TEMPERATURE CONTROLLER

N321S

OPERATING MANUAL - V1.9x A

Man 5001244

The N321S is a controller intended for solar water heating applications. It controls

the water circulation system based on the difference of temperature between the

solar collector and the storage tank (or swimming pool).

The instrument contains two NTC-type temperature sensors and a control output

for activating the water circulation pump. It provides protections against overheating

and freezing to the piping, preventing damages to the system.

SPECIFICATIONS

INPUT SENSOR:

•NTC Thermistor, 10 kΩ

ΩΩ

Ω@ 25 °C; range: –50 a 120 °C (-58 to 248 ºF);

Accuracy: 0.6 °C (1.1 ºF);

Sensor interchangeability: 0.75 ºC (1.35 ºF). This error can be compensated

by the offset parameter in the controller.

Note: Two sensors with 3 m cables (2 x 0.5 mm2) are bundled together with the

controller. The sensor cables can be extended up to 200 meters.

Measurement Resolution: ................................................0.1º from –19.9 to 119.9º

..................................................................... 1 ºC elsewhere

OUTPUT1:............... Relay SPDT; 1 HP 250 Vac / 1/3 HP 125 Vac (16 A Resistive)

POWER SUPPLY: ............................100 to 240 Vac/dc ±10%

Optionally: ...........................12 to 30 Vdc/ac

Mains Frequency: ........................ 50~60 Hz

Power Consumption: ............................ 5 VA

DIMENSIONS: Width x Height x Depth: ............................75 x 33 x 75 mm

Weight: .......................................................................100 g

Panel: ................................................................70 x 29 mm

ENVIRONMENT: Operating:............................. 0 to 40 °C (32 to 122 ºF)

Storage temperature: ..........-20 a 60 °C (-4 to 140 ºF)

Relative humidity:............ 20 to 85 % non-condensing

CASE: .................. Polycarbonate UL94-2; Protection: Front panel: IP65, Box: IP42

....................................................................................Suitable wiring: Up to 4.0 mm2

RS-485 digital communication; RTU MODBUS protocol (Optional)

Serial interface not isolated from input circuitry.

Serial interface isolated from power supply input, except in 24 V models.

INSTALLATION

It is important to follow the recommendations below:

•

Signal wires should be installed in grounded conduits and away from power or

contactor wires.

•

The instrument should have its own power supply wires that should not be

shared with electrical motors, coils, contactors, etc.

•

Installing RC filters (47 R and 100 nF, series combination) is strongly

recommended at contactor coils or any other inductor.

•

Use protection devices like circuit breakers and fuses.

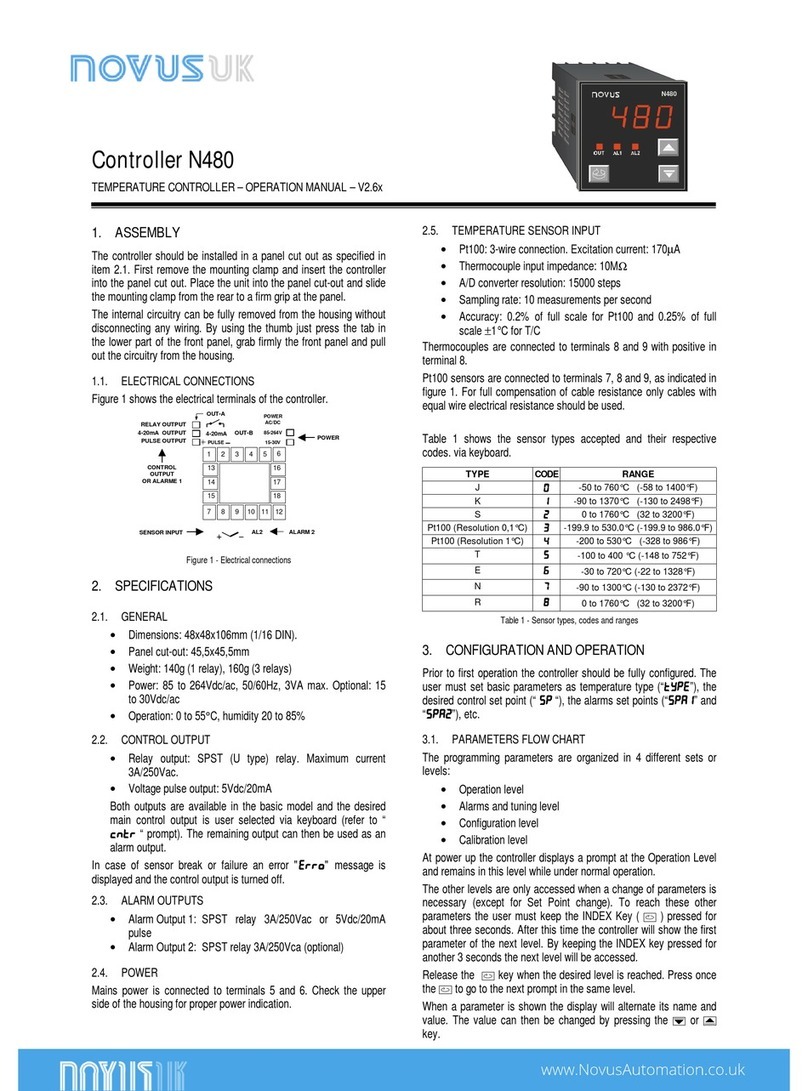

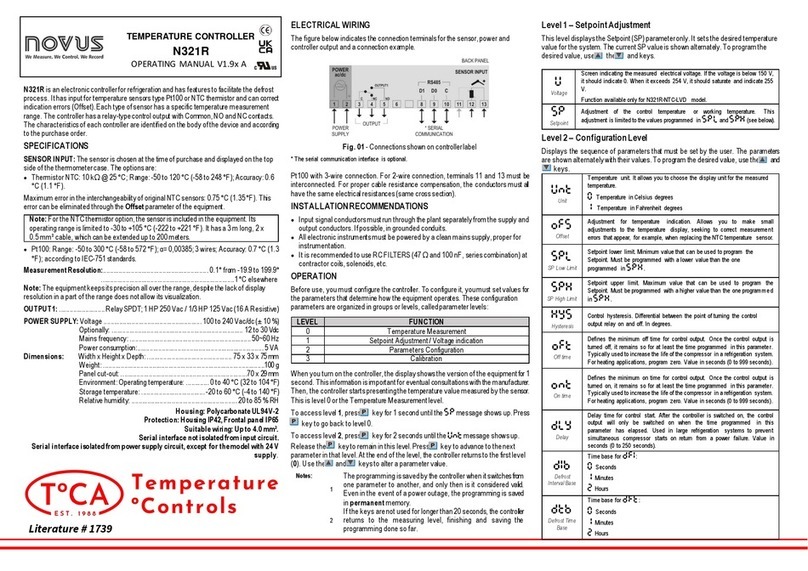

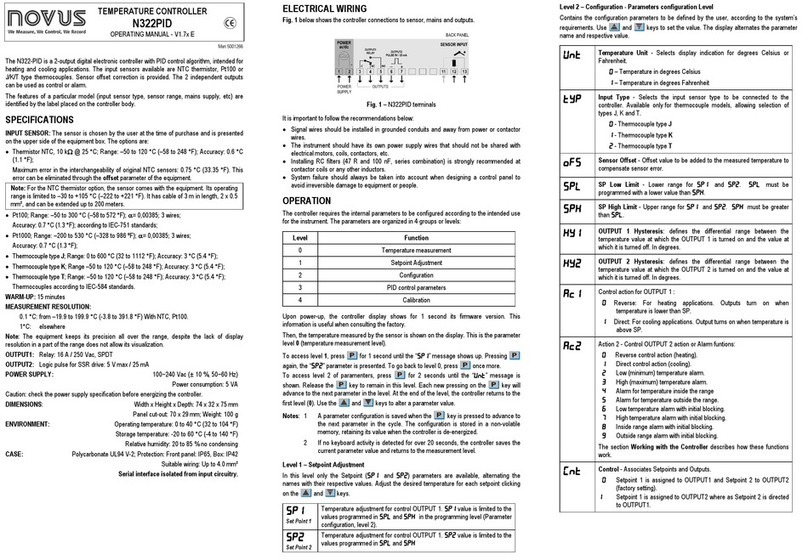

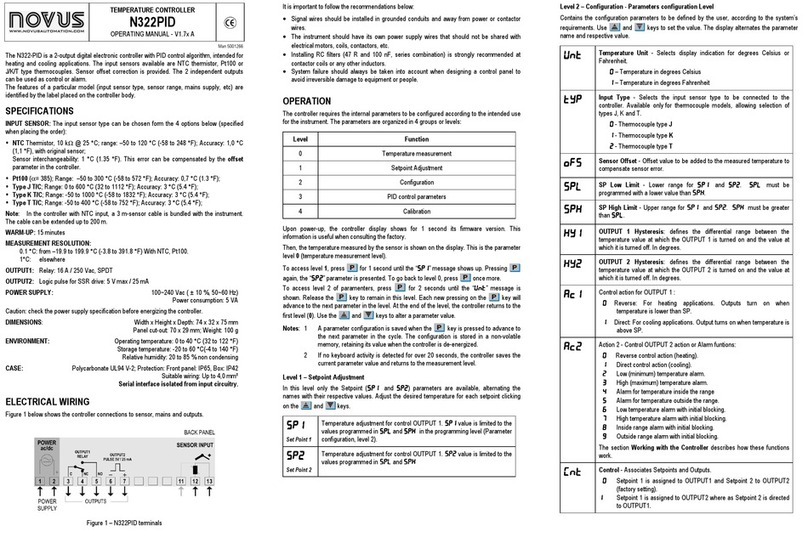

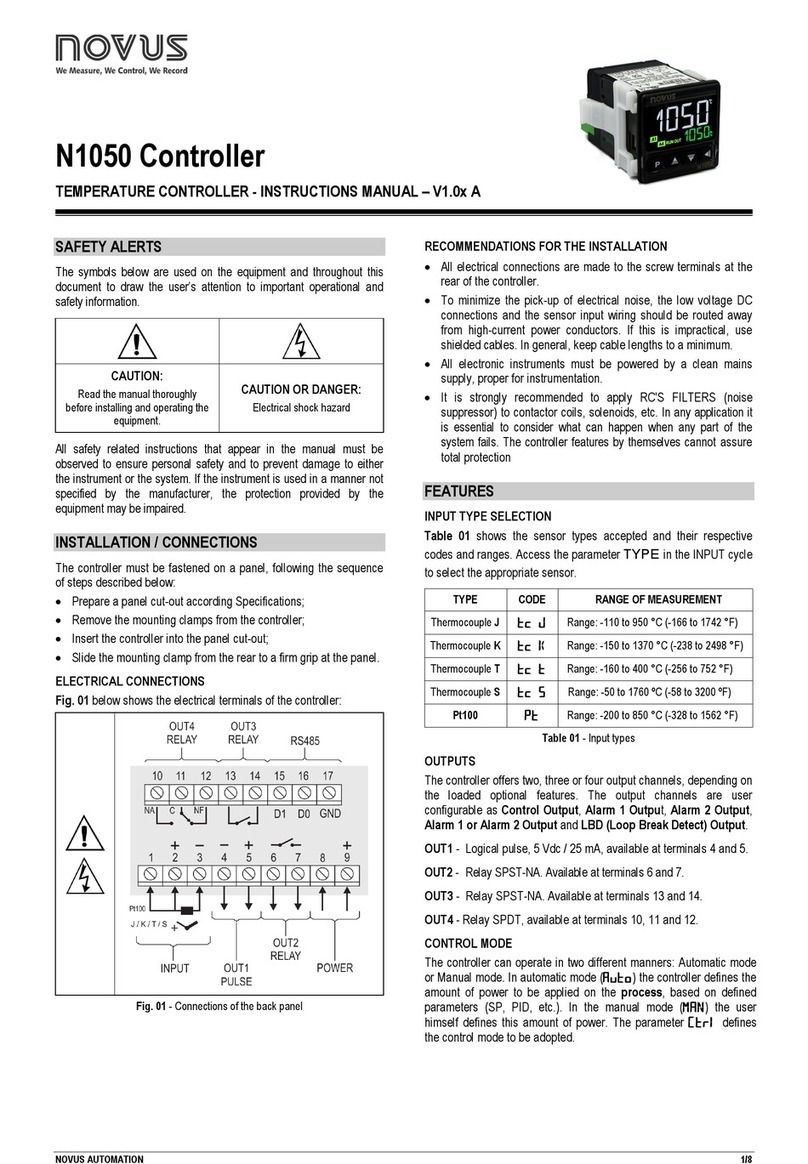

ELECTRICAL WIRING

Figure 1 below shows the controller connections to sensor, mains and outputs.

Figure 1 – N321S terminals

* The serial communication interface is optional.

OPERATION

The N321S contains several parameters that need to be configured in order to

determine system behavior.

These configuration parameters are organized in groups, the so called parameter

levels.

Level Function

0 Temperature Measurement

1 Setpoint Adjustment

2 Configuration

3 Calibration

Upon power-up, the N321S display shows for 1 second its firmware version. This

information is useful when consulting the factory.

Then, the temperatures of the sensors are displayed, according to the scheme

defined in the parameter “ind

indind

ind”

.

This is the parameter level 0(temperature

measurement level).

For accessing the level 1, press the key for 2 seconds until the “D0n

D0nD0n

D0n”

parameter appears. Release the key to remain on this level Pressing the

key sucessively the other parameters in this level are displayed.

For accessing the level 2, press the key for 4 seconds until the “unt

untunt

unt”

parameter appears. Release the key to remain on this level. Press again

to access the other parameters of this level. After reaching the last parameter, the

controller will return to the temperature measurement level.

Use the and keys to alter a parameter value. The display alternates the

parameters prompts and their respectives value.

Notes: 1 The configuration will be saved by the controller upon advancing

to the next parameter in a level.

2 If no keypad activity is detected within 20 seconds, the controller

saves the current parameter value and returns to the

measurement level.

Level 1 – Setpoint Adjustment

At this level, the display presents the setpoint parameters. They define the

differential temperatures values for the control. Use the and keys for

setting the suitable values.

D0n

D0nD0n

D0n

Differential setpoint for activating the pump.

When the difference between T1 and T2 is higher than the value

configured in d0

d0d0

d0n

nn

nthe pump will be turned on.

Max d0

d0d0

d0f

ff

fvalue: 20 ºC.

D0f

D0fD0f

D0f

Differential setpoint for deactivating the pump.

When the difference between T1 and T2 is lower than the value

configured in d0f

d0fd0f

d0f the pump will be turned off.

Adjustable between 1 ºC and D0n

D0nD0n

D0n.

Level 2 – Programming Level

This level contains other configuration parameters that are needed for establishing

a proper system performance.

Unt

UntUnt

Unt

Unit

Temperature Unit – Defines the temperature unit to be

displayed.

0

00

0Temperature in degrees Celsius

1

11

1Temperature in degrees Fahrenheit

ind

indind

ind

Indication

Temperature value exhibited on the display.

0

00

0

Temperature of the collectors (T1)

1

11

1

Temperature of the storage tank (T2)

2

22

2Temperature difference between the sensors (T1 –T2)

3

33

3Alternates the indication of (T1), (T2) and (T1-T2) at every 3s.

I(e

I(eI(e

I(e

Ice

Setpoint for low temperature.

When the temperature in the solar collector is lower than the

value here configured, the pump is turned on, preventing the

water from freezing in the pipe system and causing damages to it.

Adjustable between spl

splspl

spl and sp

spsp

spk

kk

k.

kti

ktikti

kti

High

Temperature 1

Setpoint for high temperature (at collector).

When the temperature in the collector is above the value here

configured, the pump is turned off, avoiding the overheated water

from damaging the pipe system.

Adjustable between Spl

SplSpl

Spl and SPk

SPkSPk

SPk.

K

KK

Kt2

t2t2

t2

High

Temperature 2

Setpoint for high temperature at S2 (storage tank).

When the temperature at the sensor S2 is above the value here

configured, the pump is turned off in order to avoid thermal

discomfort.

This function is useful in swimming pool heating systems which

do not use dedicated third sensor.

Adjustable between spl

splspl

spl and spk

spkspk

spk.

kys

kyskys

kys

Histeresis

Antifreezing temperature hysteresis of sensor S1 (i(e

i(ei(e

i(e). In degrees.

Adjustable between 0.1 and 50.0 ºC

Ky1

Ky1Ky1

Ky1

Histeresis 1

Overheating temperature hysteresis of sensor S1 (kt1

kt1kt1

kt1). In

degrees.

Adjustable between 0.1 and 50.0 ºC