AERO-LIFT FORCE-LIFT User manual

1/51 FORCE-LIFT

karto

Machine type:

FORCE-LIFT®Vacuum Lifter

Version:

02/2021

Built in:

2022

Application:

For the horizontal transport of airtight an porous

materials. Load capacity up to 75kg depending

on the configuration

Carefully read and observe the instruction manual!

Keep the manual readily available for future reference!

INSTRUCTION MANUAL

LEGAL INFORMATION

2/51 FORCE-LIFT®

LEGAL INFORMATION

All rights, especially the right to reproduction, distribution and translation, are reserved. No part of

this document may be reproduced in any form (print, photocopy, microfilm or another process)

nor stored, processed or distributed using electronic systems without the written consent of

AERO-LIFT Vakuumtechnik GmbH. Noncompliance will result in seeking damages to cover

losses.

The vacuum lifter complies with CE guidelines in accordance with the applicable

regulations and directives. The applied standards and guidelines are listed in the

declaration of conformity.

Copyright © AERO-LIFT Vakuumtechnik GmbH

AERO-LIFT Vakuumtechnik GmbH

Turmstraße 1

D-72351 Geislingen

Ph: +49 (0) 7428 94 514-0

Fax: +49 (0) 7428 94 514-38

www.aero-lift.de

LIST OF CONTENS

FORCE-LIFT®3/51

INHALTSVERZEICHNIS

1Safety............................................................................................................................................................... 3

Target group ....................................................................................................................................................................3

Abbreviations and definitions............................................................................................................................................4

Type label and nomenclature...........................................................................................................................................4

Further applicable documents..........................................................................................................................................4

Explanation of safety instructions.....................................................................................................................................5

Remaining risks in case of use.........................................................................................................................................7

Operator obligations and liability ......................................................................................................................................9

General safety instructions.............................................................................................................................................10

Intended use..................................................................................................................................................................10

Foreseeable misuse.......................................................................................................................................................10

2Structure and function .................................................................................................................................. 11

Technical specifications .................................................................................................................................................11

Functional Description....................................................................................................................................................12

Operator controls ...........................................................................................................................................................13

Safety devices................................................................................................................................................................14

Components...................................................................................................................................................................15

Suction feet (options).....................................................................................................................................................16

3Installation..................................................................................................................................................... 19

Installing the vacuum lifter..............................................................................................................................................19

Electrical connection......................................................................................................................................................20

4Handling and operation................................................................................................................................. 21

Transporting the product with the vacuum tube lifter ......................................................................................................21

Fastening/changing the suction foot...............................................................................................................................23

5Options, spare and wear parts ...................................................................................................................... 25

Replacement seal ..........................................................................................................................................................25

Further spare parts.........................................................................................................................................................26

AERO-LIFT Service .......................................................................................................................................................26

6Maintenance, inspection and repairs ............................................................................................................ 27

Inspection intervals ........................................................................................................................................................28

Maintenance and repairs................................................................................................................................................29

7Transport, setup and storage ........................................................................................................................ 32

8Disassembly and disposal .............................................................................................................................. 33

9EU Declaration of Conformity........................................................................................................................ 34

10 Annex............................................................................................................................................................. 35

Vacuum pump operating instructions .................................................................Fehler! Textmarke nicht definiert.

1Safety

Target group

SAFETY

4/51 FORCE-LIFT®

These operating instructions have been written for persons, who as a result of their professional

training, work experience and their current work activity have adequate technical knowledge to

safely and competently use the vacuum lifting unit and who are able to read and understand the

instructions.

Abbreviations and definitions

Abbreviation

Definitions

Explanation

UVV

Accident prevention regulations

Maintenance service for accident

prevention

VUSS

Vacuum Unit Sensing System

Flow valves integrated in the suction

feet, which turn on and off

automatically

AL

AERO-LIFT

Type label and nomenclature

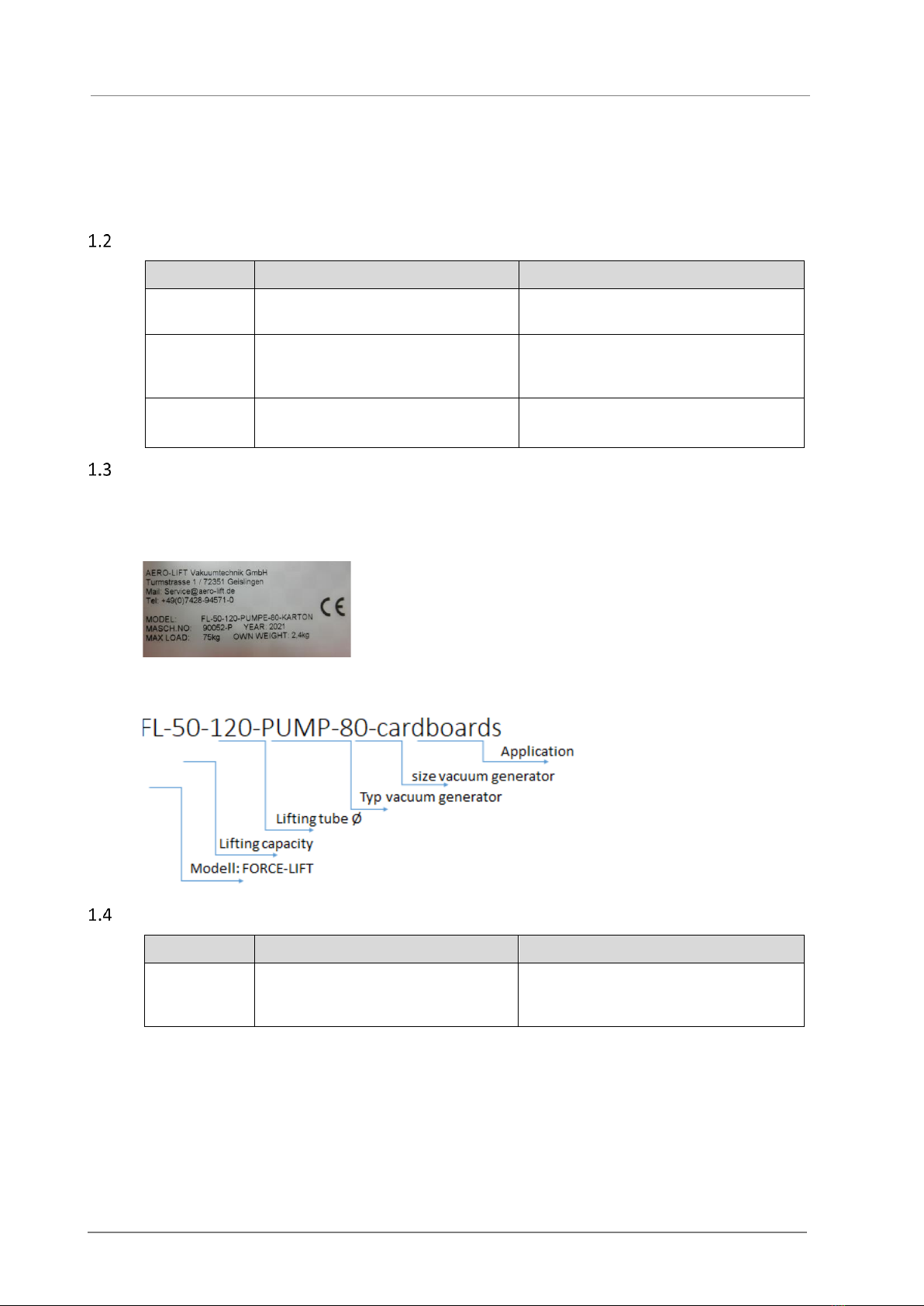

The machine number, year of manufacture and model designation are are given on the type label

for identification. We ask you to provide this information in a service case.

The type label is attached to the rear of the control head. It is structured as follows:

The specified model name can be deciphered as follows:

Further applicable documents

Appendix No.

Document

Manufacturer

1

Operating instructions, spare parts

list and instructions for sound-

proofing box of the vacuum pump

AERO-LIFT Vakuumtechnik GmbH

LIST OF CONTENS

FORCE-LIFT®5/51

Explanation of safety instructions

Safety instructions are always provided with a signal word and a warning. All persons who work

with the machine must observe and adhere to the safety instructions. The safety instructions are

arranged as follows:

(1) SIGNAL WORD

(5)

(2) Signal word classifies the danger

(3) Note text: type and source of danger + possible consequences

✓(4) Measures to be taken or prohibitions to be imposed

(5) Symbol: supporting graphic representation of the hazard

Categorization Warnings:

DANGER!

Indicates an immediate or impending danger. If appropriate measures are not taken, it

will lead to serious injury or death.

WARNING!

Warns of a potentially dangerous situation. If appropriate measures are not taken, it

may lead to serious injury or death.

CAUTION!

Warns of a potentially dangerous situation. If appropriate measures are not taken, it

may lead to minor or moderate injuries.

NOTE

Indicates possible damage to property and provides specific information

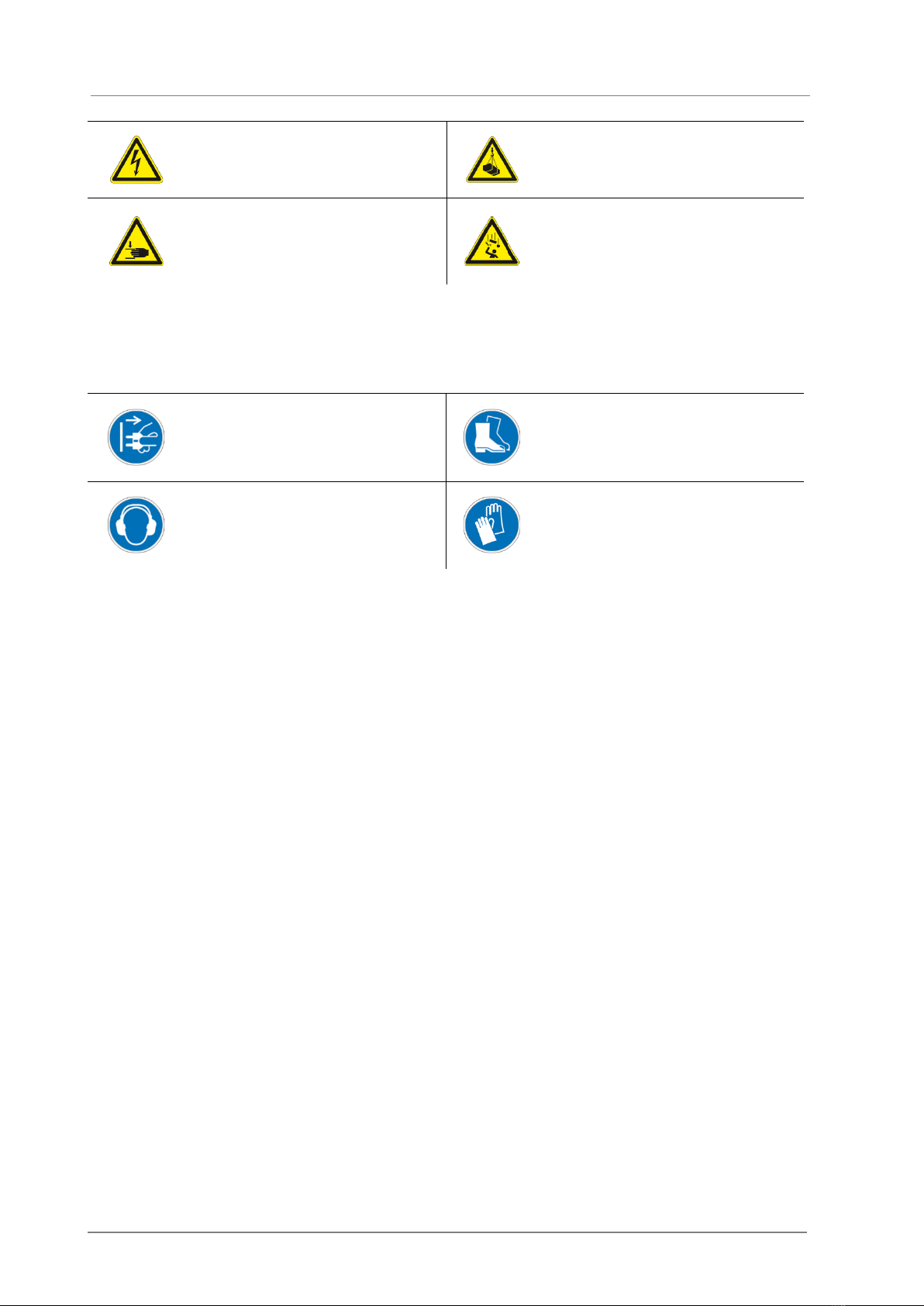

Explanation of symbols

Warning signs:

Warns or indicates a hazardous

area. Different symbols in the

warning triangle explain a danger in

more detail

Warns of tipping over and serious

injury due to crushing

SAFETY

6/51 FORCE-LIFT®

Warns of dangers due to electrical

voltage

Warns of a suspended load

Warns of serious injuries due to

crushing of limbs

Warns of falling objects

Bid signs:

Instructs personnel to unplug the

power cord

Instructs personnel to wear

protective shoes

Instructs personnel to wear

protective clothing

Instructs personnel to wear

protective gloves

LIST OF CONTENS

FORCE-LIFT®7/51

Remaining risks in case of use

DANGER!

Electrical Voltage!

Contact with live parts is life-threatening! Live parts, damaged electrical lines and

electric shock as a result of faulty or defective parts, or using water to clean may lead to

lethal injuries, burns and property damage.

✓Switch off the power supply prior to carrying out any work on the electrical

system or cleaning.

✓Pull the vacuum power supply plug (disconnect from power supply)!

✓Cleaning may only be carried out by trained personnel.

✓Maintenance of the electrical system may only be carried out by a qualified

electrician.

✓Regular visual inspection of energy chains and electrical lines for any damage.

DANGER!

Suspended loads!

Risk of crushing, shearing and other injuries due to falling or moving parts during

transport of the machine or machine parts and during operation.

Risk when moving loads!

✓Do NOT stand under suspended loads and do not climb on suspended loads!

✓Use suitable lifting gear and load handling attachments that are approved for

transport and the weight!

✓Wear personal protective equipment.

✓Move goods carefully and pick up load at its center of gravity.

✓Persons may NOT stay in the transport area.

WARNING!

Moving parts!

Crushing of fingers / hands when moving or adjusting the position of the suction plates,

during mounting or operation may lead to injuries.

✓Do NOT touch or reach between individual suction plates (double-rectangular

suction foot), quick-changing coupling and suction foot or between other

components!

✓Carefully install the vacuum lifter.

✓Do not remove the protective covers.

✓When moving, keep the one hand on the control head and the other hand on

the product being transported.

✓Always wear personal protective equipment when installing and making

adjustments!

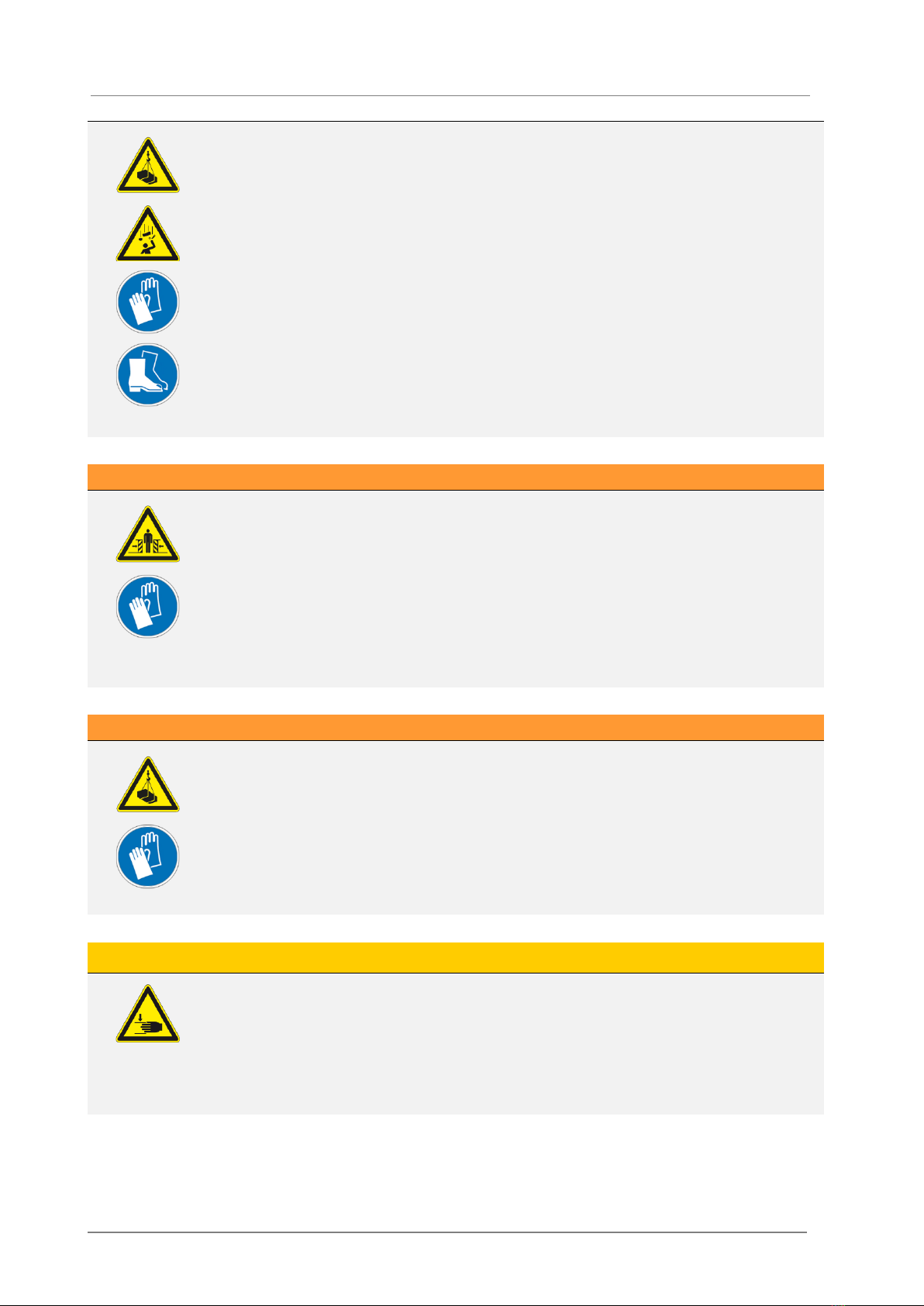

WARNING!

SAFETY

8/51 FORCE-LIFT®

Falling loads!

Incorrect pick-up and/or premature release of loads before they are fully resting can

cause severe injuries due to possible crushing, shearing or impact. Danger due to loads

falling!

✓When operating the vacuum lifter, exercise caution!

✓Pick up load only in center.

✓Only release load when it is fully resting.

✓After changing the suction plates/bases, check whether the connection has

been inserted correctly.

✓Persons may NOT stay in the transport area.

✓Always wear personal protective equipment when working on or with the

machine!

WARNING!

Manual swivelling / turning of suction foot

Risk of injury due to crushing, shearing or impact involving suction foot and/or product

being transported when manually turning and swivelling of the suction foot.

✓Exercise caution when swivelling and turning the suction foot.

✓When swivelling, keep the one hand on the control head and the other hand on

the product being transported.

✓Always wear personal protective equipment when working on or with the

machine!

WARNING!

Danger of being drawn in

Risk of injury from being drawing in, caught or severing during cleaning and

maintenance work. Danger posed by moving and rotating parts.

✓Shutdown the system for maintenance and cleaning work.

✓Always wear personal protective equipment when working on or with the

device!

CAUTION!

Risk of crushing when operating the device

Crushing of fingers/ hands at the device or between the component and device can

lead to injuries.

✓When operating the device, exercise extreme caution!

✓Always wear personal protective equipment when working on or with the device!

LIST OF CONTENS

FORCE-LIFT®9/51

Operator obligations and liability

•These original operating instructions, in particular the safety instructions, must be observed

by all persons who work with the machine.

•The laws, regulations and rules on occupational safety, accident prevention, fire prevention

and environmental protection which apply for the place of use must be observed (e.g., in

Germany: BGR500)!

•Constructive or functional changes to the machine are only permitted with the

manufacturer’s written approval.

•Unless contractually agreed otherwise, spare parts and wearing parts and recommended

accessories may only be obtained from the manufacturer.

•The machine may only be used as intended.

•The machine must be in a sound state of repair.

•The machine must undergo regular inspections and maintenance in accordance with these

operating instructions.

•The machine may only be transported, set up and stored by qualified specialists.

•There must be enough space around the machine for the operating personnel to ensure that

the machine may be operated without any obstructions.

•Persons may NOT stay in the transport area.

•The machine may only be used and checked by adequately qualified personnel. The

personnel must fulfill the following conditions:

•The personnel must have sufficient technical knowledge for safe and professional handling

of the machine as a result of their professional training, work experience and up-to-date

professional activities.

•The personnel have been instructed and briefed in the operation.

•The entrusted personnel must have read and understood the operating instructions.

•Personnel must comply with their duty to supervise during operation.

•Personnel must be at least 18 years old

•The machine must be secured against any unauthorized use if it is not used for a long

period of time.

•Only AL technicians and experienced system technicians may be employed for installation,

assembly and start-up.

•Work on the pneumatic system and vacuum equipment may only be carried out by a

specialist.

•Cleaning may only be carried out by trained personnel. Upon completion of cleaning

activities, all lines are to be checked for leaks, loosened connections, chafe marks and signs

of damage! Promptly remedy any identified deficiencies.

•Maintenance and repair activities may only be carried out by qualified personnel.

•Maintenance of the electrical equipment may only be carried out by a qualified electrician.

•Warranty and liability claims for personal injuries and property damage are excluded when

one or more of the aforementioned requirements have been disregarded.

SAFETY

10/51 FORCE-LIFT®

General safety instructions

The machine is designed and constructed in accordance with the current state of technology and

the generally accepted safety regulations. Nonetheless, its use may pose a hazard to life or limb

of the user or a third party or adversely affect the machine and other material property.

•Only operate the machine as intended!

•Refrain from any form of work that adversely affects safety!

•Only operate the machine when it is in a sound state of repair!

•Check functionality and for freedom from any deficiencies prior to starting work!

•Do not circumvent or bypass the safety functions!

•Immediately remedy or eliminate any faults that could have an adverse effect on safety!

•Observe and follow the safety instructions contained in this instruction manual!

Intended use

The FORCE-LIFT®vacuum lifter (vacuum tube lifter) is used for lifting and subsequently setting

down various goods from a wide variety of industries. In conjunction with exchangeable types of

suction feet, it is possible to move and handle vacuum-tight and porous loads of max. 75 kg.

The control head of the vacuum lifter and the suction heads are part of a complete system

comprising a vacuum pump or blower, filter unit, supply line, swivel joint and vacuum lift tube. The

vacuum lifter is attached to a pillar-mounted slewing crane with a jib, a (rigid) wall-mounted jib or

a rail system. Control head and suction feet as well as vacuum lift tube can be swivelled using

swivel joints; the suction foot can be swivelled up to 90°.

At the time the FORCE-LIFT vacuum lifter was placed on the market, it is designed/suited for the

following variations of suction feet:

•Adaptable double-rectangular suction foot for transport goods surfaces that are not

inherently stable with flexible bearing system for handling cardboard boxes, steel plates or

similar (box lifter)

•Suction foot for drums or barrels and other inherently stable or smooth transport goods

surfaces (drum lifter)

•Suction foot for handling sacks, bags and similar transport goods that are not inherently

stable and which do not have smooth surfaces (bag lifter)

•VUSS suction foot as special solution for transport goods with cut-outs and porous material

(option)

The respective suction foot can be used for the corresponding transport goods.

The vacuum lifter may only be used from the front by one person. These must be qualified

specialists.

The vacuum lifter is intended for use in halls and outdoors when milder ambient weather

conditions prevail.

The vacuum lifter may only be operated if all safety devices are fully installed and functional.

Intended use also includes observing this instruction manual as well as carrying out the necessary

Foreseeable misuse

Foreseeable misuse

The machine is NOT intended for the following applications:

•Handling of other components or variations than those approved by the manufacturer.

•Overstepping of maximum load capacity.

•Shutting off the suction plates that fall below the load capacity.

LIST OF CONTENS

FORCE-LIFT®11/51

•Load picked up out of center.

•Product to be transported is approached at an angle when being picked up.

•Storage of suction foot with suction foot facing down.

•Use in closed rooms with particular dangers (e.g. risk of explosion).

•Working in storms, inclement weather or heavy rain.

•Picking up loads with snow or ice-covered surfaces.

•Operation by untrained personnel.

2Structure and function

Technical specifications

Operating data

Nominal size

Unit

Own weight of control head

2,3

kg

Working load maximum:

75

kg

Possible goods to be transported:

Boxes, sacks, buckets, canisters,

drums, etc…

Lift tube diameter

⌀100, 120, 160

mm

Max. number of load cycles

20,000

Ambient temperature (operation)

+ 5 to + 45

°C

Ambient temperature (storage):

+15 to + 25

°C

Rel. air humidity (operation and storage)

max. 80 %

Vacuum pump: 230V/400V, 2,4KW

Vacuum blower: 400V, 3KW

Pump: VAL 50T, 80T,

Blower: SV400/2

Noise level

Pump: 56

Blower: 71

dB(A)

STRUCTURE AND FUNCTION

12/51 FORCE-LIFT®

Functional Description

The vacuum lifter consists of the following main components:

(1) Swivel joints with eyelet

(2) Lift tube

(3) Control head

(4) Suction foot

(5) Supply line

(6) Filter unit

(7) Motor protection

(8) Vacuum pump/blower

(9) Pillar-mounted slewing crane + jib

Functional description

The vacuum generator (8), pump or blower depending on the use, generates the air flow volume

and provides the vacuum. The vacuum or the generated air flow reaches the product to be

transported through the filter unit (6), via the supply line (5), the lift tube (2), the control head (3)

and then the suction foot (4).

If the suction foot is placed on the product to be transported, e.g. a cardboard box, the device

attaches itself. The external air, which previously streamed in through the suction foot, is

decreased or stops completely which in turn increases the vacuum in the entire system. With the

rapidly increasing vacuum, the previously untensioned lift tube starts to tighten. A spring is

integrated in the lift tube to ensure, among other things, that the lift tube does not implode due to

the vacuum. As soon as the lifting force (negative pressure x lift tube cross-section area) is greater

than the weight of the product to be transported, the product can be lifted.

Regulating the external air in the control head either raises or decreases the vacuum in the entire

system. Adding external air reduces the

LIST OF CONTENS

FORCE-LIFT®13/51

vacuum and thus causes the lift tube to expand lengthwise and the control head with the suction

foot and the product being transported to be lowered. Conversely, the vacuum increases with the

reduction of external air, which in turn causes the lift tube to be tensioned and contract in terms

of length - the control head with the suction foot and the product to be transported raises up.

Consequently, the product being transported can be held suspended in the air by stopping the

addition of external air to a certain extent.

Quick-change coupling, swivelling and rotating function

A quick-change coupling is available to ensure that the operator can change the suction foot in

seconds. The suction foot can also be swivelled manually by 90°.

There is also a 360° rotating function for turning the product being transported. This allows the

product to be rotated continuously.

Operator controls

(1) Quick release button

(2) Automatic unlock and suspend

function

(3) Regulating screw for transport

goods

(4) Lock mechanism quick-change

coupling

(5) 360° rotating function

(6) Lift/lower control button

The FORCE-LIFT®is operated with only one hand with the control head.

The load is lifted up using the “Lift/Lower” button (6). If it is released slowly, the load moves

downward again. The unlock button (2) must be pressed to unlock. It is used as a safety lock

mechanism for the lowering function. If it is released suddenly, the load stays at the selected

height.

The release button (1) is used to quickly and easily release the load from the suction foot (quick

release).

STRUCTURE AND FUNCTION

14/51 FORCE-LIFT®

With the regulating screw for the transport goods (3) it is possible to regulate whether air-tight or

porous materials are suctioned. If it is closed, it is possible to lift air-tight transport goods. To lift

heavy cardboard boxes, the screw has to be unscrewed some, while to lift sacks or bags it has to

be unscrewed completely.

With the regulating screw for the transport goods (3) it is possible to regulate whether air-tight or

porous materials are suctioned. If it is closed, it is possible to lift air-tight transport goods. To lift

heavy cardboard boxes, the screw has to be unscrewed some, while to lift sacks or bags it has to

be unscrewed completely.

The product to be transported can be rotated continuously using the 360° rotating function (5).

By actuating the 90° unlock button (6), the suction foot can be swivelled manually by 90°. This

means that cardboard boxes can be easily stacked, for instance.

Vacuum pump or blower is switched on and off using the power switch (not shown). Optionally,

the vacuum generators can be switched on and off via a remote control.

Safety devices

The release button (1) is protected against inadvertent actuation as a result of its position, the

required actuation force and the length of actuation.

The spring-return unlock button (2) must be pressed in order to actuate the button (7). When

actuating the button (7), the vacuum increases; while it decreases when the button is released,

provided that the unlock button (2) is pressed. If the control head is released suddenly, the unlock

button (2) closes very quickly, ensuring that the vacuum remains and that the vacuum lifter holds

the load at a constant height. This prevents the load from causing any personal injuries or property

damage when the control head is released.

A safety non-return valve (not shown) prevents a rapid drop in the vacuum in case of a power

failure and thus the load from falling. In case of a power failure, the vacuum is decreased and the

lift tube is slowly lowered.

LIST OF CONTENS

FORCE-LIFT®15/51

Components

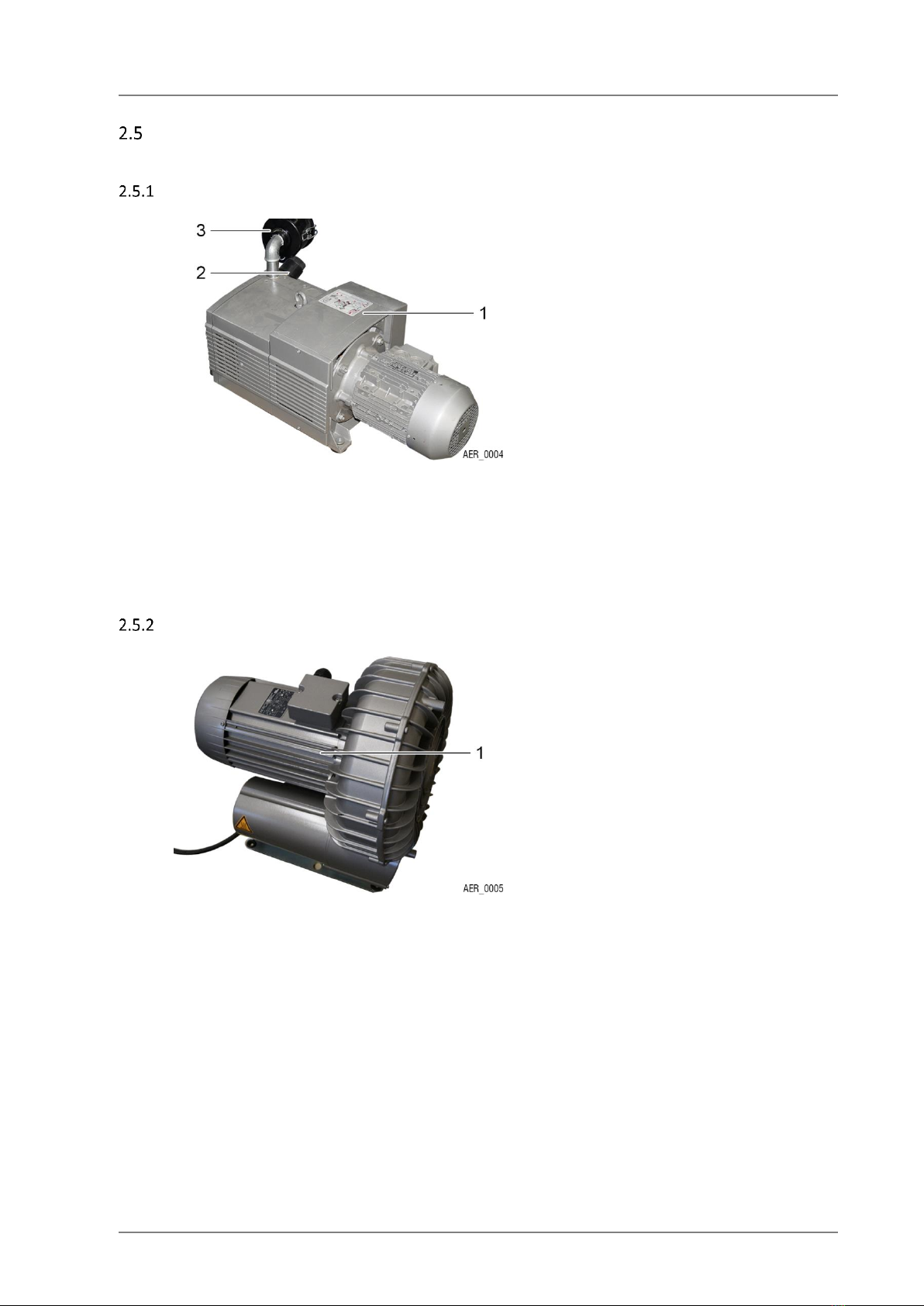

Vacuum pump

(1) Vacuum pump

(2) Vacuum control valve

(3) Vacuum filter

The vacuum for the vacuum lifter is generated using the vacuum pump. The pump consists of a

vacuum pump (1) with rotation control (2) and an upstream vacuum filter (3). It is switched on and

off using a power switch (not shown).

The selection of the pump depends on the application. Pumps from 40 to 80 m³/h can be used.

See further applicable documents.

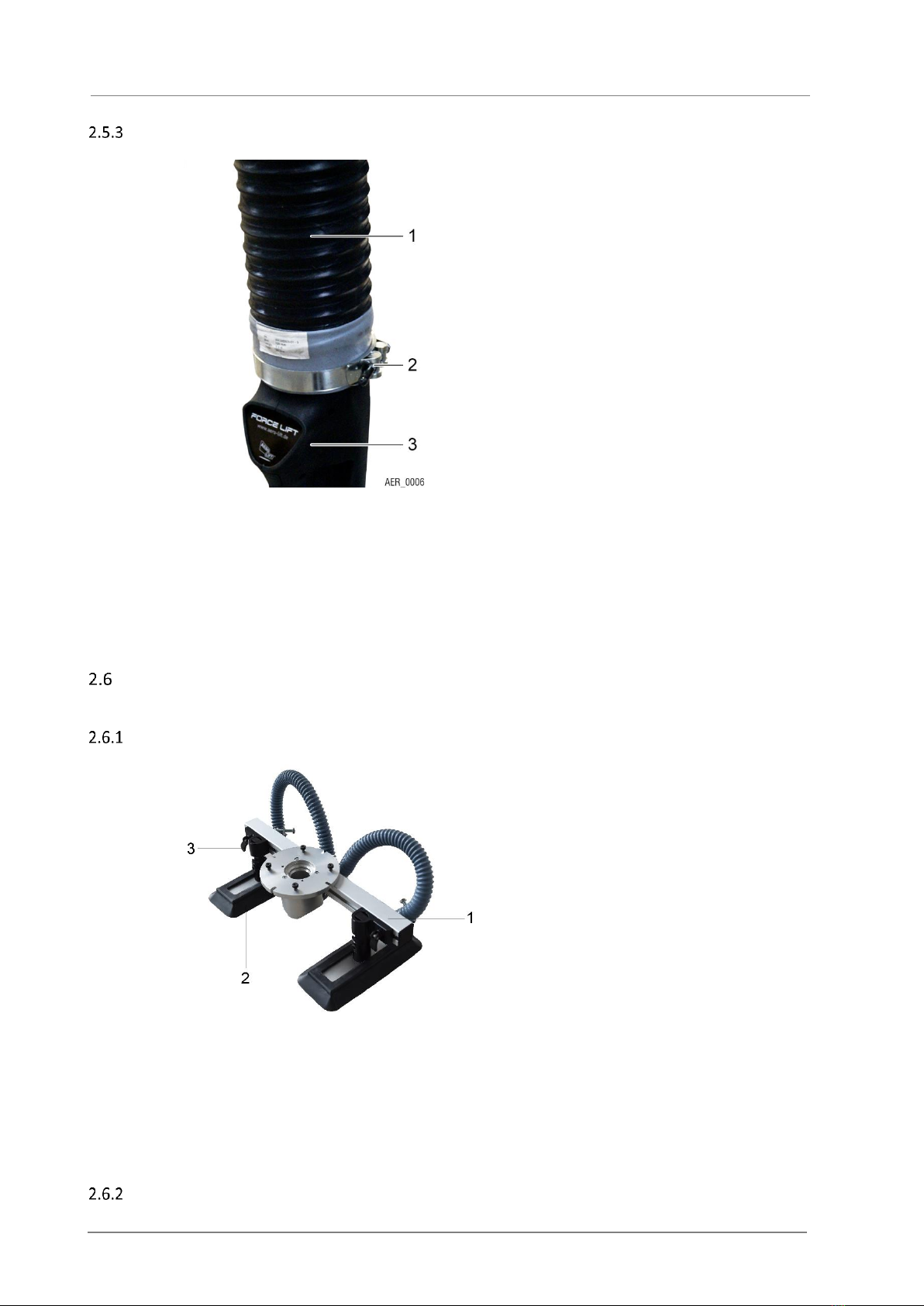

Vacuum blower

(1) Vacuum blower

The vacuum for the vacuum lifter is generated using the vacuum blower (1). The powerful blower

can be switched on and off using the power switch or a radio control.

See further applicable documents.

STRUCTURE AND FUNCTION

16/51 FORCE-LIFT®

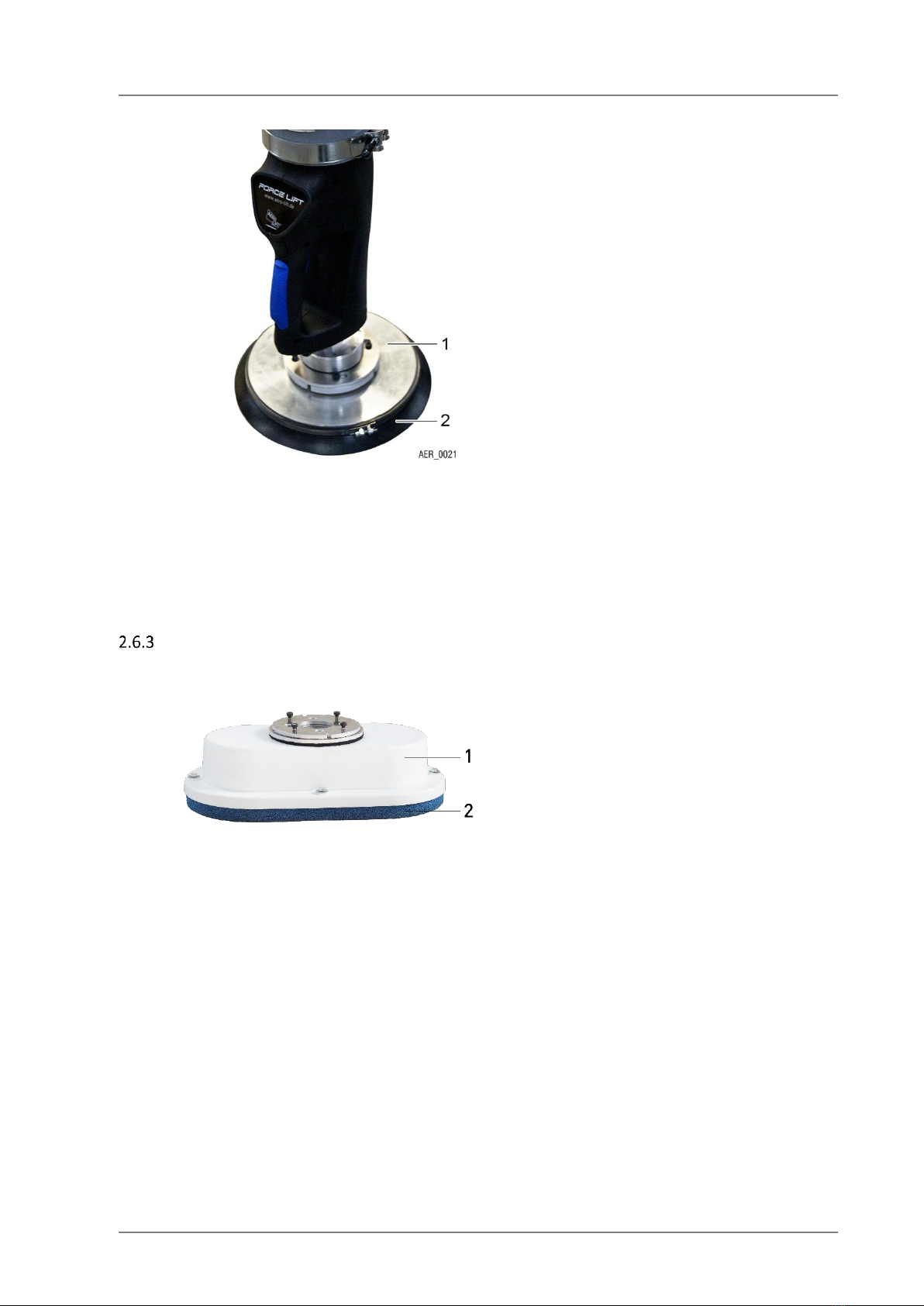

Lift tube

(1) Lift tube

(2) Clamp for fastening

(3) Control head

The lift tube (1) is used to raise, hold and lower the product to be transported. The lift tube is

suspended from a swivel joint with an eyelet on the crane. It is fastened to the control head (3)

with a clamp (2) on the bottom.

The lift tube rises when the vacuum is generated or increases and lowers when the vacuum

decreases. If the vacuum supply stops or the blower fails, it sinks slowly downward with the

product to be transported.

Suction feet (options)

Double rectangular suction foot

(1) Cardboard suction foot

(2) Suction plate

(3) Adjustment of suction foot

The card board suction food is an adjustable double-rectangular suction foot for transport goods

surfaces that are not inherently stable. It is mounted so that it can tilt and is specially designed for

handling boxes or steel plates and similar.

It consists of two suction plates (2). They can be adjusted in width with the adjustment (3) to adapt

to the width of the products to be transported.

Round suction foot

LIST OF CONTENS

FORCE-LIFT®17/51

(1) Base plate

(2) Seal

The barrels lifter is a suction foot for drums or barrels and other inherently stable or smooth

transport goods surfaces. It consists of a base plate (1) and a seal (2) that can be changed in just

a few seconds.

The suction cup-shaped design of the seal ensures an airtight seal with the surface of the product

to be transported.

Bag suction foot

(1) Basic housing

(2) Seal

The bag suction foot is designed for handling bags and similar transport goods that are not

inherently stable and which do not have smooth surfaces. The bag suction foot consists of a basic

housing (1) and the circumferential seal (2).

The sponge-like design of the lower seal can compensate for unevenness in the surface of the

product to be transported.

STRUCTURE AND FUNCTION

18/51 FORCE-LIFT®

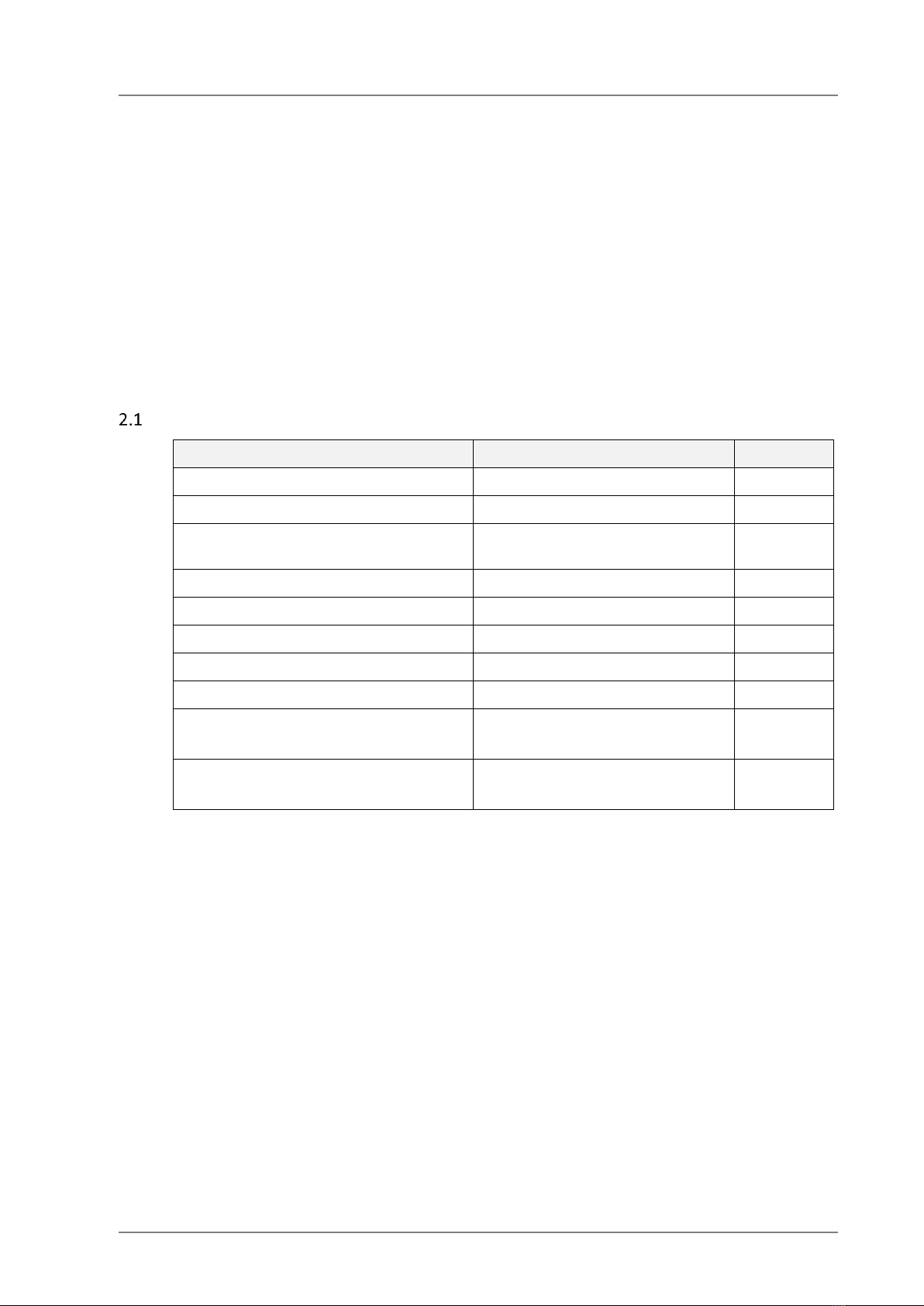

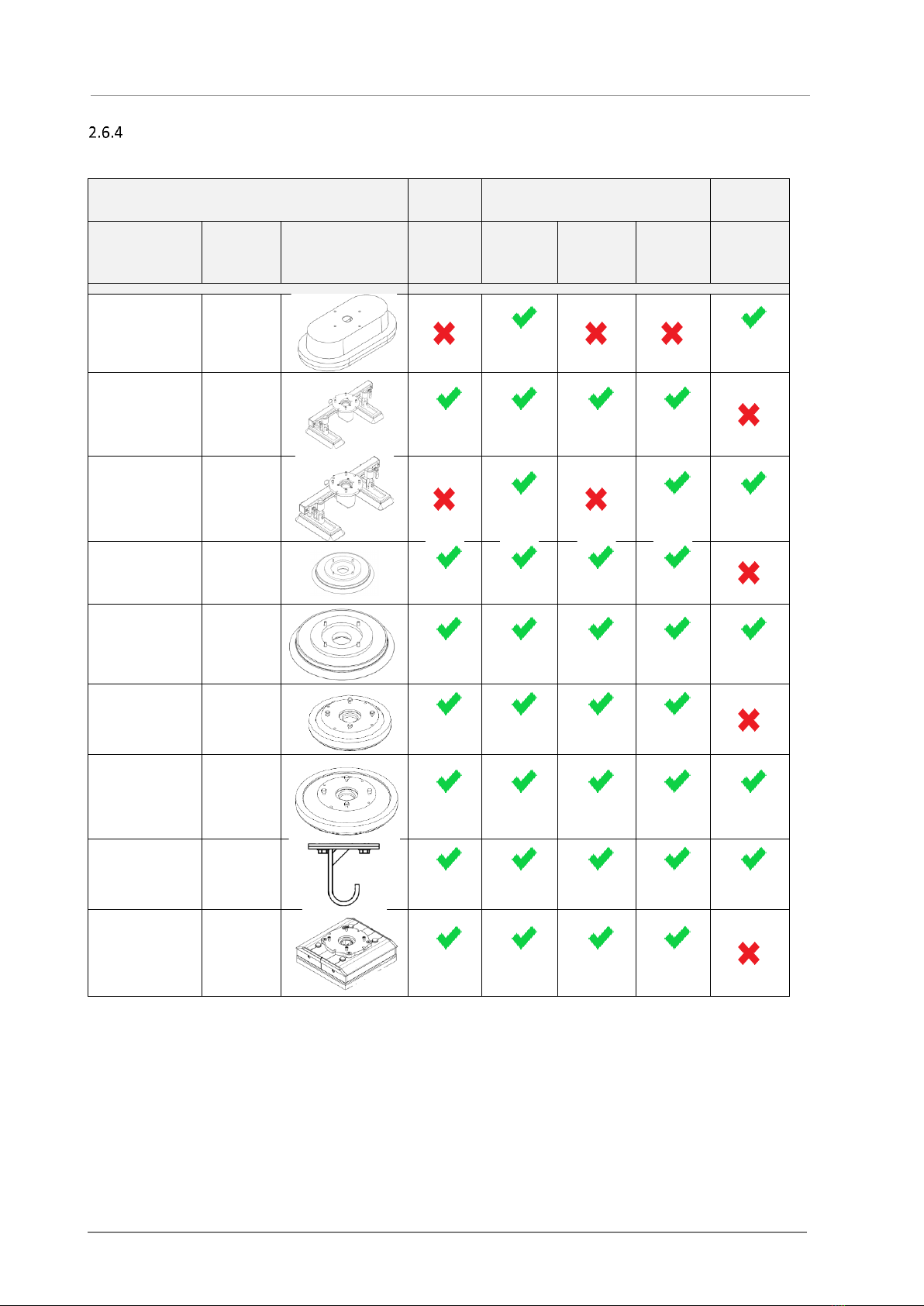

Suction foot and load capacity

Lifting tube:

Ø100

Ø120

Ø160

description

Article-

number

picture

VAL50T

SV400/2

VAL50T

VAL80T

SV400/2

bag suction

food

395x210mm

3080509

max. 25kg

at 25%

max. 50kg

at 30%

Double

rectangular

suction food

2x85x200mm

3089858

max. 20kg

at ca. 30%

max. 45kg

at 45%

max. 20kg

at 25%

max. 50kg

at 50%

Double

rectangular

suction food

2x110x300mm

3089900

max. 45kg

at 45%

max. 50kg

at 50%

max. 75kg

bei 60%

Round suction

food Ø210R

3089973

max. 40kg

at 60%

max. 60kg

at 60%

max. 60kg

at 60%

max. 60kg

at 60%

Round suction

food Ø270R

3089972

max. 40kg

at 60%

max. 60kg

at 60%

max. 60kg

at 60%

max. 60kg

at 60%

max. 75kg

at 60%

Barrel suction

food

Ø180T

3090113

max. 40kg

at 60%

max. 60kg

at 60%

max. 60kg

at 60%

max. 60kg

at 60%

Barrel suction

food

Ø220

3090109

max. 40kg

at 60%

max. 60kg

at 60%

max. 60kg

at 60%

max. 60kg

at 60%

max. 75kg

at 60%

Hook suction

food

3080511

max. 40kg

at 60%

max. 60kg

at 60%

max. 60kg

at 60%

max. 60kg

at 60%

max. 75kg

at 60%

VUSS

200x200mm

3014143

max. 20kg

at 30%

max. 45kg

at 45%

max. 20kg

at 30%

max. 45kg

at 45%

LIST OF CONTENS

FORCE-LIFT®19/51

3Installation

Installing the vacuum lifter

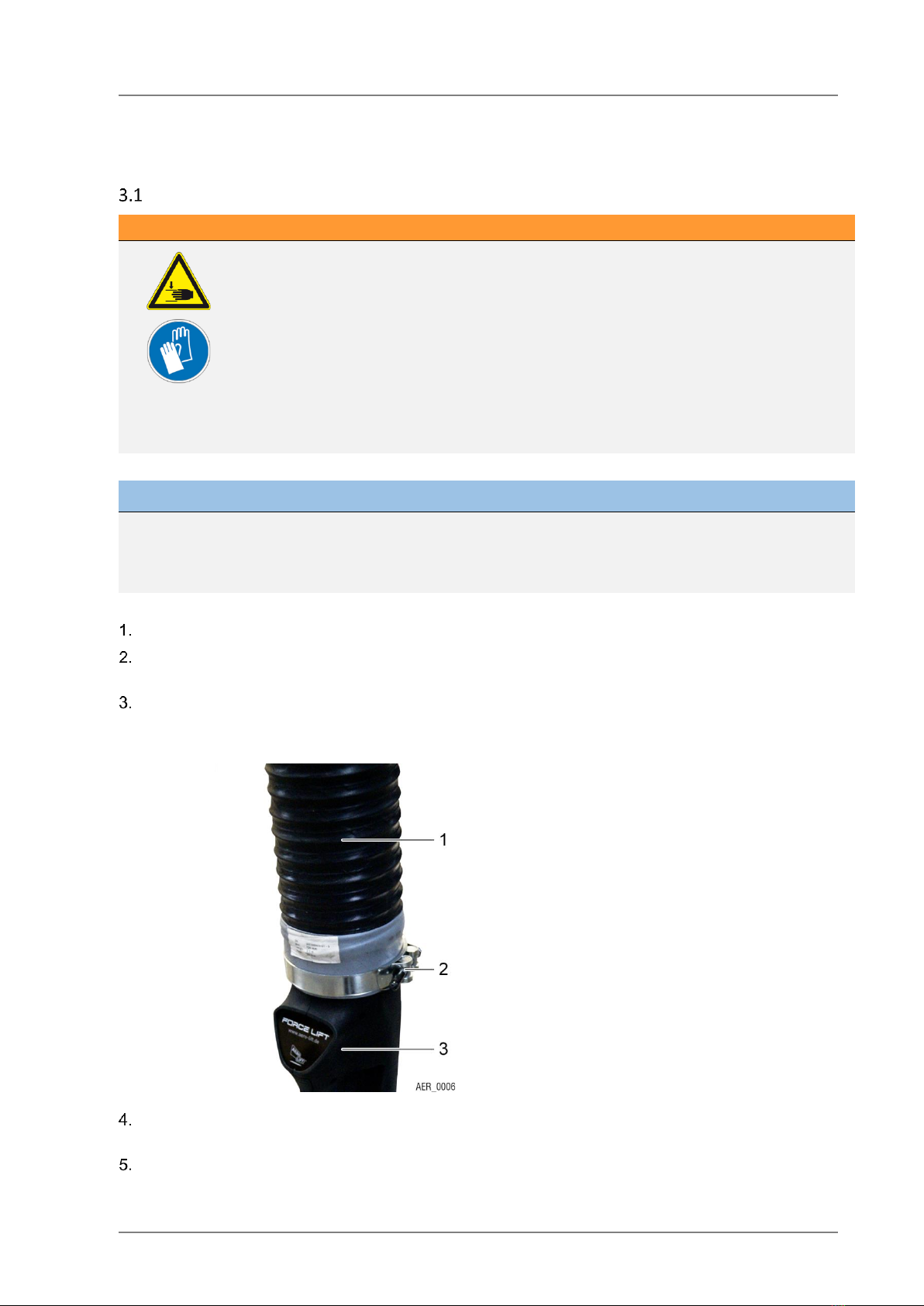

WARNING!

Moving parts!

Crushing of fingers / hands when moving or adjusting the position of the suction plates,

during maintenance work and mounting may lead to injuries.

✓Do NOT touch or reach between individual suction plates (double-rectangular

suction foot), quick-changing coupling and suction foot or between other

components!

✓Carefully install the vacuum lifter.

✓Do not remove the protective covers.

✓Always wear personal protective equipment when installing and making

adjustments!

NOTE

Placement of suction feet

Do not store or lay down the suction feet with the seal facing downwards! Placing the suction feet with

the seal facing down can damage the seals.

Unpack components of the vacuum lifter.

If necessary, mount on the crane to be used. Secure the vacuum lifter at the ends of the crossbeam

with safety screws, spring retaining pins or locking pins

Attach the vacuum supply line to the used crane or jib and connect to the vacuum pump or blower

via the filter unit. Do not yet connect the vacuum pump/ blower to the mains! Make sure that the

supply system eyelets have been fastened securely.

(1) Lift tube

(2) Fastening clamp

(3) Control head

Fasten lift tube (1) to the control head (3) using a hose clamp (2). To do so, pull the lift tube over the

upper end of the control head (3). Make sure that the closure is airtight!

Fasten the lift tube (1) to the cup with the ball bearing on top (suspension) in a positive-fit manner. In

this case, screw the wire spiral onto the groove. Make sure that the closure is airtight!

INSTALLATION

20/51 FORCE-LIFT®

Attach the desired suction foot to the control head. See section “Fastening/changing suction foot”.

Connect the vacuum pump/blower to the mains and start up the vacuum lifter. Use sound insulation

if necessary. See further applicable documents.

→Vacuum lifter was mounted.

NOTE

Vacuum pump/blower

For the start-up of the vacuum pump or blower, observe the information provided in the further applicable

documents!

Electrical connection

NOTE

Vacuum blower

When using an vacuum blower as a vacuum generator, the electrical fuse protection must be a C16 fuse.

Table of contents

Popular Lifting System manuals by other brands

probst

probst SDH-H-15 operating instructions

Bruno

Bruno OUTDOOR ELITE CRE-2110E Operator's manual

matev

matev FPS Mounting Assembly Installation Guide

Vestil

Vestil CYL-HLT Series instruction manual

Butts Tools

Butts Tools BXS0002 operating instructions

Safelift

Safelift MoveAround MA60 Original instructions

R. Beck Maschinenbau

R. Beck Maschinenbau HS 600 operating manual

Nova Technology International, LLC

Nova Technology International, LLC NAS Series quick start guide

Genie

Genie Z-60/34 Operator's manual

Screen Technics

Screen Technics INTERFIT Vertical Up Lift instructions

Drive

Drive DUPONT SAMERY Hermes user manual

Custom Equipment

Custom Equipment Hy-Brid 3 Series MAINTENANCE & TROUBLESHOOTING MANUAL