Advanced MIGRO ARAY Instruction Manual

MIGRO ARAY - Instruction Manual &

Datasheet

MIGRO-ARAY

Instruction manual and datasheet

Follow us on IG @advanced_grow_lights #advancedgrowlights

STOP –Please read all these instructions carefully especially the safety section

before unboxing and assembling

Safety

Please read this manual thoroughly before assembling and installing the

MIGRO grow lights system

Please retain this manual for reference for the lifetime for the product

The MIGRO system limits the voltage in the grow room to 96Vdc and has

built in protection for overcurrent, shorts or overheating. However, to

minimise any remaining risk please switch the power off while installing and

adjusting the MIGRO system. If the mains plug needs to be changed to suit

your power socket only a qualified person should carry out this work, in

accordance with your local codes.

The MIGRO system will operate on a supply voltage ranging from 100V to

277V AC and from 50 to 60Hz frequency. Any other supply voltage will

damage the lighting system.

The grow light and the cabling from the LED driver to the grow light is IP66

rated and can be used in a wet area. The mains power plug is not IP rated for

a wet area and should be located in a dry area outside of the grow room. If

the cable insulation or glands are damaged switch off the system

immediately and return to us for repair.

The MIGRO grow light has a highly efficient and passive cooling heatsink. In

order to function correctly air must be able to flow freely across the fins of the

heatsink. Do not cover the grow light and restrict the airflow across the

heatsink under any circumstances. This will result in heat build up which may

damage the grow light and/or cause a fire.

Do not put the grow light down on any surface when the light is on. The light

intensity and radiated heat may damage the surface.

The light intensity from each MIGRO grow light is very high. If you look

directly at the light source from less than 20cm or 9” away the intensity is

equivalent to the sun. To protect your eyes do not look directly at the light

source when less than 60cm or 2 feet away.

Setup instructions

Connect the LED bars together with the connector brackets provided. Centre

the bracket along the length of the LED bar (line it up with the Cable gland)

and screw in place using the allen-wrench provided.

Attach the ratchet hangers to the grow light at the cable splitter splitter.

ARAY 2 & 3

Attach 2 x ratchet hangers to each light fixture

ARAY 4, 8 and 12

Attach the 2 x clips to each cable splitter and attach a single ratchet hanger

to each cable

Hang the LED driver using the S hook or Carabiner clip

Dimmer adjustment - ARAY 2,3,4,8 & 12

Adjust the Light intensity using the dimmer control on the LED driver

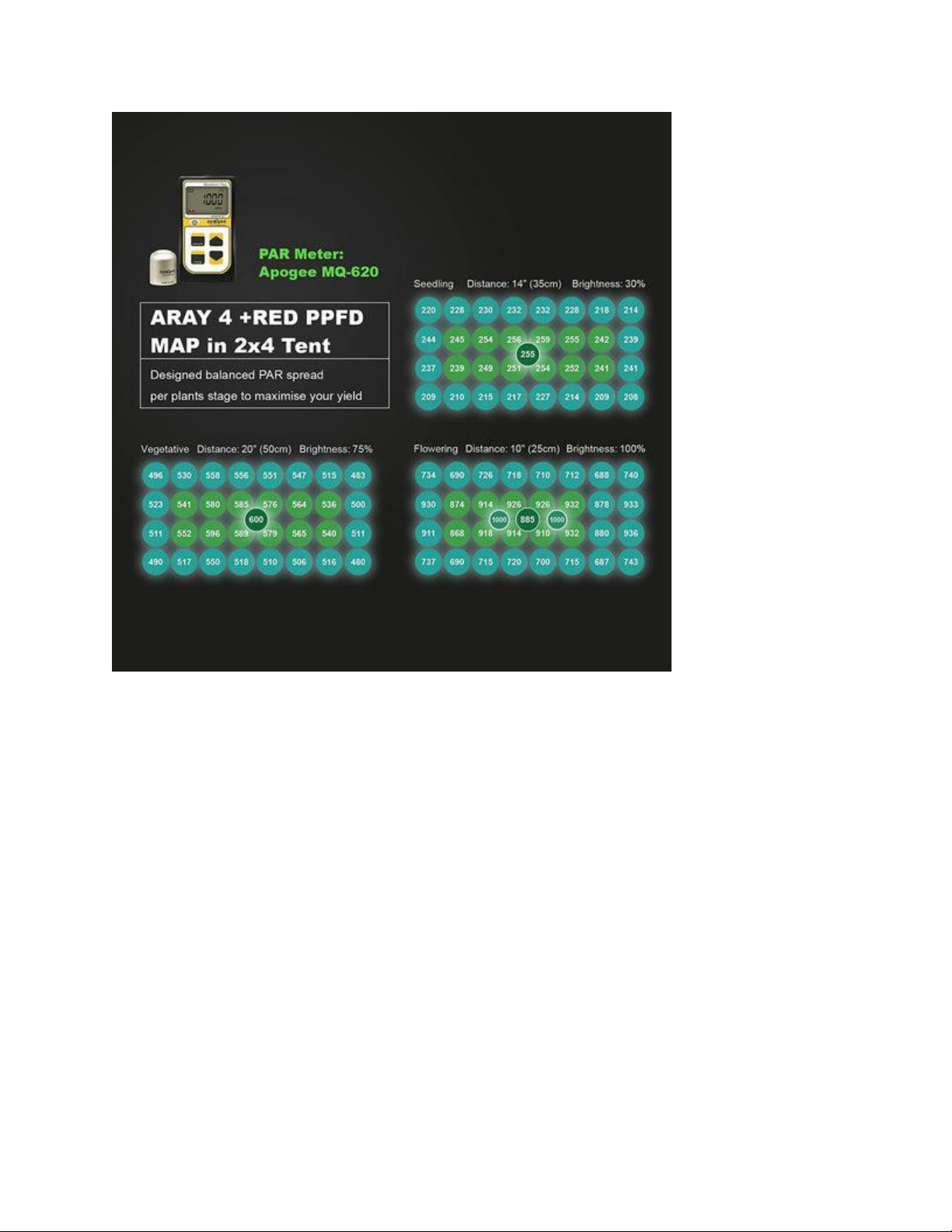

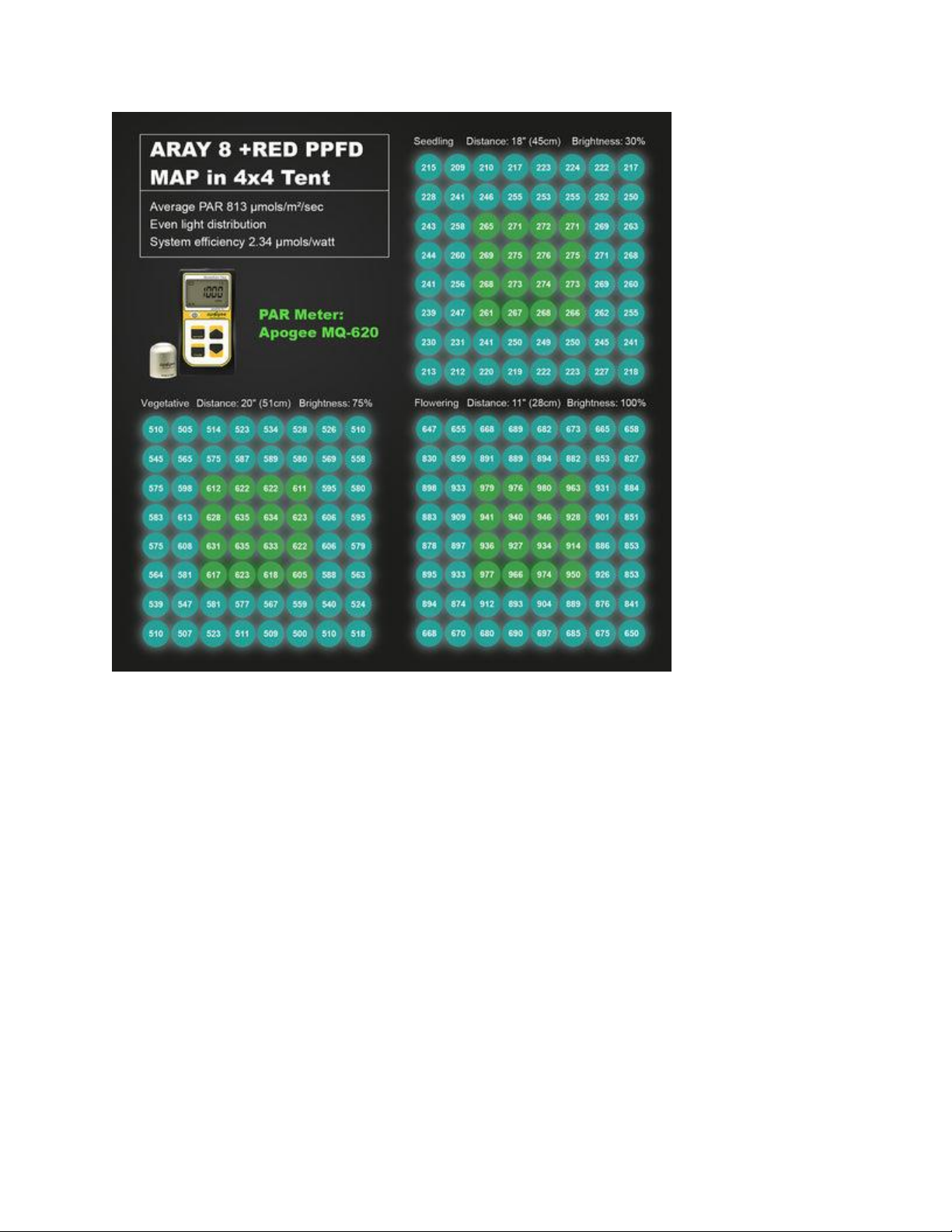

From seedling:

For Seedlings start at a 1/3 turn of the dimmer from off position (about 30%

output) and 14" or 35cm hanging height –keep at this level for the first 2 to 3

weeks until two or three sets of true leaves have developed.

Plants over three weeks old, Vegging cycle

Hang at 40cm or 16″ over the top of the plant canopy. Set the dimmer to 75%

After initial setup check them after a few hours. Look for signs of plant stress;

curled leave tips, yellowing leaf tips etc. If you see these signs reduce dimmer

by 1/5 turn and monitor.

Flowering cycle

Hang at 16cm to 25cm or 6″ to 10" over the top of the plant canopy for

maximum system efficiency and set the dimmer to 100%

Hang at 16" or 40cm for maximum uniformity and about 5% reduced PAR

reaching the canopy.

After initial setup check them after a few hours. Look for signs of plant stress;

curled leave tips, yellowing leaf tips etc. If you see these signs reduce dimmer

by 1/5 turn and monitor.

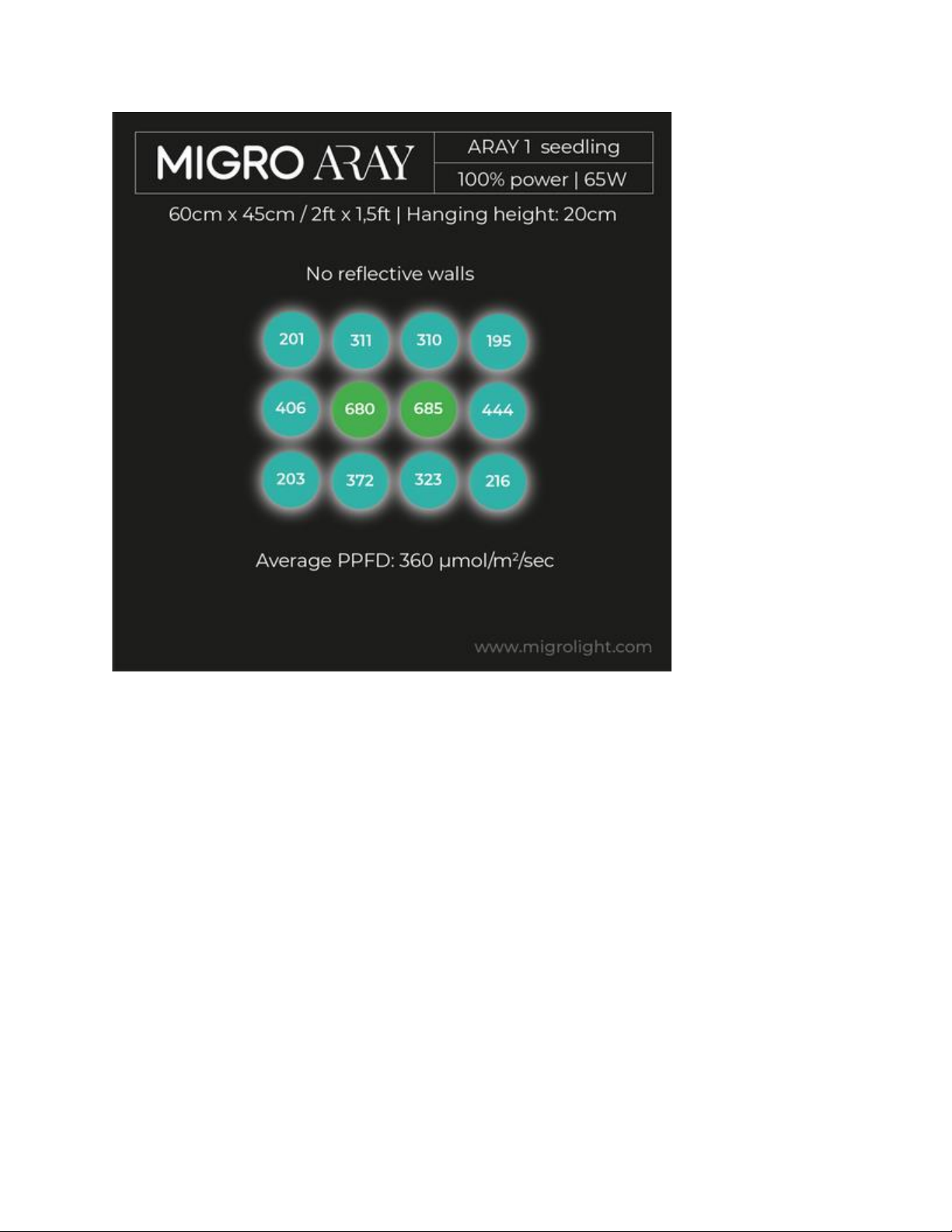

Dimmer adjustment - ARAY 1 & 1L seedling light

How much light plants need for maximum yield

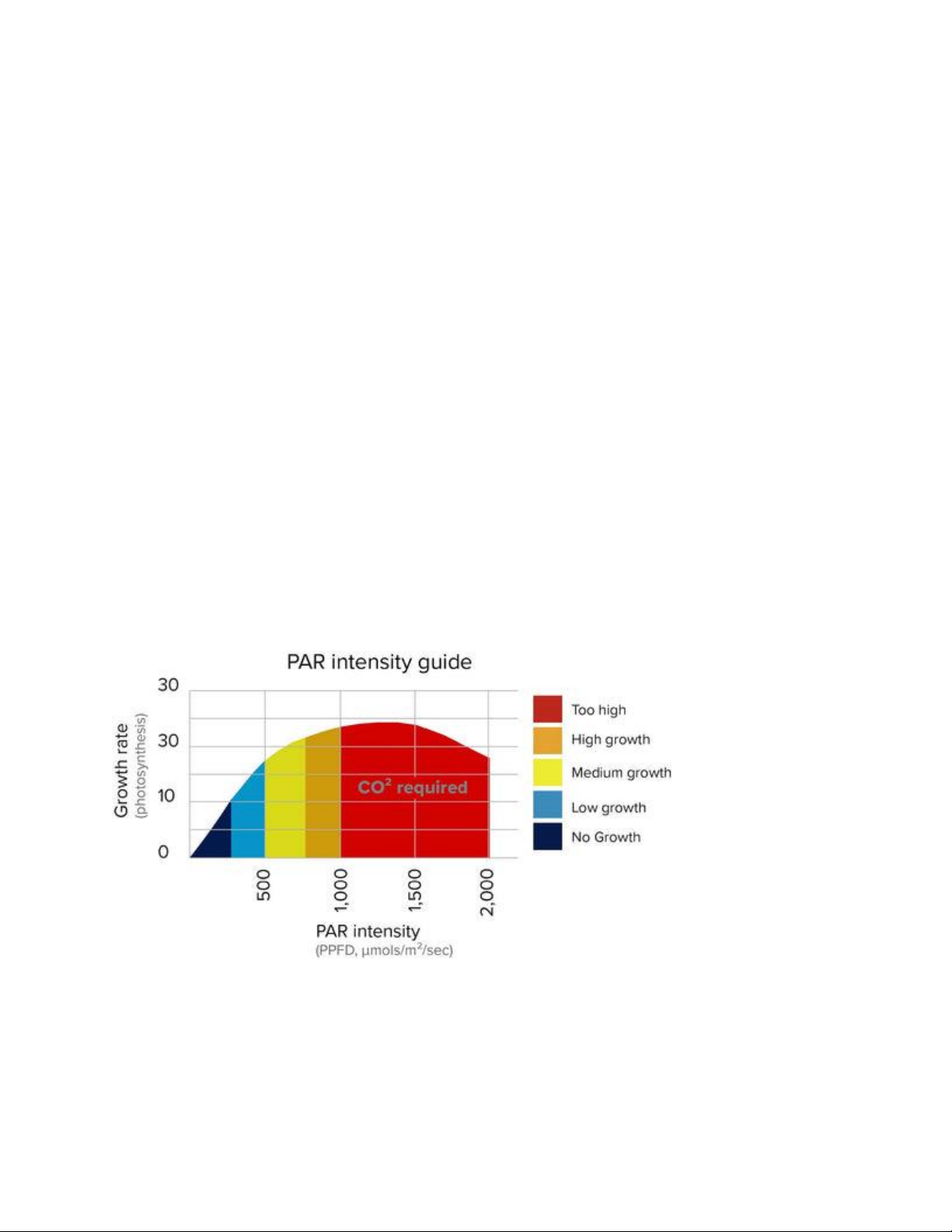

To optimize your grow it is recommended that your plants receive 500-1,000

μmols of PAR light for every m² (PPFD). Less than this and growth rates and

yield will be low.

Growth rates at higher PPFD levels do not justify the extra energy cost and

heat output and the plants require additional CO₂ to utilize the high PAR

intensity

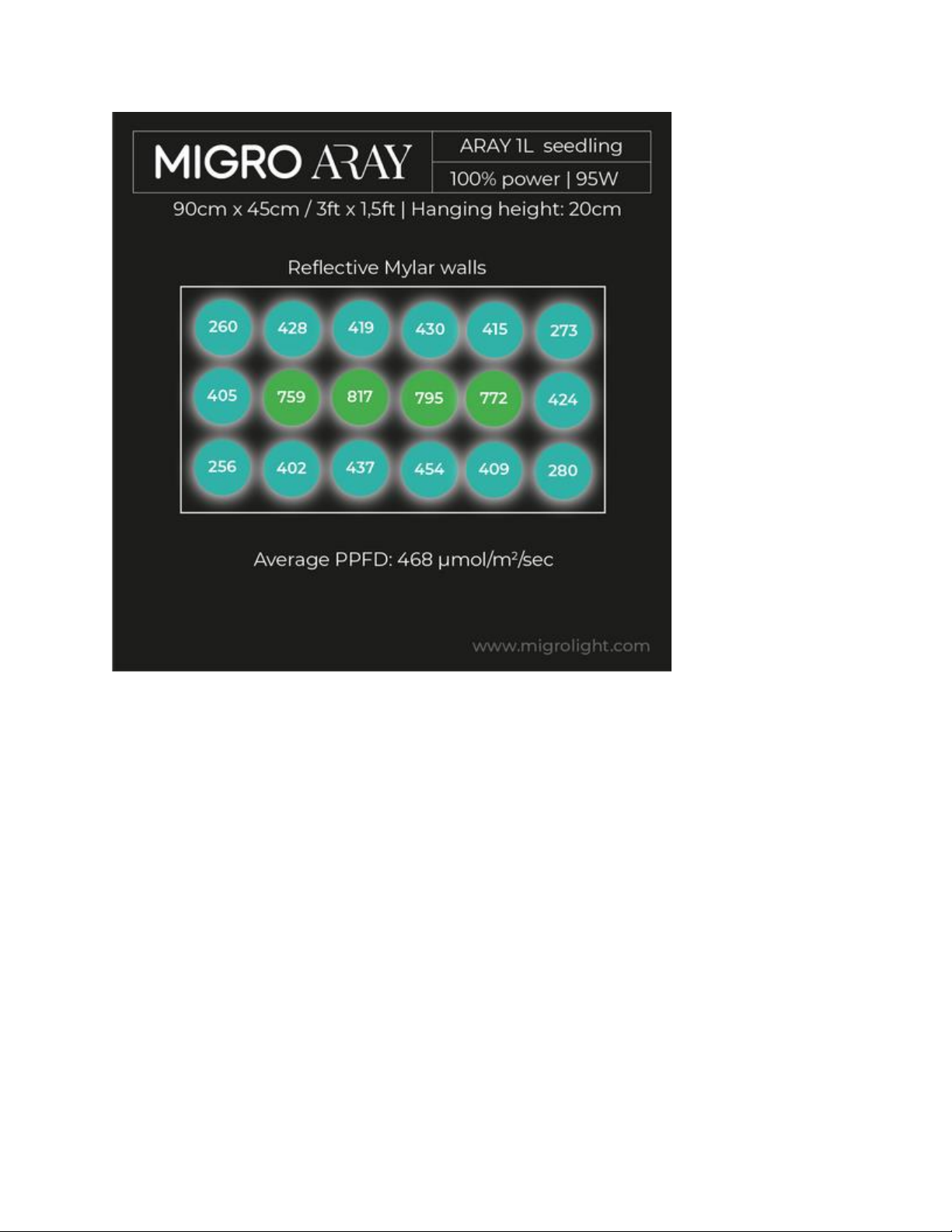

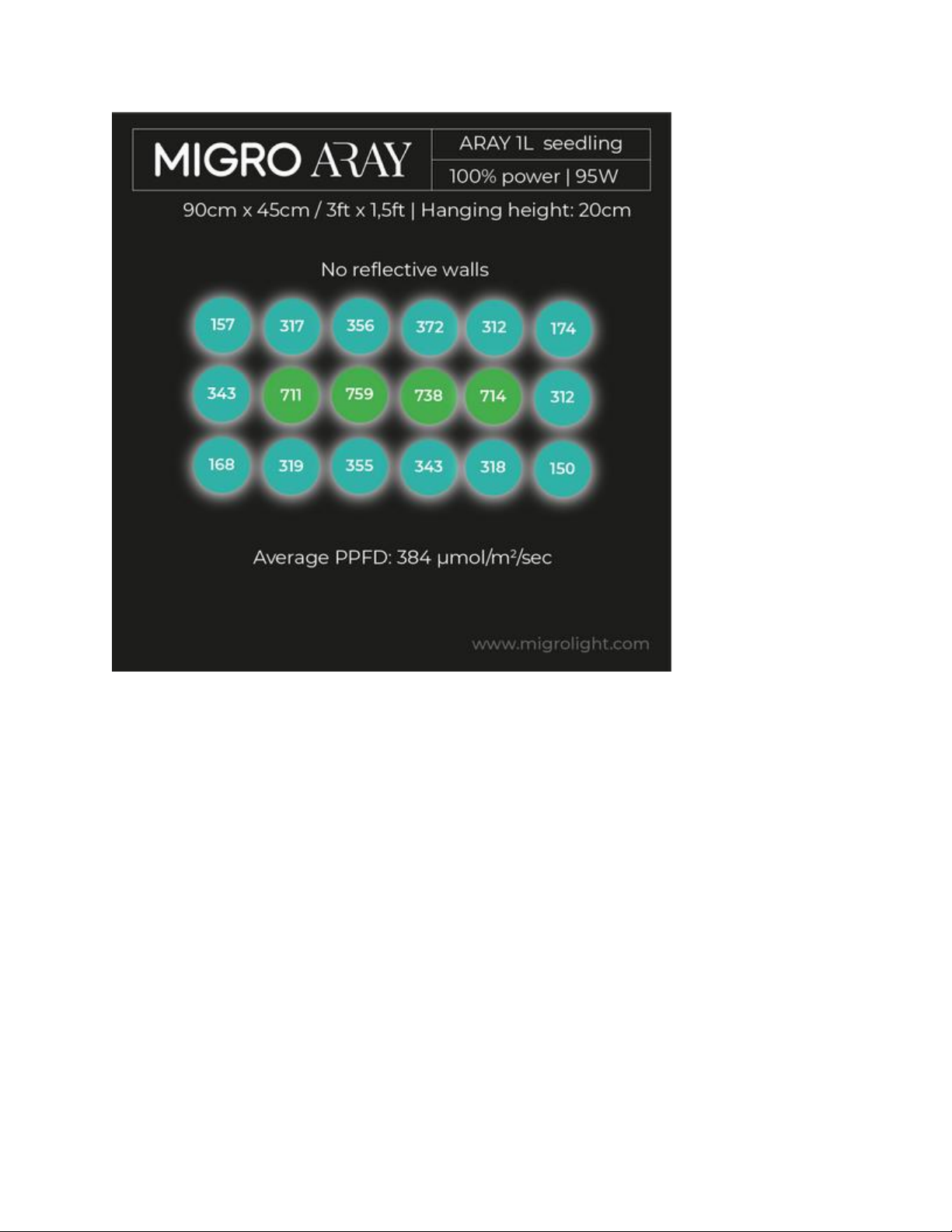

Light Intensity PAR charts

Light Spectrum

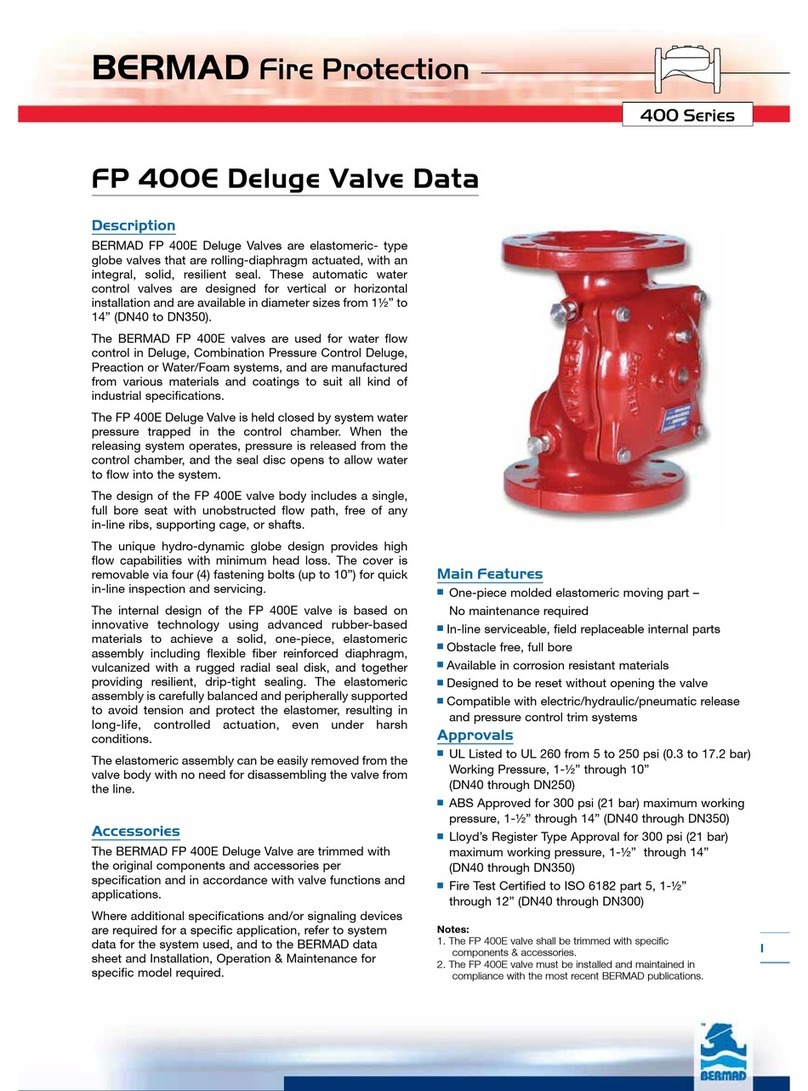

Hardware overview

LED bar

The small LEDs (surface mounted diodes, SMDs) are delicate and can be

easily damaged.

Take care putting them down and during assembly. They are protected from

water and dust with a conformal coating so they can be wiped clean of dust

and dirt.

LED driver

The LED driver is highly efficient and reliable constant current transformer

and has inbuilt protection from:

•Output over voltage

•Over temperature

•Short circuits

In the event of any of the above the driver will shut down. The driver will

automatically restart if the conditions return to normal.

The driver and the mains plug connection should be located outside of the

grow area in a dry and safe position with adequate ventilation. The life of the

LED driver is related to its operating temperature. Keeping it as cool as

possible will extend its life.

The driver is dimmer controlled and has an inbuilt dial for adjusting the

output from 10% to 100%. Up to 15 drivers can be connected together in daisy

chain connection for simultaneous dimming control.

Set the toggle switch on for master dimmer driver and off for slave dimmer

drivers.

Airflow and ventilation

Whatever position the grow light is fixed always ensure there is adequate

room for airflow around the heatsink to prevent heat buildup. There should

be at least 5cm or 2” clearance on three sides of the heatsink.

The heatsink is a ‘fast flow’ passive heatsink allowing air to move quickly over

the heatsink surface and remove the heat at a high rate.

Driver and Lamp operating temperature

Both the led bar heatsinks and led driver both operate at about 25 deg. C or

45 F above ambient temperature. So, at 25 degrees C or 77 F room temp the

driver and heatsink will be about 50 deg. C or 122 F. This is perfectly normal

and safe.

To minimize the temperature locate the driver down low at the air intake and

have the out take moving air across the heatsink.

If the driver case temperature gets to 90 Deg C or 195 F the output current

will be reduced. If the temperature does not reduce, then it powers off until

temperatures have reduced.

Maintenance

The MIGRO grow light system requires almost no maintenance. In ordinary

use the only maintenance required is to keep the heatsink and the led

surface clean. This will ensure the cooling performance and light output are

maintained, respectively.

To clean all of the components switch off the power and use warm water and

soap with a damp cloth. Do not under any circumstances use a solvent, acid

based or an abrasive cleaner on any of the components. Doing so may

damage the finish of the product and the electrical and led coating

Typical Package contents:

Email: i[email protected]m

Website: https://advancedgrowlights.com

YouTube: MIGRO channel –optimize your grow light setup

Table of contents

Popular Lawn And Garden Equipment manuals by other brands

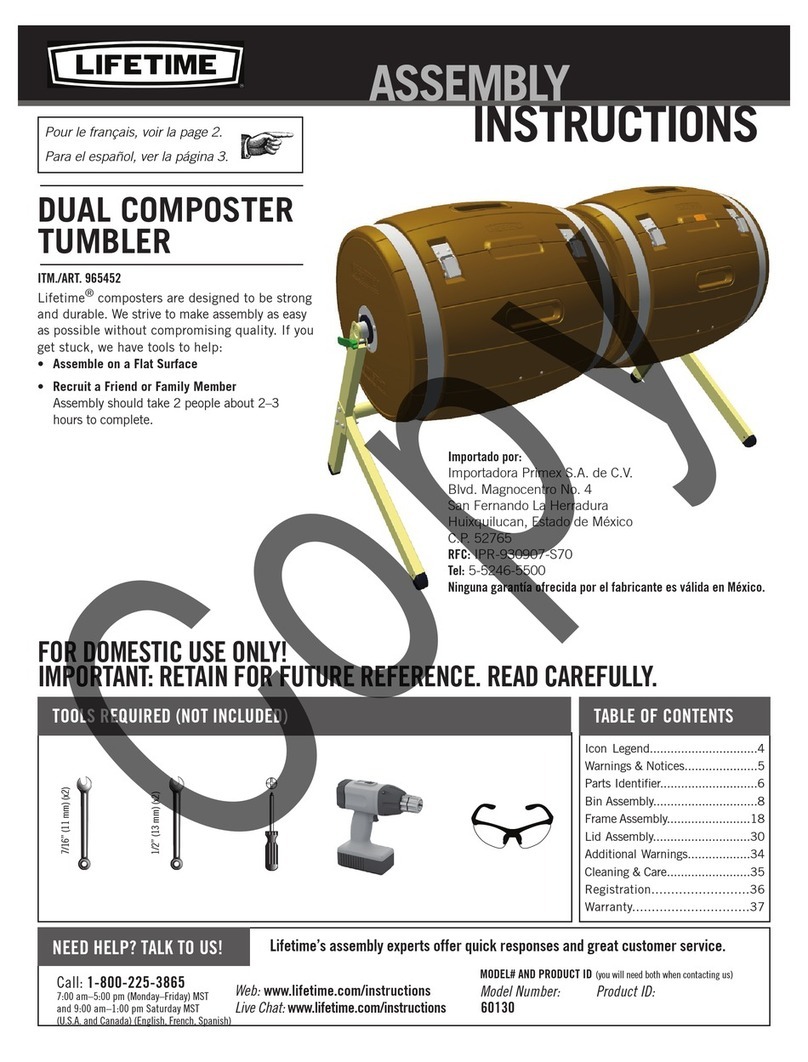

Lifetime

Lifetime 965452 Assembly instructions

Flowtron

Flowtron PV-75A Installation & maintenance instructions

Toolland

Toolland VL100 user manual

Oypla GARDEN

Oypla GARDEN 2459 user manual

Alpine

Alpine BAR254S instruction manual

Lawn Genie

Lawn Genie RAINJET CLASSIC RJ46 Installation and operating instructions