Sollatek JEA Series User manual

A3 CMYK

Important: This manual contains important safety instructions. Before using this product

please read all instructions carefully. Keep this manual handy for reference.

JEA

Advanced Energy Management Temperature Controller

with Built-in Display and Connectivity

USER MANUAL

JEA USER MANUAL

A3+ CMYK

2 I+44 (1753) 214 500

Please read the following warnings to maintain the safe function and continued performance of your Sollatek device.

INSTALLATION

Mounting of the unit must be in accordance with orientation as specied in the “Description & Install” section.

The device must only be installed and congured by trained and authorized staff as specied in the “Description &

Install” section.

WASHDOWN

The front of the unit may be exposed to water jets. The rear of the unit must not be exposed to high pressure water

jets or temporary submersion.

CHEMICALS

The Sollatek device is made of polycarbonate and should not be exposed to chemicals which attack this material.

TEMPERATURE

The Sollatek device must only be subjected to temperatures as specied in the “Technical Specications” section of

this manual.

VIBRATION AND IMPACT

The device MUST be installed in such a way as to be protected from impact in operation. Do not hit or drop the

device.

NO SERVICEABLE PARTS

There are no serviceable parts inside the device. Do NOT open the housing.

VOLTAGES

The Sollatek device must only be connected to power supplies which comply with the acceptable voltage ranges

specied in the “Technical Specication” section of this manual.

VOLTAGE FLUCTUATIONS AND SERGE

The Sollatek device has surge protection as specied in the “Technical Specication”. Exposure to surge voltages

out side these limits, or excessively repeated surges within the limits may cause damage to the electrical circuits.

CURRENTS

Outputs should not be connected to short circuits or to loads which exceed the currents specied in the “Technical

Specication” section of this manual. Care must be taken to ensure that cables and terminations are safely

terminated.

SEGREGATION OF POWER AND SIGNAL CABLING

Correct segregation of power and signal cabling must be followed. Do not run power and signal cables together in

the same conduit. Induction from power cables may corrupt data signals, leading to incorrect operation.

CONSEQUENTIAL FAILURES

The Sollatek device includes features to protect both itself and connected components. However, failure of

connected components may cause damage to the JEA controller and / or connected components. Critical or

vulnerable components should be protected independently against failure.

FIT FOR PURPOSE

The Sollatek device must only be used for the purpose and functions described in this manual. As each application

requires different conguration and setup, no liability is accepted by Sollatek UK Ltd for the correct operation of the

nal equipment.

JEA USER MANUAL sollateksupport@sollatek.comI3

A3+ CMYK

Failure to comply with the warnings may result in the device becoming damaged leading to

premature failure or unsafe operation. In extreme cases failure to comply may cause risk of

electrocution or re.

SAFETY PRECAUTIONS

Precautions should be taken when installing or disconnecting the device. Isolate power supply before

installation or servicing.

Trained and Authorised personnel only should install / service this equipment

THE DANGERS FROM ELECTRICITY

Harm can be caused to any person when they are exposed to ‘live parts’ that are either touched directly or indirectly by means

of some

Conducting object or material. Voltages over 50 volts AC or 120 volts DC are considered hazardous.

Most electrical accidents occur because individuals:

1. Are working on or near equipment which is thought to be dead but which is, in fact, live.

2. Are working on or near equipment which is known to be live, but where those involved are without adequate training or

appropriate equipment, or they have not taken adequate precautions.

3. Misuse of equipment or use electrical equipment which they know to be faulty.

REDUCING THE RISK OF ELECTRIC SHOCK

To reduce the risk of electric shock:

1. Install the device in an area free of conductive contaminants. Ambient temperature must not exceed 60°C.

2. Isolate the power to the device before installation, repair or removal.

3. Use tools with insulated handles.

FIRST-AID

Before commencing any work:

1. Find out the location of a suitably stocked rst-aid box

2. Find out the arrangements that exist on site for rst-aid, and who is responsible for taking charge of these.

DISPOSAL

Sollatek devices are subject to the EU directive 202/96/EC, and may also be subject to other national legislation for

safe disposal of e-waste.

1. The device cannot be disposed of as municipal waste and such should waste should be collected and disposed

of separately.

2. The device can be disposed of through an approved WEEE collection point, or alternatively can be returned to

Sollatek UK Ltd at the end of its working life.

3. The device may contain hazardous substances, which if disposed of incorrectly may cause harm to the

environment and/or human health.

4. Penalties may be applicable for incorrect disposal, as specied by local legislation.

Sollatek devices complies with EU directive 2002/95/EC (RoHS).

JEA USER MANUAL

A3+ CMYK

4 I+44 (1753) 214 500

CONTENTS

1. INTRODUCTION 5

2. DESCRIPTION 6

2.1 JEA Front Panel - With Display 6

2.2 JEA Front Panel - Without Display 7

2.3 Rear Connectors 8

3. INSTALLATION 10

3.1 Dimensions And Panel Cut-Out 10

3.2 Panel Mounting 10

3.3 Wiring 11

4. OPERATION 14

4.1 Overview 14

4.2 DAY and NIGHT MODE 16

4.3 NORMAL, ECO and Superfrost Mode 16

4.4 Defrost Mode 16

4.5 Winter Mode 17

5. FEATURES 18

5.1 Energy Saving 18

5.2 Self Learning 18

5.3 Protective Delays 19

5.4 Product Safety Features 21

5.5 Connectivity Solution 21

5.6 Internal Rechargeable Battery 22

6. START-UP 23

6.1 Start-UP Sequence 23

6.2 Display Characters 23

7. INTERFACE 24

7.1 JEA Front Display 24

7.2 Smart Device Application 28

7.3 Desktop Interface Software 29

8. SERVICE MODE 31

9. PARAMETERS 32

9.1 Probes Selection 32

9.2 Temperature Regulation 33

9.3 Defrost 34

9.4 Voltage Protection Control 37

9.5 Delays & Timers 37

9.6 Condenser Control 39

9.7 Lights Control 39

9.8 Door Operation 40

9.9 Power ON/OFF Button 40

9.10 Initial Pull Down 41

9.11 Evaporator FAN Management 41

9.12 Winter Mode 42

9.13 Ambient Condition Interaction 43

9.14 Learning Algorithm 44

9.15 Energy Saving 44

9.16 Interface 45

9.17 Cooler Lockout 45

10. FIRMWARE UPDATE 46

10.1 SPP03 Programmer Procedure 46

10.2 Over The Air Update 47

10.3 Bluetooth Firmware Update 48

11. ERRORS AND FAULTS 49

11.1 Regulation Probe Failure 49

11.2 Evaporator Probe Failure 49

11.3 Condenser Probe Failure 49

11.4 Ambient Sensor Failure 50

11.5 Door Switch Alarm 50

11.6 Door Switch Failure/Malfunction 50

11.7 Condenser Over Temperature 51

11.8 Condenser Under Temperature 51

11.9 Ambient Over Temperature 51

11.10 Ambient Under Temperature 51

11.11 Refrigeration Failure 52

11.12 Cooler Lockout 52

11.13 Power Cut Alarm 52

12. SPECIFICATION 53

13. ACCESSORY LIST 55

14. VERSION HISTORY 56

JEA USER MANUAL sollateksupport@sollatek.comI5

A3+ CMYK

1. INTRODUCTION

The JEA is arguably the most advanced electronic refrigeration controller / Energy Management Device (EMD) designed to

provide precise reading and efficient control of multiple outputs. The interface permits different levels of control for different

user groups.

The JEA has Self-learning capabilities by observing the usage behaviour of the cooler to construct a pattern/matrix of output

operation for the compressor, lights, fan and defrost controls to deliver an energy-saving routine which will be the most cost-

effective and extend output life.

The JEA has optional internal Bluetooth or can be connected to an external BLE device allowing remote access via the Smart

Device App to authorized service personnel to access controller data logs and configure control parameters. BLE also transmits

Eddystone and iBeacon for proximity marketing (nearby customer engagement).

The JEA is built to last meeting industry benchmarks and offering voltage protection to all connected outputs. A compact

design allows installation even when space is tight. The Front face plates are available in various colours to fit into cooler

aesthetics.

JEA USER MANUAL

A3+ CMYK

6 I+44 (1753) 214 500

2. DESCRIPTION

The JEA controller consists of three main groups of features:

• The Front Display Panel with the user interface and controls.

• The Rear Connector Panel for input, output, and data cables.

• The Main Housing includes the mounting clips, mounting screws and bezel.

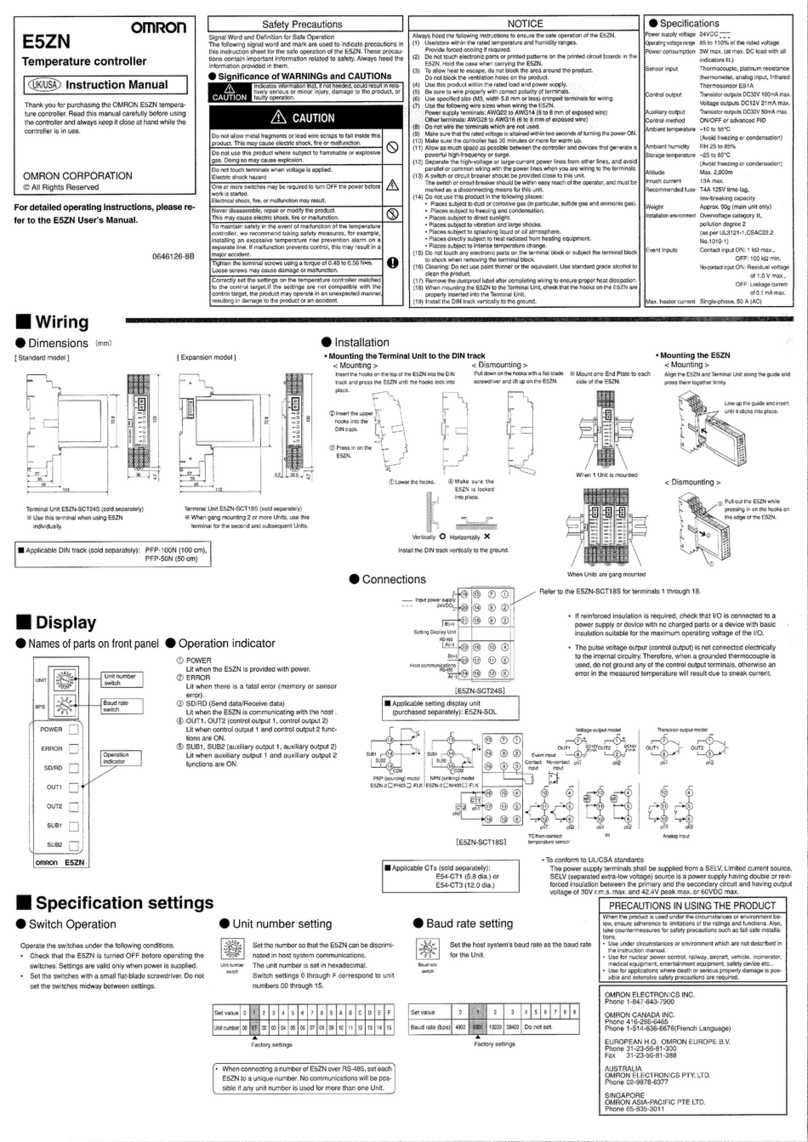

2.1 JEA FRONT PANEL - WITH DISPLAY

ICONS BUTTONS

Bluetooth Flashing when connected to a

device, otherwise OFF Left Button Enter / Exit Superfrost Mode

Back / Cancel

Compressor ON when the compressor is

on, otherwise OFF Up button Enter Menu List

ON/OFF Mode

Door ON when the door is open,

otherwise OFF Down Button Toggle Lights ON / OFF

Alarm ON when a fault occurs,

otherwise OFF Right Button Enter/Exit Eco Mode

Enter /set menu/parameter

Superfrost Mode

ON when the controller is in

superfrost mode, otherwise

OFF

Eco Mode ON when the controller is in

eco mode, otherwise OFF

Note: The first digit is used as a minus sign when needed

The display also has decimal point which is lit when needed.

Note: The controller acknowledges every button press with a beep.

JEA USER MANUAL sollateksupport@sollatek.comI7

A3+ CMYK

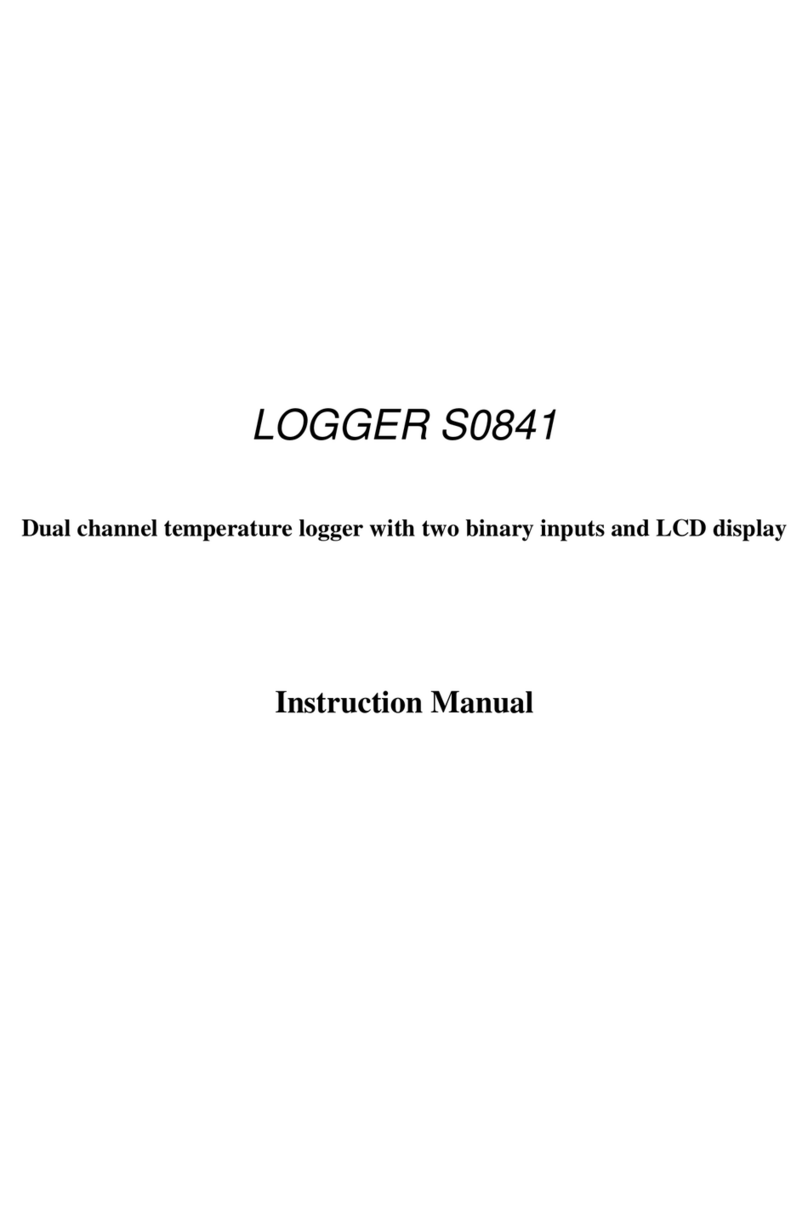

2.2 JEA FRONT PANEL - WITHOUT DISPLAY

INTELLIGENT

CONTROLLER

LED Indicators

Green Power Icon Yellow Comp Icon Red Alarm Icon Status

ON X X FFA Power Supply running

ON ON OFF Compressor ON (unit in On Mode)

ON ON ON

Compressor ON (unit in On Mode) but in under

or over voltage blind time (voltage is momentari-

ly low or high)

ON OFF Flashing (500mSec

ON/500mSec OFF) OFF Mode (mains voltage is bad)

ON Cycling (500mSec

ON/500mSec OFF)

Cycling (500mSec

ON/500mSec OFF) OFF Mode (mains frequency is bad)

ON OFF Flashing (One Second

ON/One Second OFF)

Wait Mode (temperature above cut-in, waiting for

time delay)

ON OFF Flashing (Two Seconds

ON/Two Seconds OFF) Wait Mode (temperature still below cut-in)

ON OFF Flashing (Four Seconds

ON/Four Seconds OFF) Defrost Mode

ON OFF

Flashing three

times (Two Seconds

ON/500mSec OFF)

every 10 seconds

Heater Control Mode (Winter Mode)

See Section 11. Errors & Faults for LED patterns during equipment failure events.

JEA USER MANUAL

A3+ CMYK

8 I+44 (1753) 214 500

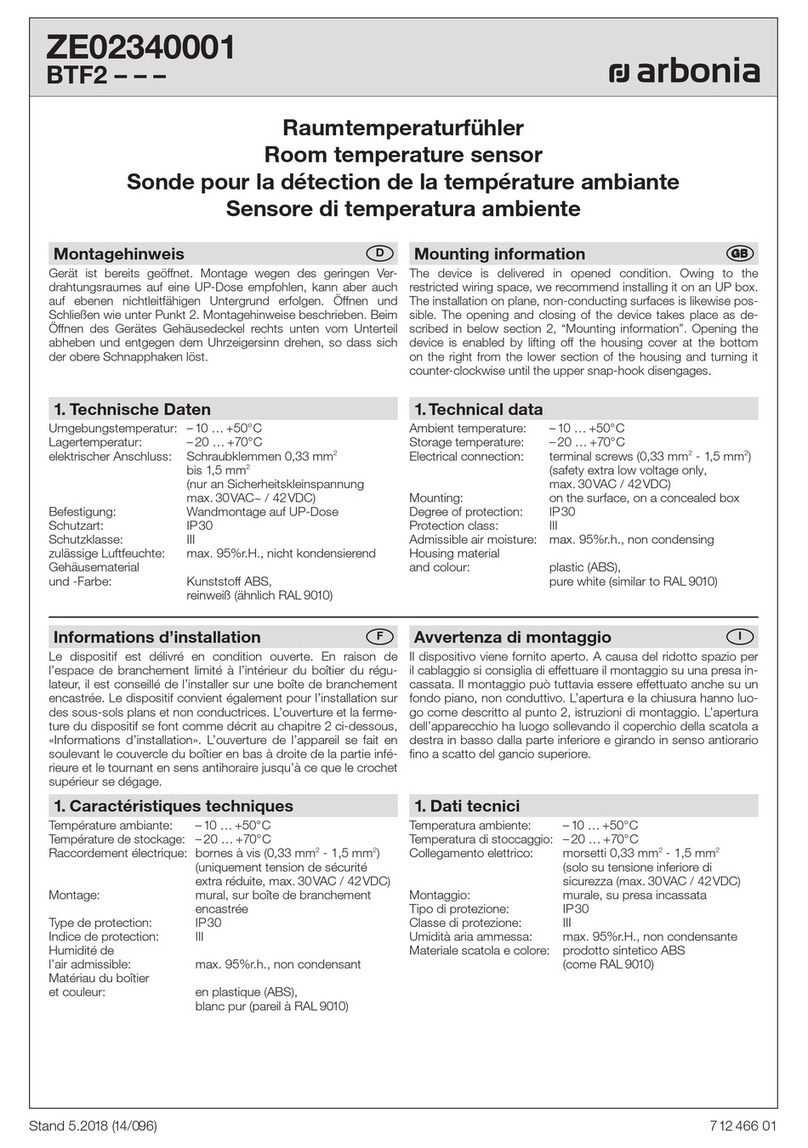

2.3 REAR CONNECTORS

2.3.1 JEA WITH 4 RELAYS

WARNING! MAINS CONNECTION

Risk of electrocution or damage to equipment. Ensure Mains is isolated before installation or repair of

the unit or any connected equipment.

1Heater 10 Amp Relay

90-250 VAC O/P

P5 Sensor I/P Door Switch

2Compressor 16 Amp Relay

90-250 VAC O/P

P1

-

P4

NTC Temperature

Sensor I/P

PIR Sensor

Humidity Sensor

10 kΩ NTC

(β25/85: 3435 k)

3Live in 90-300 VAC I/P DData Connector

External Display

FFX Expander Port

Connectivity Module

4Neutral 90-300 VAC I/P

5Evaporator Fan

5 Amp Relay

90-250 VAC or

0-24 VDC O/P

6Lights

5 Amp Relay

90-250 VAC or

0-24 VDC O/P

7Live in 2 90-300 VAC or

0-24 VDC I/P

4 RELAY CONNECTION LABEL ON PRODUCT

JEA-X4XX

Outputs

1 2 3 4 5 67

S1S2 S3 S4 S5

Inputs

1

2

3

4

5

6

7

10A

16A

L

N

5A

5A

L2

90-300Vac 45/65Hz

90-300Vac /12-24Vdc

Compresser

Heater

Fans

Lights

S1

S2

S3

S4

S5

Door Switch

Air Temp

Condenser temp

Evaporator temp

LNL2

FFX,GBR3

SPP

Ext Display

8-Way Connector

OUTPUT LOAD RELAY CONTROL

O/P1 Heater 10A, 250Vac 8A, 230Vac

O/P2 Compressor 8(6)A, 250Vac 8(6)A, 230Vac

O/P3 Fan 5A, 250Vac 2A, 230Vac

O/P4 Light 5A, 250Vac 1A, 230Vac

Ambient temp

JEA-X3XX

Outputs

2 3 4 5 6

S1S2 S3 S4 S5

Inputs

1

2

3

4

5

6

16A

L

N

5A

5A

L2

90-300Vac 45/65Hz

90-300Vac /12-24Vdc

Compresser

Fans

Lights

S1

S2

S3

S4

S5

Door Switch

LNL2

FFX,GBR3

SPP

Ext Display

8-Way Connector

OP1 COMP 8(6)A 240VAC

OP4 FAN 1(1)A 240VAC / 2A 24VDC

OP5 LIGHT 2(2)A 240VAC / 4A 24VDC (LED)

1

Air Temp

Condenser temp

Evaporator temp

Ambient temp

JEA USER MANUAL sollateksupport@sollatek.comI9

A3+ CMYK

2.3.2 JEA WITH 3 RELAYS

WARNING! MAINS CONNECTION

Risk of electrocution or damage to equipment. Ensure Mains is isolated before installation or repair of

the unit or any connected equipment.

1Compressor 16 Amp Relay

90-250 VAC O/P

P5 Sensor I/P Door Switch

2Live in 90-300 VAC I/P P1

-

P4

NTC Temperature

Sensor I/P

PIR Sensor

Humidity Sensor

10 kΩ NTC

(β25/85: 3435 k)

3Neutral 90-300 VAC I/P DData Connector

External Display

FFX Expander Port

Connectivity Module

4Evaporator Fan

5 Amp Relay

90-250 VAC or

0-24 VDC O/P

5Lights

5 Amp Relay

90-250 VAC or

0-24 VDC O/P

6Live in 2 90-300 VAC or

0-24 VDC I/P

3 RELAY CONNECTION LABEL ON PRODUCT

JEA-X4XX

Outputs

1 2 3 4 5 67

S1S2 S3 S4 S5

Inputs

1

2

3

4

5

6

7

10A

16A

L

N

5A

5A

L2

90-300Vac 45/65Hz

90-300Vac /12-24Vdc

Compresser

Heater

Fans

Lights

S1

S2

S3

S4

S5

Door Switch

Air Temp

Condenser temp

Evaporator temp

LNL2

FFX,GBR3

SPP

Ext Display

8-Way Connector

OUTPUT LOAD RELAY CONTROL

O/P1 Heater 10A, 250Vac 8A, 230Vac

O/P2 Compressor 8(6)A, 250Vac 8(6)A, 230Vac

O/P3 Fan 5A, 250Vac 2A, 230Vac

O/P4 Light 5A, 250Vac 1A, 230Vac

Ambient temp

JEA-X3XX

Outputs

2 3 4 5 6

S1S2 S3 S4 S5

Inputs

1

2

3

4

5

6

16A

L

N

5A

5A

L2

90-300Vac 45/65Hz

90-300Vac /12-24Vdc

Compresser

Fans

Lights

S1

S2

S3

S4

S5

Door Switch

LNL2

FFX,GBR3

SPP

Ext Display

8-Way Connector

OP1 COMP 8(6)A 240VAC

OP4 FAN 1(1)A 240VAC / 2A 24VDC

OP5 LIGHT 2(2)A 240VAC / 4A 24VDC (LED)

1

Air Temp

Condenser temp

Evaporator temp

Ambient temp

JEA USER MANUAL

A3+ CMYK

10I +44 (1753) 214 500

3. INSTALLATION

3.1 DIMENSIONS AND PANEL CUT-OUT

3.2 PANEL MOUNTING

WARNING!

Avoid installing the JEA in the following environments:

• Strong vibrations or knocks

• Exposure to continuous water spray

• Aggressive and polluting atmospheres to avoid corrosion

• Environments where explosive or mixes of flammable gases are present

1. Cut a rectangle aperture in the panel of the cooler where the display is to be located as per the panel cut diagram. Ensure

the aperture is free of burrs and sharp edges.

Note: The Maximum panel thickness must not exceed:

Front screw mounting: 1.6mm maximum with gasket and 3.6mm maximum without the gasket.

Side clip mounting: 6.6mm maximum with gasket and 8.6mm maximum without the gasket.

3.2.1 FRONT MOUNTING

2. Remove the bezel from the front of the JEA by pulling it off. Insert the JEA from the outside (front) of the panel.

3. Tighten the screws. After turning 90o the catch will come out of its slot and press onto the panel. Tighten the screw until the

front panel is secure, DO NOT over-tighten the screw.

4. Push the bezel back onto the front of the JEA.

JEA USER MANUAL sollateksupport@sollatek.comI11

A3+ CMYK

3.2.2 REAR MOUNTING

Note: Side mounting clips are purchased separately

1. Insert the JEA into the front of the panel.

2. Insert one of the side clips into the guides within the top and bottom of the body. Slide towards the front of the JEA until it is

securely against the panel. Repeat the same operation for the other side.

Note: Ensure the clips are securely attached to the JEA and are tight against the panel.

3.3 WIRING

3.3.1 OUTPUT WIRING

WARNING! MAINS CONNECTION

Risk of electrocution or damage to equipment. Ensure Mains is isolated before installation or repair of

the unit or any connected equipment.

3.3.1.1 JEAx4 models

Standard Wiring (All outputs supplied with 90-300 VAC)

1. Connect the Live-In wire to terminal 3 on the JEA.

2. Connect a loop from terminal 3 (Live-In) to terminal

7, Live-2-In on the JEA.

3. Connect the Neutral wire to terminal 4 on the JEA.

4. Connect the Compressor to terminal 2 of the JEA.

5. Connect the Heater to terminal 1 of the JEA, if

required.

6. Connect the fan (Evaporator or Condenser) to

terminal 5 of the JEA, if required.

7. Connect the lights to terminal 6 of the JEA, if

required.

AC And DC Supply Wiring (Compressor and Heater supplied with AC, Fan and Lights supplied by DC)

1. Connect the Live-In (do not Loop to terminal 7), Neutral, Compressor, Heater,

Fan and lights as described above.

2. Connect the DC Live to terminal 7 on the JEA.

3. Connect the fan and lights to the DC Negative.

+ -+ -+-

+-+ -

16432

L in N in

5 7

P4 P3 P2 P1

1 3 5 7

2468

L2 in

Amb.

Temp

Evap.

Temp

Cond.

Temp

Air

Temp

Door

Switch

Ext. Display

FFX Expander

Connectivity

Module

PIR

Sensor

OR

Humidity

Sensor

16432

LN

5 7

DC

+

DC

-

JEA USER MANUAL

A3+ CMYK

12I +44 (1753) 214 500

3.3.1.2 JEAx3 Models

Standard Output Wiring (All outputs supplied with 90-300 VAC)

1. Connect the Live-In wire to terminal 2 on the JEA

2. Connect a loop from terminal 2 (Live-In) to terminal

6, Live-2-In on the JEA

3. Connect the Neutral wire to terminal 3 on the JEA

4. Connect the Compressor to terminal 1 of the JEA

5. Connect the fan (Evaporator or Condenser) to

terminal 4 of the JEA, if required.

6. Connect the lights to terminal 5 of the JEA, if

required.

AC And DC Supply Wiring

1. Connect the Live-In (do not Loop to terminal 6), Neutral, Compressor, Heater,

Fan and lights as described above.

2. Connect the DC Live to terminal 6 on the JEA.

3. Connect the fan and lights to the DC Negative.

3.3.2 INPUT SENSOR WIRING

WARNING!

Separate as much as possible the input sensors and cables carrying inductive load and power. Do Not run power

and signal cables together in the same conduit.

The input connectors on the rear of the JEA are 3-way (temperature probe and PIR sensor) and 2-way (door switch) RAST

connectors.

Note: Ensure the RAST connectors of the sensors are pushed firmly onto the terminal. When fully connected, the connector will

be locked in place by a retaining clip built into the enclosure.

1. Connect the Air temperature probe to terminal P1 on the JEA.

2. Connect the Evaporator temperature probe to terminal P2 on the JEA (If required).

3. Connect the Condenser temperature probe to terminal P3 on the JEA (If required).

4. Connect the Ambient temperature probe to the P4 terminal on the JEA (If required).

Note: Temperature probe selection can be configured, if probe selection is modified then the resulting probes will have to be

connected to the responding terminal (see section 9.1 for more details). The stated above connectors are as per the default

probe selection.

A PIR sensor can be connected to any of the 4 temperature probe connectors (P1 to P4). If a PIR sensor is required, then the PIR

sensor must be enabled, and the probe connector selected in the controller configuration (see Section 8.1 for more details)

5. Connect the Door switch, to the P5 terminal on the JEA (If required).

5321

LN

4 6

DC

+

DC

-

+-+ -+-

+-+-

5321

L in N in

4 6

P4 P3 P2 P1

1357

2468

L2 in

Amb.

Temp

Evap.

Temp

Cond.

Temp

Air

Temp

Door

Switch

Ext. Display

FFX Expander

Connectivity

Module

PIR

Sensor

OR

Humidity

Sensor

JEA USER MANUAL sollateksupport@sollatek.comI13

A3+ CMYK

3.3.3 EXTERNAL DEVICES

WARNING!

Separate as much as possible the data cables and cables carrying inductive load and power. Do Not run power and

signal cables together in the same conduit.

The JEA has an 8-way connector for adding external modules to further enhance the controller’s capabilities.

You can connect:

• Displays (FFD, FDM3)

• FFX expander port with plug-in modules

• GMC4 connectivity device

• programming device (SPPO3)

Sollatek provides a connection cable for all devices which connect to the JEA to make connecting quick and easy.

1. Plug the 8-way connector of the connecting cable into the port on the rear of the JEA.

Note: The connector will only fit into the port in one orientation.

2. Plug the other end of the connecting cable into the other device (refer to the device manual for port type and location).

Connecting

Device

JEA USER MANUAL

A3+ CMYK

14I +44 (1753) 214 500

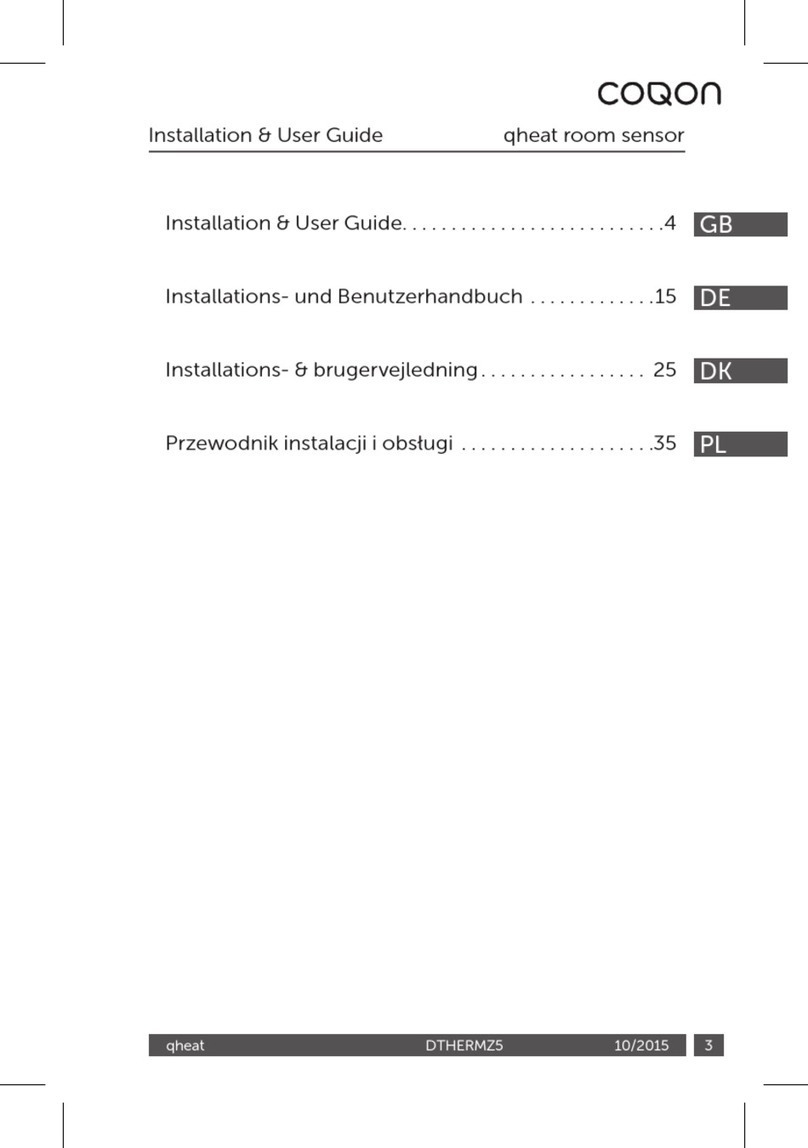

4. OPERATION

4.1 OVERVIEW

ON

Compressor

OFF

ON

Evaporator Fan

OFF

CUT IN

CUT OUT

ON

OFF

Lights

Temperature Probe

Time

DAY NORMAL

DAY - SUPERFROST NIGHT - SUPERFROST NIGHT - ECONIGHT - NORMAL

OPEN

CLOSE

Door

Pull Down

DAY - ECO

JEA USER MANUAL sollateksupport@sollatek.comI15

A3+ CMYK

4. OPERATION

4.1 OVERVIEW

ON

Compressor

OFF

ON

Evaporator Fan

OFF

CUT IN

CUT OUT

ON

OFF

Lights

Temperature Probe

Time

DAY NORMAL

DAY - SUPERFROST NIGHT - SUPERFROST NIGHT - ECONIGHT - NORMAL

OPEN

CLOSE

Door

Pull Down

DAY - ECO

JEA USER MANUAL

A3+ CMYK

16I +44 (1753) 214 500

4.2 DAY AND NIGHT MODE

In DAY mode, the temperature is lower to keep the products inside the cooler at the correct temperature for resale, and the

lights are ON for Point of Sale (POS). In NIGHT mode the regulated temperature is higher than in DAY mode as the products do

not need to be as cold, and the lights are OFF as no need for POS. This saves energy and reduces the workload of the outputs

(compressor) to extend operational life. Switching between day and night mode is controlled by either the energy-saving

feature or the self-learning algorithm (model dependant).

4.3 NORMAL, ECO AND SUPERFROST MODE

In either Day or NIGHT mode, there are 3 different temperature cut-in/cut-out settings which can be implemented: Normal, Eco

or Superfrost. The values can be customisable. Normal is the standard cut-in/cut-out temperature required for general cooler

operation. Eco has a higher cut-in/cut-out temperature than Normal and Superfrost has lower cut-in/cut-out temperature values

than Normal. These settings are manually activated by pressing buttons on the display interface.

4.4 DEFROST MODE

4.4.1 STANDARD DEFROST

Depending on customer requirements there are different parameters which can trigger the defrost mode:

Defrost can be triggered by either using the temperature of the evaporator probe or/and by time-lapse (see defrost in

parameters for different types of timers). When both settings are enabled, whichever event happens first will trigger or end the

defrost cycle.

The JEA has a minimum defrost duration and minimum duration between defrost cycles which must be satisfied before it will act

no matter the status of the other parameters. This is to ensure the defrost cycle is not stopped too early or defrost cycles are not

initiated to close together.

Time

Defrost period

Defrost is terminated

Defrost period

Defrost is terminated

>Minimum Duration between Defrost Cycles

ON

Compressor

OFF

ON

Evaporator Fan

OFF

ON

Defrost Relay

OFF

CUT IN

CUT OUT

Temperature Probe

Defrost is activated Defrost is activated

>Minimum Defrost Duration

JEA USER MANUAL sollateksupport@sollatek.comI17

A3+ CMYK

Operation during a DEFROST cycle

Compressor: OFF or ON (configurable)

Evaporator Fan: OFF or ON (configurable)

Defrost Relay (if fitted): ON

Example of Configuration

Active Heater Defrost Hot Gas Defrost

Compressor: OFF Compressor: ON

Evaporator Fan: ON Evaporator Fan: OFF

Defrost Relay (if fitted): ON Defrost Relay (if fitted): ON

4.4.2 POST DEFROST DRIPDOWN

Post Defrost Dripdown can be used only with active defrost e.g. Heater or Hot Gas defrost. After defrost has been terminated

by either time or temperature (depending on configuration), the JEA will turn the compressor, fan and defrost relay OFF until

the evaporator temperature drops to the set temperature (if an evaporator probe is fitted) or the maximum dripdown duration

has elapsed to prevent freeze up by allowing excess moisture to drip off the evaporator coil. Once dripdown is terminated the

JEA will resume normal operation.

Operation During Post Defrost Dripdown

Compressor: OFF

Evaporator fan: OFF

Defrost Relay (if fitted): OFF

4.5 WINTER MODE

Winter mode is designed for when coolers are in extremely cold temperatures (For example: outdoor coolers in cold countries

such as Russia) and require a heater to be fitted. The compressor will be turned OFF and the heater will be turned ON. This is

to warm up the inside of the cooler to ensure products in the cooler do not get too cold and freeze. Winter mode is entered

automatically based on configurable parameters.

Standard operation During Winter Mode

Compressor: OFF

Evaporator fan: ON

Cabinet Heater (if fitted): ON

JEA USER MANUAL

A3+ CMYK

18I +44 (1753) 214 500

5. FEATURES

5.1 ENERGY SAVING

The JEA tracks door openings. If no door openings are logged for a pre-set time (customisable) then the JEA will enter NIGHT

mode. This is to maximise energy saving when the outlet is closed and no customer demand.

5.1.1 NORMAL, ECO AND SUPERFROST MODE

Whichever mode: Normal, Eco or Superfrost, the JEA was running in during DAY mode, the JEA will remain in the same mode

in NIGHT mode, i.e. JEA running in DAY-Eco mode then the JEA will switch to NIGHT-Eco mode respecting the corresponding

cut-in and cut-out temperatures. The only way the JEA will switch modes (Normal, Eco or Superfrost) is by using the display

buttons to manually switch the mode.

5.1.2 BREAK-OUT FROM NIGHT MODE

The JEA will revert into DAY mode when either a day activity is seen or the Longest Night Mode Duration (customisable) has

elapsed, whichever occurs first.

5.1.3 DOOR SWITCH FAILURE

In the event of a door switch failure, the JEA will stop switching modes and will remain in DAY mode until the failure has been

rectified.

5.2 SELF LEARNING

5.2.1 LEARNING ALGORITHM

The JEA observes the usage behaviour of the cooler and constructs a daily pattern. Each day is represented by 48 slots, of

30-minute duration. Each slot is then assigned a mode, either DAY-mode or NIGHT-mode, depending on the cooler’s usage

level during that slot. The JEA learns 7 days’ worth of operation (336 slots) to reflect one week’s worth of cooler’s usage pattern.

Example Pattern: In the following sample, 8 AM to 9 PM is the cooler’s busy period.

Slot:1-2 Slot:3-4 Slot:5-6 Slot:7-8

Slot:29-30 Slot:31-32 Slot:33-34 Slot:35-36

NIGHT NIGHT DAY DAY DAY DAY NIGHT NIGHT

6 AM 7 AM 8 AM 9 AM 8 PM 9 PM 10 PM 11 PM

Week Array

When 24 hours elapses, the 24-hour array will be transferred to a Week-Array. After this, the pattern is saved in non-volatile

memory after each full week of learning. This becomes the feedback array that determines cooler functionality moving forward.

The feedback array is continually updated with outlet traffic and usage.

Note: During the first week of operation the JEA controller will remain in DAY mode while it observes the cooler’s operation

pattern. After 7 days, the JEA will begin switching from DAY to NIGHT mode based on what it has learned and saved in the

week array.

5.2.2 ADVANCED LEARNING FEATURES

5.2.2.1 Break-out of Learning:

Break out is when the JEA is in NIGHT mode and there is a door opening. If the accumulated door opening is >threshold, the

lights will turn on and the temperature settings will switch to DAY mode for this slot and the next two slots. The slot is learned as

DAY mode for the next week. Those extra slots however will not be learnt as day mode unless there are door openings in them.

If door openings occur in the following slot, then the breakout period is extended by 2 slots from that slot.

5.2.2.2 Rell Period:

The Refill period is introduced to ignore times when the cooler is being refilled with products before the shop opens. If the JEA

is in NIGHT mode, door open = 1 and door open time > 3 Minutes, then this specific door opening is ignored by the learning

timers and scheme, so the slot will remain learnt as NIGHT.

5.2.2.3 Look-Ahead:

The Look-ahead is added to allow setting the temperature of the cooler products for the products to reach the correct

temperature at the shop opening time. The Look-Ahead value is set to 3 hours (6 slots).

JEA USER MANUAL sollateksupport@sollatek.comI19

A3+ CMYK

The JEA will take the cooler pattern and then switch into DAY mode from NIGHT mode 3 hours (6 slots) earlier than the learning

pattern.

5.2.2.4 Software Irregularities Filtration:

A software filter is added to change periods of NIGHT less than the Look-Ahead value to DAY in order to overcome

irregularities.

For example, Look-Ahead = 6, then if the 24-hour array is found to be:

[D D D D N N N N N N D D D] this will be changed to [D D D D D D D D D D D D D]. Every 24 hour the filter will be applied to

the 24-hour array elements that has been saved.

5.2.3 DOOR SWITCH FAILURE

In the event of a door switch failure, the JEA will stop updating its learning pattern based on the cooler usage and will remain in

DAY mode until the failure has been rectified.

After the door switch operation is restored (failure has been rectified), then the unit will reset its learning pattern and will start

the learning process from the beginning.

5.3 PROTECTIVE DELAYS

5.3.1 TEMPERATURE BLIND TIME

The software will ignore the sensor temperature reading for the first few seconds (a pre-set value of 10 seconds) after the

compressor is switched on. This is to prevent short-term thermal effects such as those caused by the fan starting to operate

causing disconnection.

Less than

Temperature

Blind Time

CUT IN

CUT OUT

ON

Temperature

Probe

OFF

Compressor

Time

JEA USER MANUAL

A3+ CMYK

20 I+44 (1753) 214 500

5.3.2 BAD VOLTAGE BLIND TIME

The JEA provides high and low voltage protection by disconnecting the supply from the compressor and outputs if the

voltage exceeds the set High Voltage Disconnect (HVD) or falls below the Low Voltage Disconnect (LVD) (both configurable).

Once the voltage has returned with the reconnection voltage and delay timers have been satisfied, the JEA will automatically

reconnect the outputs. The JEA permits high and low mains voltages transitions for short periods of time preventing inadvertent

compressor stop-starts. Pre-set values of 0.5 and 2 seconds (configurable) respectively are implemented.

HVD

LVD

ON

Mains

Voltage

OFF

Compressor

Time

Intelligent Time Delay

Less than 2 secs

Intelligent Time Delay

Less than 0.5 secs

5.3.3 INTELLIGENT TIME DELAY

The JEA controller has a built-in intelligent time delay of up to 5 minutes (customer configurable). After a compressor

disconnection period, either from cycling OFF, defrost or HVD / LVD the JEA will automatically adjust the time delay on the

disconnection period before allowing the compressor to turn ON. For example, if the Time delay is set to 3 minutes, a 2-minute

disconnection will result in only a 1-minute additional delay, making the total delay 3 minutes. Any disconnection of 3 minutes or

over and the JEA will immediately turn the compressor ON.

The time delay is essential in allowing compressor gases to neutralise, ensuring that the mains power has stabilised before re-

connection and avoiding a locked rotor condition.

Intelligent Time

Delay (1 min)

Disconnection Period

(2 mins)

Disconnection Period

(7 mins)

ON

OFF

Compressor

ON

OFF

Compressor

Table of contents