1

I

N

A

U

S

T

R

A

L

I

A

P

R

O

U

D

L

Y

B

U

I

L

T

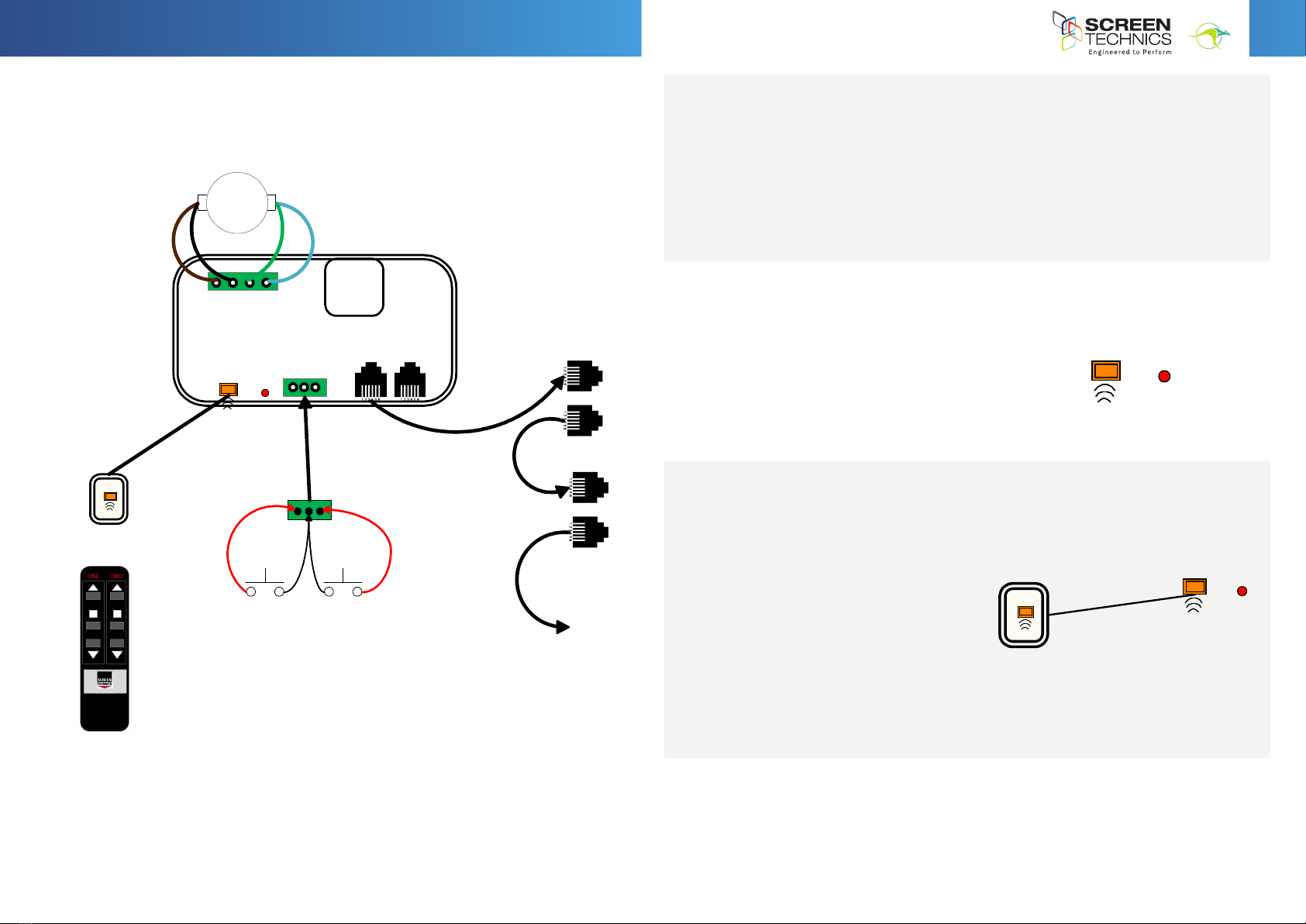

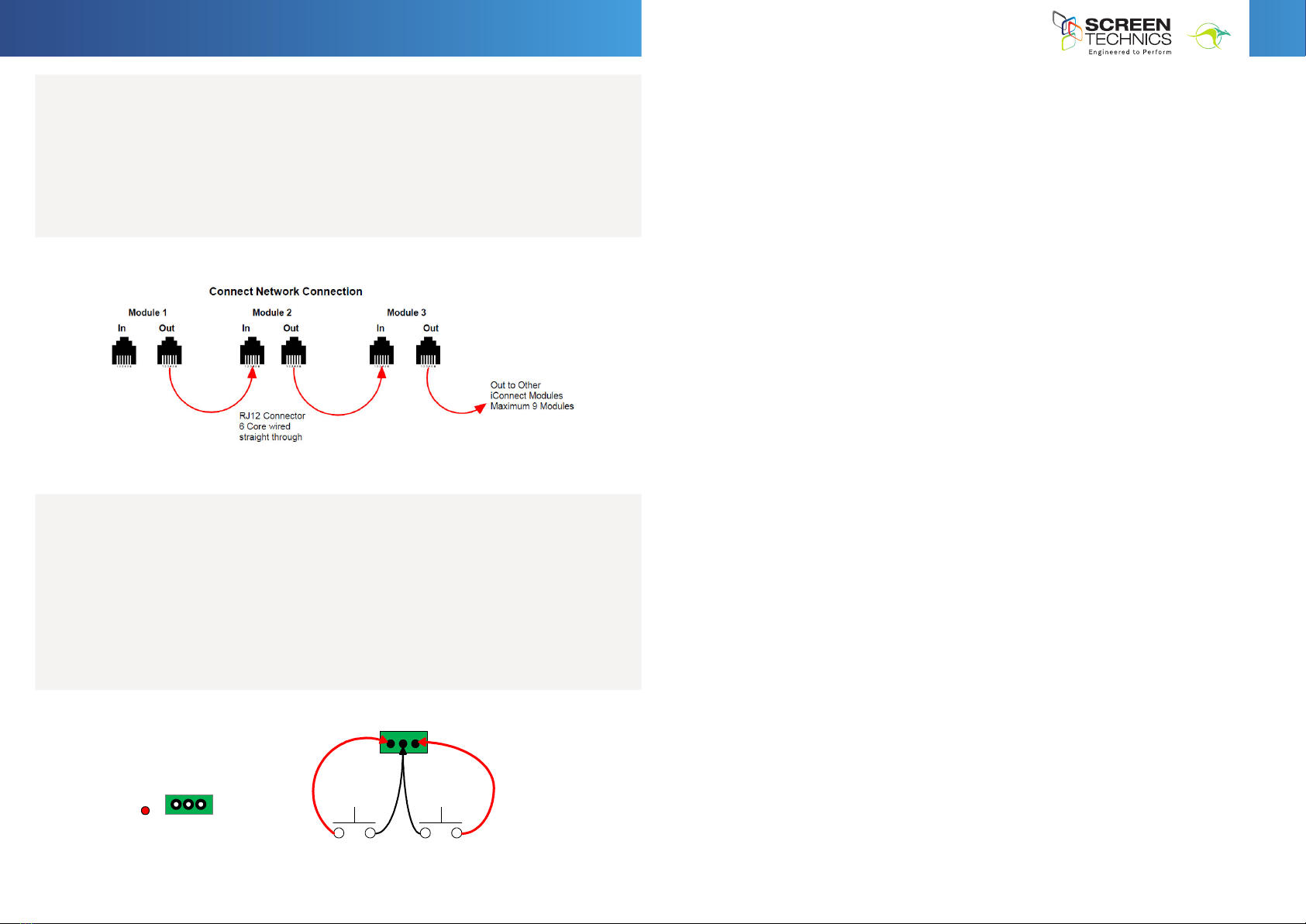

Front of unit - see horizontal mount plates - with overlapping slots for differing mount holes

STEP 4. To mount the panel unit utilise the long overlapping slots as the bolt positions, located

on the horizontal mounting plates (bolt heads cannot exceed l0mm).These plates are

also adjustable up and down in their slotted tracks. Always ensure that the bolts holding the

horizontal plates on are done up tight as they will be supporting the panel weight.

STEP 5. Install the power and data cables into the cable management system, this being a U

channel that moves up with the unit behind the lifting arms. use cable ties to keep cables in

position and allow enough slack so that no stretching or pinching of cables occurs during the

up/down travel.

Note: The cable management system can be reversed if required, you will need to readjust the back

attachment brackets in order to achieve this

STEP 6. Test that the unit will raises and lower safely and correctly.

Continued Over.../

INSTRUCTIONS - INTERFIT Vertical Up Lift

Thank you for purchasing a Screen Technics InterFit Vertical Up Lift and

please ensure to read the instruction fully before proceeding to install the

unit.

GENERAL ADVICE

• Beware of having your hands within the unit if operating up or down to avoid any ngers getting

caught or jammed.

• Please note operating the lift without a panel attached will need a weighted hand to ensure

smooth travel and to avoid fouling of the cables.

INSTALLATION ADVICE

• The unit is attached into / against a structure using the 4 off bottom base plate holes (10mm) and

the 2 off back support brackets. The back support brackets must be used in every installation to

stabilise the unit during operation.

• If attaching the lifting unit into an enclosed space the minimum internal dimensions are :

- Panel width plus 50mm

- Panel height Plus 50mm (can be reduced to 25mm if required).

- Panel thickness plus 115mm

• The lifter as a stand alone item is very quiet, but when placed in cabinetry will tend to

reverberate and make some noise, and as such you should ensure to increase the box (cabinet)

size if possible and to t sound deadening material inside the box, and this will greatly reduce the

environmental noise during operation.

STEP 1. Once the lifter is attached to the structure of the cabinet, provide power to the unit and

drive the lift upwards till it reaches it upper limit and stops.

STEP 2. Lower the lift using the motor while physically pushing down on the unit itself, as

normally it uses the weight of the panel to operate properly.

STEP 3. When you are satised the unit is operating properly raise it once again and install the

monitor screen.

•

•

•

Interfit Plasma Lift Vertical Up

•

•

•

Interfit Plasma Lift Vertical Up

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

info@screentechnics.com.au

screentechnics.com.au

AUSTRALIA

22-24 Suttor Road, Moss Vale NSW 2577

+61 2 4869 2100

NEW ZEALAND

44 Mahana Road, Te Rapa, Hamilton

0800 022 821

I

N

A

U

S

T

R

A

L

I

A

P

R

O

U

D

L

Y

B

U

I

L

T