Advantech LNC M5800 Series User manual

A-LNC Milling

Machine Series

Operation Manual

Leading Numerical Controller

Version: V01.00.003(4408230007)

Advantech-LNC Technology Co., Ltd.

Milling Machine Series

Table of Contents

IAdvantech-LNC Technology Co., Ltd.

Table of Contents

_Toc448762604

1CNC operations .............................................................................................1

1.1 Type of operation device........................................................................................................................ 1

1.1.1 M5800 series............................................................................................................................ 1

1.1.2 M6800 series............................................................................................................................ 8

1.2 Screen and function instructions........................................................................................................... 13

1.3 Monitoring group (MONITOR) .............................................................................................................. 15

1.3.1 Monitoring ............................................................................................................................ 15

1.3.2 Coordinate switching.............................................................................................................. 21

1.3.3 Variables................................................................................................................................ 24

1.3.4 Machining settings ................................................................................................................. 26

1.3.5 Machining data ...................................................................................................................... 29

1.3.6 Relative coordinates............................................................................................................... 30

1.3.7 Wear ..................................................................................................................................... 31

1.3.8 MDI ....................................................................................................................................... 32

1.3.9 Figures................................................................................................................................... 33

1.3.10 Load ...................................................................................................................................... 34

1.3.11 Program restart...................................................................................................................... 35

1.4 Program group (PROG)......................................................................................................................... 39

1.4.1 Select a file to be opened ....................................................................................................... 39

1.4.2 Preview ................................................................................................................................. 42

1.4.3 Supplementary commands ..................................................................................................... 43

1.4.4 Program editing ..................................................................................................................... 44

1.4.5 File management ................................................................................................................... 45

1.4.6 Manufacturer macros............................................................................................................. 49

1.4.7 Plot settings........................................................................................................................... 54

1.5 Compensation group (OFFSET) ............................................................................................................. 56

1.5.1 Coordinate system ................................................................................................................. 56

1.5.2Tool management .................................................................................................................. 61

1.5.3 Tool service life ...................................................................................................................... 64

1.5.4 Wear management................................................................................................................. 65

1.5.5 Tool registration ..................................................................................................................... 66

1.5.6 Automatic tool alignment ....................................................................................................... 67

1.6 Diagnosis group (DGNOS)..................................................................................................................... 72

Milling Machine Series

Table of Contents

II Advantech-LNC Technology Co., Ltd.

1.6.1 Alerts and warnings ............................................................................................................... 72

1.6.2 Ladder diagram ...................................................................................................................... 74

1.6.3 IOCSA .................................................................................................................................... 75

1.6.4 Timer/counter........................................................................................................................ 76

1.6.5 System information ................................................................................................................ 77

1.6.6 Alert history........................................................................................................................... 78

1.6.7 Operation history................................................................................................................... 79

1.6.8 R value .................................................................................................................................. 80

1.6.9 Waveform monitoring ............................................................................................................ 81

1.7 Maintenance group (MAINTE) .............................................................................................................. 82

1.7.1 User parameters .................................................................................................................... 82

1.7.2 Language settings................................................................................................................... 83

1.7.3 Network settings.................................................................................................................... 84

1.7.4 Changing identity ................................................................................................................... 85

1.7.5 Hardware contact................................................................................................................... 86

1.7.6 Parameters ............................................................................................................................ 87

1.7.7 Backup .................................................................................................................................. 88

1.7.8 System update ....................................................................................................................... 90

1.7.9 Tuning functions .................................................................................................................... 91

1.7.10 Period of use.......................................................................................................................... 94

1.7.11 Page permissions ................................................................................................................... 96

1.7.12 Change password ................................................................................................................... 97

1.7.13 Date and time ........................................................................................................................ 98

1.7.14 Version information ............................................................................................................... 99

1.7.15 Project settings .................................................................................................................... 100

1.8 Usage instructions ............................................................................................................................. 101

1.8.1Opening and editing a file..................................................................................................... 101

1.8.2 Execute machining ............................................................................................................... 109

1.8.3 Using the MDI function .........................................................................................................111

1.8.4 Program restart.....................................................................................................................113

1.8.5 Automatic tool alignment ......................................................................................................116

1.8.6 Network settings and connections ........................................................................................ 124

1.8.7 System update ..................................................................................................................... 127

1.8.8 System data backup - export................................................................................................. 131

1.8.9 System data backup - import ................................................................................................ 135

1.8.10 Preview function.................................................................................................................. 139

1.8.11 Editing and using manufacturer macros................................................................................. 145

Milling Machine Series

Table of Contents

IIIAdvantech-LNC Technology Co., Ltd.

1.8.12 Tool offset settings ............................................................................................................... 148

1.8.13 Coordinate system settings ................................................................................................... 150

1.8.14 Parameter settings ............................................................................................................... 153

1.8.15 File backup - import ............................................................................................................. 158

1.8.16 File backup - export.............................................................................................................. 163

1.8.17 Waveform monitoring function............................................................................................. 167

1.8.18 OnLine Help ......................................................................................................................... 174

1.8.19 Switching multiple paths ...................................................................................................... 174

2Control panel operations ........................................................................... 176

2.1 Operating panel ................................................................................................................................ 176

2.1.1 M5800 series........................................................................................................................ 176

2.1.2 M6800 series........................................................................................................................ 176

2.2 LED signal light (LED SIGNAL) .............................................................................................................. 177

2.3 Axis selection (AXIS SELECTION).......................................................................................................... 178

2.4 Mode selection (MODE SELECTION) .................................................................................................... 179

2.5 Spindle operation & spindle speed adjustment .................................................................................... 182

2.6 Supplementary function keys ............................................................................................................. 182

2.7 Emergency stop (EMG-STOP).............................................................................................................. 189

2.8 Program start (CYCLE START) & program pause (FEED HOLD) ................................................................ 190

2.9 Feed rate adjustment......................................................................................................................... 191

2.10 Program protection lock..................................................................................................................... 191

2.11 Seven-segment display of tool number ............................................................................................... 192

2.12 Power on/off..................................................................................................................................... 192

Milling Machine Series

CNC operations

1

Advantech-LNC Technology Co., Ltd.

1CNC operations

1.1 Type of operation device

The operation panel can be divided into the LCD liquid crystal display, MDI data input panel, and OP operation panel. The

main function of the MDI data input panel is to allow users to edit or modify a program and set numerical values. The OP

operation panel is a control panel for meeting all machining requirements; it is equipped with various switches and

function keys, and a pulse generator (hand wheel), etc. The operation panel can have different designs based on different

machines, but this system contains a set of standard panels which can be selected by the machine manufacturer.

1.1.1 M5800 series

Keys shown on the LCD liquid crystal display:

Function keys: There are 10 horizontal keys right below the LCD. They allow users to select functions which are

shown in the lower part of the screen.

Milling Machine Series

CNC operations

2

Advantech-LNC Technology Co., Ltd.

LCD liquid crystal display

Function keys

Milling Machine Series

CNC operations

3

Advantech-LNC Technology Co., Ltd.

Keys shown on the MDI panel:

MDI data input panel

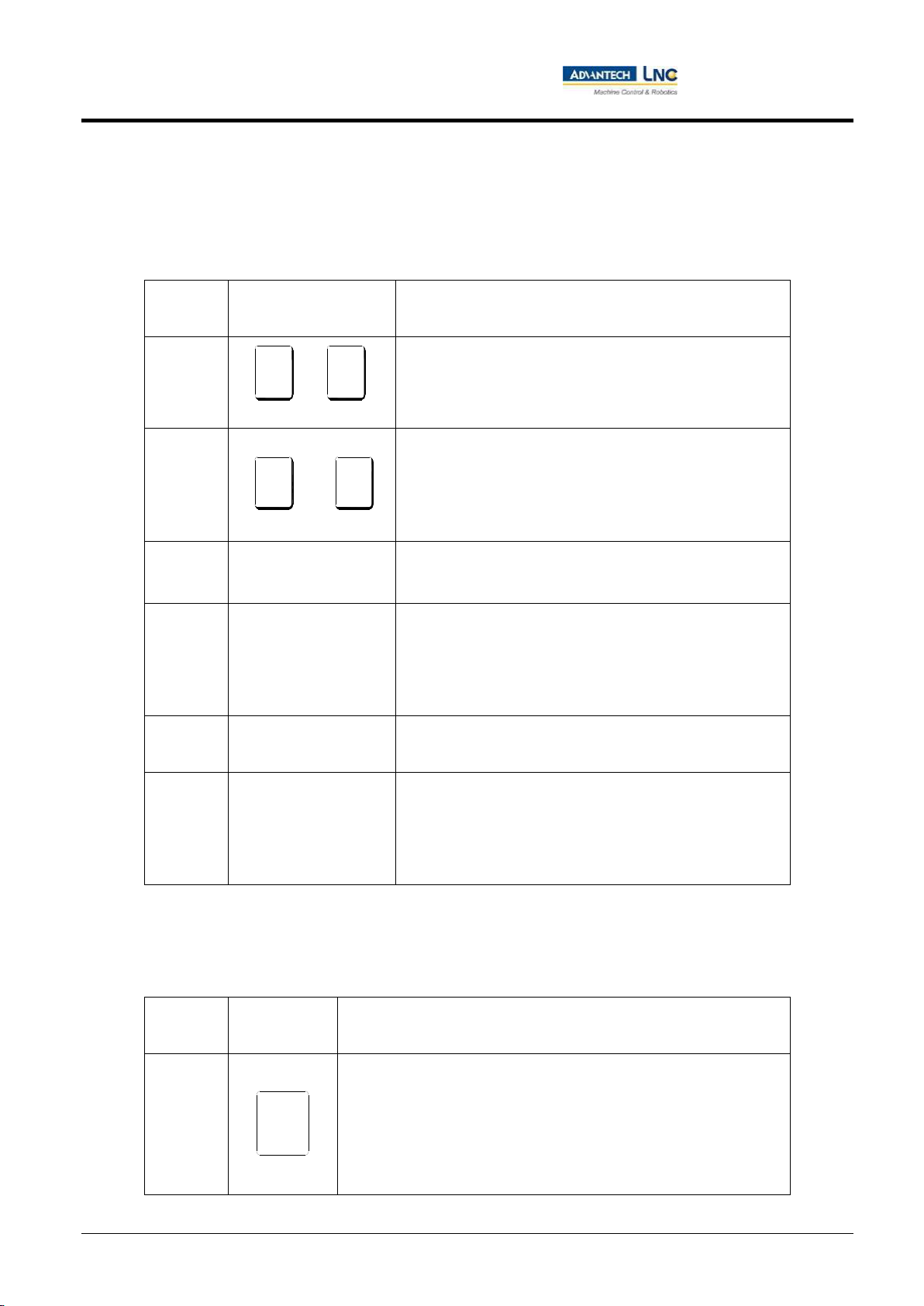

A. CNC function group key:

Name

Function group

key

Description

Monitoring

group

The group of screens showing various coordinates and machining data.

Program

group

All screens related to program information (in coordination with 1.

Editing mode, 2. Memory mode, 3. Manual mode).

Compensation

group

Sets the tool offset.

Diagnosis

group

Shows real time information from the diagnosis screen.

Milling Machine Series

CNC operations

4

Advantech-LNC Technology Co., Ltd.

Name

Function group

key

Description

Maintenance

group

System related settings.

Milling Machine Series

CNC operations

5

Advantech-LNC Technology Co., Ltd.

B. Text symbol and numerical symbol keys:

These letters, symbols, and digits are used mainly for program editing and data input. Some of the symbols are

minimized below the keys. The SHIFT key and the text symbol key must be pressed simultaneously to use these

minimized symbols.

Name

Supplementary editing

keys

Description

Letter

~

There are 26 letter keys from A to Z which can be used for

location or argument commands.

Number

?

9

0

=

~

?

9

0

=

There are 10 number keys from 0 to 9 which can be used for

numerical values or input data.

Symbol

/

The section requiring diagonal jump during program editing

Symbol

;

1. Pressing this key during program editing will indicate the

end of input program section.

2. If this key is placed at the very beginning of a program

block, it means this block of code will not be executed.

Symbol

﹒

The numerical value needs to be separated by a decimal point

during program editing.

Symbol

(、)、<、>、,、: 、

&、*、?、[、]、$、%、

^、!、@、#、+、=、-、

_、

Symbols to be used during program editing.

C. Supplementary editing keys:

These keys can be used in coordination with cursor and the highlighted row on the screen for program

modification, data setting, and page switching.

Name

Supplementary

editing keys

Description

System

reset

1. Default values of system rest status.

2. Cancel alert after the abnormal situation has been cleared.

3. Cancel the machining process after cycle start.

4. Return the cursor to highlight the program header in editing

mode.

X

U

Z

W

Reset

/ /

/ /

Reset

/ /

/ /

Milling Machine Series

CNC operations

6

Advantech-LNC Technology Co., Ltd.

Name

Supplementary

editing keys

Description

Go to

previous

page

<Page Up>

Field on the screen for navigating to the previous page.

Go to next

page

<Page Down>

Field on the screen for navigating to the next page.

Input

<Enter>

1. After entering a numerical value in the input area, press <Enter> to

store the numerical value into the field.

2. In windows explorer, move the cursor to the program location and

press <Enter> to open the file.

3. Press <Enter> in editing mode to insert a blank line.

Moves the

cursor up

1. Moves the cursor up while in program editing status.

2. Moves the cursor on this page upward.

Moves the

cursor down

1. Moves the cursor down in program editing status.

2. Moves the cursor on this page down.

Moves the

cursor left

1. Moves the cursor to the left in program editing status.

2. Moves the cursor on this page to the left.

Moves the

cursor right

1. Moves the cursor to the right in program editing status.

2. Moves the cursor on this page to the right.

Whitespace

Space

Enter the whitespace character.

Character

shift

Shift

It can be used for entering special symbols in combination with

symbol/number keys.

Please note: Character shift can only be done by simultaneously

pressing the SHIFT key and the text symbol key.

Row header

position

Home

Return the cursor for highlighted row to the character position at row

header during program editing.

Milling Machine Series

CNC operations

7

Advantech-LNC Technology Co., Ltd.

Name

Supplementary

editing keys

Description

End of row

position

End

Return the cursor to the last character position of the selected row

during program editing.

Please note: it must be used in combination with SHIFT key.

Cancel

character

CAN

Cancels the unwanted character at previous position.

Milling Machine Series

CNC operations

8

Advantech-LNC Technology Co., Ltd.

1.1.2 M6800 series

Keys shown on the LCD liquid crystal display:

Function keys: There are 12 horizontal keys right below the LCD. They allow users to select functions which are

shown in the lower part of the screen.

Milling Machine Series

CNC operations

9

Advantech-LNC Technology Co., Ltd.

LCD liquid crystal display

Function keys

Milling Machine Series

CNC operations

10

Advantech-LNC Technology Co., Ltd.

Keys shown on the MDI panel:

A. CNC function group keys:

Name

Function group

key

Description

Monitoring

group

The group of screens showing various coordinates and machining data.

Program

group

All screens related to program information (in coordination with 1.

Editing mode, 2. Memory mode, 3. Manual mode).

Compensation

group

Sets the tool offset.

Diagnosis

group

Shows real time information from the diagnosis screen.

Maintenance

group

System related settings.

CNC function group key

Milling Machine Series

CNC operations

11

Advantech-LNC Technology Co., Ltd.

B. Text symbol and numerical symbol keys:

These letters, symbols, and digits are used mainly for program editing and data input. Some of the symbols are

minimized below the keys. The SHIFT key and the text symbol key must be pressed simultaneously to use these

minimized symbols.

C. Supplementary editing keys:

These keys can be used in coordination with cursor and the highlighted row on the screen for program

modification, data setting, and page switching.

Name

Supplementary

editing key

Description

System

reset

1. Default values of system rest status.

2. Cancel alert after the abnormal situation has been cleared.

3. Cancel the machining process after cycle start.

4. Return the cursor to highlight the program header in editing

mode.

Go to

previous

page

( PgUp )

1. Field on the screen for navigating to the previous page.

Go to next

page

( PgDn )

1. Field on the screen for navigating to the next page.

Letter/symbol keys

Number/symbol

keys

Milling Machine Series

CNC operations

12

Advantech-LNC Technology Co., Ltd.

Name

Supplementary

editing key

Description

Input

1. After entering a numerical value in the input area, press <Enter> to

store the numerical value in the field.

2. After selecting a key in the child window, press <Enter> to confirm.

3. Press <Enter> in editing mode to insert a blank line.

Moves the

cursor up

1. Moves the cursor up while in program editing status.

2. Moves the cursor on this page upward.

Moves the

cursor down

1. Moves the cursor down in program editing status.

2. Moves the cursor on this page down.

Moves the

cursor left

1. Moves the cursor to the left in program editing status.

2. Moves the cursor on this page to the left.

Moves the

cursor right

1. Moves the cursor to the right in program editing status.

2. Moves the cursor on this page to the right.

Deletes the

character

1. Deletes the unwanted character at the next position.

Whitespace

1. Enter the whitespace character.

Character

shift

1. It can be used for entering special symbols in combination with

symbol/number keys.

Please note: Character shift can only be done by simultaneously

pressing the SHIFT key and the text symbol key.

Row header

position

1. Return the cursor for highlighted row to the character position at

row header during program editing.

End of row

position

1. Return the cursor to the last character position of the selected row

during program editing.

Milling Machine Series

CNC operations

13

Advantech-LNC Technology Co., Ltd.

1.2 Screen and function instructions

This controller can be divided into 5 function groups: Monitoring (MONITOR), program (PROG), offset (OFFSET), diagnosis

(DIAGN), and maintenance (MAINTE). In this manual, 【】represents function keys in the lower part of screen, and <

> represents keys on the MDI panel.

Layout of the display screen:

Note: Different models are equipped with different numbers of function keys in the lower part of screen.

1

2

3

4

5

6

7

8

9

10

11

12

Milling Machine Series

CNC operations

14

Advantech-LNC Technology Co., Ltd.

1: Path information. (It will only be shown when the multi-path function is available)

Note: numerator is the current path number, and denominator is the total number of paths.

2 : Name of currently assigned program.

Note: it refers to the filename currently being used by the controller.

3 : CNC mode information.

Note: 1. Jog, 2. Reference point, 3. Manual, 4. Incremental, 5. Hand wheel, 6. Automatic

4 : Machine's status information.

Note: 1. Not ready, 2. Ready, 3. Cycle start, 4. Machine paused, 5. Section stopped.

5 : Current function group.

Note: 1. Monitoring, 2. Program, 3. Offset, 4. Diagnosis, 5. Maintenance.

6 : Name of current page.

Note: it refers to the function page currently accessed by the controller.

7 : System time and user level.

Note: it refers to the current user level between L1 to L7.

8 : Range of each screen's display area.

Note: the range of variation to be shown by switching among function pages of each group.

9 : Input area/section.

Note: provided by the controller for users to input values in various fields on each page.

10: Summary information reminder section.

Note: the controller will provide an operation information summary prompt to remind users.

11: Display areas corresponding to the keys on the screen.

Note: this area is to be used for corresponding keys on the screen. If there are keys listed in this manual but they

cannot be seen on the controller, it means that current user does not have the proper permission level.

12: Error messages.

Note: Alerts and warnings.

Milling Machine Series

CNC operations

15

Advantech-LNC Technology Co., Ltd.

1.3 Monitoring group (MONITOR)

1.3.1 Monitoring

On the monitoring page, users can view various information such as the filename of the current program,

current operating mode, current machine status, has an alert being issued, feeding % status, spindle % status,

number of workpieces undergoing the machining process, maximum number of machining pieces, time required

for single machining, total time of machining accumulated, and various coordinates.

Description of various fields:

Users can inspect the current machining program's filename on the monitoring page as shown in the figure

below.

This manual suits for next models

1

Table of contents

Other Advantech Power Tools manuals

Popular Power Tools manuals by other brands

Bosch

Bosch GST Professional Series Original instructions

Metabo

Metabo STE 100 PLUS - operating instructions

Zimmer

Zimmer LKE Series Installation and operating instructions

Fein

Fein ASg 636 Kinetik operating instructions

Tyco Electronics

Tyco Electronics PRO-CRIMPER III instruction sheet

Josef Kihlberg

Josef Kihlberg B561PN Repair instructions