Aentron AEC900500R User manual

aentron Energy Storage System

AEC900500R - aentron Energy Controller

A48100F - aentron Lithium-Ion Module

A24100F - aentron Lithium-Ion Module

12 to 900 V DC

Version 1.3

Operating Manual

English

English

Table of Contents

aentron GmbH aentron energy storage system Page 1/100

Version 1.03

Table of Contents

1. Introduction ............................................................................... 4

1.1. General ....................................................................................... 4

1.2. Terminology ................................................................................ 5

1.3. Explanation of Symbols .............................................................. 6

1.3.1. Structure of the Safety Instructions ............................................ 6

1.3.2. Symbols, Warning Signs and Mandatory Signs ......................... 6

1.3.3. Abbreviations .............................................................................. 7

1.4. Labelling ..................................................................................... 9

1.5. Contact Address ....................................................................... 10

2. Basic Information About the System Structure .................. 11

2.1. System Components ................................................................ 11

2.2. HV System Requirements ........................................................ 11

2.3. System Architecture ................................................................. 17

2.4. Specification of the aentron Energy Storage System............... 18

3. About the aentron Energy Storage System ......................... 22

3.1. Using the aentron Energy Storage System .............................. 22

3.1.1. Intended Use ............................................................................ 22

3.1.2. Foreseeable Misuse ................................................................. 22

3.2. Technical Data.......................................................................... 23

3.2.1. Dimensions ............................................................................... 23

3.2.2. Electrical Specification ............................................................. 25

3.2.3. Additional Specifications .......................................................... 25

3.2.4. Ambient Conditions .................................................................. 26

3.2.5. Power Consumption ................................................................. 26

3.3. Scope of Delivery ..................................................................... 27

3.3.1. Versions of the aentron Energy Storage System ..................... 29

4. Safety ....................................................................................... 30

4.1. Basic Functional Safety ............................................................ 30

4.2. Obligations of the Operating Company .................................... 31

4.3. Obligations of the Personnel .................................................... 32

4.3.1. Training of personnel ................................................................ 32

4.4. Warnings of a General Nature .................................................. 33

4.5. Thermal Hazards ...................................................................... 34

4.6. Electrical Hazards .................................................................... 34

4.7. Dangers Caused by Materials and Substances ....................... 34

4.8. Safety Equipment ..................................................................... 35

5. Preparation for Use ................................................................ 36

5.1. Layout and Controls ................................................................. 36

Table of Contents

aentron GmbH aentron Energy Storage System Page 2/100

Version 1.03

5.2. Interfaces External Systems ..................................................... 38

5.3. Transport and Storage ............................................................. 40

5.3.1. Unpacking ................................................................................. 41

5.4. Installation ................................................................................ 42

5.4.1. Installation Site of the aentron Energy Storage System .......... 42

5.4.2. Electrical Connection ................................................................ 43

5.4.3. Switching On, Functions and CAN Bus .................................... 46

5.4.4. Checking the Functions ............................................................ 49

5.4.5. System Check with the CAN bus Diagnostic System .............. 50

5.5. Commissioning and Self-Diagnostic......................................... 50

5.5.1. Setting Up the aentron Battery Interface (ABI) ......................... 51

6. Operation the aentron Energy Storage System .................. 63

6.1. General ..................................................................................... 63

6.2. Operating Modes ...................................................................... 63

6.2.1. Parallel Connection .................................................................. 64

6.2.2. Serial Connection ..................................................................... 65

6.3. Use ........................................................................................... 66

6.3.1. Use Examples .......................................................................... 66

6.3.2. Charging ................................................................................... 69

6.3.3. Charging Method ...................................................................... 70

6.3.4. Charge Equalisation ................................................................. 70

6.3.5. Saving Power ........................................................................... 70

7. Maintenance ............................................................................ 71

7.1. Maintenance Guidelines for aentron Energy Storage System . 71

7.2. Preventing Deep Discharging ................................................... 71

7.3. Operating Lifetime .................................................................... 72

7.4. Cycle Lifetime ........................................................................... 73

7.5. Servicing and Repairs .............................................................. 73

7.5.1. Packaging ................................................................................. 73

7.5.2. Dangerous Goods Labelling on the Shipping Package ........... 75

7.5.3. Transport Operator ................................................................... 75

8. Cleaning and Battery Care .................................................... 76

8.1. Cleaning ................................................................................... 76

8.2. Battery Care ............................................................................. 76

9. Decommissioning and Disposal ........................................... 77

9.1. Decommissioning ..................................................................... 77

9.2. Storage ..................................................................................... 78

9.3. Winter Storage.......................................................................... 79

9.3.1. Long-Term Storage .................................................................. 80

9.4. Disposal and Recycling ............................................................ 80

Table of Contents

Page 3/100 aentron Energy Storage System aentron GmbH

Version 1.03

10. Faults and Notifications ......................................................... 81

10.1. Troubleshooting ........................................................................ 81

10.2. Emergencies ............................................................................. 83

10.3. Frequently Asked Questions (FAQ) ......................................... 83

11. Legal Information ................................................................... 86

11.1. Warranty Conditions ................................................................. 86

11.2. Copyright and Property Rights ................................................. 86

11.3. Material and Legal Defects ....................................................... 87

11.4. Approvals and EU Declaration of Conformity ........................... 87

11.5. EMC .......................................................................................... 89

12. Schedules ................................................................................ 90

12.1. Maintenance Schedule ............................................................. 90

12.2. Maintenance Protocol ............................................................... 91

13. Appendix ................................................................................. 97

13.1. Index ......................................................................................... 97

Introduction

General

aentron GmbH aentron Energy Storage System Page 4/100

Version 1.03

1. Introduction

1.1. General

This operating manual enables the safe and efficient handling of the aentron

energy storage system and describes all the essential functions.

This operating manual ensures the safe operation of the aentron energy storage

system in accordance with the intended use.

This document contains:

■ Description of the design, functions and features of the aentron energy

storage system

■ Notes on possible dangers, their consequences and on measures for

hazard prevention

■ Detailed specifications on the standard operation of the aentron energy

storage system.

The operating manual is part of the aentron energy storage system and must be

stored away safely for users to be able to access at any time. Please read the

operating manual carefully before placing the aentron energy storage system

into operation. For the safe and efficient use, all the safety instructions and

handling instructions of this operating manual must be read and understood.

In this operating manual, the latest version of the aentron energy storage system

is described. If changes or supplements are required in the future, the operating

manual is amended, and all amendments are included in the next revision.

The respective version of the operating manual is displayed on the cover sheet

and in the footer; this operating manual is version "1.0". The version will be

increased by "1" with every revision.

aentron GmbH reserves the right to make changes to systems and

documentation without notifying users of previous versions.

TIP

If the aentron energy storage system is passed or sold on to third

parties, the following documents must be passed on to the new user:

This operating manual

Documentation of repair work carried out.

Introduction

Terminology

Page 5/100 aentron Energy Storage System aentron GmbH

Version 1.03

1.2. Terminology

Cell

The cell is the smallest part of an electrochemical storage system and stores the

chemical energy.

Module

A grouping of multiple cells or cell blocks, fitted with a battery management

system.

Battery

A battery refers to when several lithium-ion module are connected in parallel or in

series.

Battery system

If several lithium-ion module are connected in parallel or in series and are

controlled by an energy controller, this is referred to as a battery system.

Safety voltage (DIN ISO 16315:2016 - Small craft - Electrical drive systems)

The safety voltage must not exceed 50 Vdc.

Grounding (GND)

The ground is connected in such a way that an immediate and safe discharge of

the electrical energy is always guaranteed.

Fuse

Opens the circuit when the current has exceeded a specific value for a certain

time.

Circuit breaker

Is a mechanical switching device which can carry and interrupt currents.

Protective conductor (PE)

A conductor intended for safety purposes (e.g. protection against electric shock).

Disconnector

A disconnector is a mechanical switching device that provides a separation

distance in the open position according to the specified requirements.

Introduction

Explanation of Symbols

aentron GmbH aentron Energy Storage System Page 6/100

Version 1.03

1.3. Explanation of Symbols

1.3.1. Structure of the Safety Instructions

The safety instructions in this document are presented with a standardised

format and symbols. Depending on the probability of occurrence and the severity

of the consequences, the following hazard classes are used:

DANGER

Indicates a hazardous situation which could lead to serious

physical injury or death.

Measures for preventing the hazard

NOTICE

Indicates a situation that could lead to property damage.

Measure for preventing the property damage

TIP

Application tips and particularly useful information

1.3.2. Symbols, Warning Signs and Mandatory Signs

Warning of a hazard point

Warning of electrical voltage

Warning of corrosive substances

Warning of a fire hazard

Application tips and other useful information

Use protective gloves

Use eye protection

Introduction

Explanation of Symbols

Page 7/100 aentron Energy Storage System aentron GmbH

Version 1.03

Symbols on the components of the aentron Energy Storage System

Pay attention to the manual

Not for disposal with domestic waste

CE mark

ECE R10 mark

UN38.3 mark

1.3.3. Abbreviations

Abbreviation Meaning

+L: Charger PIN

AES aentron Energy System

AEC aentron Energy Controller

AEM aentron Energy Module

APR: Average Power Rating

BLK: Black

BMS: Battery Management System

CAN: Control Area Network

CCCV: Constant Current, Constant Voltage

Cp: Capacity

C-Rate: Charge (Capacity Current) Rate per Hour

DoD: Depth of Discharge

EDO: Every Day Operation

EMC: Electro Magnetic Compatibility

EN: Engineering Norm

EoL: End of Life

EOS: End of Service

E-Switch: Electronic Switch

GND: Chassis Ground

H: High

I: Current

IP: Ingress Protection - Rating

iR: Internal Resistance

L: Low

Introduction

aentron GmbH aentron Energy Storage System Page 8/100

Version 1.03

Abbreviation Meaning

Li-ion: Lithium Ion

MMS: Module Management System

NTC: Negative Thermal Couple

OCV: Open Circuit Voltage

P: Power

PPR: Peak Power Rating

RTC: Real Time Clock

SoC: State of Charge

SoH: State of Health

SOP: Standard Operating Procedure

SR: Safety Related

t: Time

T: Temperature

TBD: To Be Defined

U: Voltage

UV: Ultra Violet

Introduction

Labelling

Page 9/100 aentron Energy Storage System aentron GmbH

Version 1.03

1.4. Labelling

Every energy controller and every lithium-ion module from aentron GmbH is

fitted with a type plate. This is located on the top of the energy controller or on

the front of the lithium-ion module.

Figure 1: Type plate Energy Controller (example)

1 Type name

2 Voltage, Capacity, Energy

3 Safe operating voltage, operating temperatures

4 Part number

5 CAN node ID number

6 Date of manufacture

7 Serial number

8 Contact details

Introduction

Contact Address

aentron GmbH aentron Energy Storage System Page 10/100

Version 1.03

Figure 2: Type plate Lithium-Ion Module 10 kWh Type F (example)

1 Type name

2 Voltage, Capacity, Energy

3 Safe operating voltage, operating temperatures

4 Battery identification according to EN 62620:2015

5 Part number

6 CAN node ID number for 01T = Terminator

7 Date of manufacture

8 Serial number

9 Contact details

1.5. Contact Address

aentron GmbH - Energy Solutions

Dornierstraße 21

82205 Gilching

GERMANY

Phone: +49 8105 398 98-0

Fax: +49 8105 398 98-29

www.aentron.com

info@aentron.com

Basic Information About the System Structure

System Components

Page 11/100 aentron Energy Storage System aentron GmbH

Version 1.03

2. Basic Information About the System Structure

2.1. System Components

Designation aentron ID

AEC900500R - energy controller (12 - 900 Vdc) AEN01500 / AEN01501 /

AEN01502 / AEN01503

A48100F - lithium-ion module

(48 Vdc / 10 kWh / 203 Ah module)

AEN00098

A24100F - lithium-ion module

(24 Vdc / 10 kWh / 406 Ah module)

AEN00727

Busbar 4/8-pin SAEN00411 / SAEN00415

Busbar and busbar protection box SAEN00564

CAN bus communication cable (optional) SAEN01000 / SAEN01001 /

SAEN01003

120 Ohm Terminator SAEN00927

2.2. HV System Requirements

Observe the following requirements for the safe integration and operation of the

energy storage system.

Electrical design

Make sure that the installation personnel are familiar with all aspects of the

equipment so that the drive system components can be integrated into the

aentron energy storage system in a consistent and safe manner.

Rating:

During installation, ensure that

■ the rated power of each electrical load component is matched to the load

requirements.

■ the aentron energy storage system can be electrically separated from other

electrical systems.

■ AC systems (e.g. chargers) are grounded to a neutral conductor.

■ DC systems are either grounded or fully insulated.

Please note the special requirements for insulation resistance.

Basic Information About the System Structure

gg System Requirements

aentron GmbH aentron Energy Storage System Page 12/100

Version 1.03

■ a three-wire system (e.g. DC +48 V / 0 / -48 V) with a grounded neutral

conductor is used for DC drives operating at voltages above the safety

voltage (< 50 Vdc) to limit the prospective contact voltage.

■ precautions against the risk of electrical shock are observed in DC

applications and other electrical installations with rated voltages above the

safety voltage.

Safety recommendations

DC applications may have one or more large capacity batteries as the main

power source.

Please observe the following points in particular:

■ Cooling requirement for battery bank or battery compartment;

■ Requirements for an overcurrent device and a disconnector for each drive

battery bank or each battery pack;

■ Circuit protection requirements for permanently live circuits powered by a

battery bank or battery pack.

The electrical drive circuits must be designed to protect against the following

hazards:

■ Fire: Protection through overcurrent protection, grounding, terminal

protection as well as conductor type and conductor size

■ Shock: Protection through housing, conductor and terminal insulation,

automatic shutdown and

■ Protection of the grounding system.

Insulation and grounding (GND)

DC applications must be insulated accordingly. Other equipment and circuits

must be connected directly to the common direct current source(s) and must

also be fully insulated. Every connected electrical equipment or circuit must be

equipped with an overcurrent / fault protection device.

Integrated electrical and electronic devices other than the aentron energy

storage system must operate under the normal voltage and frequency variations

that may occur during normal operation of the electric drive system. This also

includes short-term overloads caused by the startup of the drive system.

Basic Information About the System Structure

gg System Requirements

Page 13/100 aentron Energy Storage System aentron GmbH

Version 1.03

DC systems must be designed for operation within the following limit values:

■ The nominal DC voltage tolerance of the terminals (for all DC devices) is -

25% to + 33%

■ When using chargers / battery combinations as DC systems, appropriate

measures must be taken to keep the charging voltage within the specified

limits during charging, fast charging and also when discharging the battery.

■ Observe the limit values of the aentron energy storage system, see chapter

3.2 Technical Data.

Notes on electrical installation

■ Mark all cables and conductors with a label (cables, multi-core cables,

single-core cables).

■ Mark all conductors > 50 Vdc orange or otherwise as > 50 Vdc and ensure

that they have the correct polarity.

■ Conductors for DC and AC drives and other electrical distribution systems

connected to a common source must be selected in accordance with

IEC 60092-352.

■ The drive system conductors must be installed in piping or ducts, on special

circuit boards or by clamps or other methods directly on surfaces in

accordance with IEC 60092-352. Please observe the requirements of

ISO 10133 and ISO 13297.

■ During and after installation, check that all protective conductors and

connections which connect conductive parts to the protective conductor are

functioning correctly.

The value of the earth resistance may not exceed 1.0 Ω.

All aentron energy storage systems are supplied according to the above

requirements.

Overcurrent protection

Each drive system must be protected against overload by circuit breakers or

fuses. The circuit breakers must be selected in accordance with IEC 60947 or

IEC 60898-1. Each fuse or circuit breaker at the source of a circuit must be

designed to protect the conductor with the smallest cross-section in the circuit

which is to be protected.

The output circuit of the aentron energy storage system must be protected by a

fuse with a fault current determined by the maximum short-circuit current.

The fuse must be as close as possible and within 1.8 m of the battery output

terminals measured at the conductors.

Basic Information About the System Structure

gg System Requirements

aentron GmbH aentron Energy Storage System Page 14/100

Version 1.03

Battery system / circuit breaker insulation

aentron GmbH provides an easily accessible disconnector for each lithium-ion

module, which can be disconnected from the DC mains.

In addition, you should install an additional mechanical disconnector / circuit

breaker directly next to the battery compartment and downstream of the aentron

energy controller. A two-pin disconnector should be placed as close as possible

to the battery output terminals (AEC) and be within 1.8 m of the conductor.

Converter: DC/DC / AC/DC

Connected converters must comply with the requirements of IEC 60146. The

converters must be installed according to the instructions of the component

manufacturer.

Housing

Protect current-carrying parts of electrical equipment against accidental contact

by means of housings.

Areas and facilities (> 50 Vdc) which could endanger the safety of persons (e.g.

battery compartments, electrical components) may only be accessible with tools

or keys and must be marked in accordance with the danger they pose.

Live parts must be protected against unintended contact, e.g. by means of fuses,

busbars, disconnectors, terminals, cable interfaces or by housing or basic

insulation which can only be bypassed through their destruction. aentron GmbH

offers a protection class of at least IP4X.

All aentron components and the connection of external components must

comply with a minimum insulation resistance of 1,000 Ω/V for DC components

and 1,000 Ω/V for AC components.

Control system, monitoring, system warnings

Control systems must control and limit the flow of energy to prevent damage

between the battery and/or the power sources and the system in both directions.

This requirement must be implemented in addition to regular system protection.

Make sure that the on/off control can be locked in the "off" position.

Emergency stop / aentron service shutdown

The "Emergency stop" switch must "lock" when actuated and must be resettable

manually. The "service disconnector" of the energy controller serves as an

emergency stop switch and is thus permanently connected to the internal

electrical system (12 V / 24 Vdc) of the aentron energy storage system.

Basic Information About the System Structure

gg System Requirements

Page 15/100 aentron Energy Storage System aentron GmbH

Version 1.03

Mechanical installation:

During operation, the aentron energy storage system must be secured against

movement and protected against impact and falling objects by means of the

supplied mounting rails.

Permanently live circuits

The following systems can be connected after the disconnector and the battery

pack or battery bank connections:

■ Electronic devices with protected storage and protective devices must be

individually protected by a circuit breaker or fuse as close as possible to the

battery terminals;

■ Chargers which are connected to the aentron power lines and left

unattended (e.g. solar cells, wind generators) must be individually protected

by one or more fuses or circuit breakers as close as possible to the battery

terminals.

Battery ventilation and protection class

The aentron energy storage system does not require ventilation under normal

operating conditions to prevent the formation of explosive gases.

Enclosures should be air-cooled naturally with a sufficient number of ventilation

holes or sufficient cooling surface to dissipate heat, so that the enclosed devices

can operate within the temperature limits of the aentron energy storage system.

Ventilation by general cooling is recommended to ensure that the operating

temperature remains between 0 °C and +30 °C to maximise the operating life.

The aentron energy storage system does not have any special requirements to

prevent the battery from leaking.

All aentron energy storage systems have a protection class of IP66 or higher.

The lithium-ion cell technology used by aentron GmbH is a dry cell technology

that does not leak during normal operation.

In the unlikely event of escaping gas due to cell leakages, the aentron battery

housing catches all leaking fluids in a designated area.

Load test and testing of electrical components (rating test):

During and after integration, all consumers should be placed as close as

possible to the load to avoid significant voltage drops > 10 m.

During and after the integration, check all consumers on whether the maximum

normal operating load causes overheating, the maximum rated power is

exceeded or whether the safety equipment of the batteries is damaged.

This serves to ensure that there are no faulty connections or incorrect rating

data.

Basic Information About the System Structure

gg System Requirements

aentron GmbH aentron Energy Storage System Page 16/100

Version 1.03

Switches, circuit breakers and control systems must be operated under load to

verify their suitability and to demonstrate that the operation of over-voltage,

under-voltage and reverse-current or reverse-power protection devices is

electrically and mechanically satisfactory.

System alarms / error messages

The installer should preset the following system messages and error messages

for the operating company to ensure reliable and safe operation. These are

available as standard via the aentron energy storage system's CAN bus.

1) Battery temperature (°C)

2) Low battery charge (%)

3) Battery voltage (V)

4) Battery current (A)

5) Battery output (kW)

6) Remaining battery life (min)

7) Insulation resistance, faults (IR) (for fully insulated DC systems)

8) Warnings (low/high voltage, under/over temperature, faults)

The aentron GmbH offers various instrumentation alternatives. Contact your

authorised aentron dealer for more information.

Basic Information About the System Structure

System Arcgitecture

Page 17/100 aentron Energy Storage System aentron GmbH

Version 1.03

2.3. System Architecture

Figure 3: System architecture – Example

The aentron energy storage system is divided into the following three levels:

Level 1: AES – Electrical Energy Storage

aentron GmbH defines the overall aentron energy storage system as an Electric

Energy Storage (EES) This includes all cells, the entire E/E hardware and

software as well as the mechanical components.

Level 2: AEC - HV Energy Controller (12 - 900 Vdc)

aentron GmbH defines the energy controller as an E/E component that

communicates with the customer application via an OPEN CAN bus. The energy

controller controls and monitors the modules via an OPEN CAN bus

(Daisy Chain) communication network.

Level 3: AEM - MMS (Module Management System)

aentron GmbH defines the MMS as an E/E component which is connected to

the energy controller via a CAN communication network. The MMS controls and

monitors all important functions of the module and the cells.

Basic Information About the System Structure

Specification of the aentron Energy Storage System

aentron GmbH aentron Energy Storage System Page 18/100

Version 1.03

2.4. Specification of the aentron Energy Storage System

The aentron energy storage system enables the implementation of a modular

and scalable battery solution. The management of the aentron energy storage

system consists of two essential standard components:

■ aentron energy controller (AEC)

■ module management system (MMS)

All lithium-ion modules can be combined with each other and used as a single

product or in conjunction with products from other manufacturers.

Documentation for our products is available on request. All energy storage

systems are conforming to standards and can be used for the following

applications:

■ E-mobility

■ E-maritime

■ E-industry

■ E-building

Figure 4: System architecture – BMS functions

Basic Information About the System Structure

Specification of the aentron Energy Storage System

Page 19/100 aentron Energy Storage System aentron GmbH

Version 1.03

Main functions

The following comprehensive safety and control functions for managing a

modular energy storage device are implemented:

■ Communication interfaces: CAN bus / USB

■ Data logging with real time clock

■ System internal firmware updates via CAN bus or USB

■ Monitoring of up to 25 lithium-ion modules per controller unit

■ Relay control

■ Heating and cooling controls (optional on request)

■ Series and parallel string control

■ SoC and SoH calculation

■ Independent hardware security layer

■ Operating temperature range energy controller (-40°C to +80°C)

■ IP class: IP66

■ Redundant power supply DC out 12 V / 25 W

■ Insulation monitoring

■ Highly efficient internal 12/24 Vdc power supply

■ Active power consumption 100 - 600 mW

■ Power consumption shutdown 0 mW

Interfaces:

■ CANopen bus communication (standard 250 kbit/s, 11-bit ID) (ISO 11898)

Provides access to all relevant system information and

parameter changes

Allows communication between energy controller and the

customer application

Facilitates establishing control circuits for charging and/or

discharging

Receives firmware updates via USB 1.1 to 3.0

■ Galvanically isolated up to 1,000 Vdc

This manual suits for next models

2

Table of contents

Popular Control Unit manuals by other brands

Mutable Instruments

Mutable Instruments Blades user manual

Siemens

Siemens SIMATIC ET 200S IM151-1 FO STANDARD manual

Viessmann

Viessmann EM-P1 Installation and service instructions for contractors

schmersal

schmersal SRB 301AN operating instructions

Telect

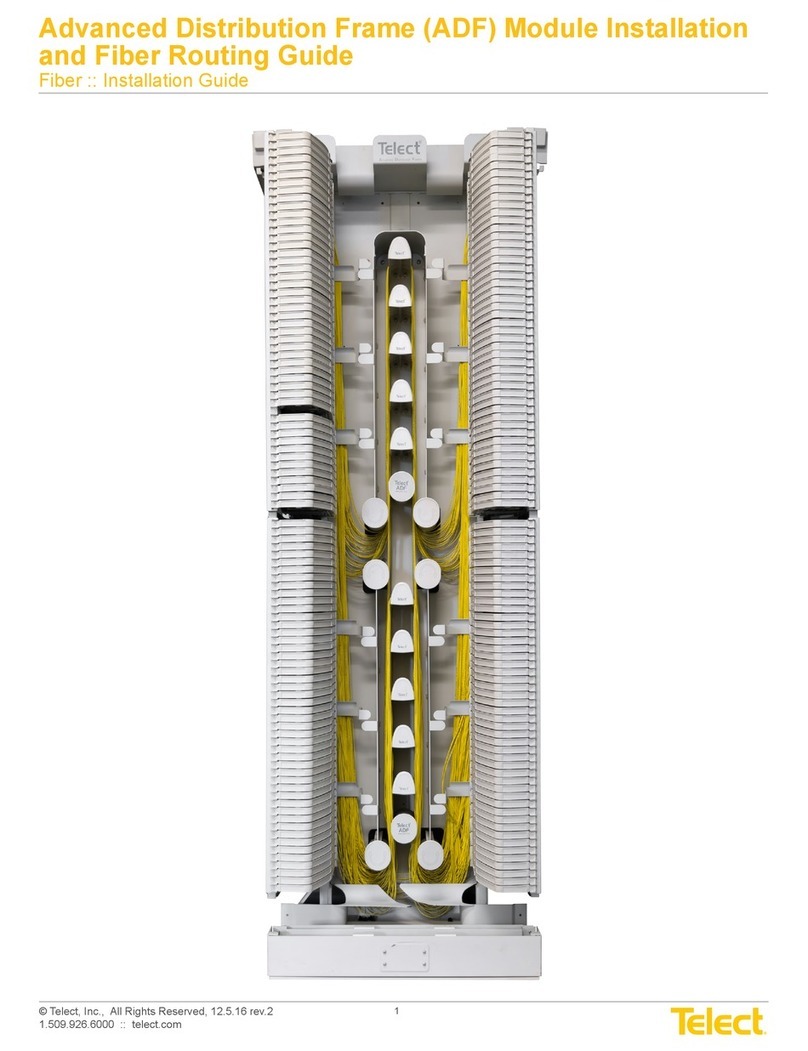

Telect ADF installation guide

ADLINK Technology

ADLINK Technology PXI-7931 user manual