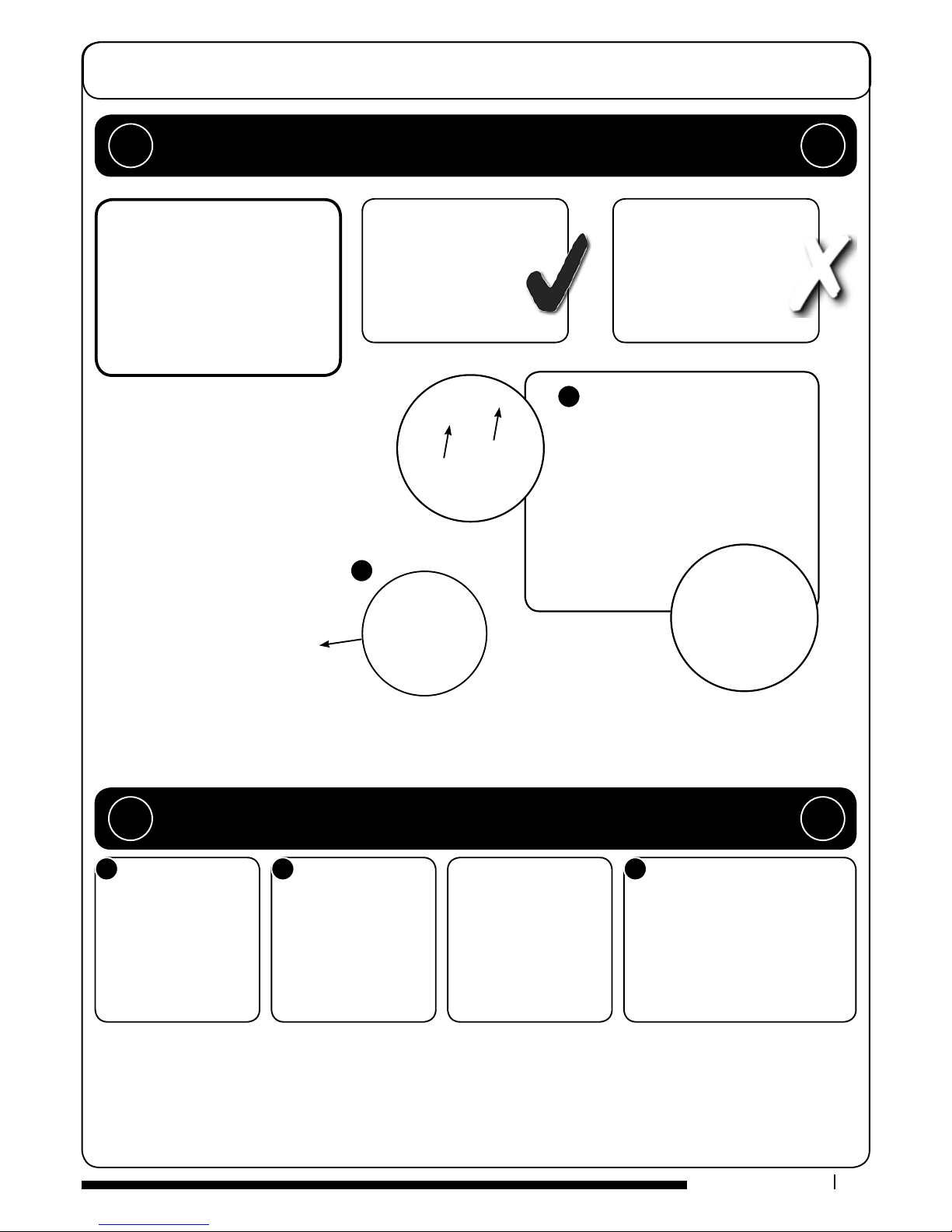

After the removal of

all the packaging,

carefully open and

check the contents

● Owner Manual

● Battery Charging Lead

● Key Switch

● 2 x 40 Amp Fuse

● Maxi Fuse-puller

PLEASE

READ

BEFORE

COMMENCING

OPERATION

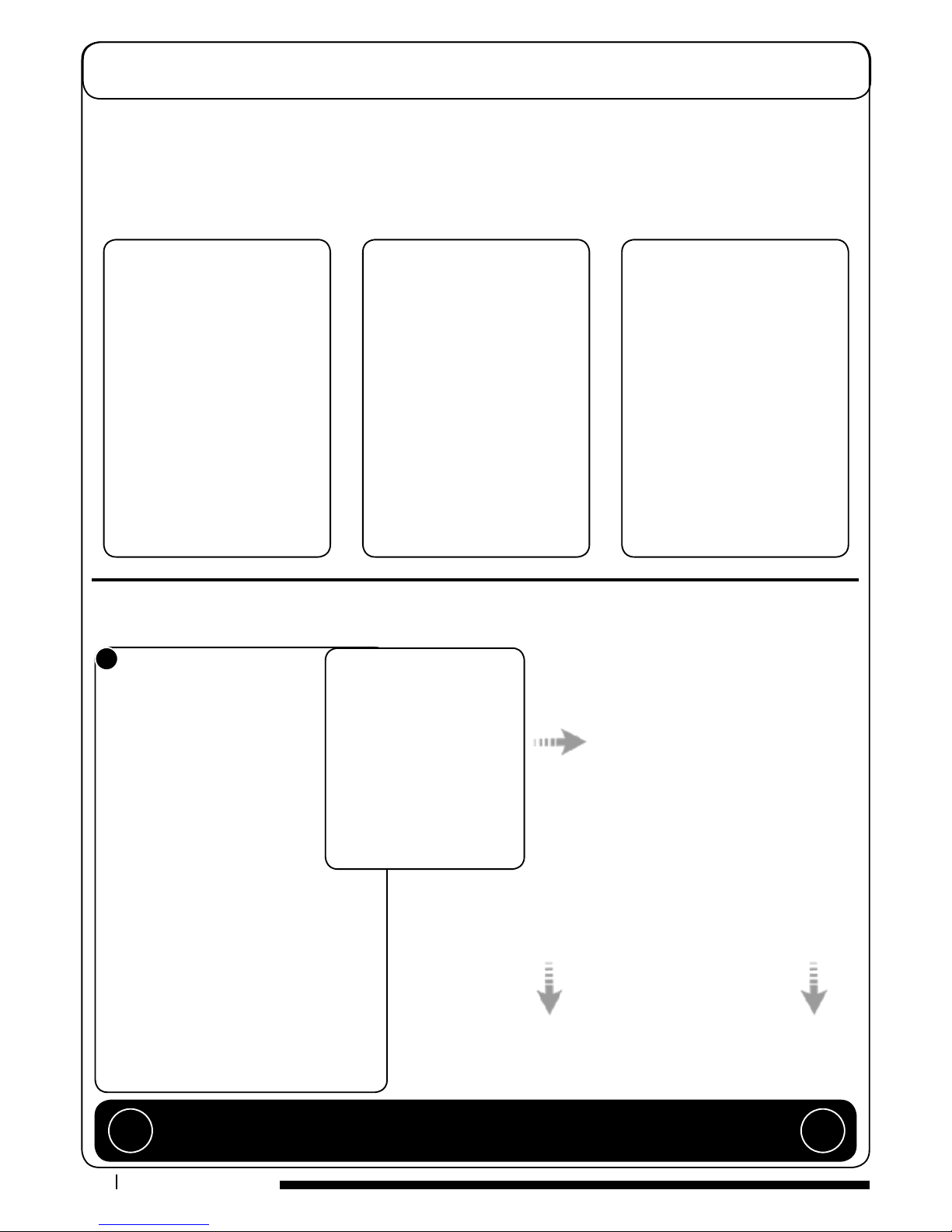

1Operator control panel

2Brush load adjuster knob

3Brush deck release lever

4Brush deck foot pedal

5Clean water tank ll point

6Side pod and skirt

7Brush deck motors x 2

8Side pod release lever

9Floor-tool raise / lower lever

10 Seat adjustment lever

11 Separator release catches

12 40 Amp battery fuses x 2 (4 Battery Machine)

13 Gel batteries

14 Charger

15 Accelerator pedal

16 Clean-water tank emptying hose

17 Semi parabolic oor-tool

18 Vacuum hose

19 Waste-water emptying hose

20 Floor-tool vacuum hose

21 Air separator assembly

22 Pedestrian warning light

23 Water Pump

TRO 650 / 200T

Machine Overview ................................ Pages 2-3

Control Panel Overview ................................ Page 4

Machine Set up Guide ................................ Pages 5-10

Fitting the Floor tool ................................ Page 6

Fitting the Hose ................................ Page 7

Breakaway Floor tool Feature ......................... Page 7

Fitting the brush ................................ Page 8

Filling the Clean Water Tank ............................ Page 8

Maximum Speed Control ................................ Page 9

Emergency Stop Button and Horn ................ Page 9

Adjusting the Seat .............................. Page 9

Raise / Lower Brush Deck ............................. Page 10

Raise / Lower Floor-Tool ................................ Page 10

Setting the Cleaning Controls ......................... Page 11

Fill Level Indicator ................................ Page 11

Brush Pressure Adjustment............................. Page 11

Hi / Lo Vacuum Setting ................................ Page 12

Machine Cleaning ................................ Page 13

Changing Floor tool Blades............................. Page 14

Machine Charging ................................ Page 15

Battery Care ................................ Page 16

Free-Wheel Function ................................ Page 13

Changing Floor tool Blades............................. Page 14

Machine Charging ................................ Page 15

Battery Care ................................ Page 16

Free-Wheel Function ................................ Page 17

O-aisle Cleaning Kit ................................ Page 18

Warning Lights ................................ Pages 19-20

Trouble Shooting ................................ Page 21

Specications ................................ Page 21

Rating Label / Personal Protective Equipment /

Recycling ................................ Page 22

Safety Precautions ................................ Pages 23-24

Recommended Spare Parts .......................... Page 25

Schematic Diagram ................................ Page 25

Battery Wiring ................................ Page 26

EU Declaration Document ............................. Page 27

Warranty ................................ Page 28

Company Address ................................ Page 32