aeolus UC-1901M User manual

Distributor Contacts

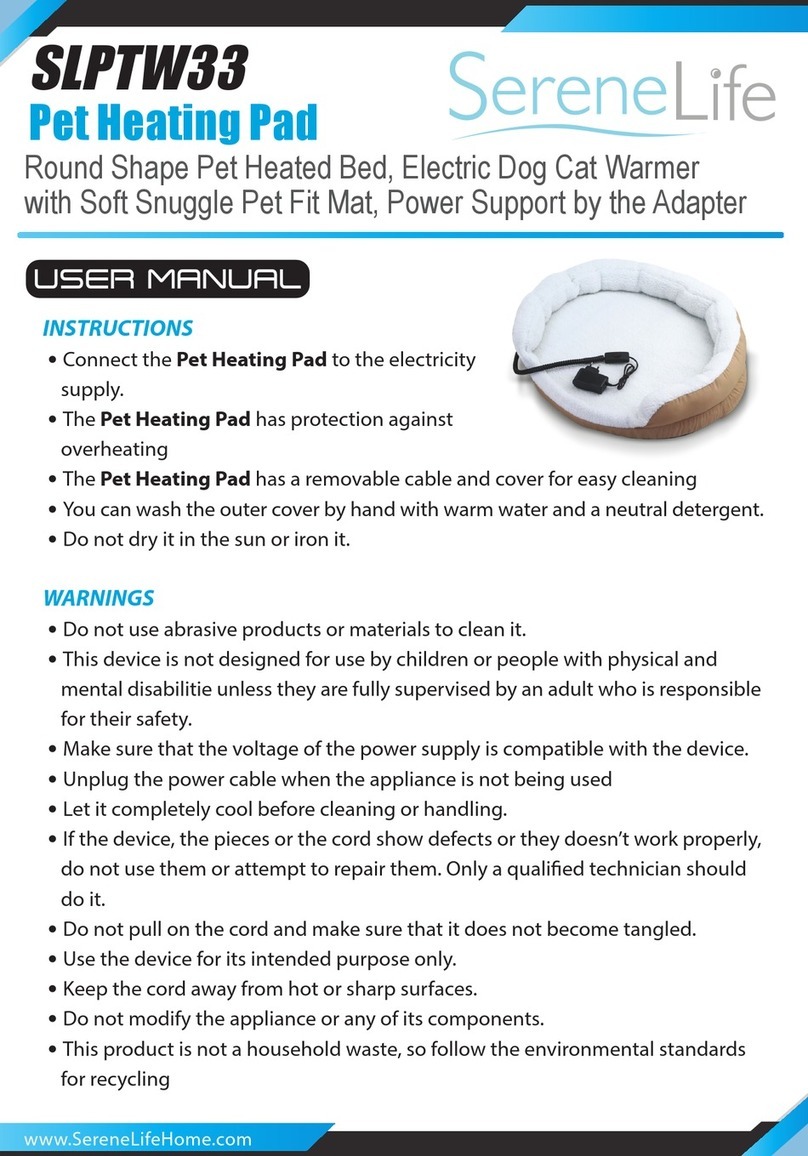

UC-1801

KO2-10FKO2-2F

UC-1901

Professional Multifunctional

Veterinary Intensive Care Unit

WMS-1501

Professional Vet Equipments Supplier

User Manual

01

Overview

CONTENTS

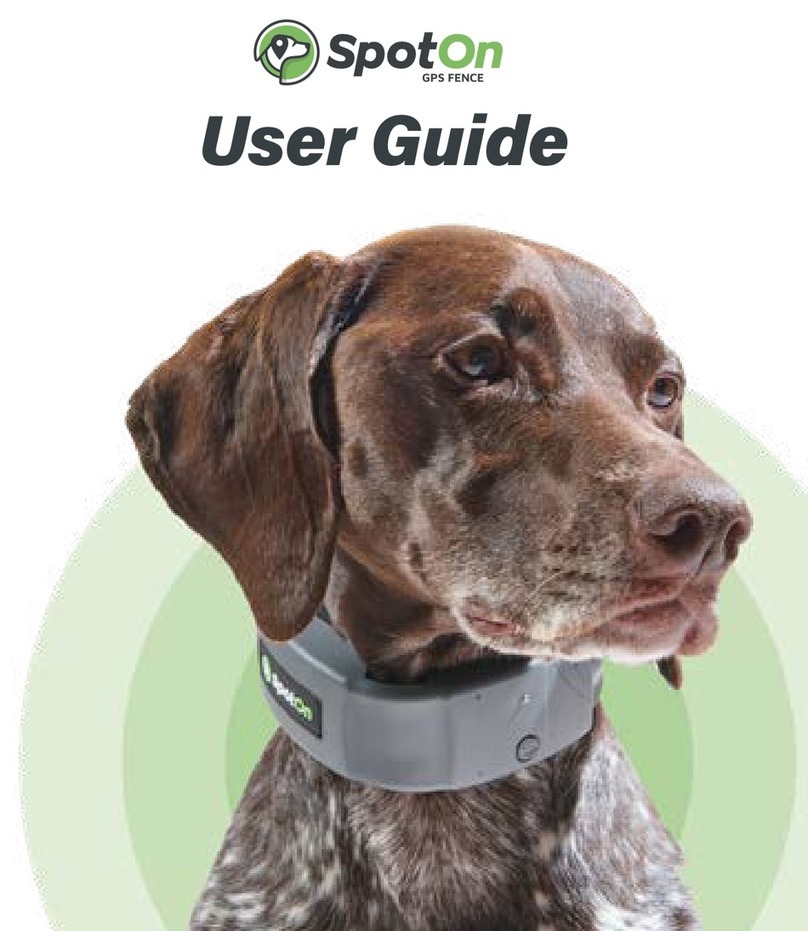

Side View

Top View

Front View Rear View Separated View

Overview …………………………………………..............................

Product dimensions …………………………………………….........

General usage guidelines ………………………………….…….......

General opreation tips ………………………………........................

Radio requency interferece ………………………………................

Choosing the working space for the unit ......................................

Parameters ……………………………………………......................

Operation guidance …………………………………………….........

Setting interface ……………………………………………..............

Setting mode ……………………………………………...................

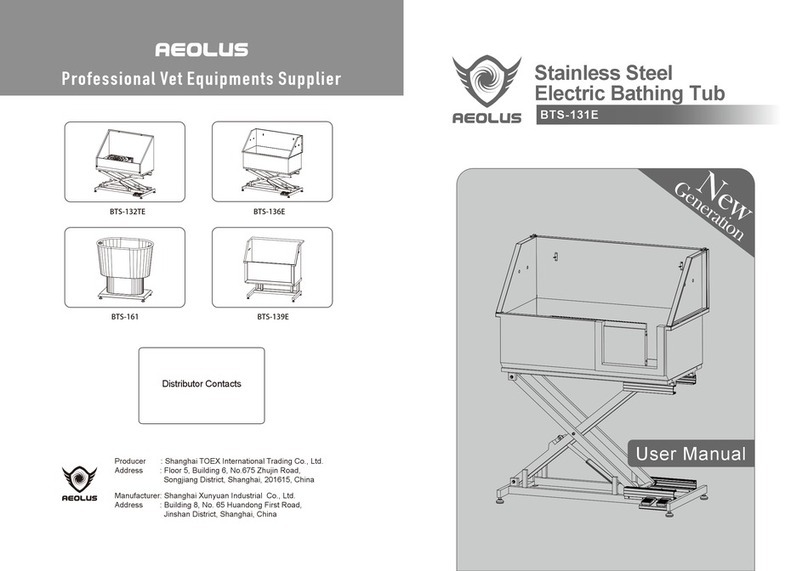

Trouble shooting …………………………………………...................

Non-alarming components .....……………………………................

Maintenance and cleaning …………………………………….…....

01

02

03

03

03

04

05

06

07

08

14

17

18

02

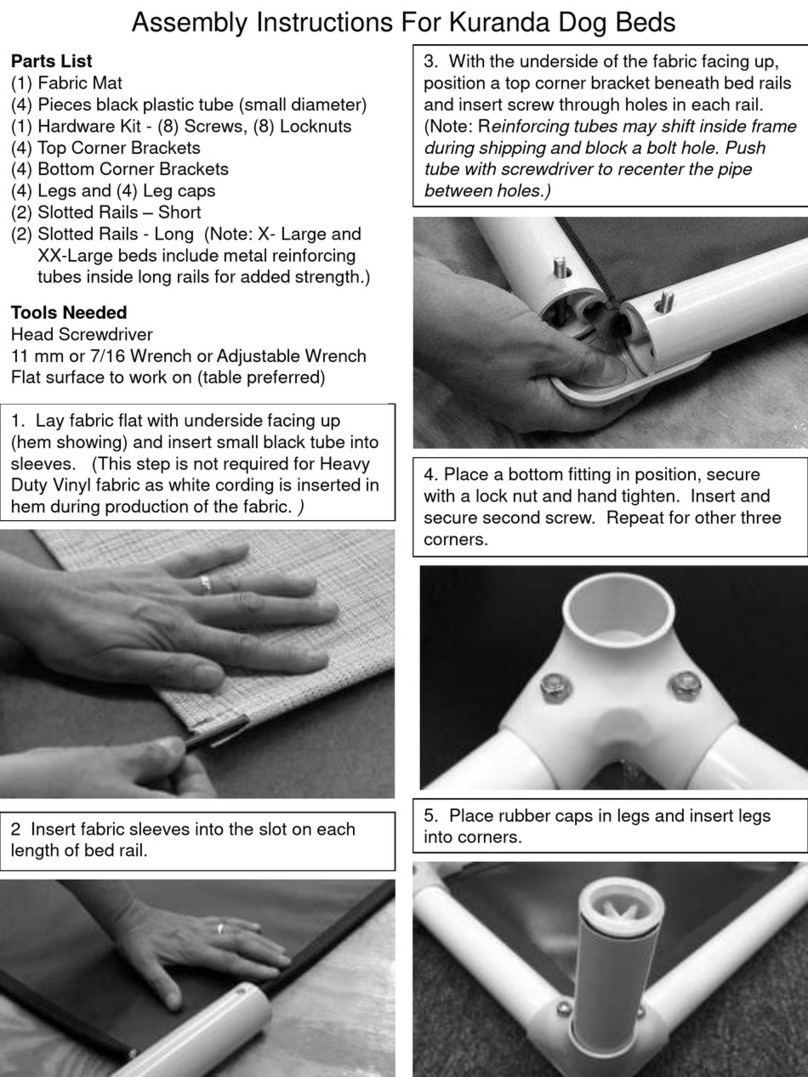

Product Dimensions General Usage Guidelines

General Operation Tips

Radio Requency Interferece

03

Internal dimension of large compartment: 1236×600×695mm (4 ft 21/32 inch × 1 ft 11 5/8 inch × 2

ft 3 23/64 inch)

Internal dimension of medium compartment: 550×600×485mm (1 ft 9 21/32 inch × 1 ft 11 5/8 inch

× 1 ft 7 3/32 inch)

The KaniStar UC-1901 Multifunctional Veterinary Intensive Care Unit is For Animal Use Only.

There is no reference in this handbook for human hospitals or home users.

Normothermia maintenance, fluid transfusion, oxygen supplement, blue light therapy, nebulization

treatment, emergency rescue, in house observation can all be carried out by this unit.

All normal operations and maintenance of the unit should be done by a qualified trained operator under

the supervision of a licensed qualified veterinarian.

The manufacturer will not be responsible or liable for the results of any incorrect use.

The full instruction manual should be read prior to use.

The manufacturer is not liable for any damage caused by a third party "Transport or Delivery Company”.

The day the unit is delivered, an inspection of the outer packing should be made for any damage to the

packing box.

Then the unit should be unpacked carefully; all components, accessories, spare parts and the machine

itself should be inspected for any damage or loss.

If any damage is evident, the carrier or dealer should be notified immediately.

The machine needs to be turned on with temperature set, running for 3 -5 minutes prior to actual usage

of any other functions.

A strict non-smoking policy should be applied.

The unit should Not be used as a table or have anything placed on it at anytime.

The air filtration system should be checked and cleaned regularly; an unclean filtration system can

cause an increase of carbon dioxide in the compartment.

The self-diagnostic system and repair guide can be used for any malfunctions of the machine.

We recommend disconnecting the power supply to this unit at the mains supply if it will not be in use

for extended periods.

Please only use a mild household cleaner or “Aseptic Plus” clinical grade disinfectant and a non-abra-

sive cloth or sponge when needed, for cleaning the transparent doors.

Radio Frequency Interference (RFI) influences most electronic equipment. CAUTION should be

exercised with regard to the use of portable communication equipment in the area around such

equipment.

25.0 OFF

30.0

0

04 05

Parameters

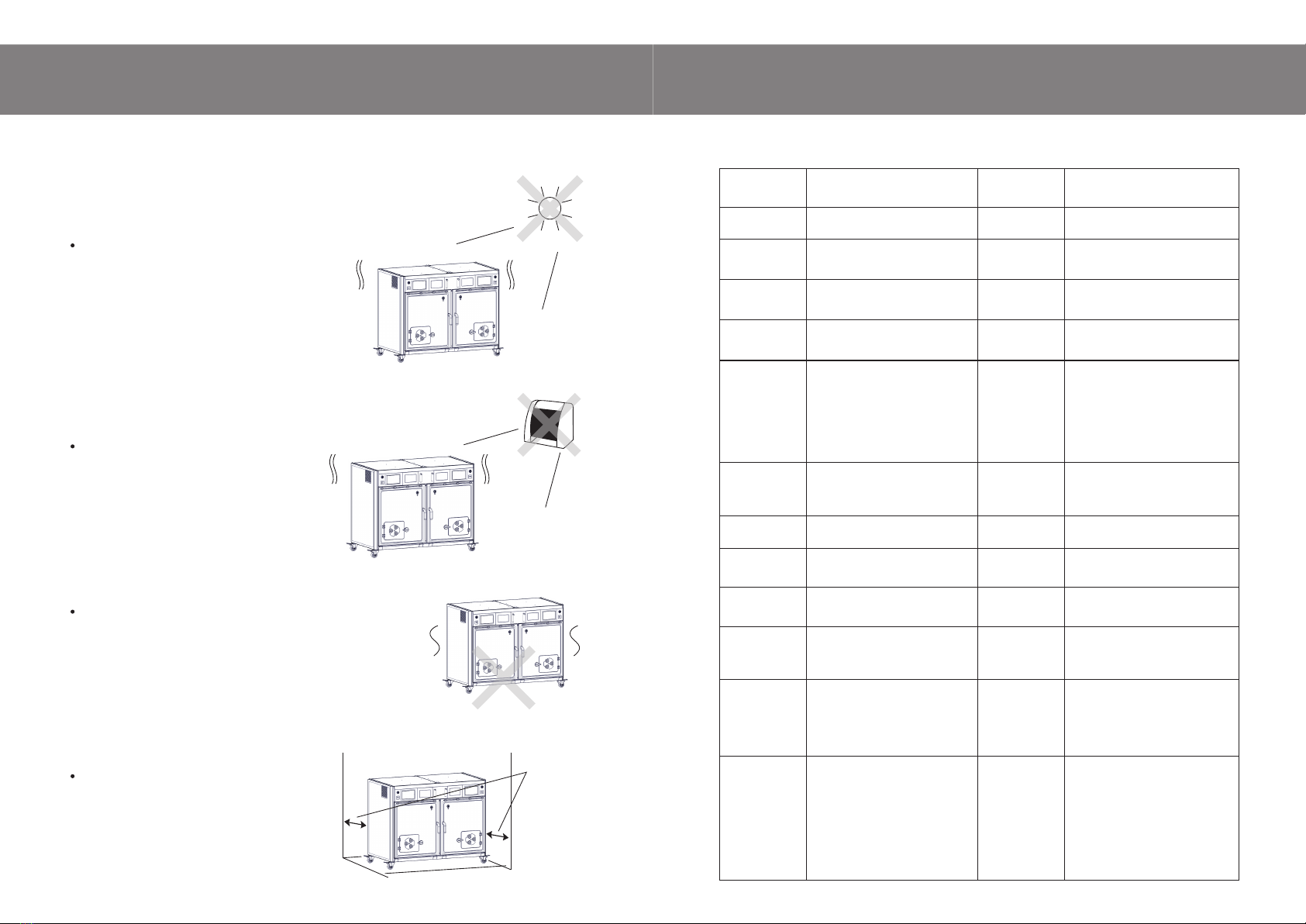

Choosing The Working

Space For The Unit

≥15cm

The unit should be used indoors only, in a cool

dry room with stable temperature and humidi-

ty, kept out of direct sunlight, away from any

heat sources, excess moisture or naked

flames.

This unit should only be operated in a

temperature range of 10° to 40° C (50° to 103°

F). It should not be placed in the direct path of

a room air conditioning outlet.

The full unit weighs 300 kg (660lbs); it should

be placed on a level stable floor.

It should never be placed on a soft or uneven

surface like bedding materials or shaggy

carpets.

The unit should be placed in a well-ventilated

position, and all inlets and outlets should be

unobstructed, there should be a 15cm or

6-inch clearance on all sides.

Care should be taken when choosing the working space for this unit.

Product Name

Model Number

Dimension

Weight

Power Supply

Environment

Control

Air Purification

Temperature

Setting Range

Oxygen Concen-

tration Setting

Carbon Dioxide

Monitoring and

Removal

Alarms

Dehumidification

8.4”, 171mmW×128mmH

Resistive

1.3KW

0.5KW

Emergency Ventilation Port

7.2×106pcs/cm3

Negative Ion Generator

Smart Control Needle Type Printer

253nm UV Sterilization

415nm Blue Therapeutic Light

Treatment

≥0.2ml/min, particle size:

0.5 -2μm, noise≤ 40dB(A)

Control Panel

Screen Type

Max. Power

Consumption

Average Power

Consumption

Power Supply

Failure Protection

Negative Ion

Generator

Accessories

Built-in Printer

Ultra-violet

Sterilization

Blue Light

Therapy

Medical

Nebulizer

LED Illumination

Ventilation Fan

Control

Professional Veterinary

Intensive Care Unit

UC-1901M/L/BK

1509mmW×884mmD×1899mmH

(59.5”W×35”D ×75”H)

Approximate 300kg (660lbs)

AC100~120V /220~240V

50/60Hz (Grounded)

4 Compartments Controlled

Separately, Cooling and Heating.

Two Medium Compartments on

Top Tier, One Large Compartment

on Bottom Tier which could be

divided into two medium com-

partments when needed.

Ultra Violet Sterilization, High

Concentration Negative Ion Air

Purification.

-10~40°C (Indoor)

15~38°C, Tolerance at 0.5°C

21~65%, Tolerance at ±1%.

200 -5000PPM,

Tolerance at ±10PPM,

Built-in CO2 Sensor and Remover

Automatic Dehumidification,

High/Middle/Low Three Stages,

High: 45%~50%,

Middle: 40%~44%,

Low: 30%~39%.

O2 Concentration Alarm, Tempe-

rature Alarm, Sensor Alarm, Door

Opening Alarm, CO2

Concentration.

Alarm, Emergency Ventilation Port

Malfunction Alarms.

Soda Lime CO2 Absorption

Powder, Equipment Mount Grid,

Door Shade Curtain.

Working

Condition

Low/Middle/High, Three-Stage Speed

Control.

Defaults:

Oxygen Input On: Low Speed.

Temperature Control: High Speed

Emergency Port Open: High Speed

Ultra-violet Sterilization On: Middle

CO2 Concentration Level Alarm On:

High

Pure White Cold Light for

Examination, 10 Stage Adjustable

Yellow .

Comfort Light for Illumination.

06 07

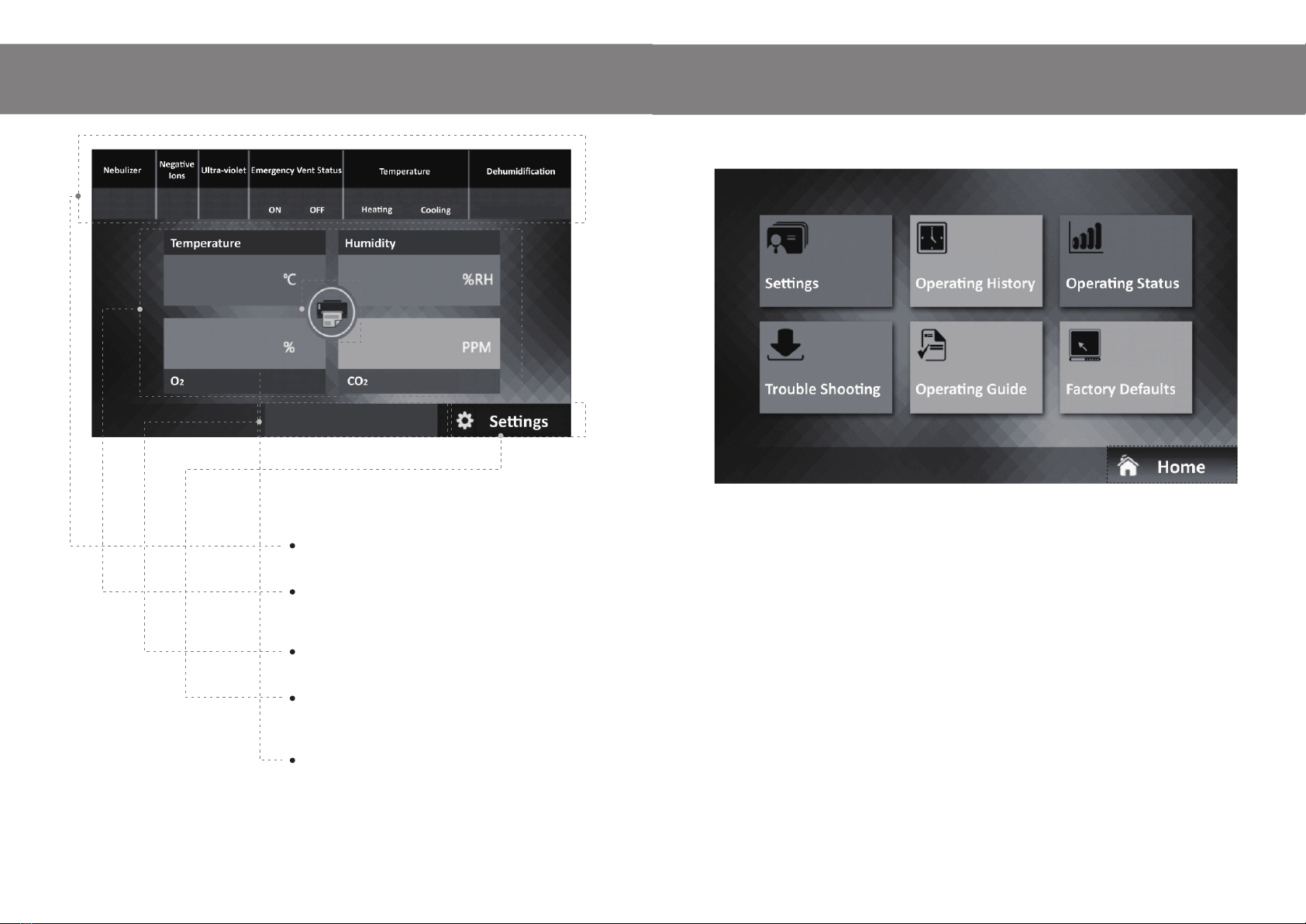

Operation Guidance Setting Interface

Main Interface Navigation

Operating Status – Indicating the varied functions

running in real time.

Key Parameters – Displaying the key figures,

Temperature, Humidity, O2Density and CO2Density

Trouble Shooting – Instructions with pictures for all

problem solving.

Settings Button – Clicking the “Setting” button; this

will open the detailed setting page. The settings can

now be changed from this page.

Printing Button – Located at the center of the 4 icons

parameter boxes, on the running status display page

pressing and holding the button for 5 seconds will

print the real-time running status instantly.

On this interface, you will find the following functions and displays.

1. Setting Mode

Allows the operator to switch on/off and set all the changeable running parameters for most functions.

2. Operating History

Allowing the operator to view a complete operational status of “Temperature”, “Humidity”, “CO2Density”

and “O2Density”, displayed in intuitive curves, allows up to 72 hours /3 days maximum historical

tracking.

3. Operating Status

Real-time operating status for most parameters.

4. Trouble Shooting

Providing an easy-to-follow on screen step-by-step guide with problem solving solutions with visual

instructions for all “alarming components” and "non-alarming components".

5. Operating Guide

An on-screen Basic Operation Guide with photographs.

6. Factory Defaults

The defaults settings for all main components can only be accessed with the factory pass codes, they

should only be adjusted under the careful guidance from our factory technicians if necessary.

0908

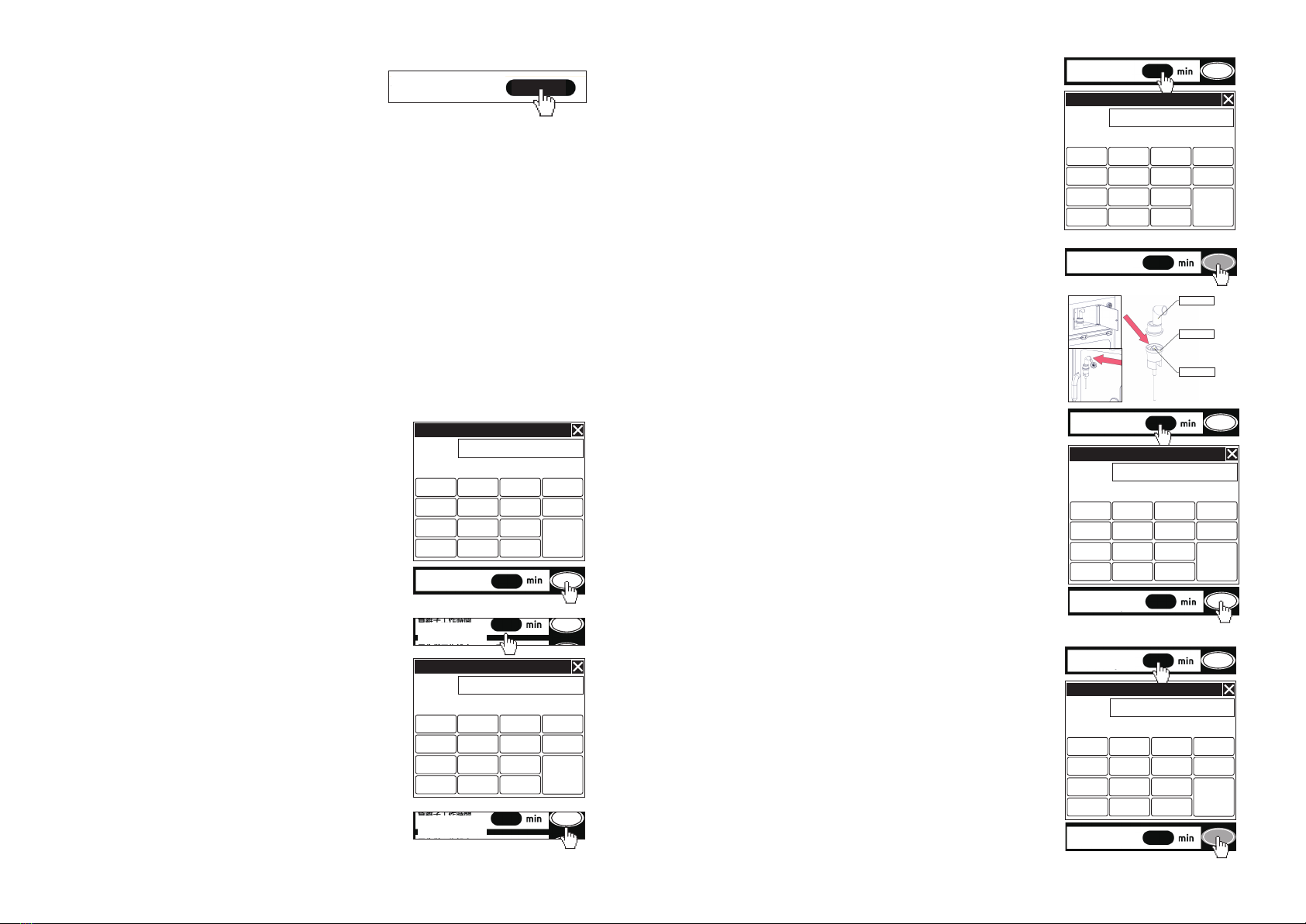

Setting Mode

Temperature

1 2 3

456

7 8 9

+/- 0.

CLR

DEL

Enter

15.0~38.0

25.0

25.0 OFF

OFF

OFF

OFF

OFF

30.0

50

1500

3

Auto

中

0

0

1

9

8

+

-

Humidity

1 2 3

4 5 6

7 8 9

+/- 0.

CLR

DEL

Enter

25.0~50.0

30.0

25.0 OFF

OFF

OFF

OFF

OFF

30.0

50

1500

3

Auto

中

0

0

1

9

8

+

-

1. Temperature Setting

a) Enter “Setting Mode”.

b) Click the existing temperature figure in “Tempera-

ture” bar.

c) Set the desired temperature by clicking the numbers in the

newly opened settings box, within the range of 15 -38 Celsius

Degrees (59 -100.5 Fahrenheit).

d) Click “Enter” to set and save the new value, and then click

the “X” in the top right corner of the settings box to close the

settings box.

2. Humidity Setting

a) Enter “Setting Mode”.

b) Click the existing humidity figure in “Humidity” bar.

c) Set the desired humidity by clicking the numbers in the

newly opened settings box, within the range of 25 -50%, click

the “X” in the top right corner of the settings box to close the

settings box.

Temperature

Humidity

3. Oxygen Density Setting

a) Enter “Setting Mode”.

b) Click the existing oxygen figure in “O2Density” bar.

c) Input the desired oxygen density value by clicking the newly

opened setting box, within the range of 21 -65%.

d) Click “Enter” to set the new oxygen level, click the “X” in the

top right corner of the Settings box to close the settings box.

4. Carbon Dioxide Density Set

a) Enter “Setting Mode”.

b) Click the existing carbon dioxide figure in “CO2Density” bar.

c) Input the desired carbon dioxide density by clicking the

newly displayed setting box, within the range of 200

-2000ppm.

d) Click “Enter” to set the new carbon dioxide level, click the

“X” in the top right corner of the settings box to close the

settings box.

5. Illumination Light Set

a) Enter “Setting Mode”.

b) Click the existing time figure in “Light Timer” bar.

c) Input the desired working time for illumination light by

clicking the newly displayed setting box, within the range of 1

-360 minutes.

d) Click “Enter” to set the illumination light working time, click

the “X” in the top right corner of the settings box to close the

settings box.

6. Light Brightness Set

On “Setting Mode” interface, the light brightness can be

adjusted by pressing either “+” or “-“ button on “Light

Brightness” bar, displayed in the graph here.

Once the level of brightness is set, illumination light will start.

7. Ventilation Fan Control

a) Enter “Setting Mode”.

b) Click the existing fan speed on “Fan Speed” bar, to shift

fan speed through “high”, “middle” and “low”.

O2Density

1 2 3

4 5 6

7 8 9

+/- 0.

CLR

DEL

Enter

21~65

50

25.0

30.0

50

1500

3

Auto

中

+

-

CO2 Density

1 2 3

4 5 6

7 8 9

+/- 0.

CLR

DEL

Enter

200~2000

1500

25.0

30.0

50

1500

3

Auto

中

+

-

Light Timer

1 2 3

4 5 6

7 8 9

+/- 0.

CLR

DEL

Enter

0~360

3

+

-

25.0

30.0

50

1500

3

Auto

中

+

-

25.0

30.0

50

1500

3

Auto

中

+

-

O2Density

CO2Density

Light Brightness

Fan Speed

Light Timer

Remarks: Fan running speed will affect heating or cooling efficiency, please make decisions

according to actual needs based on animal patients status and ambient temperature.

MIDDLE

10 11

OFF

OFF

OFF

OFF

OFF

0

0

1

9

8

OFF

OFF

OFF

OFF

OFF

0

0

1

9

8

OFF

OFF

OFF

OFF

OFF

0

0

1

9

8

OFF

OFF

OFF

OFF

OFF

0

0

1

9

8

9. Exam Light

a) Enter “Setting Mode”.

b) Click the existing time figure in “Exam Light” bar.

c) Input the desired working time for the pure white exam light

by clicking the newly opened displayed setting box, in the range

of 1 -360 minutes.

d) Click “Enter” to set the exam light working time, click the “X” in

the top right corner of the settings box to close the settings box.

e) Switch on exam light when needed by shifting OFF button to

ON as displayed. The light can be switched off by shifting from

ON to OFF at anytime.

10. Blue Light Therapy

a) Enter “Setting Mode”.

b) Click the existing time figure in “Blue Light Therapy” bar.

c) Input the desired working time for blue light by clicking the

displayed setting box, in the range of 1 -360 minutes.

d) Click “Enter” to set the blue light working time, click the “X” in

the top right corner of the settings box to close the settings box.

e) Switch on blue light when needed by shifting OFF button to

ON as displayed below.

Remarks:

When therapeutic blue light is on, exam light and illumination

yellow light will be shut down automatically; once the blue light

finishes working, other lights will resume.

25.0 OFF

OFF

OFF

OFF

OFF

30.0

50

1500

3

Auto

中

0

0

1

9

8

+

-

25.0 OFF

OFF

OFF

OFF

OFF

30.0

50

1500

3

Auto

中

0

33

1

9

8

+

-

25.0

OFF

OFF

OFF

OFF

OFF

30.0

50

1500

3

Auto

中

0

0

1

9

8

+

-

Exam Light

123

456

789

+/- 0.

CLR

DEL

Enter

0~360

30

Blue Light Therapy

1 2 3

4 5 6

7 8 9

+/- 0.

CLR

DEL

Enter

0~360

33

OFF

OFF

OFF

OFF

50

1500

3

Auto

中

0

1

9

8

+

-

8. Emergency Vent Setting

The emergency ventilation port is designed as a fail-safe, for

necessary fresh air in critical situations like a power supply

failure.

The fan is powered by a Lithium battery pack, which will allow several operations without a power

supply from the mains power.

a) Enter “Setting Mode”.

b) Select suitable vent opening mode by shifting the “ON”, “OFF” and “AUTO” on “Emergency Vent

Setting” bar.

Note: There are three working modes of Emergency Vent, ON, OFF and AUTO.

A. ON, means the vent will stay open unconditionally.

B. OFF, means the vent will be shut unless power supply failure is detected, then it will

be opened for fresh air.

OFF mode is NOT recommended to be used.

C. AUTO, means the vent will be opened in the following conditions.

C1: Power supply failure.

C2: O2Density in compartment drops to lower than 15%.

C3: O2 Density ≤25% and CO2Density stabilizes at the level of greater than CO2

Density Alarm setting for over 3 minutes.

C4: O2 Density ≥25% and CO2Density level exceeds 4500ppm.

Blue Light

Therapy

Exam Light

Blue Light

Therapy

MIDDLE

12. Nebulizer and Timer

a) Open the nebulizer chamber door on front control panel of

the machine.

b) Gently take the nebulizer assembly out from the chamber, be

careful not to stretch the pipeline too much.

c) Open nebulizer nozzle cap by twisting counterclockwise.

d) Pour medicine liquid into the medicine cup, replace nozzle

cap clockwise.

e) Attach the cup nozzle part into the silicon port at the left

upper corner of the transparent door.

f) Enter “Setting Mode”.

g) Click the existing time figure in “Nebulizer Timer” bar.

h) Input the desired working time for nebulizer by clicking the

newly opened displayed setting box, in the range of 1 -90

minutes.

i) Click “Enter” to set the nebulization working time; click the “X”

in the top right corner of the settings box to close the settings

box.

j) Turn the nebulizer on when needed by shifting OFF button to

ON as displayed below.

Remarks: During nebulization treatment, cooling, heating and

ventilation functions will shut down, for better preservation of

medicine atmosphere in the compartment.

13. Ultra-violet Timer

a) Enter “Setting Mode”.

b) Click the existing time figure in “Ultra-violet Timer” bar.

c) Input the desired working time for ultra-violet sterilization by

clicking the displayed setting box, in the range of 1 -90 minutes.

d) Click “Enter” to set the ultra-violet sterilization working time;

click the “X” in the top right corner of the settings box to close

the settings box.

e) Switch on ultra-violet sterilization light when needed by

shifting OFF button to ON as displayed below.

Note: There must be No Animals in the unit when this function is

being used.

11. Negative Ion Set

a) Enter “Setting Mode”.

b) Click the existing time figure in “Negative Ion Timer” bar.

c) Input the desired working time for negative ion gener-

ator by clicking the newly opened displayed setting box, in

the range of 0 -72 hours.

d) Click “Enter” to set the negative ion working time; click the

“X” in the top right corner of the settings box to close the

settings box.

e) Switch on negative ion generator when needed by shifting

OFF button to ON as displayed below.

Nozzle cap

Medicine cup

Cone gasket

Nebulizer Timer

1 2 3

4 5 6

7 8 9

+/- 0.

CLR

DEL

Enter

0~90

20

1 2 3

4 5 6

7 8 9

+/- 0.

CLR

DEL

Enter

0~72

2

25.0

NO

NO

ON

OFF

OFF

30.0

50

1500

3

Auto

中

0

0

2

9

8

+

-

25.0

NO

NO

ON

OFF

OFF

30.0

50

1500

3

Auto

中

0

0

2

9

8

+

-

25.0

OFF

OFF

OFF

OFF

OFF

30.0

50

1500

3

Auto

中

0

0

0

9

8

+

-

1 2 3

4 5 6

7 8 9

+/- 0.

CLR

DEL

Enter

0~90

15

25.0

OFF

OFF

OFF

OFF

OFF

30.0

50

1500

3

Auto

中

0

0

1

9

0

+

-

25.0

NO

NO

NO

OFF

ON

30.0

50

1500

3

Auto

中

0

0

2

9

15

+

-

Timer

Timer

25.0

OFF

OFF

OFF

OFF

OFF

30.0

50

1500

3

Auto

中

0

0

0

9

8

+

-

Nebulizer Timer

Nebulizer Timer

12 13

25.0

OFF

OFF

OFF

OFF

OFF

30.0

50

1500

3

Auto

中

0

33

1

9

8

+

-

25.0

OFF

OFF

OFF

OFF

OFF

30.0

50

1500

3

Auto

中

0

33

1

20

8

+

-

14. Printing Intervals Set

a) Enter “Printing Intervals”.

b) Click the existing time figure in “Printing Intervals” bar.

c) Input the suitable printing intervals by clicking the newly

opened setting box, in the range of 0 -60 minutes. Setting it at

0 min will shut down this printing function.

d) On the printing slip, four key parameters can be displayed,

Temperature, Humidity, Oxygen Density and Carbon Dioxide

Density.

e) “Hospital or Clinic” names can be printed on the slip as a

customization option; please contact your local supplier for

more details.

f) Switch on printing function when needed by shifting OFF

button to ON as displayed below.

15. Running Status

On the Running Status page, all real-time running

status will be displayed.

16. CO2Remover Replacement Reminder

Depending on varied types of soda lime powder

from different suppliers, the effective validation

time may be different; the operator can set

17. Parameter Calibrations

The Parameter Calibration needs to be managed

by trained qualified technician, or under the

guidance and supervision of our technicians.

On this page, you can make adjustments to these

parameters below.

Temperature Setting Zero and Full.

Humidity Setting Zero and Full.

Ambient Temperature and Auxiliary Temperature.

CO2Density Setting Zero and Full.

25.0 OFF

OFF

OFF

OFF

OFF

30.0

50

1500

3

Auto

中

0

0

1

9

8

+

-

OFF

0

1 2 3

4 5 6

7 8 9

+/- 0.

CLR

DEL

Enter

0~60

30

25.0 OFF

OFF

OFF

OFF

OFF

30.0

50

1500

3

Auto

中

0

0

1

9

8

+

-

ON

30

CO2

Replacement Reminder RENEW

② ③④

different replacement reminding times accordingly.

At the bottom of the above page for “Running Status”, the estimated CO2remover replacement time

is displayed.

Click the boxes shown above to set effective time for soda lime CO2remover reminder.

In box 4, it shows the elapsed working time from last replacement; box 2 is for resetting the validation

time for different suppliers’ soda lime.

If you are using the soda lime from our company, please click “RENEW” button to set it at 800 hours

after replacing.

Note: It’s highly recommended to use our soda lime to ensure a reliable working efficiency and

service life.

18. History

The running status of four key parameters,

temperature, humidity, CO2density and O2density,

will be recorded every minute.

In our system, the operation history can be tracked

for up to 72 hours /3 days as maximum.

All the curves will be displayed on this interface, you

can click on any of them to enlarge the whole curve

and get more detailed statistics.

19. Operation Guide

All the instructions shown above are also

installed in the control panel system; they can

be found in the Operation Guide page shown.

The instructions are displayed with detailed

wording and photos.

20. Accessories Mount Installation

This stainless steel wire grid is designed for

mounting all necessary accessories, such as IV

pole, infusion pump, syringe pump, monitor, etc.

Please insert the bottom foot into the fixture hole

on top of the large compartment first, then match

and insert the top pin into the triangle connector

between the two medium compartments as

indicated by the picture.

21. Door Shade Curtain Installation

A slide track and four hooks are installed on top of

the transparent doors on each compartment, to

hang the shade curtains helping cut out light and

noise transmissions to the compartment and calm

the patients.

No other function can be set when the unit is being disinfected. The disinfecting process can be

cancelled at any time returning the unit to its previous settings. All other lights will be cancelled and all

functions will be stopped during the disinfection process.

O2Density Setting Zero and Full.

Note: You need a pass code to enter this page, please contact your local supplier or service center

for further assistance.

1514

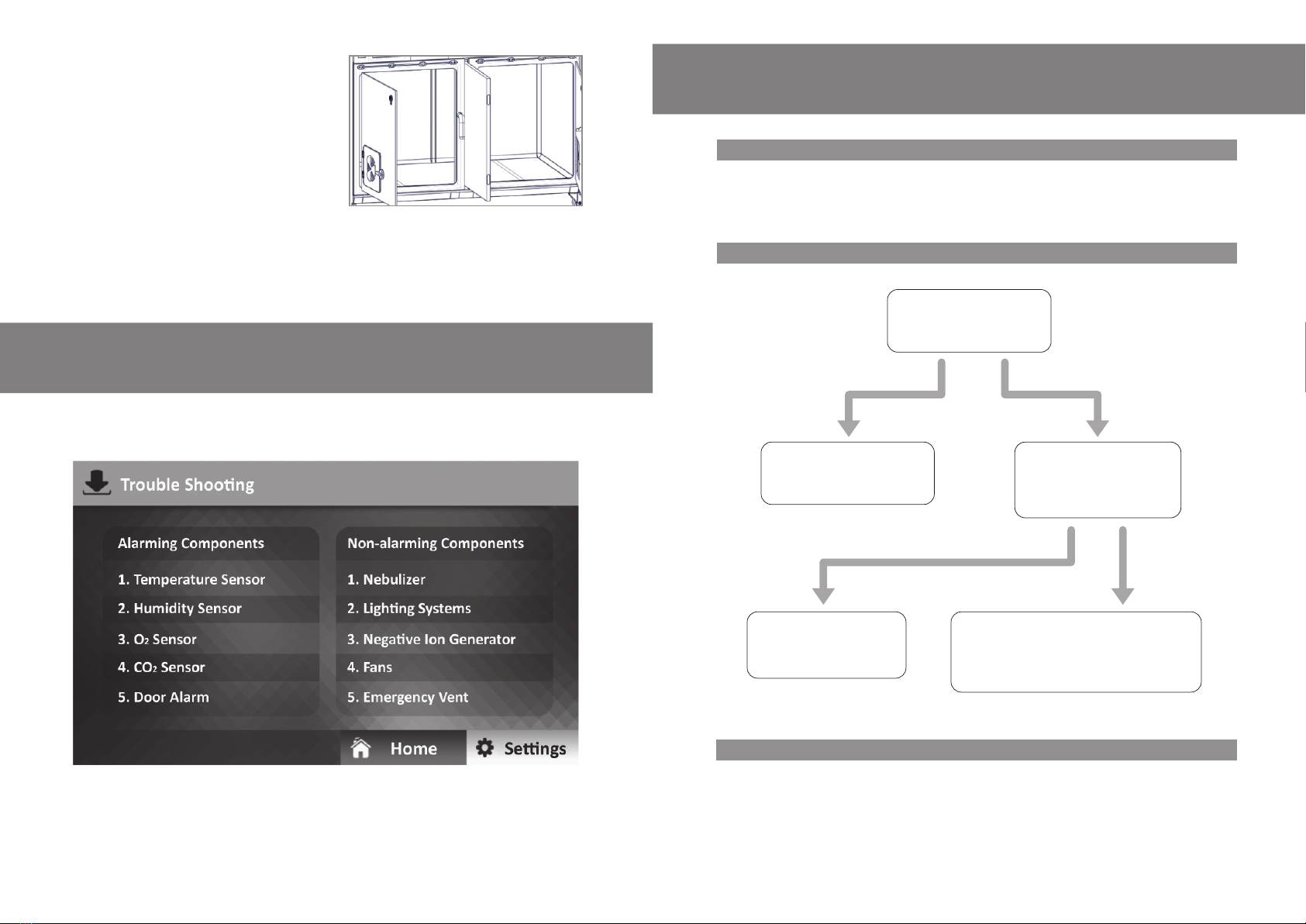

Troubleshooting

Alarming Components

On the Trouble Shooting page, most common potential faults are displayed, with both alarming

components and non-alarming ones combined.

Please follow the instructions below if you have a fault.

22. Large Compartment Divider Application

With this very unique and practical feature, the large

compartment can be divided into two separately

controlled medium compartments.

By loosening the two latches on top of the front

column in the middle of the large compartment, it can

be pulled out at the top then up to remove, then the

middle hidden divider will be exposed.

Pull out the middle divider gently; the two medium

compartments will become one large unit. The detector switch on the back wall of the compartment

will be released, the left sided control panel will be shut down, and the right-sided control panel will

now manage the whole large compartment.

When the middle divider is replaced, both control panels on left and right compartments will start to

operate.

1. Temperature Sensor & Humidity Sensor Replacement

Both Temperature and humidity sensors can be found can be found at the innermost top corner of the

compartment. Open the cover grid, both sensors will be exposed, please replace the faulty compo-

nent according to the instructions displayed on control panel screen.

2. O2Sensor Replacement

If O2

.

isn’t

is

The door alarm will be triggered if the front door stays open for more than 3 minutes.

Please check the front door status when alarm sounds; close the door securely to eliminate the alarm

when needed.

3. Door Alarm

16 17

4. CO2Sensor

1. Nebulizer

2. Lighting Systems 3. Negative Ion Generator

If CO2

isn’t

is

Non-alarming components

a) Please check if foreign objects or drug residue have blocked the medicine cup or nebulizer pipeline.

b) Open and remove the top cover on the ICU compartment to expose internal components.

c) Please find the nebulizer pump and check if it’s damaged; replace it when needed.

Note: There is a backup nebulizer pump inside, please double check and diagnose which one is

broken before replacing.

Open the grid at the top corner nearest to the

door hinge.

Locate faulty light component and replace it

when needed.

Open and remove the top cover on ICU

compartment to expose internal components.

Please find the negative ion generator, check if

it’s broken.

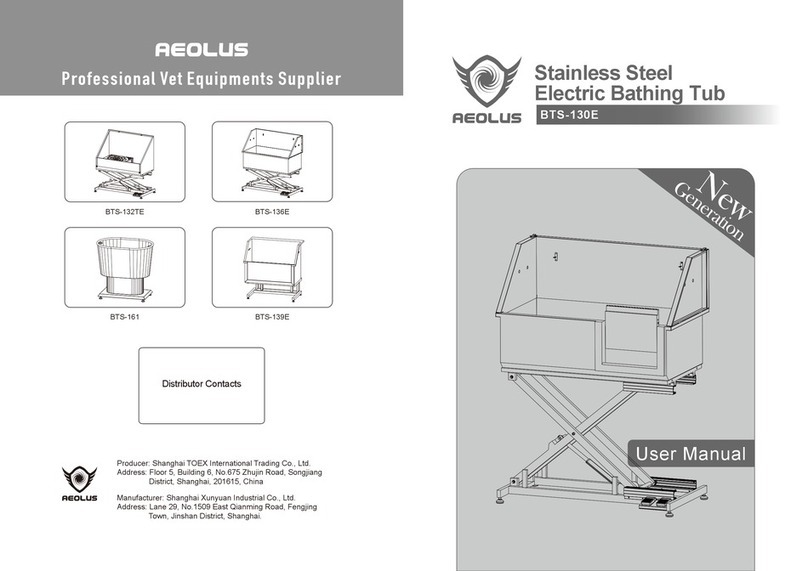

Open and remove the protective cover on the

emergency ventilation fan on the back of the

unit, as indicated in Figure below.

Replace the entire emergency vent assembly.

Open the top cover of the ICU unit; locate the

fan assembly as indicated by the red arrow in

Figure below.

Replace the fans when necessary.

Note: The PTC heating assemblies will need to

be removed before replacing the fans.

4. Fans 5. Emergency Vent

Both inside and outside of the machine can be wiped clean regularly with a mild cleaning agent that

is non-abrasive, such as “Aseptic Plus” clinical grade disinfectant.

Clean the control panel with a mild household cleaner and non-abrasive cloth or sponge at least one

time each week.

All inlet vents should be vacuumed regularly to remove any dust; they can be wiped clean with a soft

cloth using a mild cleaning agent. We suggest the filters are removed and washed clean regularly,

then allowed to dry before replacing.

In between usages, the compartment should be cleaned with a soft cloth or sponge using a mild

cleaning agent; then turn the ultra-violet sterilization on for at least 3 minutes to disinfect the whole

unit.

Regular testing of the emergency vent should be done between usages; the unit can simply be

powered off to check if the vent opens.

Maintenance And Cleaning

This manual suits for next models

2

Table of contents

Other aeolus Pet Care Product manuals

aeolus

aeolus BTS-132TE User manual

aeolus

aeolus BTS-131E User manual

aeolus

aeolus TD-907 User manual

aeolus

aeolus BTS-130E User manual

aeolus

aeolus UC-1801-RCK User manual

aeolus

aeolus PW-001 User manual

aeolus

aeolus KaniStar Warmology WMS-1501 User manual

aeolus

aeolus UC-1701 User manual

aeolus

aeolus BTS-138E User manual

aeolus

aeolus TD-905 User manual

Popular Pet Care Product manuals by other brands

BIGLEASH

BIGLEASH VIBRATION TRAINER V-10 owner's guide

Premier Pet

Premier Pet GAL00-16809 product manual

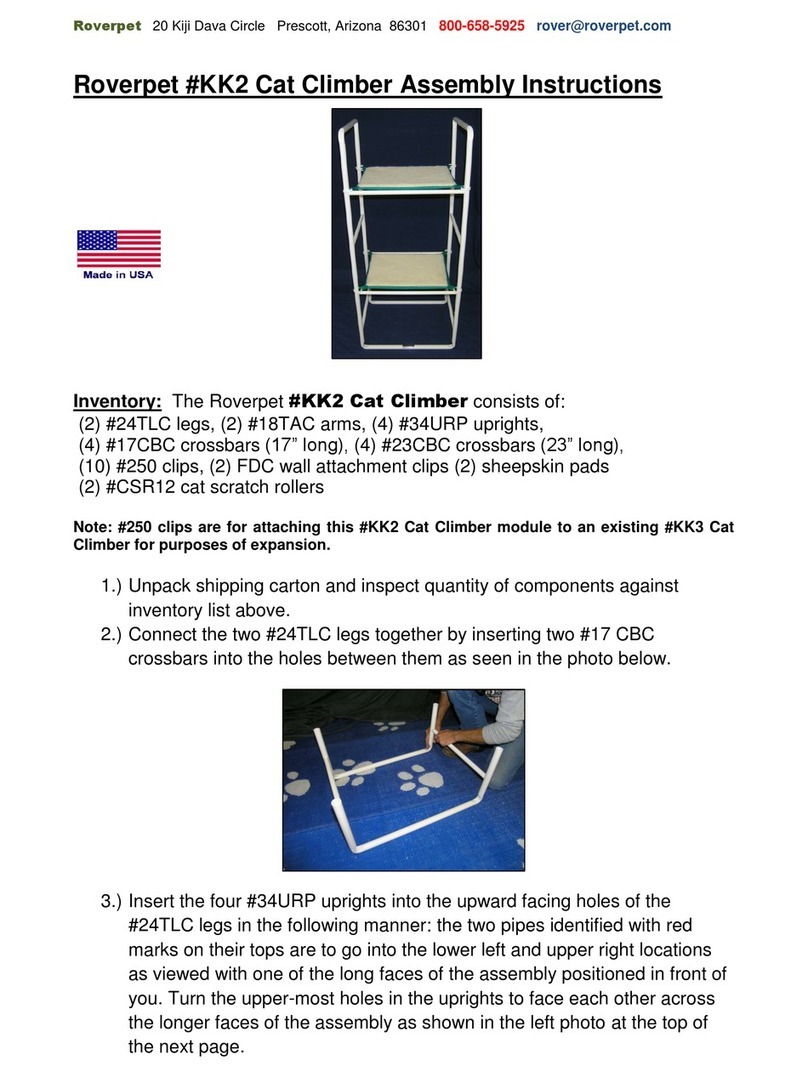

Roverpet

Roverpet KK2 Assembly instructions

Richell

Richell 94193 instruction manual

SportDOG

SportDOG YARD TRAINER 100 Operating and basic training guide

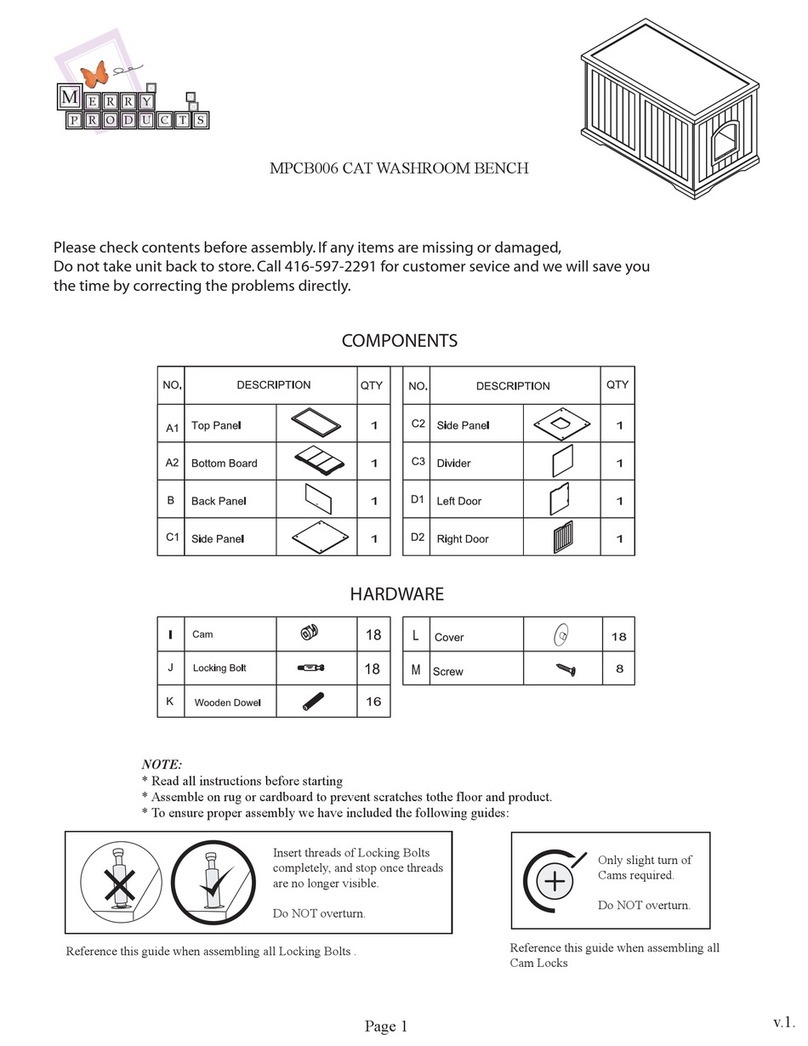

Merry Products

Merry Products CAT WASHROOM BENCH MPCB006 manual