Designer's Notes - "Evolution of the Weasel"

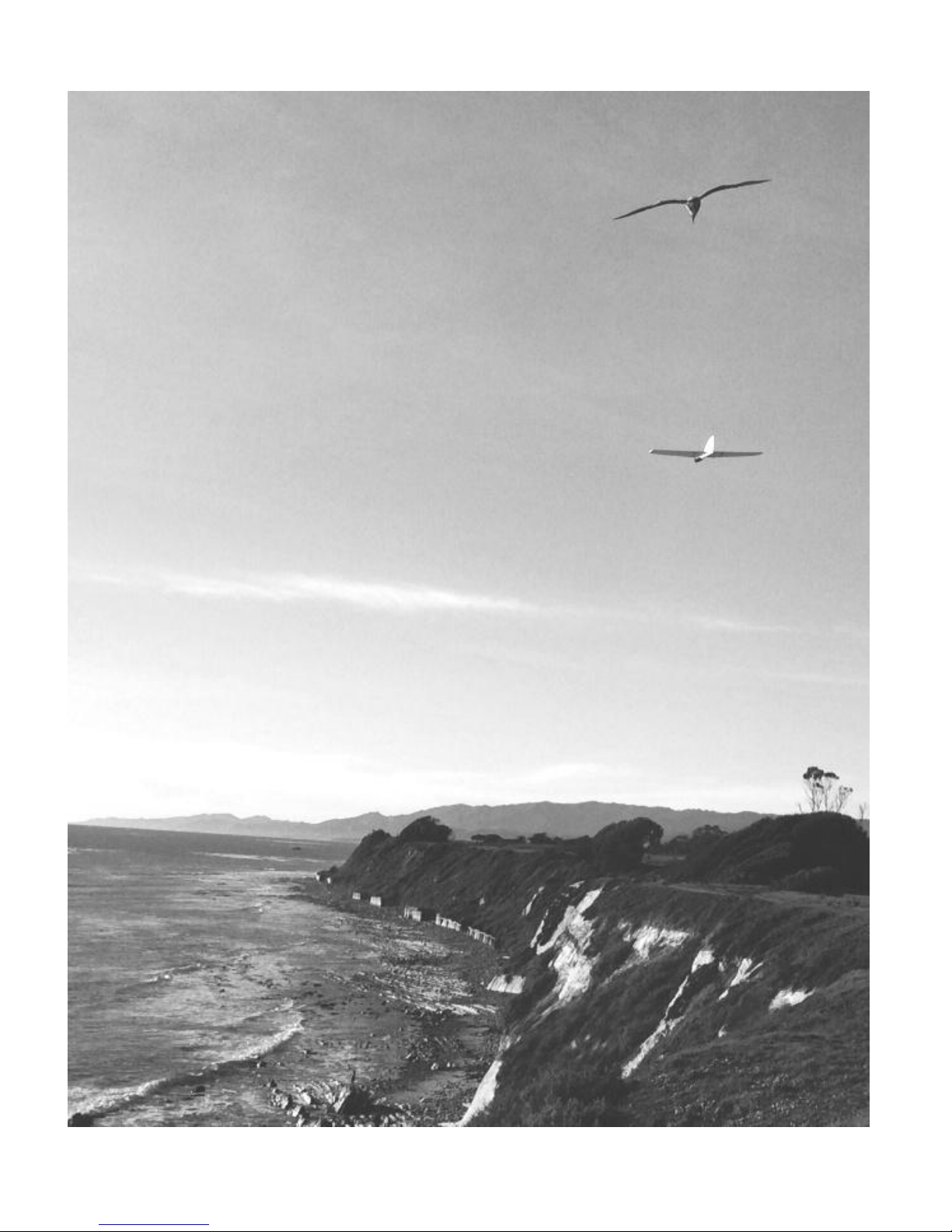

"It was back in the mid-1990s that I was approached by

a local Santa Barbara RC glider pilot, who asked if I

might cut him some one-off foam wing cores based on a

flying wing design called the "Little Devil", by British aero

modeler Duncan Simey. I was presented with the 1994

issue of Silent Flight, which included the build article for

this particular model. The tapered, ultra-wide chord of the

Little Devil design immediately caught my eye - it looked

fun! I was in High School at the time on summer break with

plenty of time to spare, so I decided to give it go.

The original build article called for a plywood-sheeted

wing, which seemed quite heavy for our light coastal

breezes. To reduce weight, I used a packing tape-

covered foam wing with balsa sheet control surfaces for

simplicity. The foam material was scrounged from a

damaged hot tub cover (I still recall the strong smell of

chlorine-saturated foam!).

The foam and tape prototype was an immediate success! It

flew like nothing else on the slope and outperformed most

chevron-style combat wings that were popular at the time.

It was nimble, had an extremely wide speed range, could

slow down to a kite-like hover in very light wind, and the

stout, yet lightweight shape allowed it to take the tumbles.

All these attributes allowed me to take more chances, and

soon I found myself creating a new style of in-your-face

slope soaring. When everybody else was into slope

combat at the time destroying servos and airframes left

and right, I was enjoying this creative freestyle form of

RC soaring; pylon turns around shrubs and small trees,

touch and goes off park benches, quick rolls three feet off

the deck, grass skimming, hand catches instead of the

traditional landing; all became part of the new routine,

and my piloting and reflexes improved quickly as a

result.

After flying the foam and tape prototype for a couple

months, I came to find that the aircraft had character,

more so than any other airplane I had flow in the past. It

was slow yet fast, extremely quick in the turns, could