2600 series Hydraulic Tooling (HK914) Alcoa Fastening Systems

8

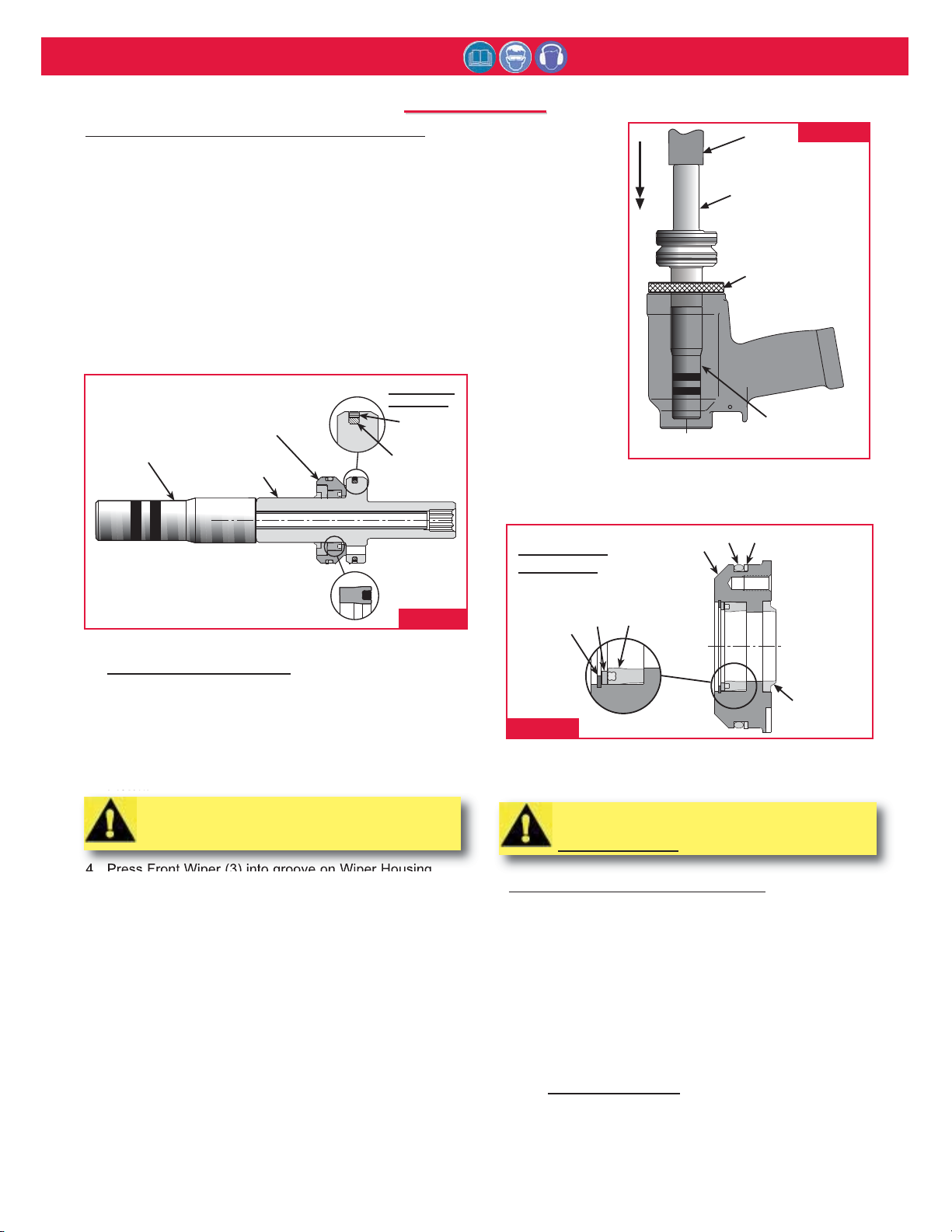

TO INSTALL A HUCKBOLT® FASTENER

1. Check work and remove excessive gap in the

space between sheets. Gap is excessive if not

enough pintail sticks through the collar for the

nose assembly jaws to grab onto.

2. Put fastener into hole.

3. Slide collar over fastener. (The beveled end of the

collar must be towards the nose assembly and

tool.)

4. Push nose assembly onto the fastener until the

nose assembly anvil stops against the collar. Tool

and nose assembly must be held at right angles

(90°) to the work.

5. Depress tool switch to start installation cycle.

6. When forward motion of nose assembly anvil

stops and pintail breaks off, release switch. Tool

will go into its return stroke, push off the installed

fastener and eject the pintail.

7. The tool and nose assembly is ready for the next

installation cycle.

O

OPERATING

PERATING I

INSTRUCTIONS

NSTRUCTIONS

WARNING: Reasonable care of installation

tools by operators is an important factor in

maintaining tool effeciency and in reducing

repair downtime. Do not abuse the tool by

dropping it, using it as a hammer, or

otherwise, causing unnecessary wear and

tear. Be sure there is adequate clearance

for the tool and operator’s hands before

proceeding. Do not connect tool’s hoses to

each other or use hoses as a handle for

carrying.

WARNING: Do not pull on a fastener

without a collar. If a fastener is pulled

without a collar, the fastener will eject

forcibly when the pintail breaks off.

S

SERVICING

ERVICING

THE

THE T

TOOL

OOL

See S

SPECIFICATIONS

PECIFICATIONS for fluid type. Dispose of fluid in

accordance with local environmental regulations. Recycle

steel, aluminum, and plastic parts in accordance with local

lawful and safe practices.

PREVENTIVE MAINTENANCE

NOTE: For supplementary information refer to

T

TROUBLESHOOTING

ROUBLESHOOTING, Parts Lists, and D

DISASSEMBLY

ISASSEMBLY

AND

AND

A

ASSEMBLY

SSEMBLY procedures in this manual.

SYSTEM INSPECTION

Operating efficiency of the installation tool is directly related to

performance of the complete system, including the tool with

nose assembly, hydraulic hoses, trigger and control cord, and

POWERIG. Therefore, an effective preventive maintenance

program includes scheduled inspections of the system to

detect and correct minor troubles.

1. Inspect tool and nose for external damage.

2. Verify that hydraulic hose fittings and couplings and

electrical connections are secure.

3. Inspect hydraulic hose for signs of damage or aging.

Replace hoses if damaged.

4. Inspect tool, hose, and POWERIG during operation to

detect abnormal heating, leaks, or vibration.

POWERIG MAINTENANCE

Maintenance instructions and repair procedures are in the

appropriate POWERIG Instruction Manual.

TOOL MAINTENANCE

At regular intervals, depending on use, replace all O-rings and

back-up rings in the tool. Spare Parts Kit 2600KITshould be

kept on hand. Inspect cylinder bore, piston and piston rod and

unloading valve for scored surfaces, excessive wear or

damage, and replace as necessary.

NOSE ASSEMBLY MAINTENANCE

Daily cleaning of the nose assembly is recommended. This

can usually he accomplished by dipping nose assembly in

mineral spirits, or other suitable solvent, to clean jaws and

wash away metal chips and dirt. If more thorough cleaning or

maintenance is necessary, disassemble the nose assembly.

Use a sharp pointed “pick” to remove imbedded particles from

the pull grooves of the jaws.

CAUTIONS:

- Consult MSDS before servicing tool.

- Keep dirt and other material out of

hydraulic system.

- Separated parts most be kept away

from dirty work surfaces.

- Dirt/debris in hydraulic fluid causes

Dump Valve failure in Tool and in

POWERIG® Hydraulic Unit’s valves.

- Always check tool assembly drawing

for the proper direction of the flats on

the Dump Valve.

CAUTION: Do not use TEFLON®* tape on

pipe threads. Pipe threads may cause tape

to shred resulting in tool malfunction.

(Slic-Tite is available in stick form as

Huck P/N 503237.)

CAUTION: Always replace seals, wipers,

and back-up rings when tool is

disassembled for any reason.