system is free to rotate and devoid of foreign objects

- open the plastic crankcase and remove any traces of dust inside

It is also advisable to thoroughly clean the fuel storage tank at least annually, in order to avoid

dust accumulation and presence of foreign bodies.

8.1 Spare parts

To guarantee longevity and optimum performance of the product, it is recommended to use only

original spare parts.

8.2 End-of-life

The disposal of packaging, accessories and machine must be executed in accordance with

applicable laws, ensuring the recycling of any of the core components.

Fuse

SPARE PART DESCRIPTION

Gear motor 15 W

Electronic board (plastic frame)

Covering carter

Suction case with motorized nozzle

14

18/07/22 Rev:1.0.5

9 SAFETY REQUIREMENTS FOR FUEL STORAGE TANKS

SAFETY REQUIREMENTS

for pellet storage tanks

with capacity up to 10 t

Keep the doors closed. Access is permitted only

to authorized personnel under the supervision of a

person outside

Do not smoke and approach flames or other sources

of ignition.

Danger of death due to high concentrations of carbon

monoxide (CO) and lack of oxygen.

In the 4 weeks after the fuel filling, enter only with a

CO detector.

Aerate the storage room for at least 15 minutes

before entering and keep the door open during your

permanence.

Ensure an adequate and permanent aeration of the

storage room through vent covers, openings or fans.

Wounding risk for moving systems

Turn off the boiler at least one hour before the pellet

is delivered.

Proceed to the filling according to the requirements of

the boiler manufacturer and the pellet supplier.

Protect pellets from humidity

In case of fire suspect keep the front door and any

other opening of the storage room close and call the

firemen.

15

English

18/07/22 Rev:1.0.5

10 WARRANTY

PRODUCT LIMITED WARRANTY CONDITIONS

The Manufacturer guarantees to the original purchaser the absence of defects in material and

workmanship of the product for the period stated, from the date of purchase. Except as prohibited

by applicable law, this warranty is non transferable and it is limited to the

original purchaser. The present warranty gives the buyer specific legal rights and the possibility

to claim rights which can vary under local laws.

Read all warnings and instructions before using the product purchased.

The entire liability of the manufacturer and your exclusive remedy for any breach of warranty will

be at the discretion of the Manufacturer:

(1) To repair or replace the product, or (2) refund the purchase price, provided that the product

has been returned to the point of purchase, or such other place as may be specified by the

manufacturer, with a copy of the sales receipt or detailed and dated receipt. The shipping and

handling are not free of charge, except in cases where this is prohibited by applicable law.

To repair and replace the product, the manufacturer may, at their own discretion, use new,

refurbished or used parts in good working condition. Any replacement product will be warranted

for the remaining time of the original warranty period, or for any period of time that complies with

the provisions of the current law.

This warranty does not cover problems or damage resulting from (1) accident, abuse,

misapplication, repair, alteration or unauthorized disassembly; (2) maintenance operation, use

which is not in accordance with the product instructions or connection to an improper voltage

supply; or (3) use of consumables and spare parts which are not supplied by the manufacturer

or authorized service center.

Valid warranty claims are generally processed through the point of purchase of the product.

Please agree this detail with the retailer where you purchased the product.

The Warranty claims that cannot be processed through the point of purchase, as well as any

other product related questions, should be addressed directly to the manufacturer. Addresses

and contact information for customer support can be found at the website.

Except as stated by relevant laws in force, any implied warranty or condition of

merchantability or suitability for a particular purpose relating to this product is limited to the

duration of the Limited Warranty period for the specific product purchased.

Some jurisdictions do not allow limitations on the duration of implied warranties or the exclusion

or limitation of incidental or consequential damages, so the above limitation may not apply to you.

This warranty gives you specific legal rights and you may have other rights that vary from state

to state, or from jurisdiction to jurisdiction.

Consumers have legal rights under applicable national legislation governing the sale of

consumer products. Such rights are not affected by the warranties in this Limited Warranty.

No dealer, agent, or employee of the manufacturer is authorized to make any modification,

extension or addition to this warranty.

Suction case with motorized nozzle

16

18/07/22 Rev:1.0.5

11 CERTIFICATION

Declaration of absence of harmful substances

The manufacturer declares that their products and equipment are made with materials compliant

with the current regulations regarding protection of health and the environment and does not

contain substances classified as SVHC (Substance of Very High Concern) in accordance with

Regulation EC 1907/2006 (REACH, or registration, evaluation, authorization and restriction of

chemical substances).

Although in the working cycles of raw materials and our products such substances are not

used, their presence in the size of p.p.m. (parts per million) cannot be excluded due to micro-

pollution of raw materials.

EC declaration of conformity

The Manufacturer declares that its products and equipment comply with the following standards:

EN ISO 12100:2010 (Risk Assessment Calculator)

EN ISO 14121-1 (Safety of machinery)

And following directives:

N° 2006-42-CE

N° 2014/35/UE (LVD)

N° 2014/30/UE (EMC)

17

English

18/07/22 Rev:1.0.5

Suction case with motorized nozzle

18

18/07/22 Rev:1.0.5

Table of contents

Popular Scrubber manuals by other brands

Fimap

Fimap MY50 Use and maintenance manual

Bona

Bona Power Scrubber AM400201100 Original instructions

Viper

Viper AS510B user manual

DiamaPro Systems

DiamaPro Systems AS-1000 owner's manual

PowerPoint

PowerPoint P21350XBSS Use and maintenance

Nilfisk-Advance

Nilfisk-Advance 56303004 Mechanical repair service manual

Imac

Imac NGS 1000 Installation, operation & maintenance instructions

Minuteman

Minuteman 260 Series Operation service parts care

Kärcher

Kärcher BD 70 W Classic Bp Original operating instructions

Dustbane

Dustbane Hurricane 450 XTT Guide rapide

Kruger

Kruger KF50E manual

Numatic

Numatic TRO 650/200T Owner's instructions