GB-12

GB

8 Read the burner pressure at the pressure test

point for pGand readjust if necessary. Measure

the λ and O

2

values with a calibrated flue gas

measuring instrument and adjust according to

the values in the table:

Gas type

Inlet

pressure

pu[mbar]

Burner

pressure

pG[mbar]

Lambda

λO[%]

min. max. max. min. max. min. max.

Natural gas L

G25 25 100 15.5 1.2 1.35 3.5 5.4

Natural gas

K gas (G+) 25 100 15.5 1.2 1.35 3.5 5.4

Natural gas

H G20 20 100 11.5 1.2 1.35 3.5 5.4

LPG butane

G 30 29 100 18.7 1.2 1.35 3.5 5.4

LPG

propane

G 31

29 100 22.0 1.2 1.35 3.5 5.4

▷

If the burner pressure is ≤ the value in the ta-

ble and the minimum λ and O

2

values are not

reached, reduce the burner pressure until the λ

and O2values are between the min./max. limits.

▷If the burner pressure is ≤ the value in the table

and the maximum λ and O

2

values are exceeded,

increase the burner pressure by a maximum

of 5%.

▷

If the measured values correspond to the details

on the type label and in the table, the heater has

been set correctly. Otherwise, continue with the

measurement and fine adjustment until the heater

is correctly set.

▷Heater adjustment is now complete.

CAUTION

To avoid damage to the heater RGA100, please

observe the following:

– The low-fire rate may only be set by author-

ized trained personnel by agreement with the

manufacturer.

▷A service form can be found inside the housing

cover. All settings for the future use of the heater

and any guarantee claims are to be kept up-to-

date on this form.

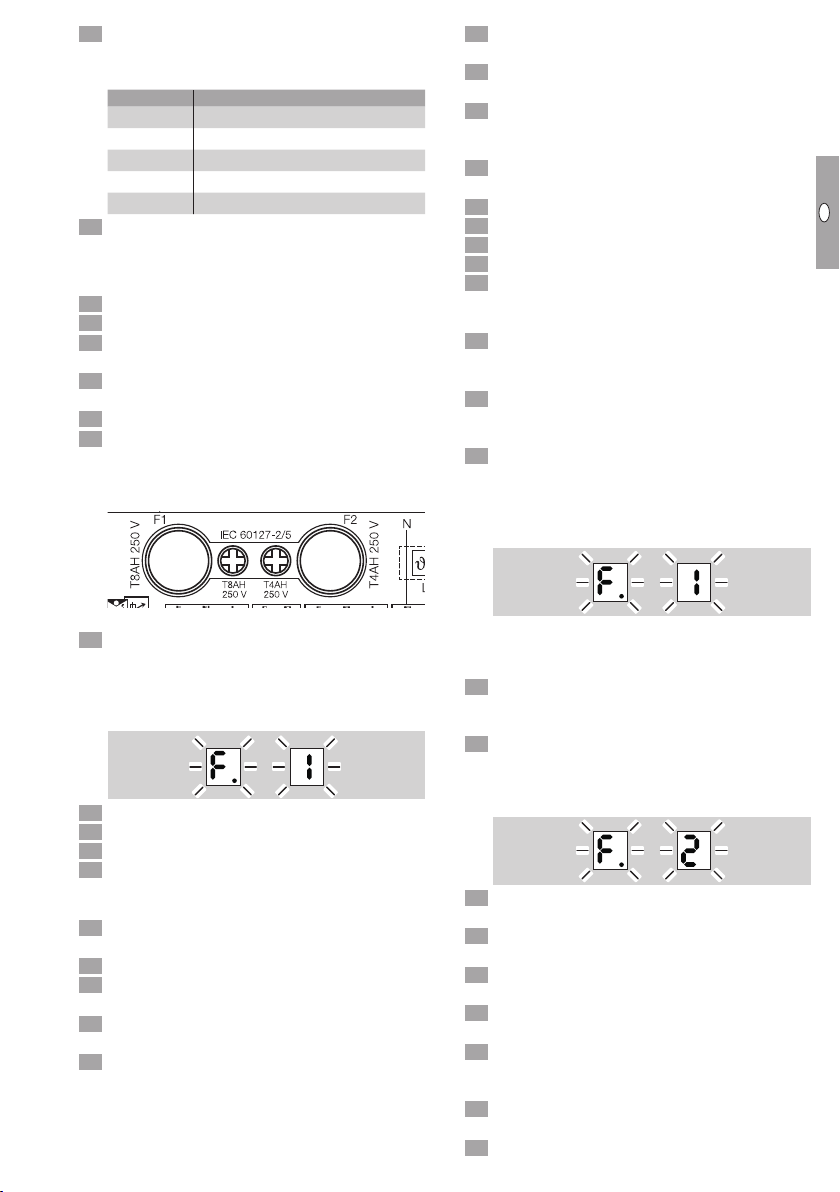

Flame signal

▷

The flame signal can be displayed when the

burner is operating.

Pressing the RESET button displays the flame

signal.

▷It is shown in coded form as a number from 0

to9. This number must be multiplied by a factor

of2. The result of this multiplication is the level

of the flame signal inµA. Example: the number 3

corresponds to a flame signal of 6–8µA.

Display Flame

current [µA] Display Flame

current [µA]

00 – 2 510 – 12

12 – 4 612 – 14

24 – 6 714 – 16

36 – 8 816 – 18

48 – 10 918...

Check the flame signal.

▷The flame signal is displayed for 20s.

Press the RESET button to exit the flame signal

display.

▷If the flame signal is <2µA, fault F(flame fault)

1or 2is displayed, see page14 (Assistance

in the event of malfunction).

Cleaning

CAUTION

To ensure that no damage occurs during operation

and cleaning, please observe the following instruc-

tions. Otherwise, injuries or damage to the device

may occur and/or the function of the device may

be impaired, and the manufacturer’s warranty will

be cancelled.

– Sharp-edged metal sheets. Always wear protec-

tive gloves.

– After cleaning, check that the components on

and in the heater are in good condition. The

device may only be restarted if all safety devices

have been installed and the safety functions

have been checked.

– Clean the heater once a year when used in

horticulture and at regular intervals as well as

after each fattening period when used in agricul-

ture, as described below. Inadequate or irregular

cleaning can cause the device to overheat and

can thus lead to fire damage or damage to the

device. For example, dirt particles can catch

fire and can be blown out of the heater.

▷The RGA100 is made of high-quality stainless

steel and is resistant to external influences such

as dirt and moisture.

▷It is designed so that it can be cleaned carefully

both inside and outside with a high-pressure

cleaner.

▷

The housing cover and cable glands on the

burner control unit must be closed during the

cleaning process.