AEM VCU200 User manual

AEM Performance Electronics Phone (8am-5pm M-F PST): 310-484-2322

2205 W 126th Street, Unit A Fax: 310-484-0152

Hawthorne, CA 90250 sales@aemev.com

tech@aemev.com

Revision History

Revision

Date

Change Description

A

5/29/2020

Initial Release

B

6/1/2020

Additional sections added

Warranty Statement added

C

6/3/2020

Update Cautions and Warnings section

Cautions and Warnings

Working on tractive systems (which includes but is not limited to motor(s), inverter(s), high voltage battery packs and

high voltage cables) requires special experience and training. AEM EV has implemented fault detection and failsafe logic

into its vehicle control units (“VCU”), however this does not mean that your VCU installation will be safe or effective, or

that your VCU installation will not interfere with other systems on your vehicle and create a hazardous situation. It is the

responsibility of the installer to understand the implications of each stage of tractive system installation and testing and

to recognize what might be unique about your application that presents potential hazards or safety issues – and it is the

responsibility of the installer to solve or address any such hazards or issues.

The following list includes basic recommended practices. This is not a comprehensive list; as noted below, if you are not

well-versed in the appropriate installation and testing procedures, you should refer the installation and calibration to a

reputable installation facility or contact AEM EV for a referral in your area.

• When access is required near the battery pack, the cell segments must be separated by using an appropriate

maintenance disconnect plug.

• When working on the battery pack or tractive system, safety gloves with side shields and appropriate insulated

tools must be used.

• Always wear Class 0 gloves rated at 1000V with leather protectors.

• Only use CAT III rated digital multimeters (DMM) and test leads.

• When working on the battery pack or tractive system, work with one hand while keeping the other behind your

back.

• During initial system power up and testing, the vehicle must be raised off the ground and supported

appropriately. Wheels and tires should be removed.

• During the VCU firmware upgrade process, battery cell segments must be separated using an appropriate

maintenance disconnect plug.

• Do not make calibration changes when the inverter pulse width modulation (PWM) is enabled.

USE THIS VCU WITH EXTREME CAUTION. MISUSE AND/OR IMPROPER INSTALLATION CAN CAUSE SIGNIFICANT DAMAGE

TO YOUR VEHICLE AND PROPERTY BELONGING TO YOU OR OTHERS, AS WELL AS PERSONAL INJURY OR DEATH. IF YOU

ARE NOT WELL VERSED IN THE INSTALLATION OF TRACTIVE SYSTEMS OR CONFIGURING THE CALIBRATIONS IN THE AEM

EV VCU THAT ARE NECESSARY TO CONTROL THE VEHICLE, YOU SHOULD REFER THE INSTALLATION AND VCU

CALIBRATION TO A REPUTABLE INSTALLATION FACILITY, OR CONTACT AEM EV FOR A REFERRAL IN YOUR AREA. IT IS THE

6/3/2020, Revision C AEM EV VCU200 User Guide Page 2 of 15

AEM Performance Electronics Phone (8am-5pm M-F PST): 310-484-2322

2205 W 126th Street, Unit A Fax: 310-484-0152

Hawthorne, CA 90250 sales@aemev.com

tech@aemev.com

RESPONSIBILITY OF THE INSTALLER TO ULTIMATELY CONFIRM THAT THE INSTALLATION AND CALIBRATIONS ARE SAFE

FOR ITS INTENDED USE.

ADVANCED ENGINE MANAGEMENT CO., INC. (“AEM”) AND ITS AFFILIATES, SHAREHOLDERS, DIRECTORS, OFFICERS,

AGENTS, REPRESENTATIVES, SUCCESSORS AND ASSIGNS (COLLECTIVELY, THE “AEM PARTIES”) HOLD NO RESPONSIBILITY

FOR ANY DAMAGE OR INJURY THAT RESULTS FROM INSTALLATION OR MISUSE OF ANY AEM PRODUCTS. EXCEPT FOR, TO

THE EXTENT APPLICABLE TO THE PRODUCTS YOU HAVE PURCHASED, AEM’S 12 MONTH LIMITED WARRANTY (WHICH

CAN BE FOUND AT https://www.aemelectronics.com/about-us/warranty-returns ), ALL AEM PRODUCTS ARE PROVIDED

“AS IS” AND THE AEM PARTIES EXPRESSLY DISCLAIM ALL WARRANTIES, WHETHER EXPRESS, IMPLIED, STATUTORY OR

OTHERWISE. THE AEM PARTIES SPECIFICALLY DISCLAIM ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE, AND ALL WARRANTIES ARISING FROM COURSE OF DEALING, COURSE OF PERFORMANCE,

USAGE OR TRADE PRACTICE.

UNDER NO CIRCUMSTANCES SHALL ANY AEM PARTY BE LIABLE TO YOU OR ANY OTHER PERSON OR ENTITY FOR ANY

DAMAGES OF ANY AMOUNT OR CHARACTER (INCLUDING, WITHOUT LIMITATION, ANY GENERAL, INDIRECT, SPECIAL,

INCIDENTAL, EXEMPLARY, CONSEQUENTIAL OR PUNITIVE DAMAGES) ARISING OUT OF, RELATED TO, OR IN CONNECTION

WITH (1) YOUR INSTALLATION OF ANY AEM PRODUCTS OR (2) YOUR MISUSE OF ANY AEM PRODUCTS. IN NO EVENT

SHALL ANY AEM PARTY BE LIABLE TO YOU OR ANY OTHER PERSON OR ENTITY FOR ANY LOST OR CORRUPTED DATA,

LOST PROFITS, LOST REVENUES, LOSS OF USE, DIMINUTION IN VALUE, LOSS OF OTHER INTANGIBLES OR ANY SPECIAL,

INCIDENTAL, INDIRECT, EXEMPLARY, PUNITIVE OR CONSEQUENTIAL DAMAGES, WHETHER ARISING OUT OF BREACH OF

CONTRACT, TORT (INCLUDING NEGLIGENCE) OR OTHERWISE, REGARDLESS OF WHETHER SUCH DAMAGES WERE

FORESEEABLE AND WHETHER OR NOT THE AEM PARTIES WERE ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

SOME JURISDICTIONS MAY NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL

DAMAGES, SO THE ABOVE EXCLUSIONS SHALL ONLY APPLY TO THE EXTENT PERMISSIBLE UNDER APPLICABLE LAW.

Electrical Safety Insulation Monitoring

The high voltage system in an electric vehicle is designed to be ungrounded (floating) with respect to the vehicle chassis

(frame). Insulation faults can cause electric shock, personal injury and even death. An insulation monitoring device

(IMD) must be used to protect against these faults. See Bender https://www.benderinc.com/ for more information.

6/3/2020, Revision C AEM EV VCU200 User Guide Page 3 of 15

AEM Performance Electronics Phone (8am-5pm M-F PST): 310-484-2322

2205 W 126th Street, Unit A Fax: 310-484-0152

Hawthorne, CA 90250 sales@aemev.com

tech@aemev.com

Hardware Overview

AEM Part Number

30-8000

Microprocessor

NXP MPC5607B

Clock Speed

64 MHz

Environmental

IP6k7 Compliant

Operating Temperature

-40°C to +105°C

Operating Voltage

9 – 16V

16V is the absolute maximum rating. The module is not designed for use

with 16V battery systems as they typically require ~18V to charge.

Overvoltage Protection

16V

Current Draw: Off-State Current

<1 mA

Wake Switch Power-on threshold

3.7V minimum

Wake Switch Power-down threshold

1.5V maximum

Communication Channels

CAN1, 500k, Internally Terminated, PC Comms

CAN2, 500k, Internally Terminated, Peripheral Device Comms

CAN3, 500k, Internally Terminated, Peripheral Device Comms and Data

Transmit

CAN4, RESERVED

Internal Logging Memory

None -External logging possible with AEM Dash units with logging

capability and other compatible 3

rd

party displays and data loggers.

About this document

This document is not a comprehensive step by step guide to every feature available. It is intended to get the VCU

powered up properly and running quickly in a bench top environment. Along the way you will become familiar with

certain core features. Your primary source for detailed information about VCU functionality is AEMCal. Nearly all

features are described using tool tips, compiled help or description pane help. The AEMCal screen capture images in this

document are accurate at the time of publication. However, AEMCal and the AEMCal layout files provided by AEM will

be updated over time. In the event of a discrepancy, always follow the instructions contained within the layout file.

Software Tools Installation

Go to https://www.aemev.com/documentation/download to download the installers for AEMCal and AEMData. Run

both installers to install both tools. During the installation, choose to install the desktop icon. After the installation,

restart your PC.

Launch AEMCal from the desktop icon.

6/3/2020, Revision C AEM EV VCU200 User Guide Page 4 of 15

AEM Performance Electronics Phone (8am-5pm M-F PST): 310-484-2322

2205 W 126th Street, Unit A Fax: 310-484-0152

Hawthorne, CA 90250 sales@aemev.com

tech@aemev.com

A Quick Start pane will provide options. Click Show Help

to launch the online help for AEMCal. Read and

understand all sections before continuing. The

instructions that follow assume you have read the

AEMCal online help content.

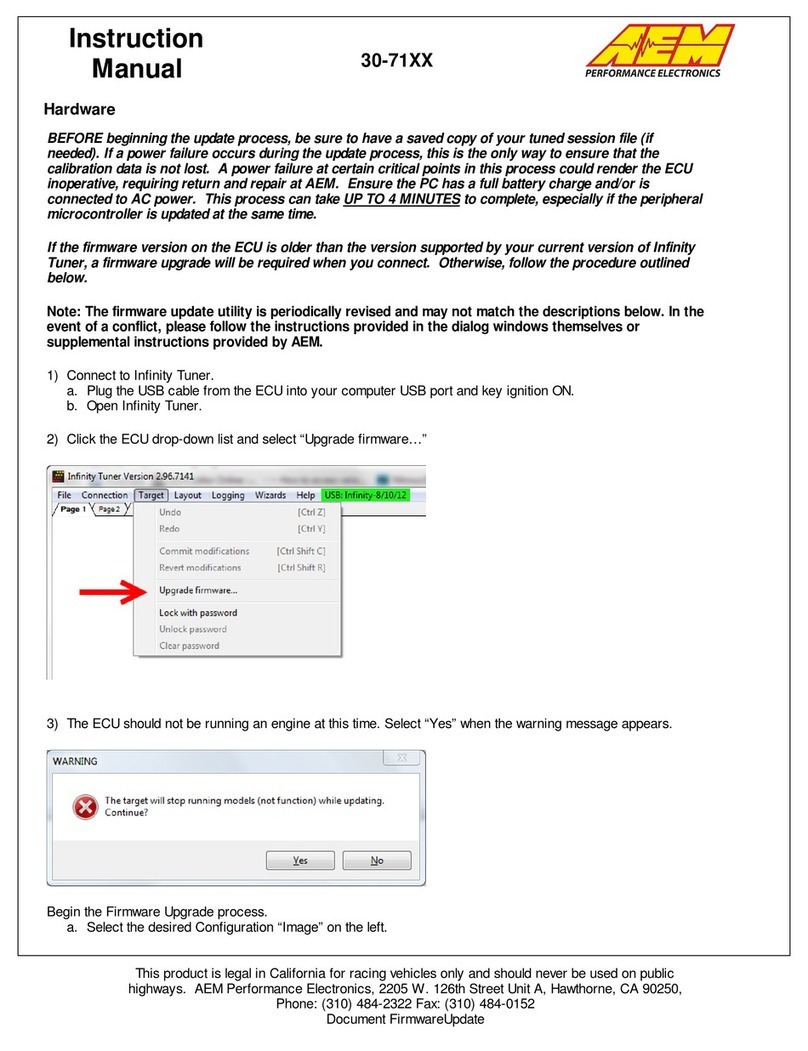

PC Communications with AEMCal

The VCU200 communicates with the PC over the CAN1 network. A CAN to USB converter device is required. For best

performance, AEM recommends the Kvaser Leaf Light HS v2 https://www.kvaser.com/product/kvaser-leaf-light-hs-v2/

Once you have the adapter, navigate to the Kvaser DOWNLOADS tab and click the Download button for the Kvaser

Drivers for Windows. Note that the Version may not necessarily match the Version in the example image below. Run

the executable to install the hardware drivers. It is always a good idea to restart your PC after installing new hardware

drivers. Please do so.

Harness Connectors and Required Tools

A mating Plug & Pin Kit is available from AEM under PN 30-3709. Following is a list of Molex recommended tools for

working with these connector assemblies. There may be similar and/or compatible tools available in the market.

However, AEM will not be responsible for connector housing damage caused by misuse or use of improper tools. If you

are not comfortable working with high density connector housings, please seek help from an experienced automotive

harness builder. A properly planned and assembled harness is critical for performance and safety.

Tool

Molex Part Number

Large Terminal Crimp

063811-8900

Small Terminal Crimp

063811-9100

Large Terminal Depinning

063813-2300

Small Terminal Depinning

063813-2400

6/3/2020, Revision C AEM EV VCU200 User Guide Page 5 of 15

AEM Performance Electronics Phone (8am-5pm M-F PST): 310-484-2322

2205 W 126th Street, Unit A Fax: 310-484-0152

Hawthorne, CA 90250 sales@aemev.com

tech@aemev.com

Minimum Power and Programming Requirements

AEM recommends that you familiarize yourself with the VCU200 basic functionality within a bench top environment

AND NOT ON A VEHICLE during the first power up and test.

1. Launch AEMCal. A USB connection to the VCU

hardware is not required yet.

2. Open the FactoryBase calibration which should

be in the

\Documents\AEM\AEMcal\Calibrations\Factory

folder.

3. Load the Default200 layout file which should be

in the \Documents\AEM\AEMcal\Layouts\Factory

folder.

4. Select the Setup-Hardware group

Familiarize yourself with the Hardware Pinout. There are

multiple tabs in this pane (Pinout1-5).

Select the MinimumPowerReq tab which includes an

example wiring schematic and general information about

power distribution. Use the Hardware Pinout and the

Minimum Power schematic shown to build a test bench

harness that can be powered from a 12V bench top

power supply.

6/3/2020, Revision C AEM EV VCU200 User Guide Page 6 of 15

AEM Performance Electronics Phone (8am-5pm M-F PST): 310-484-2322

2205 W 126th Street, Unit A Fax: 310-484-0152

Hawthorne, CA 90250 sales@aemev.com

tech@aemev.com

Select the PC Connection tab. Assemble and add a PC

communications stub to your harness. Use the example

schematic for reference. The VCU200 communicates

with your PC via a CAN to USB adapter. If you do not

have experience assembling harnesses for use in vehicle

networks, please seek help from an experienced

automotive harness builder. The VCU200 functions as a

CAN network data hub. Proper network wiring is critical

for performance and safety.

1. Connect your CAN to USB adapter to an available

USB port on your PC.

2. Within AEMCal, go to ECU | Connection Setup…

3. In the Port pane, ensure your settings match the

example at left.

4. Select your CAN to USB adapter from the CAN

Port dropdown selection list. If your device

drivers were installed correctly, your adapter

should appear in this list. The example shows the

Kvaser Leaf Light v2. If it does not appear, try

restarting AEMCal. If you still have problems,

there may be an issue with your adapter device

driver installation. Stop and contact the adapter

manufacturer for troubleshooting support.

1.

Connect the power leads of your test harness to

your 12V bench top power supply.

2. Set the power supply current limit to

approximately 1.0 amp.

3. Turn the power supply switch on.

4. Using your harness, turn the VCU ‘Key Switch’ on.

5. At power up, the VCU should draw between 100

and 500 mA depending on other loads present in

the harness. A lighted switch may create more

current draw. If the current is not within this

range, double check your power distribution

wiring.

6. Connect the CAN to USB adapter to your harness

DB9 communications interface.

7. Go to ECU | Connect or the Shift+F7 hotkey

combo. AEMCal will attempt to connect to your

VCU.

6/3/2020, Revision C AEM EV VCU200 User Guide Page 7 of 15

AEM Performance Electronics Phone (8am-5pm M-F PST): 310-484-2322

2205 W 126th Street, Unit A Fax: 310-484-0152

Hawthorne, CA 90250 sales@aemev.com

tech@aemev.com

AEMCal will present a similar window to the one shown

at left. A scroll bar will indicate connection progress as

AEMCal retrieves calibration data from your VCU. If you

do not see this progress bar at first, click Abort and:

1. Make sure there are no other devices connected

or applications running that may be using your PC

USB ports.

2. Double check the pinout of the harness DB9

interface connector.

3. Disconnect the CAN to USB adapter from your PC

then plug it back in.

4. Try restarting AEMCal and repeating the process.

If you got this far, congratulations! Your VCU is powered

up and communicating with AEMCal.

Basic VCU Function Check & AEMCal Work Space Tour

1.

Within AEMCal, navigate to the Setup-Hardware group and select the MinimumPowerReq tab.

2. Live data from the VCU will be presented in the Channels list. Note the green Online indication in the lower

right. Note the Description Pane. If you do not see the Description Pane, go to View | Descriptions or hit

Cntrl+D.

3. Ensure that:

a. The VCU_12V_Input internal measurement matches (approximately) the output from your power

supply.

b. The VCU_5V_Output internal measurement is close to 5 volts.

c. The Run_Time_Counter is incrementing.

d. The EEPROM_State indicates Loaded Saved Values – Normal Startup.

Congratulations! Another milestone passed.

6/3/2020, Revision C AEM EV VCU200 User Guide Page 8 of 15

AEM Performance Electronics Phone (8am-5pm M-F PST): 310-484-2322

2205 W 126th Street, Unit A Fax: 310-484-0152

Hawthorne, CA 90250 sales@aemev.com

tech@aemev.com

Safety Warning Acknowledgement

1. Within the Warnings group, view the

WarningStatement tab.

2. Read the warning statement.

3. After reading and acknowledging the

statement, Select Yes for the

SafetyWarningAknowledgment

setting.

The VCU must be powered up and connected

to AEMCal before making this change. If you

do not acknowledge this statement, the VCU

will only allow a 0.0 N.m torque command

regardless of any other calibration settings.

Fundamental Configuration Options

There are several fundamental configuration settings

required.

1. Go to the Setup-ConfigOptions group and select

the Configuration tab.

2. Select each setting and read the Description field

for definitions and instructions.

3. Make your selections to configure the VCU for

your application.

Minimum Required Inputs Setup

The following sections describe setup of the minimum required inputs. These steps assume the inputs are connected to

the VCU and the VCU is powered up and running. Before proceeding, use the VCU pinout table in the Setup-Hardware

group, HardwarePinout tab as a reference for adding the inputs to your harness. These include:

1. Ignition Switch

2. Accelerator Pedal

3. Brake Switch

4. Drive Mode PRND inputs

5. Main HVIL Loop

6. IMD

6/3/2020, Revision C AEM EV VCU200 User Guide Page 9 of 15

AEM Performance Electronics Phone (8am-5pm M-F PST): 310-484-2322

2205 W 126th Street, Unit A Fax: 310-484-0152

Hawthorne, CA 90250 sales@aemev.com

tech@aemev.com

AEM recommends adding these inputs to your bench test harness. It is much easier to debug harness assembly

problems within a bench test environment.

Ignition Switch

1. Go to the Setup-Inputs group and select the

IgnitionSwitch tab.

2. Read the notes, Descriptions and wiring diagram.

3. Configure the settings for your application.

Accelerator Pedal

Select the AccelPedal tab. This tab is large but for

most applications, there are only a handful of

settings changes required. The basic pedal

calibration process is as follows. See notes and

Descriptions in the tab for more details.

1. With the pedal closed, monitor the

channel APPX_Volts vs the option

APPX_Min. Set APPX_Min = APPX_Volts.

2. With the pedal fully open, monitor the

channel APPX_Volts vs the option

APPX_Max. Set APPX_Max = APPX_Volts.

3. Set the APPX_Hi_Thresh and

APPX_Lo_Thresh slightly outside these

calibration limits. These will be your fault

detection thresholds.

6/3/2020, Revision C AEM EV VCU200 User Guide Page 10 of 15

AEM Performance Electronics Phone (8am-5pm M-F PST): 310-484-2322

2205 W 126th Street, Unit A Fax: 310-484-0152

Hawthorne, CA 90250 sales@aemev.com

tech@aemev.com

Brake Switch

A properly setup and configured Brake Switch input is

critical for safety and functionality.

1. Go to the Setup-Inputs group and select the

BrakeSwitch tab.

2. Use the example wiring diagram to add the Brake

Switch input to your VCU.

3. Read the notes and Descriptions and configure

for your application.

Drive Mode PRND Inputs

Discrete PRND switch inputs are required for indirect

drive applications. There is a choice between discrete

switch inputs or the AEM 8-Button CAN Keypad for direct

drive applications.

1. Go to the Setup-Inputs group and select the

PRND tab.

2. Use the example wiring diagram to add the

switch inputs to your VCU.

3. Read the notes and Descriptions and configure

for your application.

6/3/2020, Revision C AEM EV VCU200 User Guide Page 11 of 15

AEM Performance Electronics Phone (8am-5pm M-F PST): 310-484-2322

2205 W 126th Street, Unit A Fax: 310-484-0152

Hawthorne, CA 90250 sales@aemev.com

tech@aemev.com

Main HVIL Loop

A completed Main HVIL loop is required for high voltage

contactor function.

1. Go to the Setup-Inputs group and select the

HVILMain tab.

2. Use the example wiring diagram to add the loop

to your VCU.

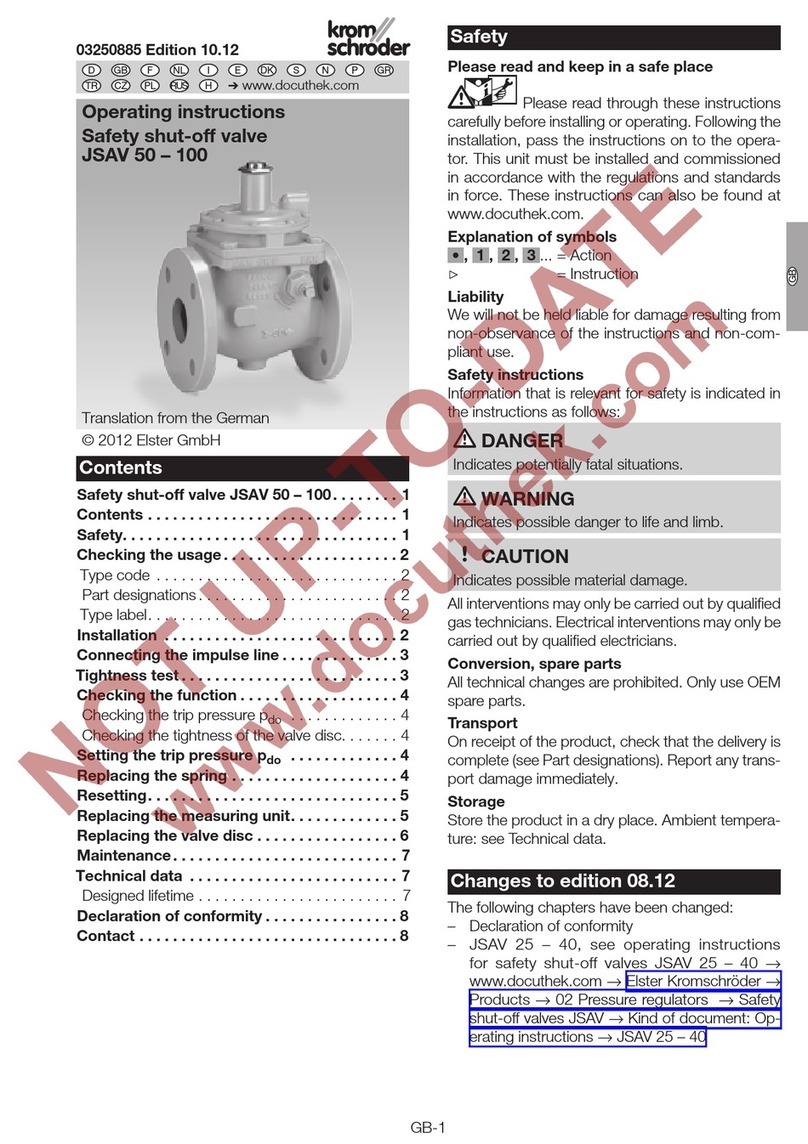

IMD Setup

The high voltage system in an electric vehicle is designed

to be ungrounded (floating) with respect to the vehicle

chassis (frame). Insulation faults can cause electric shock,

personal injury and even death. An insulation monitoring

device (IMD) must be used to protect against these faults.

See Bender https://www.benderinc.com/ for more

information.

1. Go to the Setup-Inputs group and select the IMD

tab.

2. Read all notes and Description text and configure

for your application.

VCU Outputs Setup

In most cases, there are options for output control. In cases where an AEM PDU-8 control output is available, we

recommend using the PDU-8 over other methods. The current limiting and fault detection features increase safety and

reliability. This is especially important for high voltage contactor control.

6/3/2020, Revision C AEM EV VCU200 User Guide Page 12 of 15

AEM Performance Electronics Phone (8am-5pm M-F PST): 310-484-2322

2205 W 126th Street, Unit A Fax: 310-484-0152

Hawthorne, CA 90250 sales@aemev.com

tech@aemev.com

1. Go to the Setup-Outputs group and select the PDU8-1 and PDU8-2 tabs.

2. Review the pinout table for VCU functions for each output channels. These output

functions are not re-assignable.

3. Manual override settings are available for testing each output. Set the _OvrVal to 1

then set the _OvrSts to override to override the the output logic.

4. Refer to the user instructions provided with the AEM PDU8 for more information on

hardware capabilities and wiring.

CAUTION!

Do not manually override high voltage contactor drivers when they are connected to the

battery pack.

6/3/2020, Revision C AEM EV VCU200 User Guide Page 13 of 15

AEM Performance Electronics Phone (8am-5pm M-F PST): 310-484-2322

2205 W 126th Street, Unit A Fax: 310-484-0152

Hawthorne, CA 90250 sales@aemev.com

tech@aemev.com

Inverter PreCharge Setup

1. Go to the Setup-Outputs group and select the

HighVoltageContactors tab.

2. These settings must be configured properly

for your high voltage battery pack range.

Familiarize yourself with the Description for

each option and channel.

3. Configure the settings for your application.

The ContactorPreConditions channel list is helpful

information for first time setups. Read the

Description for each channel and monitor during

Inverter PreCharge.

CAUTION!

Do not manually override high voltage contactor drivers when they are connected to the battery pack.

Additional Features and Functions

This document is just an introduction to the many features and functions of the VCU200. See the AEM factory layout

along with the help content within AEMCal for more detailed information.

6/3/2020, Revision C AEM EV VCU200 User Guide Page 14 of 15

AEM Performance Electronics Phone (8am-5pm M-F PST): 310-484-2322

2205 W 126th Street, Unit A Fax: 310-484-0152

Hawthorne, CA 90250 sales@aemev.com

tech@aemev.com

12 Month Limited Warranty

AEM Performance Electronics warrants to the consumer that all AEM Electronics products will be free from defects in

material and workmanship for a period of twelve months from the date of the original purchase. Products that fail

within this 12-month warranty period will be repaired or replaced when determined by us that the product failed due to

defects in material or workmanship. This warranty is limited to the repair or replacement of the AEM Electronics part.

This warranty applies only to the original purchaser of the product and is non-transferable. All implied warranties shall

be limited in duration to the said 12-month warranty period. Improper use or installation, accident, abuse, unauthorized

repairs or alterations performed by the user on any AEM Electronics products voids this warranty.

In no event shall this warranty exceed the original purchase price of the AEM Electronics part nor shall AEM Electronics

be responsible for special, incidental or consequential damages or cost incurred due to the failure of this product.

AEM Electronics disclaims any liability for consequential damages due to breach of any written or implied warranty on

all of its products.

Warranty returns will only be accepted by AEM Electronics when accompanied by a valid Return Merchandise

Authorization (RMA) number and a dated proof of purchase. The product must be received by AEM Electronics within 30

days of the date the RMA is issued. Warranty claims to AEM Electronics must be shipped to us prepaid (we recommend

a shipping service with package tracking capability). Once your package is received by our warranty and repairs

department you will be notified and provided with updates.

PROCEDURES FOR ISSUANCE OF A RETURN MERCHANDISE AUTHORIZATION (RMA) NUMBER–

Please note that before AEM Electronics can issue an RMA for any product, it is first necessary for the installer or end-

user to contact our technical support team to discuss the problem. Most issues can be resolved over the phone. Under

no circumstances should a system be returned, or an RMA requested before our support team is contacted. This will

ensure that if an RMA is needed that our team is able to track your product through the warranty process.

You can reach our Tech Support Team for support on all AEM Electronics performance products by phone at 1-800-423-

0046. To contact us by email for engine management systems, email us at emstec[email protected]. For all other

products, email us at gen[email protected].

AEM Electronics will not be responsible for products that are installed incorrectly, installed in a non-approved

application, misused, or tampered with. In the case of AEM Electronics Fuel Pumps, incorrect polarity (+&-wires

crossed) will not be warranted. Proper fuel filtration before and after the fuel pump is essential to fuel pump life. Any

pump returned with contamination will not be warranted.

PRODUCTS OUTSIDE OF WARRANTY PERIOD

Any AEM Electronics product, excluding discontinued products, can be returned for repair if it is out of the warranty

period. There is a minimum charge of $50.00 for inspection and diagnosis of AEM Electronics parts. Parts used in the

repair of AEM Electronics components will be extra. AEM Electronics will provide an estimate of repairs and must

receive written or electronic authorization from you before repairs are made to a product.

6/3/2020, Revision C AEM EV VCU200 User Guide Page 15 of 15

This manual suits for next models

1

Table of contents

Other AEM Control Unit manuals

Popular Control Unit manuals by other brands

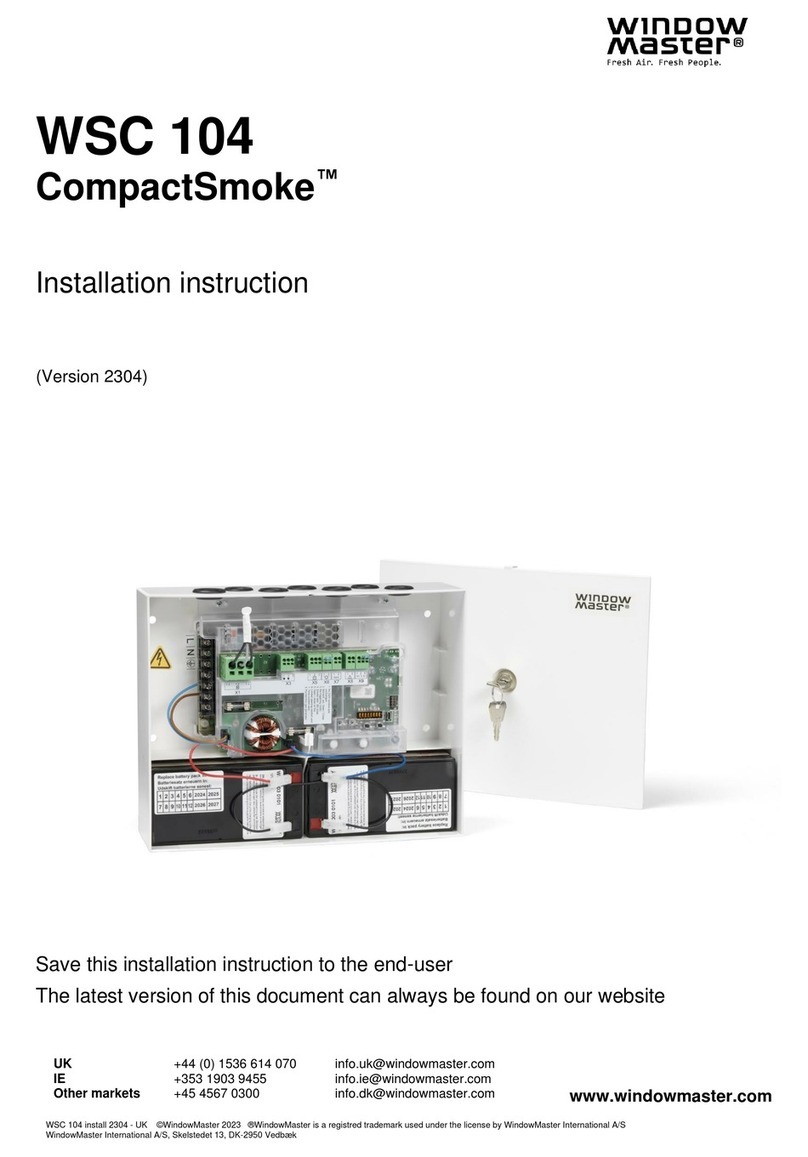

WindowMaster

WindowMaster CompactSmoke WSC 104 Installation instruction

Alarmcom

Alarmcom Simon XT installation guide

UNIONCOMMUNITY

UNIONCOMMUNITY MCP-040 installation guide

Care Fusion

Care Fusion Alaris 8600 Technical & service manual

Keyautomation

Keyautomation 900CT-24M instruction manual

Delta

Delta MultiChoice T27897 Series owner's manual

ITS Telecom

ITS Telecom EKSELANS IPC 24 user manual

mr. steam

mr. steam Home Wizard Installation and operation instructions

Delta

Delta TECK II 81T201BT manual

Tecnocontrol

Tecnocontrol CITY CE408P user manual

Paradox

Paradox MAGELLAN RTX3 V1.5 instructions

Saia Burgess Controls

Saia Burgess Controls PCD2.F2100 manual