16 | English

1 619 929 J70 | (23.9.11) Bosch Power Tools

Battery Charging

fUse only the battery chargers listed on the accessories

page. Only these battery chargers are matched to the lith-

ium ion battery of your power tool.

Note: The battery is supplied partially charged. To ensure full

capacity of the battery, completely charge the battery in the

batterychargerbefore usingyour power toolfor the firsttime.

The lithium-ion battery can be charged at any time without re-

ducing its service life. Interrupting the charging procedure

does not damage the battery.

The lithium-ion battery is protected against deep discharging

by the “Electronic Cell Protection (ECP)”. When the battery is

empty, the machine is switched off by means of a protective

circuit: The inserted tool no longer rotates.

Do not continue to press the On/Off

switch after the machine has been au-

tomatically switched off. The battery can be damaged.

The battery is equipped with a NTC temperature control

which allows charging only within a temperature range of be-

tween 0 °C and 45 °C. A long battery service life is achieved

in this manner.

Observe the notes for disposal.

Removing the Battery

The battery 3is equipped with two locking levels that should

preventthebatteryfromfalling out when pushing the battery un-

lockingbutton 4unintentionally. As long asthe battery is insert-

ed in the power tool, it is held in position by means of a spring.

Toremove the battery 3, press the batteryunlocking button 4

and pull the battery toward the rear out of the power tool. Do

not exert any force when doing this.

Battery Charge-control Indication

(only for 3.0 Ah battery) (see figure A)

The three green LEDs of the battery charge-control indicator

16 indicate the charge condition of the battery 3. For safety

reasons, it is only possible to check the status of the charge

condition when the machine is at a standstill.

Press button 15 to indicate the charge condition. This is also

possible when the battery 3is removed.

When no LED lights up after pushing button 15, then the bat-

tery is defective and must be replaced.

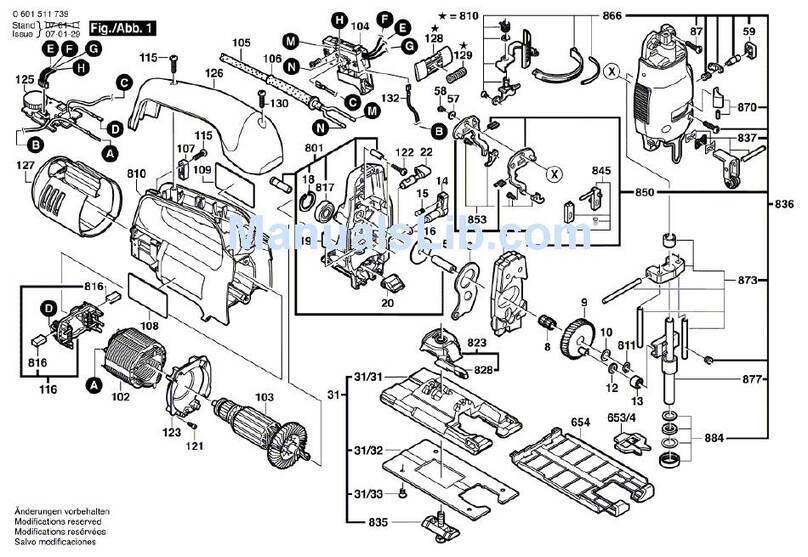

Replacing/Inserting the Saw Blade

fWhenmounting thesaw blade, wear protective gloves.

Danger of injury when touching the saw blade.

Selecting a Saw Blade

An overview of recommended saw blades can be found at the

endof theseinstructions.UseonlyT-shanksaw blades.Thesaw

blade should not be longer than required for the intended cut.

Use a thin saw blade for narrow curve cuts.

Inserting the Saw Blade (see figure B)

fClean the shank of the saw blade before inserting it. An

unclean shank cannot be fastened securely.

Insert the saw blade 11 into the stroke rod 17 until it latches.

The SDS lever 12 automatically snaps to the rear and the saw

blade is locked. Do not manually press the lever 12 toward

the rear, otherwise you could damage the machine.

While inserting the saw blade, pay attention that the back of

the saw blade is positioned in the groove of the guide roller 9.

fCheck the tight seating of the saw blade. A loose saw

blade can fall out and lead to injuries.

Ejecting the Saw Blade (see figure C)

fWhen ejecting the saw blade, hold the machine in such

a manner that no persons or animals can be injured by

the ejected saw blade.

Turn the SDS lever 12 forward towards the contact protector

13 to the stop. The saw blade is released and ejected.

Dust/Chip Extraction

fDusts from materials such as lead-containing coatings,

some wood types, minerals and metal can be harmful to

one’s health. Touching or breathing-in the dusts can cause

allergic reactions and/or lead to respiratory infections of

the user or bystanders.

Certain dusts, such as oak or beech dust, are considered

as carcinogenic, especially in connection with wood-treat-

ment additives (chromate, wood preservative). Materials

containing asbestos may only be worked by specialists.

– Asfar as possible, use a dust extraction system suitable

for the material.

– Provide for good ventilation of the working place.

– It is recommended to wear a P2 filter-class respirator.

Observe the relevant regulations in your country for the

materials to be worked.

fPrevent dust accumulation at the workplace. Dusts can

easily ignite.

Connecting the Dust Extraction (see figures D–E)

Insert the vacuum connection 18 into the opening of base

plate 7.

Place a vacuum hose 19 (accessory) onto the vacuum connec-

tion 18. Connect the vacuum hose 19 with a vacuum cleaner

(accessory).An overview for the connectionof various vacuum

cleaners can be found at the end of these instructions.

To enable optimum dust extraction, use the splinter guard 20

if possible.

The vacuum cleaner must be suitable for the material being

worked.

When vacuuming dry dust that is especially detrimental to

health or carcinogenic, use a special vacuum cleaner.

Splinter Guard (see figure F)

The splinter guard 20can prevent fraying of the surface while

sawingwood.Thesplinterguardcanonly be used with certain

saw blade types, and only at a cutting angle of 0°. When saw-

ing with the splinter guard, the base plate 7may not be offset

to the rear for sawing close to edges.

Insert the splinter guard 20 into base plate 7from the front.

LED Capacity

Continuous lighting 3 x green ≥2/3

Continuous lighting 2 x green ≥1/3

Continuous lighting 1 x green <1/3

Flashing light 1 x green Reserve

WARNING

OBJ_BUCH-1257-002.book Page 16 Friday, September 23, 2011 11:26 AM