AEROCET 2200 User manual

ISSUE

DATE:

4/14/2009

Incorporated

PAGE

1 of 103

TITLE: ICA Maintenance Manual for

FILE NO.

A-10035

REVISION

DATE:

3/4/10

SUBTITLE: 2200 Floats on PA-18

Piper, Super Cub model

REVISION

03

MAINTENANCE MANUAL AND INSTRUCTIONS FOR CONTINUED

AIRWORTHINESS

FOR

AEROCET MODEL 2200 TWIN SEAPLANE FLOATS

INSTALLED ON A SUPER CUB AIRPLANE

Aerocet, Inc.

P.O. Box 2119

265 Shannon Lane

Priest River, Idaho 83856

Phone: (208) 448-0400

Fax: (208) 448-1644

This ICA must be followed when Aerocet 2200 Floats are installed in

accordance with Supplemental Type Certificate (STC) No. SA02000SE.

The information contained in this document supplements or supercedes the basic

manuals only in those areas listed herein. For limitations, procedures, and

performance information not contained in this manual, consult the basic aircraft

ICA or maintenance manual.

ISSUE

DATE:

4/14/2009

Incorporated

PAGE

2 of 103

TITLE: ICA Maintenance Manual for

FILE NO.

A-10035

REVISION

DATE:

3/4/10

SUBTITLE: 2200 Floats on PA-18

Piper, Super Cub model

REVISION

03

This page intentionally left blank.

ISSUE

DATE: 4/14/2009 Incorporated PAGE 3 of 103

TITLE: ICA Maintenance Manual for FILE NO. A-10035

REVISION

DATE: 3/4/10

SUBTITLE: 2200 Floats on PA-18

Piper, Super Cub model

REVISION

03

LOG OF REVISIONS

Revision Pages Affected Description Date Approved

00 All Initial Release 4/14/2009 --

01 All Re-arranged and added multiple per FAA

comments. Added 1.2 Availability and

Revisions. Added Heading 1.4

Dimensions, Locations and

Nomenclature. Moved all of Sec. 4 to

Section 2. Added 2.6 Inspections

Heading; 2.10.10 Placards; 2.11

Troubleshooting. Sec. 4 changed to

Airworthiness Limitations, all new.

4/30/09

02 10

21

31, 34 & 38

89-97 [New]

Spelling correction, Fig. 1.4.6.

Corrected Fig. # from 8 to 2.9.1.1.

Added references to applicable drawings

for PA-18 Wide Body Installations.

Added Appendix A.

No changes to limitations. No FAA

review required.

6/16/09

03 (Old pg. #’s 59,

61, 62) (Figures)

65, 67, 68

Flying wires corrected, 22-34035 and

22-34036 were reversed fore and aft.

Formatting – all Sections to start on odd

pages.

3/4/10

This document is maintained by Fliegen Works Inc. and is on file as FW-ART481-13

ISSUE

DATE:

4/14/2009

Incorporated

PAGE

4 of 103

TITLE: ICA Maintenance Manual for

FILE NO.

A-10035

REVISION

DATE:

3/4/10

SUBTITLE: 2200 Floats on PA-18

Piper, Super Cub model

REVISION

03

This page intentionally left blank.

ISSUE

DATE:

4/14/2009

Incorporated

PAGE

5 of 103

TITLE: ICA Maintenance Manual for

FILE NO.

A-10035

REVISION

DATE:

3/4/10

SUBTITLE: 2200 Floats on PA-18

Piper, Super Cub model

REVISION

03

TABLE OF CONTENTS

Log of Revisions .....................................................................................................3

Table of Contents.....................................................................................................................5

1. Introduction............................................................................................................7

1.1. How to Use This Supplemental Manual..........................................................7

1.2. Availability and Revisions................................................................................8

1.3. General Description..........................................................................................9

1.4. Dimensions, Locations and Nomenclature....................................................10

2. Maintenance Manual...........................................................................................15

2.1. General Practices ............................................................................................15

2.2. Product Listings ..............................................................................................15

2.3. Fastener Torque..............................................................................................16

2.4. Fastener Torque Values (Except where otherwise noted)...........................17

2.5. Fastener Use and Discretion...........................................................................19

2.6. Inspections .......................................................................................................20

2.7. Special Inspections..........................................................................................22

2.8. Float Handling and Jacking...........................................................................23

2.9. Floats Installation............................................................................................23

2.10. Conversion from Wheels to Floats.................................................................35

2.11. Troubleshooting ..............................................................................................46

2.12. Conversion from Floats to Wheels.................................................................46

3. Repair Manual .....................................................................................................49

3.1. Struts ................................................................................................................49

3.2. Composite Float Hulls ....................................................................................49

3.3. Repair Types and Procedures........................................................................50

3.4. Impregnation of Fabric ..................................................................................51

3.5. Resin Mixing....................................................................................................51

3.6. Preparation of Fiberglass Materials..............................................................52

3.7. Surface Coat Application (Gel Coat) ............................................................53

3.8. Keel and Wear Strip Attachment..................................................................53

4. AIRWORTHINESS LIMITATIONS ................................................................55

5. Illustrated Parts Catalogue.................................................................................57

5.1. List of Figures..................................................................................................57

APPENDIX A. Catalog Pages for PA-18 “Wide Body”.....................................................89

ISSUE

DATE:

4/14/2009

Incorporated

PAGE

6 of 103

TITLE: ICA Maintenance Manual for

FILE NO.

A-10035

REVISION

DATE:

3/4/10

SUBTITLE: 2200 Floats on PA-18

Piper, Super Cub model

REVISION

03

This page intentionally left blank.

ISSUE

DATE:

4/14/2009

Incorporated

PAGE

7 of 103

TITLE: ICA Maintenance Manual for

FILE NO.

A-10035

REVISION

DATE:

3/4/10

SUBTITLE: 2200 Floats on PA-18

Piper, Super Cub model

REVISION

03

1. INTRODUCTION

Thank you for choosing Aerocet Floats. This manual covers the installation and

maintenance of the 2200 floats as installed on the PA-18 Piper Super Cub airplane (and

similar models), including instructions for installing the struts, steps, water rigging, and

float structure. An IPC is also provided.

1.1. How to Use This Supplemental Manual

Used in conjunction with the Piper Owner's Manual, and Illustrated Parts Catalogue

for a Super Cub, airplane, this supplemental manual provides the operator with a source

of information for installing, removing, repairing, and maintaining Aerocet Model 2200

Twin Seaplane Floats on a Super Cub.

This manual is organized as follows:

Maintenance Manual. Instructions and information necessary to maintain, install,

and remove the Aerocet Model 2200 Twin Seaplane Floats on a Piper Super Cub

airplane.

Repair Manual. Instructions necessary to repair Aerocet Model 2200 Twin

Seaplane Floats installed on a Piper Super Cub airplane.

Instructions for Continued Airworthiness. Instructions necessary to inspect and

maintain an airworthy state with Aerocet Model 2200 Twin Seaplane Floats on a Piper

Super Cub airplane. These instructions include Preflight, Daily, Periodic, and Special

inspections.

Illustrated Parts Catalog. Drawings and parts necessary to use the Aerocet Model

2200 Twin Seaplane Floats on a Piper Super Cub airplane.

ISSUE

DATE:

4/14/2009

Incorporated

PAGE

8 of 103

TITLE: ICA Maintenance Manual for

FILE NO.

A-10035

REVISION

DATE:

3/4/10

SUBTITLE: 2200 Floats on PA-18

Piper, Super Cub model

REVISION

03

1.2. Availability and Revisions

One complete, hard (paper) copy of this manual shall be provided with each new set

of Aerocet Model 2200 floats. Additional copies and minor revisions shall be available

via email, U.S.P.S (Mail), UPS or FedEx by request. Fees and delivery charges may

apply.

Notification of any changes that require service for airworthiness shall be

distributed to all applicable Aerocet owners on record with Aerocet, Inc. In such a case,

copies of the applicable, revised portions of this manual shall be provided.

Aerocet, Inc. maintains record of purchasers and/or owners collected at the time of

purchase in order to comply with the above as well as to maintain a high standard of

service. If you have moved since your original purchase, have purchased a used product

or otherwise have reason to believe that the contact information on file is incorrect,

please provide the following information to Aerocet, Inc: (Aerocet contact information is

on the front of this document.)

Float Information:

Float Model: _________________________________

Float S/N (R/L) _______________________________

Aircraft Information:

Aircraft Make/Model __________________________

Aircraft Registration ___________________________

Aircraft S/N _________________________________

Owner Information: (as applicable)

Previous Owner ______________________________

Previous Address _____________________________

Present Owner _______________________________

Present Address ______________________________

Present Phone Number ________________________

Present Email Address _________________________

ISSUE

DATE:

4/14/2009

Incorporated

PAGE

9 of 103

TITLE: ICA Maintenance Manual for

FILE NO.

A-10035

REVISION

DATE:

3/4/10

SUBTITLE: 2200 Floats on PA-18

Piper, Super Cub model

REVISION

03

1.3. General Description

The Aerocet Model 2200 Twin Seaplane Floats are all-composite float hulls. The

float hulls are separated by spreader bars that slide into the float assemblies. The float

design uses a double-fluted bottom contour from the step forward, and has a flat top deck

design with built-in antiskid. Each float offers a large storage locker.

Water rudders are mounted on the stern of each float for water-taxi operations, and

are connected directly to the airplane’s rudder. The retract system, which is compatible

with OEM and other approved cockpit handles, is installed in the standard manner.

Each float is attached to the airplane by forward, mid, and aft struts. Bolted to the

upper end of the forward and mid struts is an attachment block, and to the upper end of

the aft struts, a swivel fitting. The forward and mid struts are attached to the landing gear

fitting. At the lower end, the forward struts are bolted to an attachment fitting, which in

turn, is bolted to the forward attachment lug on the float. The mid and aft struts' forked

attachment fitting is bolted to the rear lug on the float.

ISSUE

DATE:

4/14/2009

Incorporated

PAGE

10 of 103

TITLE: ICA Maintenance Manual for

FILE NO.

A-10035

REVISION

DATE:

3/4/10

SUBTITLE: 2200 Floats on PA-18

Piper, Super Cub model

REVISION

03

1.4. Dimensions, Locations and Nomenclature

Figure 1.4.1

Figure 1.4.2

ISSUE

DATE:

4/14/2009

Incorporated

PAGE

11 of 103

TITLE: ICA Maintenance Manual for

FILE NO.

A-10035

REVISION

DATE:

3/4/10

SUBTITLE: 2200 Floats on PA-18

Piper, Super Cub model

REVISION

03

Figure 1.4.3

Figure 1.4.4

ISSUE

DATE:

4/14/2009

Incorporated

PAGE

12 of 103

TITLE: ICA Maintenance Manual for

FILE NO.

A-10035

REVISION

DATE:

3/4/10

SUBTITLE: 2200 Floats on PA-18

Piper, Super Cub model

REVISION

03

Figure 1.4.5

ISSUE

DATE:

4/14/2009

Incorporated

PAGE

13 of 103

TITLE: ICA Maintenance Manual for

FILE NO.

A-10035

REVISION

DATE:

3/4/10

SUBTITLE: 2200 Floats on PA-18

Piper, Super Cub model

REVISION

03

Figure 1.4.6

ISSUE

DATE:

4/14/2009

Incorporated

PAGE

14 of 103

TITLE: ICA Maintenance Manual for

FILE NO.

A-10035

REVISION

DATE:

3/4/10

SUBTITLE: 2200 Floats on PA-18

Piper, Super Cub model

REVISION

03

This page intentionally left blank.

ISSUE

DATE:

4/14/2009

Incorporated

PAGE

15 of 103

TITLE: ICA Maintenance Manual for

FILE NO.

A-10035

REVISION

DATE:

3/4/10

SUBTITLE: 2200 Floats on PA-18

Piper, Super Cub model

REVISION

03

2.

2. MAINTENANCE MANUAL

2.1. General Practices

1. Metal Parts: check for corrosion (rust), stress cracks or metal distortion, elongation of

holes, and rivet damage.

2. Critical Bolts: check for corrosion (rust), wear, and torque. It is recommended that

some form of corrosion-inhibiting compound be applied to all threaded fasteners and

other similar parts. Possible products used include those listed in the Product Listings

that follow, but are not limited to these products. Apply per manufacturer

recommendations only.

3. Composite Parts: check for stress cracks, gel coat presence (UV protection), and

punctures. (Section 5 covers repair and re-work of composite parts.)

4. All parts/fasteners that penetrate float structures, such as a bulkhead or the float deck,

must be sealed with marine-grade urethane adhesive such as Sikaflex 292.

2.2. Product Listings

1. Float Sealant for Bolts and Chine Strip Attachment: Sika Manufacturing

Sikaflex 292.

2. Rust (corrosion) Protection: ACF-50, Corrosion X, Boeing Company Boeshield T9.

3. Bolt Protection: PUR-AL-KETONE, which is distributed by Lake and Air; LPS

Industries LPS 3; Zip Chemical Company Zip D-5029NS.

4. United EZ Turn Lubricant: Produced by United Erie 1-800-377-7561, and available

through distributors.

5. Composite Materials for Hull Repair: Contact Aerocet, Inc., for resin, cloth, gel-coat,

resin thickeners.

ISSUE

DATE:

4/14/2009

Incorporated

PAGE

16 of 103

TITLE: ICA Maintenance Manual for

FILE NO.

A-10035

REVISION

DATE:

3/4/10

SUBTITLE: 2200 Floats on PA-18

Piper, Super Cub model

REVISION

03

2.3. Fastener Torque

2.3.1. Torque Value Conversion:

To convert in.-lbs. to ft.-lbs: Value (ft.-lbs.) x 12 = Value (in-lbs.)

To convert ft.-lbs. to in.-lbs: Value (in-lbs.) x 0.0833 = Value (ft.-lbs.)

2.3.2. Tooling Requirements:

Calibrated torque wrench

Adapters that affect the length of the torque wrench will affect the required

torque indication and must be calculated according to Figure 1.4.3.

2.3.3. Hardware Cleanliness

All hardware is to be free of dirt, grit and grease. All dirty hardware shall be

thoroughly cleaned and lubricated with a dry film lubricant such as LPS 1, or

Teflon products per manufacturer instructions. It is recommended that all

stainless hardware be thoroughly lubricated with anti-seize lubricant of good

quality to prevent galling upon assembly.

2.3.4. Torque Procedure

Assure that hardware is clean and properly prepared for installation. Assemble

nuts to bolts, measuring the tension required to turn the nut and add this to the

required final torque. Where possible apply torque to the nut, and not to the

fastener head. Apply a smooth, even pressure, stopping and re-torquing if

chattering or premature loading occurs. This may warrant disassembly and

subsequent inspection for burrs or galling. Replace any damaged hardware.

Access panels should be torqued only to "hand tight", the fiberglass should

exhibit only mild deformation. A portable hand drill could be used, provided

that the clutch is set properly. Do not apply more pressure to the hatch screws

than is necessary to engage the tool to the fastener head as this will risk

damaging the Tinnerman style nuts below.

All other nuts shall be torqued per Section 1.4 unless otherwise noted.

ISSUE

DATE:

4/14/2009

Incorporated

PAGE

17 of 103

TITLE: ICA Maintenance Manual for

FILE NO.

A-10035

REVISION

DATE:

3/4/10

SUBTITLE: 2200 Floats on PA-18

Piper, Super Cub model

REVISION

03

2.4. Fastener Torque Values (Except where otherwise noted)

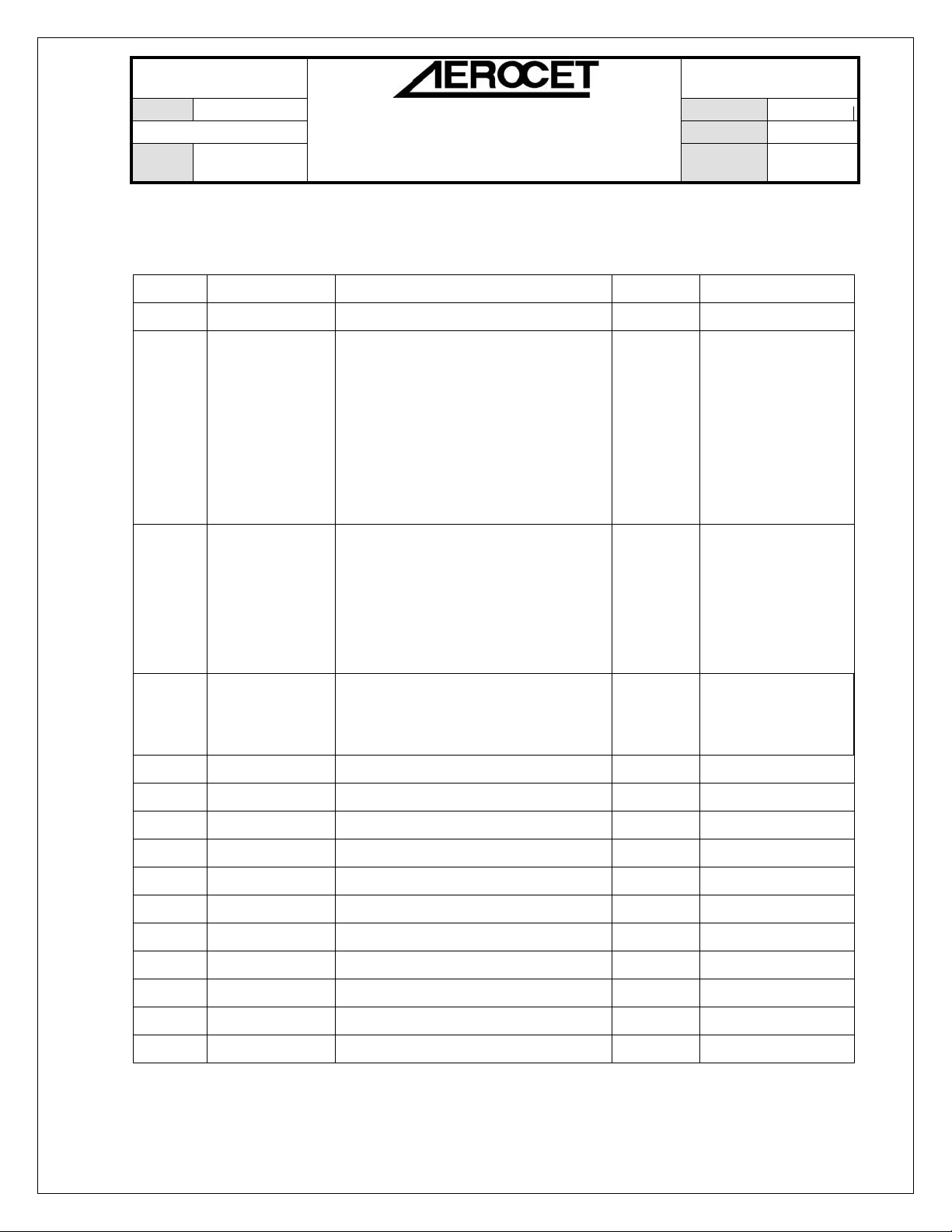

Figure 2.4.1 Recommended Torque Values (inch-pounds)

(from AC43.13-1B, Table 7-1)

Figure 2.4.2 Minimum Prevailing Torque Values for Re-used Self-Locking Nuts

(from AC43.13-1B, Table 7-2)

Self-Locking Nuts:

Self-locking nuts, when re-used, must

have at least the minimum prevailing

torque listed in figure to the left. Nuts that

are smaller than those listed in the table

shall not be used if they can be run up by

hand.

ISSUE

DATE:

4/14/2009

Incorporated

PAGE

18 of 103

TITLE: ICA Maintenance Manual for

FILE NO.

A-10035

REVISION

DATE:

3/4/10

SUBTITLE: 2200 Floats on PA-18

Piper, Super Cub model

REVISION

03

Figure 2.4.3 Torque Wrench with Various Adapters

(from AC43.13-1B, Figure 7-2)

ISSUE

DATE:

4/14/2009

Incorporated

PAGE

19 of 103

TITLE: ICA Maintenance Manual for

FILE NO.

A-10035

REVISION

DATE:

3/4/10

SUBTITLE: 2200 Floats on PA-18

Piper, Super Cub model

REVISION

03

2.5. Fastener Use and Discretion

2.5.1. Fastener Lengths

Rivets: Where replacement or repair of rivets is required, use rivets of proper

specifications only. For instance, MS203426AD4-xxx. Lengths may be

determined by measuring the thickness of the material(s) to be assembled and

adding 1.5" X Diameter of the rivet to be used. Over-sized rivets may be

substituted where holes have been drilled out.

Bolts and screws shall have a minimum of one thread visible through the nuts upon

final torque.

Washers may be rearranged if necessary to accommodate proper fit, up to two

washers beneath the nut and one beneath the fastener head. Typically, Aerocet

intends to put one thin washer beneath the fastener head and one thicker washer

beneath the nut.

2.5.2. Fastener Reuse

Fasteners are to be inspected per Section 4 of this manual for condition. Such

fasteners that are acceptable, may be cleaned, re-lubricated and re-installed as

determined. Self-locking nuts shall meet the minimum prevailing torque as listed in

Figure 1.4.2, or shall be replaced.

ISSUE

DATE:

4/14/2009

Incorporated

PAGE

20 of 103

TITLE: ICA Maintenance Manual for

FILE NO.

A-10035

REVISION

DATE:

3/4/10

SUBTITLE: 2200 Floats on PA-18

Piper, Super Cub model

REVISION

03

2.6. Inspections

2.6.1. Part 1, Preflight

Conduct Preflight inspections according to existing Piper owner's manual, and

add the following to the Airframe group:

1. Check Float lockers secured.

2. Pump out all compartments to assure no damage has occurred.

Anything more than 4-5 full pumps should be investigated.

2.6.2. Part 2, Daily Inspections

Conduct daily inspections according to existing Piper Owner's Manual, and

refer to Table 1, Recommended Airworthiness Service Schedule, below.

2.6.3. Part 3, Periodic Inspections

Conduct periodic inspections according to existing Piper owner’s Manual

section 4, and add the following inspections in Table 4.5, Recommended

Service Schedule, below.

Table of contents

Other AEROCET Aircraft manuals

Popular Aircraft manuals by other brands

Bruce Goldsmith Design

Bruce Goldsmith Design DUAL 2 manual

Ozone

Ozone XXLite 2 Pilot's manual

Dream-Flight

Dream-Flight r2106gf Flight manual

AEROPRAKT

AEROPRAKT A22LS-POH-04 Pilot operating handbook

EUROFLY

EUROFLY Firefox Minifox Assembly wing's instructions

Pipistrel

Pipistrel ALPHA Trainer LSA Pilot operating handbook