Advanjet Diaphragm-Jet 60-2257 User manual

Instructions

Temperature Controller

3A5912A

Diaphragm-Jet™Technology EN

Replacement temperature controller P/N 60-2257 for the Advanjet HV-2000C,

HV-2100C, and HM-2600C Jet Controller.

For professional use only.

Important Safety Instructions

Read all warnings and instructions in this manual and all related

manuals before using this equipment. Save these instructions.

PROVEN QUALITY. LEADING TECHNOLOGY.

Contents

Related Manuals............................................................................................................ 2

1. Repair Procedure................................................................................................ 3

2. HV-2000C............................................................................................................. 4

2.1 HV-2000C Jet Temperature Controller Connections ................................. 4

2.2 HV-2000C Jet Temperature Controller Settings ........................................ 5

3. HV-2100C............................................................................................................. 6

3.1 HV-2100C Jet Temperature Controller Connections ................................. 6

3.2 HV-2100C Jet Temperature Controller Settings ........................................ 7

4. HM-2600C ............................................................................................................ 8

4.1 HM-2600C Jet and Fluid Temperature Controller Connections ................. 8

4.2 HM-2600C Jet and Fluid Temperature Controller Settings ........................ 9

Graco Standard Warranty........................................................................................... 10

Related Manuals

Manuals are available at www.graco.com. Component manuals below are in English:

3A5856

HV-2000C Jet Controller Setup and Operation

3A6226

HV-2100C Jet Controller Setup and Operation

3A6166

HM-2600C Hotmelt Jet Controller Setup and Operation

Page 2 of 10 Advanjet Temperature Controller Repair 3A5912A

1. Repair Procedure

This document describes the procedure for replacing the temperature controller

(P/N 60-2257) for the Advanjet HV-2000C, HV-2100C, and HM-2600C Jet Controllers.

This procedure replaces the temperature controller and installs the Advanjet settings.

Use the power switch on the controller front panel to turn the main power OFF.1.

Disconnect the power cord on the rear of the controller.

Remove the controller top cover.2.

Disconnect the wires from the pins of the old controller(s). Remove and recycle3.

the old controller(s) per local regulations.

Use the appropriate pin connection chart and diagram in Section 2 (HV-2000C),4.

Section 3 (HV-2100C), or Section 4 (HM-2600C) to install the new temperature

controller.

Replace the controller top cover.5.

Reconnect the controller power cord and turn the main power ON.6.

Use the appropriate controller settings chart in Section 2, 3, or 4 to change the7.

temperature controller default manufacturer settings to the values required for the

Advanjet controller.

WARNING

ELECTRIC SHOCK HAZARD

Improper setup, usage, or grounding of the system can cause electric shock.

• Turn off power and disconnect power cord before removing the Advanjet controller cover.

• Be sure that all power is off when disconnecting and reconnecting wires.

• Replace Advanjet controller cover before reconnecting the power cord.

3A5912A Advanjet Temperature Controller Repair Page 3 of 10

2. HV-2000C

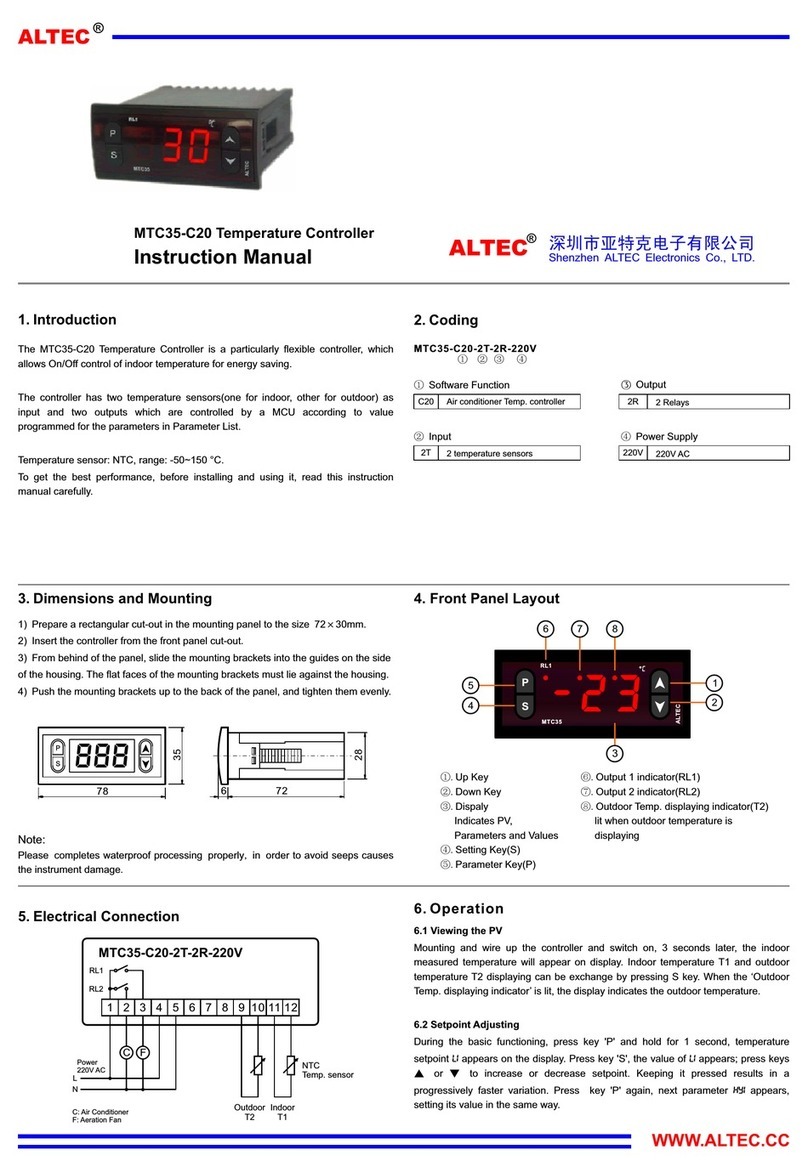

2.1 HV-2000C Jet Temperature Controller Connections

WARNING

ELECTRIC SHOCK HAZARD

Improper setup, usage, or grounding of the system can cause electric shock.

• Turn off power and disconnect power cord before removing the Advanjet controller cover.

• Be sure that all power is off when disconnecting and reconnecting wires.

• Replace Advanjet controller cover before reconnecting the power cord.

PIN

COLOR

1

BROWN

2

RED

3

ORANGE

4

YELLOW

5

GREEN

6

--

7

--

8

--

9

WHITE

10

BLACK

11

BLACK (A/C – L)

12

WHITE (A/C – N)

13

BLUE

14

VIOLET

15

GRAY

Page 4 of 10 Advanjet Temperature Controller Repair 3A5912A

2.2 HV-2000C Jet Temperature Controller Settings

After installing the new temperature controller, the manufacturer’s default settings must

be changed to the following settings. These are the values required to use the Advanjet

HV-2000C controller and the HV-2000 Jet nozzle plate for the majority of applications.

Use the keys to adjust values. Press once to save changes,

and then press again to return to the previous menu.

OPERATION

Description

Setting

Value

Press

Control Run/Stop setting

r-S

Upper-limit alarm 1

AL1H

3

Lower-limit alarm 1

AL1L

3

Upper-limit alarm 2

AL2H

3

Lower-limit alarm 2

AL2L

3

LOC

oFF

REGULATION

Description

Setting

Value

Press once, then press

PB (Proportional band)

P

4

Ti (Integral time)

i

20

Td (Derivative time)

d

5

Default value of Integral Volume

ioF

0

Heating Control Cycle Setting

HtPd

10

Process Temperature Offset

tPoF

0

INITIAL SETTINGS

Description

Setting

Value

Press and hold

Input temperature sensor type

inPt

Pt2

Temperature unit display selection

tPUn

C

Upper-limit of temperature range

tP-H

75

Lower-limit of temperature range

tP-L

-20

Control method

Ctrl

PiD

Heating/Cooling control Selection

S-HC

HEAt

Alarm 1 type

ALA1

1

Alarm 2 type

ALA2

1

Data Format

C-5L

ASCII

Communication write-in selection

Co5H

on

Controller Address

C-no

1

Baud Rate Setting

bP5

9600

Communication Data Length

LEn

8

Communication Parity Bit

Prty

nonE

Communication Stop Bit

Stop

1

3A5912A Advanjet Temperature Controller Repair Page 5 of 10

3. HV-2100C

3.1 HV-2100C Jet Temperature Controller Connections

WARNING

ELECTRIC SHOCK HAZARD

Improper setup, usage, or grounding of the system can cause electric shock.

• Turn off power and disconnect power cord before removing the Advanjet controller cover.

• Be sure that all power is off when disconnecting and reconnecting wires.

• Replace Advanjet controller cover before reconnecting the power cord.

PIN

COLOR

1

BROWN

2

RED

3

ORANGE

4

YELLOW

5

YELLOW JUMP TO PIN #4

6

--

7

--

8

--

9

WHITE

10

BLACK

11

BLACK (A/C – L)

12

WHITE (A/C – N)

13

BLUE

14

VIOLET

15

GRAY

Page 6 of 10 Advanjet Temperature Controller Repair 3A5912A

3.2 HV-2100C Jet Temperature Controller Settings

After installing the new temperature controller, the manufacturer’s default settings must

be changed to the following settings. These are the values required to use the Advanjet

HV-2100C controller and the HV-2100 Jet nozzle plate for the majority of applications.

Use the keys to adjust values. Press once to save changes,

and then press again to return to the previous menu.

OPERATION

Description

Setting

Value

Press

Control Run/Stop setting

r-S

Upper-limit alarm 1

AL1H

3

Lower-limit alarm 1

AL1L

3

Upper-limit alarm 2

AL2H

3

Lower-limit alarm 2

AL2L

3

LOC

off

REGULATION

Description

Setting

Jet

Press once,

then press

PB (Proportional band)

P

9

Ti (Integral time)

i

20

Td (Derivative time)

d

5

Default value of Integral Volume

ioF

0

Heating Control Cycle Setting

HtPd

10

Process Temperature Offset

tPoF

0

INITIAL SETTINGS

Description

Setting

Jet

Press and hold

Input temperature sensor type

inPt

Pt2

Temperature unit display selection

tPUn

C

Upper-limit of temperature range

tP-H

150

Lower-limit of temperature range

tP-L

-20

Control method

Ctrl

PiD

Heating/Cooling control Selection

S-HC

HEAt

Alarm 1 type

ALA1

1

Alarm 2 type

ALA2

1

Data Format

C-5L

ASCII

Communication write-in selection

Co5H

on

Controller Address

C-no

1

Baud Rate Setting

bP5

9600

Communication Data Length

LEn

8

Communication Parity Bit

Prty

nonE

Communication Stop Bit

Stop

1

3A5912A Advanjet Temperature Controller Repair Page 7 of 10

4. HM-2600C

4.1 HM-2600C Jet and Fluid Temperature Controller Connections

JET TEMPERATURE CONTROLLER

FLUID TEMPERATURE CONTROLLER

PIN

COLOR

PIN

1

BROWN

1

VIOLET (2)

2

BLACK

2

BLACK (2)

3

ORANGE

3

GRAY

4

YELLOW

4

WHITE

5

YELLOW

jump to JET pin #4

5

WHITE

jump to FLUID pin #4

6

--

6

--

7

--

7

--

8

--

8

--

9

WHITE

9

WHITEjump to JET pin #9

10

BLACK

10

BLACKjump to JET pin #10

11

BLACK (A/C - L)

11

BLACK (A/C - L) jump to JET pin #11

12

WHITE (A/C – N)

12

WHITE (A/C – N jump to JET pin #12

13

BLUE

13

BLUE jump to JET pin #13

14

VIOLET

14

VIOLET jump to JET pin #14

15

GRAY

15

GRAY

jump to JET pin #15

WARNING

ELECTRIC SHOCK HAZARD

Improper setup, usage, or grounding of the system can cause electric shock.

• Turn off power and disconnect power cord before removing the Advanjet controller cover.

• Be sure that all power is off when disconnecting and reconnecting wires.

• Replace Advanjet controller cover before reconnecting the power cord.

JET

FLUID

Page 8 of 10 Advanjet Temperature Controller Repair 3A5912A

4.2 HM-2600C Jet and Fluid Temperature Controller Settings

After installing the new temperature controller, the manufacturer’s default settings must

be changed to the following settings. These are the values required to use the Advanjet

HM-2600C controller and the HM-2600 Hotmelt Jet nozzle plate and fluid heater for the

majority of applications.

Use the keys to adjust values. Press once to save changes,

and then press again to return to the previous menu.

OPERATION

Description

Setting

Jet

Fluid

Press

Control Run/Stop setting

r-S

Upper-limit alarm 1

AL1H

3

3

Lower-limit alarm 1

AL1L

3

3

Upper-limit alarm 2

AL2H

3

3

Lower-limit alarm 2

AL2L

3

3

LOC

off

off

REGULATION

Description

Setting

Jet

Fluid

Press once,

then press

PB (Proportional band)

P

9

9.6

Ti (Integral time)

i

20

25

Td (Derivative time)

d

5

6

Default value of Integral Volume

ioF

0

66

Heating Control Cycle Setting

HtPd

10

10

Process Temperature Offset

tPoF

0

0

INITIAL SETTINGS

Description

Setting

Jet

Fluid

Press and hold

Input temperature sensor type

inPt

Pt2

Pt2

Temperature unit display selection

tPUn

C

C

Upper-limit of temperature range

tP-H

150

120

Lower-limit of temperature range

tP-L

-20

-20

Control method

Ctrl

PiD

PiD

Heating/Cooling control Selection

S-HC

HEAt

HEAt

Alarm 1 type

ALA1

1

1

Alarm 2 type

ALA2

1

1

Data Format

C-5L

ASCII

ASCII

Communication write-in selection

Co5H

on

on

Controller Address

C-no

1

2

Baud Rate Setting

bP5

9600

9600

Communication Data Length

LEn

8

8

Communication Parity Bit

Prty

nonE

nonE

Communication Stop Bit

Stop

1

1

3A5912A Advanjet Temperature Controller Repair Page 9 of 10

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from

defects in material and workmanship on the date of sale to the original purchaser for use. With the exception of any special,

extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace

any part of the equipment determined by Graco to be defective. This warranty applies only when the equipment is installed,

operated and maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused

by faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or

substitution of non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility

of Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design,

manufacture, installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any

defect in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor,

and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no

other remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or

property, or any other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within

two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

A PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD

BUT NOT MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches,

hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in

making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal

proceedings entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les

parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et

procédures judiciaires exécutés, donnés ou intentés, à la suite de ou en rapport, directement ou indirectement, avec les procédures

concernées.

Graco Information

For the latest information about Advanjet products, visit www.advanjet.com.

For patent information, see www.graco.com/patents.

For customer service and technical assistance, e-mail info@advanjet.com

TO PLACE AN ORDER, contact orders@advanjet.com

If calling from the US: 800-333-4877

If calling from outside the US: +1-760-294-3392

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 3A5912A

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2019, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

www.graco.com

Revision A, March 2019

Table of contents