Advers PLANAR 44D 12 User manual

MANUFACTURER:

LLC Advers

11 Lesnaya Street,

Samara, 443100 Russia

Tel. (846) 270-68-64

Fax (846) 270-65-09

E-mail: advers-ts@yandex.ru

Air Heaters

PLANAR 44D 12

Operation Manual

ADVR.105.00.00.000 RE

ADVR.105.00.00.000 RE. Sheet 2 of 24

TABLE OF CONTENTS

Sheet

1 Introduction 3

2 Basic Parameters & Specifications 3

3 Safety Measures 4

4 Description of Heater Structure and Operation 5

5 Control Unit 8

6 Scope of Supply 8

7 Control Panel Functions 10

8 Installation Requirements 16

9 Post-Assembly Testing 21

10 Recommendations 21

11 Remedial Procedure for Heater Ignition Problems 22

12 Transportation and Storage 23

13 Warranty 23

14 The certificate on packing and acceptance 24

ADVR.105.00.00.000 RE. Sheet 3 of 24

1 Introduction

This Operation Manual is intended to familiarize the User with salient features,

operation, assembly and operating procedures for PLANAR 44D-12 (hereinafter

ended for heating a vehicle driver workplace and various

compartments of a motorized vehicle at atmospheric temperatures as low as -45°

(-113 F).

The complete operative scope of the heater comprises the following functions:

- provision of controllable air heating for an inhabited enclosed area in accordance

with the atmospheric air temperature,

- provision of forced air ventilation for an inhabited enclosed area.

Minor changes performed on the heater structure by the Manufacturer may not be

documented in this Operation Manual.

When placing an order or referring to the heater in documents pertaining to other

types of equipment, the heater codes will read as follows:

Diesel Air Heater PLANAR 44D-12 TU4591-008-40991176-2005,

2 Basic Parameters & Specifications

The basic heater specifications are quoted in Table 1.

The basic parameters are quoted to a margin of 10% tolerance at a temperature of

20 (68 F) at a nominal voltage.

Table 1

Parameter Code Version

PLANAR 44D 12

Nominal Supply Voltage, V 12

Fuel Type Diesel Oil in compliance with GOST 305,

atmospheric temperature-dependent

Heating Efficiency:

max, kW,

min, kW,

4

1

Heated Air Volume:

Max , m3 /h (cf/h)

Min, m3 /h (cf/h)

120 (4238)

70 (2472)

Fuel Consumption at:

Max power, l/h (gal/h)

Min power, l/h (gal/h)

0.49 (0.13)

0.12 (0.03)

Start/Stop Mode Manual

Maximum Weight, kg (lb) 8 (17.6)

Heater power consumption, W

mode

Max, W

Min, W

62

10

ADVR.105.00.00.000 RE. Sheet 4 of 24

3 Safety Measures

3.1 The installation of the heater and its fittings shall be performed by authorized

organizations only.

3.2 The heater may only be used for the purposes specified herein.

3.3 The fuel supply line shall not be installed inside the passenger compartment or

cabin of a motor vehicle.

3.4 A vehicle that uses the heater shall be equipped with a fire extinguisher.

3.5 The environment where the heater is to be used shall be free of highly

inflammable vapors and a large quantity of dust.

3.6 To prevent the possibility of exhaust gas poisoning, the heater shall not be used

when the vehicle is in an enclosed area (garage, workshop, etc).

3.7 When refueling the vehicle, the heater shall be switched off.

3.8 When performing welding operations on the vehicle or repairs on the heater,

disconnect the heater from the vehicle battery.

3.9 When assembling or dismantling the heater, observe the safety measures

specified by electric work regulations for the fuel supply system and

wiring system.

3.10 The heater shall not be connected to the vehicle electric circuit while the

engine is running or the battery is switched off.

3.11 The heater electric power supply must not be disconnected before the

end of the purge cycle.

3.12 The heater connectors must not be connected or disconnected while the

electric power supply is turned on.

3.13 Wait 5 to 10 seconds before switching the heater back on.

3.14 In the event of two subsequent ignition failures, contact the maintenance

department to report a malfunction.

3.15 In the event of a failure in heater operation, contact a designated repair

organization authorized by the Manufacturer.

3.16 Manufacturer warranty shall not apply if the above requirements are not

adequately met.

ADVR.105.00.00.000 RE. Sheet 5 of 24

4. Description of Heater Structure and Operation

The heater operates independently from the vehicle engine.

The fuel and electric power supply is provided by the vehicle. See Figure 4.1 for

the heater wiring diagram.

The heater is a self-contained heating device comprising the following:

- Heating device (See Figure 4.2 for basic components thereof);

- Fuel supply pump providing fuel for the combustion chamber;

- Ignition and indicator device (control panel);

- Wiring harness connecting heater fittings to the vehicle battery.

The operating principle is based on heating air driven through the heater

heat exchange system.

The heat sources are fuel combustion gases from the combustion chamber. The

resulting heat warms the walls of the heat exchanger, which is air-blown from the

outside. Air passes through the ribbing of the heat exchanger and enters the passenger

compartment or other compartments of the vehicle.

Upon ignition, control unit of heater checks the heater to ascertain whether fittings

such as the flame indicator, the overheat sensor, air pump motor, plugs, fuel supply

pump and the electric circuits thereof are working properly.

If no problem is detected, the ignition process starts.

In accordance with the preset sequence, the combustion chamber is fore-purged

and the heating plug warms up to the required temperature. Air and fuel starts to enter

the combustion chamber under the same procedure, whereupon the ignition process is

initiated. Once stable combustion is achieved, the heating plug switches off. Flame

control is provided by the flame indicator. All processes involved in heater operation

are monitored by the control unit.

The control unit controls heat exchanger temperature and halts the combustion

process as soon as the temperature exceeds the specified limit. The heater may be

switched off at any time.

Pressing the heater deactivation command stops the fuel entering and the

combustion chamber is purged with air.

During automated operation control of the heater in emergency situations, bear in

mind the following:

1) In the event of ignition failure, the process will be repeated. The heater will

switch off following two consecutive ignition failures,

2) If a combustion failure occurs while the heater is in operation, the heater will

switch off,

3) If the heat exchanger is overheated (maybe as a result of closure of the heater

inlet/outlet vents), the heater will switch off automatically,

4) If voltage drops below 10 V or exceeds 16 V the heater will switch off.

5) In the event of emergency shutdown, the indicator will show the information

according to the code of malfunction (see table 7.1).

ADVR.105.00.00.000 RE. Sheet 6 of 24

X 3, 4 S3, S4

XP1

XS1

Control unit

Heat er

Vehicle

-

+12V

Battery

Flame indicator

black*

red*

Glow plug

Bi- metall

ter mo breaker

X 1

XS1

2

1

4

Circuit

input data

General

output data 3

+12V

Control Panel

fuel pump

XS4

XP4

1

+12V

Circuit

- 12V 2Supply har ness

Air pump

black*

black*

1

2

Circuit

+12V

General

green*

yellow*

X 6 XS6

1 2 1

2

white

yellow

green

brown

red

red

black

2

1

4

General

3

+ 12V

Circuit

XS5

X 5

Output data

input data

blue

red

black

25

25

red

C

o

n

t

r

o

l

P

a

n

e

l

h

a

r

n

e

s

s

2

Control

General

1

XP6

XS6

Fuel pump har ness

blue

2

1

XS3 XP3

blue

red

Control

General

brown

yellow

white

green

Circuit Circuit

X 5 XS5

* - the colorof mar king on flameindicator and air pump wiring .

black

red

2

1

Circuit

XP2

XS2

Sensor

General Cabin temperature sensor

XS2

XP2

1

2Alumel

Chromel

Circuit

1

2

Circuit

PWM

Revolutions

black

red

1

2 2

1

X 3, 4 S3, S4

XP1

XS1

Control unit

Heat er

Vehicle

-

+12V

Battery

Flame indicator

black*

red*

Glow plug

Bi- metall

ter mo breaker

X 1

XS1

2

1

4

Circuit

input data

General

output data 3

+12V

Control Panel

fuel pump

XS4

XP4

1

+12V

Circuit

- 12V 2Supply har ness

Air pump

black*

black*

1

2

Circuit

+12V

General

green*

yellow*

X 6 XS6

1 2 1

2

white

yellow

green

brown

red

red

black

2

1

4

General

3

+ 12V

Circuit

XS5

X 5

Output data

input data

blue

red

black

25

25

red

C

o

n

t

r

o

l

P

a

n

e

l

h

a

r

n

e

s

s

2

Control

General

1

XP6

XS6

Fuel pump har ness

blue

2

1

XS3 XP3

blue

red

Control

General

brown

yellow

white

green

Circuit Circuit

X 5 XS5

* - the colorof mar king on flameindicator and air pump wiring .

black

red

2

1

Circuit

XP2

XS2

Sensor

General Cabin temperature sensor

XS2

XP2

1

2Alumel

Chromel

Circuit

1

2

Circuit

PWM

Revolutions

black

red

1

2 2

1

figure 4.1- Wiring Diagram

ADVR.105.00.00.000 RE. Sheet 7 of 24

83

100

83

100

Figure 4.2 Basic Heater Components

ADVR.105.00.00.000 RE. Sheet 8 of 24

5. Control Unit

The control unit and the control panel control the heater.

The control unit performs the following functions:

) initial diagnostics (serviceability check) of heater fittings during ignition,

b) diagnostic of heater elements throughout operation,

c) heater activation/deactivation by command from control panel;

d) combustion process control;

e) automated switching of ventilation after the combustion process stopped;

f) automated deactivation of the heater occurs:

- in the event of failure of one of the controlled elements,

- when any parameter exceeds the specified limit (heat exchanger temperature,

supply voltage, combustion chamber flame failure)

6. Scope of Supply

See Figure 6.1 for scope of supply and connection diagram of basic heater

components. For list of basic heater components, see Table 6.1.

22

11

4* *

20* *

21* *

51* *

19

30

38

43

1

52

36

36

38 (4 .)

41 (4 .)

43 (4 .)

27 (4 .)

25

18

30

38

17

30

38

17

30

38

30

38

43

2

36

30

38

43

50 (8 .)

7

8 (3 .)

36 (3 .)

33 (6 .)

38 (6 .)

41 (6 .)

43 (6 .) 9

18

S1

S3

P13

6

53

12

+

-

13*

49*

5

P2

P1

S2

Sur face of cabin

(vehicle)

10

Fuel

10

Figure 6.1 Connection Diagram of Basic Heater Components

ADVR.105.00.00.000 . Sheet 9 of 24

Table 6.1

No.

Designation Pieces Per

Set

1 Heater 1

2 Control panel -8 with harness 1

4**

Fuel Supply Pump, Holder, Clamp (Set)

, Gasket(set)

(installation kit)

1

5 Cab temperature sensor 1

6 Fuel Supply Pump Harness 1

7 Fuel tank 1

8 Holder with gasket 3

9 Heat insulation 1

10 Fuel supply intake 1

11 Air Intake 1

12 Power Supply Harness 1

13*

Screen 1

17 Holder 2

18 Exhaust Pipe Clamp 3

19 Air Inlet Clamp 1

20**

Shock absorber 1

21**

Holder 1

22 Exhaust Pipe 1

25 Connecting Tube (polyamide) L = 5500 mm 1

27 Socket L= at least 70 mm (or one hose L= 4 x 70 = 280 mm) 4

30 Bolt 7

33 Bolt M6x20 6

36 Screwm 6.4 16 7

38 Nut 17

41 Enlarged Flat Washer 6 10

43 Split Washer 6 14

49*

Clamp Torro 20 32/9W1 1

50 Clamp \9 8

51**

Clamp Torro 35 50/C7W1 1

52 Clamp 1 26 1

53 Plastic Clamp 8

*Delivery of an exhaust pipe 22 with not established screen 13 is possible.

Screen installation to make according to fig. 6.1.

**Delivery of the fuel pump with not established holder 21, Clamp 51 and shock

absorber 20 is possible.

ADVR.105.00.00.000 . Sheet 10 of 24

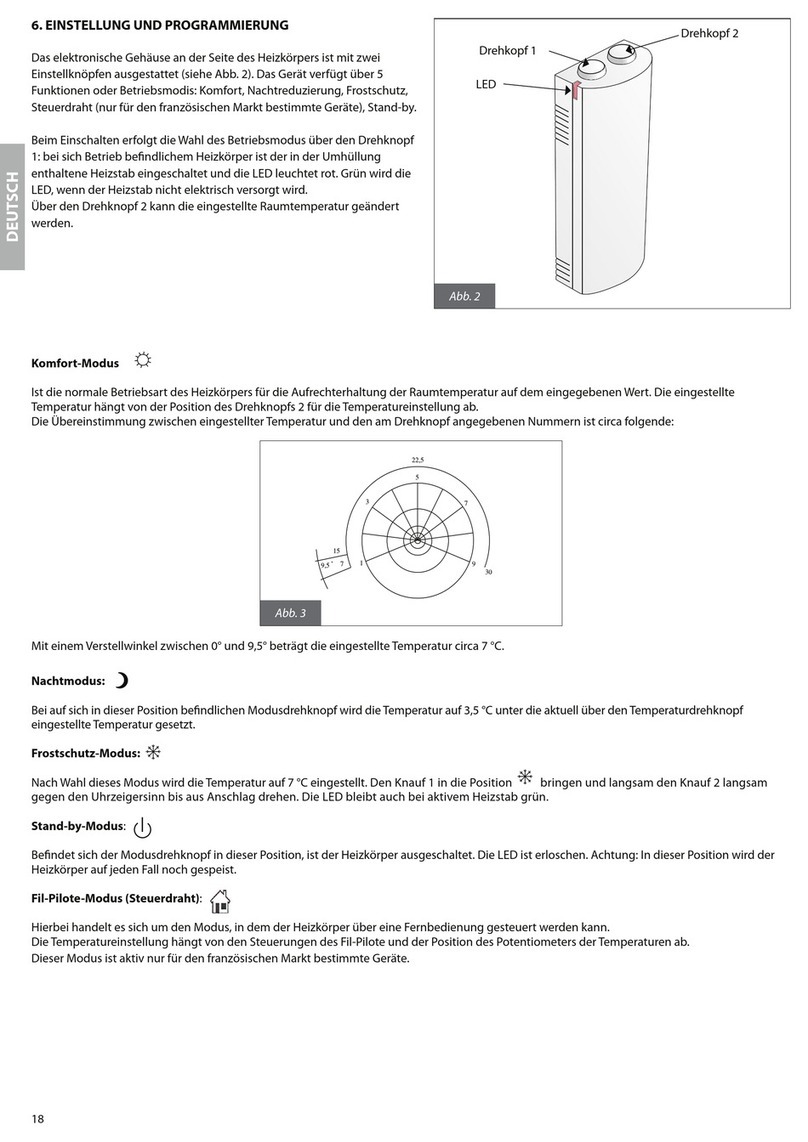

7. Control Panel Functions

7.1 The control panel is intended for:

-heater activation and deactivation in manual mode;

-setting operation mode according to desired power or temperature;

-heater status indication (from the sensor integrated in the heater, control panel unit or

external sensor if connected);

-failure code indication in case of heater failure while operation.

The front board of the panel contains: four-digit light emitting diode (LED)

indicator, two LEDs and three knobs. Functionality of the knobs and LEDs. (fig.7.1)

LED indicat or N1

(t emper at ur e mode)

(power mode)

LED indicat or N2

mode select ing/ decr easing

of power or t emper at ur e Sensor select ing/ incr easing of

power or t emper at ur e

Set ting of oper at ion mode/ heat er

ON- OFF knob

12

C

a

b

i

n

t

e

m

p

e

r

a

t

u

r

e

s

e

n

s

o

r

(if connect ed)

Heat er t emper at ur e

sensor

Cont r ol panel

t emper at ur e sensor

LED indicat or N1

(t emper at ur e mode)

(power mode)

LED indicat or N2

mode select ing/ decr easing

of power or t emper at ur e Sensor select ing/ incr easing of

power or t emper at ur e

Set ting of oper at ion mode/ heat er

ON- OFF knob

12

C

a

b

i

n

t

e

m

p

e

r

a

t

u

r

e

s

e

n

s

o

r

(if connect ed)

Heat er t emper at ur e

sensor

Cont r ol panel

t emper at ur e sensor

Fig. 7.1- Control panel

While first time the heater is connected to electric circuit of the car or after

breaks of power supply, according to environmental temperature there will be

following information on the panel (for example)- the temperature in the area of the

sensor installed in the heater is -12°C (drawing 7,2), if the temperature in the area of

figure.

1212

fig 7.2- View of the indicator after connection to electric circuit of the heater (initial

stage of the indicator)

ADVR.105.00.00.000 . Sheet 11 of 24

With the view to energy saving , the indicator stops glowing 20 seconds after last

pressing of any knob, while this LED#1 or LED#2 is :

- lightning constantly if the heater is activated;

- blinking rarely (1 time per 1,5 second) if the heater is not activated;

- blinking while fault (1 time per second);

- blinking frequently (5 times per second) while deactivation of the heater (while

purging)

7.2 Succession of work with the control panel

7.2.1 Operation mode set up.

mode. Pressing knob with

temperature. According to the choice the LED#1 orLED#2 is lightning. After selecting

choose the sensor, according which the temperature of the heater will be controlled.

7.2.2 Activation and setting the power or temperature.

start working and t - the power mode or

temperature mode according to your choice.(see fig. 7.3 or 7.4)

1212

Fig. 7.3 (power mode) Fig. 7.4 (temperature mode)

ADVR.105.00.00.000 . Sheet 12 of 24

you can set up the necessary power (see fig. 7.3)which can be set

within 1 to 4 kW. The indicator shows the scale according which the power is set up.

you can set up the necessary temperature (see fig. 7.4). The

temperature is set within 15° (59°F) to 30°C (86°F).

Attention!

1. The heater Operation mode (according to power or temperature) is saved

until new set up.

2. If cabin temperature sensor circuits are disconnected heater will go

working on middle power Operation mode.

3.While heater activation without setting operation modes it is necessary to

one time if the indicator is lightning, and 2 times if the

indicator is not lightning.

7.2.3 Heater deactivation.

While this the heater is in switching

off mode, that means that the combustion process in combustion chamber is stopped

and the process of purging is started. According to the mode the indicator will show

information(for example) (see pictures 7.5 or 7.6), the LED#1 or LED#2 will be

blinking frequently until the process of purging is stopped.

1212

Picture 7.5-Purge Picture 7.6- Purge

Attention!

It is forbidden to switch off electric power supply before purge cycle is

finished.

ADVR.105.00.00.000 . Sheet 13 of 24

7.2.4 Indication of malfunction code while failures in heater operation

While heater activation and operation there can be malfunctions. In case of

malfunction the control unit deactivates the heater automatically. Every malfunction is

coded and automatically appears on the indicator (see fig 7.7). While this, malfunction

ibed in table 7.1. Pressing of any knob of the

control panel will switch off indication of the malfunction code and bring the control

panel in initial state.

0202

fig 7.7 The panel the indicator at heater malfunction

Table 7.1-Malfunction codes

Malfunction code

Problem description Commentary

Problem solution

01 Heat Exchanger overheating

Check the inlet/outlet pipe

of the heater for

unpumped heated air

f

low. Check the overheat

sensor on the heat

exchanger, replace if

necessary.

02 Possible overheating on

temperature sensor. The sensor

temperature (control unit) is more

than 55°C

While purging before start

the control unit is not

cooled enough or control

unit is overheated during

operation. Check

inlet/outlet pipe of the

heater for unpumped

heated air flow and repeat

activation to cool the

heater.

04 Built-in temperature sensor on

control unit failure

Replace the control unit

ADVR.105.00.00.000 . Sheet 14 of 24

05 Flame indicator failure

Check the flame indicator

circuit

for disconnection

fault with sensor

disconnected of its plate.

Resistance between

contacts should not

exceed 10 Ohm.

Replace

the indicator if it is not

operational.

08 Flame failure Check the fuel level and

fuel supply system. Check

combustion air system

and the exhaust pipe line.

If the heater can be

s

tarted, check fuel pump

and replace if necessary.

09 Heating plug failure Check the plug and

replace if necessary.

10 Air pump motor failure Check the wiring of the

air pump, replace motor if

necessary.

12 Shutdown, voltage boost Check the battery,

regulator and power

supply wiring. The

voltage between 1 contact

and 2 contact of connector

XS4 (see connection

layout picture 4.1) should

not exceed 16V

13 No further activation attempt is

possible

If possible quantity of

activation attempts is

used, check the heating

plug, fuel level and fuel

supply system. Check

combustion air system

and exhaust pipe line.

15 Shutdown, low voltage Check the battery,

regulator and power

supply wiring. The

voltage between 1 contact

and 2 contact of connector

XS4 (see connection

layout pic

ture 4.1) should

be not less 10V

ADVR.105.00.00.000 . Sheet 15 of 24

16 Ventilation period takes longer

than usual

The heater is not cooled

sufficiently during the

purge. Check the

combustion air supply

system and exhaust pi

pe

line. Check the flame

indicator and replace if

necessary.

17 Fuel pump failure

Check fuel pump wiring

for short-circuit fault or

disconnection fault.

Replace the pump if

necessary.

20 No connection between Control

panel and the heater

Check wiring, co

nnectors.

27 Air pump motor fault. Motor

Check air pump motor

wiring, connector, replace

motor if necessary.

28 Air pump motor fault. Motor

switch off, go on rotation

Check air pump motor

wiring, replace motor if

necessary.

7.3 Control Panel installation and connection

Control Panel is installed in cabin or passengers compartment on the dashboard or

any other comfortable for the driver place.

The control Panel is fixed with double-faced adhesive tape, which is stuck to the

back side of the Control Panel. You can take out wires of the unit from its back or side

cover. It is necessary to degrease the surface used for Control panel installation. Take off

protective film from the tape and install the Control Panel on the prepared surface.

The connection of the Control panel to the heater is performed according wiring

diagram (see fig. 4.1)

7.4 Complex checkup of the Control Panel after installation

After installation and connection of the Control panel to the heater the checkup is

performed in following way:

-set up the necessary operation mode on the Control panel;

-check activation and deactivation of the heater;

-check deactivation of the heater while artificial failure (take off the connector

from the fuel pump during operation mode of the heater), while this the malfunction

code appears on the indicator.

7.5 Possible malfunctions

If after pressing any knob of the Control Panel the indicator is not lightning, there

should be checked:

- fuses-25A;

- connectors and wires.

The Control Panel is not subjected to repair, it should be replaced for a new one.

ADVR.105.00.00.000 RE. Sheet 16 of 24

8 Installation Requirements

8.1 Heater Installation

Installed the heater indoors while bearing in mind the permissible operating

positions shown in Figure 8.1. The figure 8.1 shows the two maximum assembly

positions of the heater. Positioned the inlet vent in such a way to prevent

absorption of vehicle/heater exhaust gas in normal operating conditions. The gap

between the walls/partitions and the edge of the inlet vent shall be at least 50 mm (see

Figure 8.1). When assembling or operating the heater, ensure that no foreign objects

enter the inlet/outlet vents. Prior to assembly, ensure availability of spare heating plug

and bear in mind dismantlement requirements, as this will permit easier maintenance in

future. See Figure 8.2 for how to position mounting holes to install the heater into the

motor vehicle casing. Overall and mounting Dimensions are on the fig.8.3

ATTENTION !! To ensure reliable performance, follow the above

recommendations carefully. Install the heater horizontally as shown in Figure 8.1.

50

Heater harness (possible

variant) ) - wall- mounted

b) - Floor- mounted

Prohibited

Prohibited

Prohibited

Prohibited

50

Heater harness (possible

variant) ) - wall- mounted

b) - Floor- mounted

Prohibited

Prohibited

Prohibited

Prohibited

Figure 8.1

Variants of installation of a heater.

ADVR.105.00.00.000 RE. Sheet 17 of 24

1 8

5 5

2 5

2 1

6 , 5

4

.

1 1

Figure 8.2 Mounting Holes Used for Heater Installation

R26

18

32

397,5

160,5 28

55

150,5

7150

17

119

15

15

R26

18

32

397,5

160,5 28

55

150,5

7150

17

119

15

15

Figure 8.3- Heater dimensions

8.2 Air Inlet Installation

Air necessary for burning, should not be soaked up from salon or a cabin and a car

luggage space. Position the air inlet vent to prevent snow entering or

choking the pipe and to allow incoming water to run off. The entrance aperture of

an air inlet is forbidden to have against a running air stream at car movement.

8.3 Exhaust Pipe Installation

When installing the exhaust pipe, be mindful of its high operating temperature. Cut

the exhaust pipe (a flexible corrugated metal hose) to size. Fix the exhaust pipe in

place using clamps and position it at a slight angle following the trajectory of gas flow.

To protect some parts of the vehicle (electric wiring and other harness) from high

temperatures, there must be heat insulation installed.( pos.9, fig.6.1)

ADVR.105.00.00.000 RE. Sheet 18 of 24

To achieve a tight fit, prior to connecting the exhaust pipe to the heater pipe, make

a saw-cut of about 15mm along the length of the exhaust pipe without going beyond

the gripped part of the pipe. Ensure that the end of the exhaust pipe does not come into

contact with the rubber seal of the heater. Direct exhaust gas outside. Position the gas

outlet vent and the air inlet vent in such a way as to prevent exhaust gas from entering

the combustion chamber. Ensure that exhaust gas does not enter the passenger

compartment of the vehicle and that it does not get sucked in through the vehicle fan.

Do not allow exhaust gas to affect the performance of vehicle components. Position

the exhaust pipe outlet vent so as to prevent snow entering or choking the pipe and to

allow incoming water to run off. At the vent of the exhaust pipe the screen is installed,

this necessary for stable operation of the heater while working low idle. If this screen is

not installed, install it according fig.6.1 The exhaust outlet of an exhaust pipe is

forbidden to have against a running air stream at car movement.

8.4 Installation of Heater Fuel Supply System

A feeding of a heater by fuel can be carried out from a fuel tank entering into the

delivery complete set (pos. 7 on fig. 6.1) or from a regular fuel tank of the car.

At a feeding of a heater by fuel from a regular tank of the car in a car tank it is

established fuel supply intake (pos.10 on fig. 6.1).

8.4.1 Installation of Heater fuel pump

To prevent emergency situations, follow these instructions carefully.

The fuel supply pump should be mounted as close to the fuel tank as possible

and positioned below the lower fuel level.

To prevent the possibility of fuel leaking out of the tank (due to gravity flow) as

a result of faulty sealing of the fuel supply pump, the fuel tank should be positioned in

such a way that the maximum fuel level is below the incision in the heater fuel tube.

The spatial position of the fuel supply pump must comply with Figure 8.4

(preferably in a vertical position).

lift height up to 700 mm (2 ft); b delivery lift between fuel supply pump and

heater up to 1500 mm (5 ft).

Figure 8.4- Permissible Mounting Position of Fuel Supply Pump

ADVR.105.00.00.000 RE. Sheet 19 of 24

8.4.2 Installation of a fuel tank on the car

A fuel tank it is necessary to have so that the exit of fuel which can flow out from

its bulk mouth, on the earth was provided.

The bulk mouth of a fuel tank should not be in salon, a luggage carrier, in a motor

compartment. If the bulk mouth is located on a vehicle lateral face the filler cap in the

closed position should not support body dimensions. Fuel which can spill at

filling of a fuel tank, should not get on exhaust systems and electro wires. It should be

taken away on a ground.

For the purpose of an exception of leak of fuel from a fuel tank by gravity at

infringement of tightness of the fuel pump, a fuel tank it is preferable to have so that

the fuel maximum level was below a cut of a fuel tube of a heater.

8.4.3 Installation a fuel supply intake in a regular tank of the car

Fuel can enter the heater through a fuel supply intake from the regular fuel tank of the

car. Fuel supply intake must be installed into regular fuel tank of the car according to

fig. 8.5,a. Perform installation of special washer with fuel supply intake to the tank

inlet according to fig.8.5,b) Perform installation of the fuel supply line from fuel

supply intake to the heater according to fig.8.6.

6

2

4

3

16

5

5

Wall of a fuel t ank

1

16

1

6

2

4

3

16

5

5

Wall of a fuel t ank

1

16

1

1 -

fuel supply intake

4-washer

8

2- nut M

8

5- special washer

3- washer 8

6-gasket

Fig 8.5 Fuel supply intake installation in a regular tank of the car

ADVR.105.00.00.000 RE. Sheet 20 of 24

Attention! 1. A fuel feeding from a regular fuel tank of the car with the help of fuel

supply intake less preferable, because of complexity of its installation

2. At manufacturing of a hole in a regular fuel tank of the car it is

necessary to fulfil safety precautions requirements on job with tank which was filled

with combustible and explosive fuel.

2

1 5

5

5

4 3

3

6

1 regular fuel tank of car

4 - fuel pump

2 - fuel supply intake 5 - sleeve

3 fuel supply line d=2mm 6 fuel supply line d=5mm

Figure 8.6 Installation Diagram for Heater Fuel Supply System Using a fuel supply

intake

When installing the fuel supply line, do not allow connecting sleeves to bend.

Use a sharp knife to cut the fuel tube as in Figure 8.8. The cutting location shall be free

of indentations, hairs and must not restrict flow through the tube.

Figure 8.8 Tube Cutting Prior to Installation

Correct Incorrect

Table of contents

Other Advers Heater manuals

Popular Heater manuals by other brands

ermaf

ermaf RGA 100 ACU operating instructions

EINHELL

EINHELL NKH 1500 D operating instructions

ARDES

ARDES AR4P21W Instructions for use

AUTOTERM

AUTOTERM PLANAR-4DM2-12/24-P Operation manual

Herschel

Herschel CALIFORNIA 2000R Installation & operating instructions

Nova Florida

Nova Florida Simun EA Series Installation and maintenance manual