1DISCLAIMER OF LIABILITY

Taking into consideration the inherent risk in paragliding or hang gliding, (free flying and motorized), it must be expressly understood that the manufacturer and seller do not

assume any responsibility for accidents, losses and direct or indirect damage following the use or misuse of this product.

APCO Aviation Ltd. is engaged in the manufacture and sale of hang gliding, paragliding, motorized Para/hang gliding and emergency parachute equipment.

This equipment should be used under proper conditions and after proper instruction from a qualified instructor. APCO Aviation Ltd. has no control over the use of this

equipment and a person using this equipment assumes all risks of damage or injury.

APCO Aviation Ltd. disclaims any liability or responsibility for injuries or damages resulting from the use of this equipment.

The glider is designed to perform in the frame of the required class as certified.

2INTRODUCTION

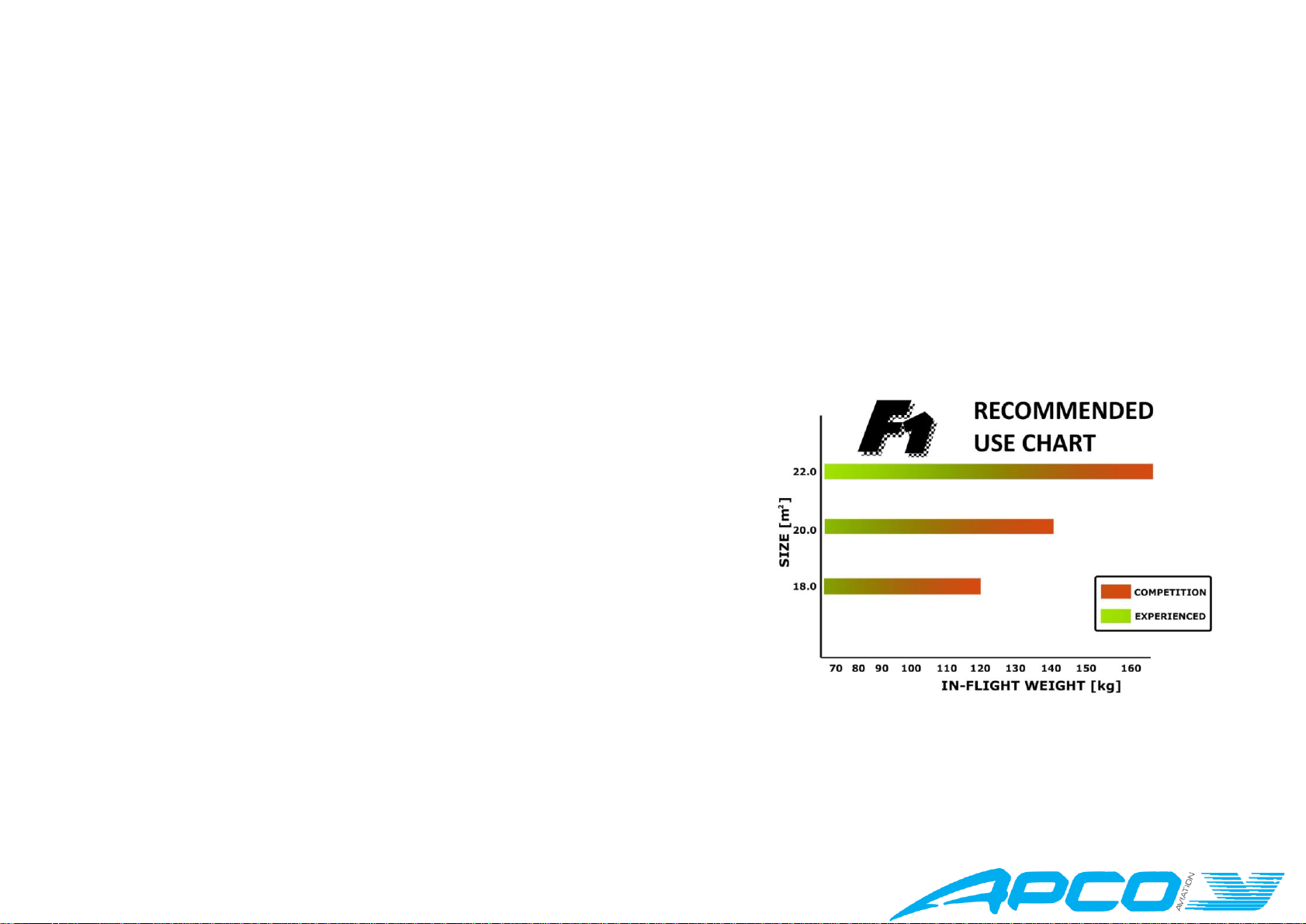

The F1 is the result of our quest to bring safe, top speed and performance at incredible efficiency to

experienced pilots across all paramotor disciplines.

The F1 uses an advanced Reflex profile, to increase both performance and stability throughout the

speed range.

The sail tension has been optimised to give the wing incredible rigidity without negatively affecting

performance, so the wing is and feels very solid and reassuring in flight.

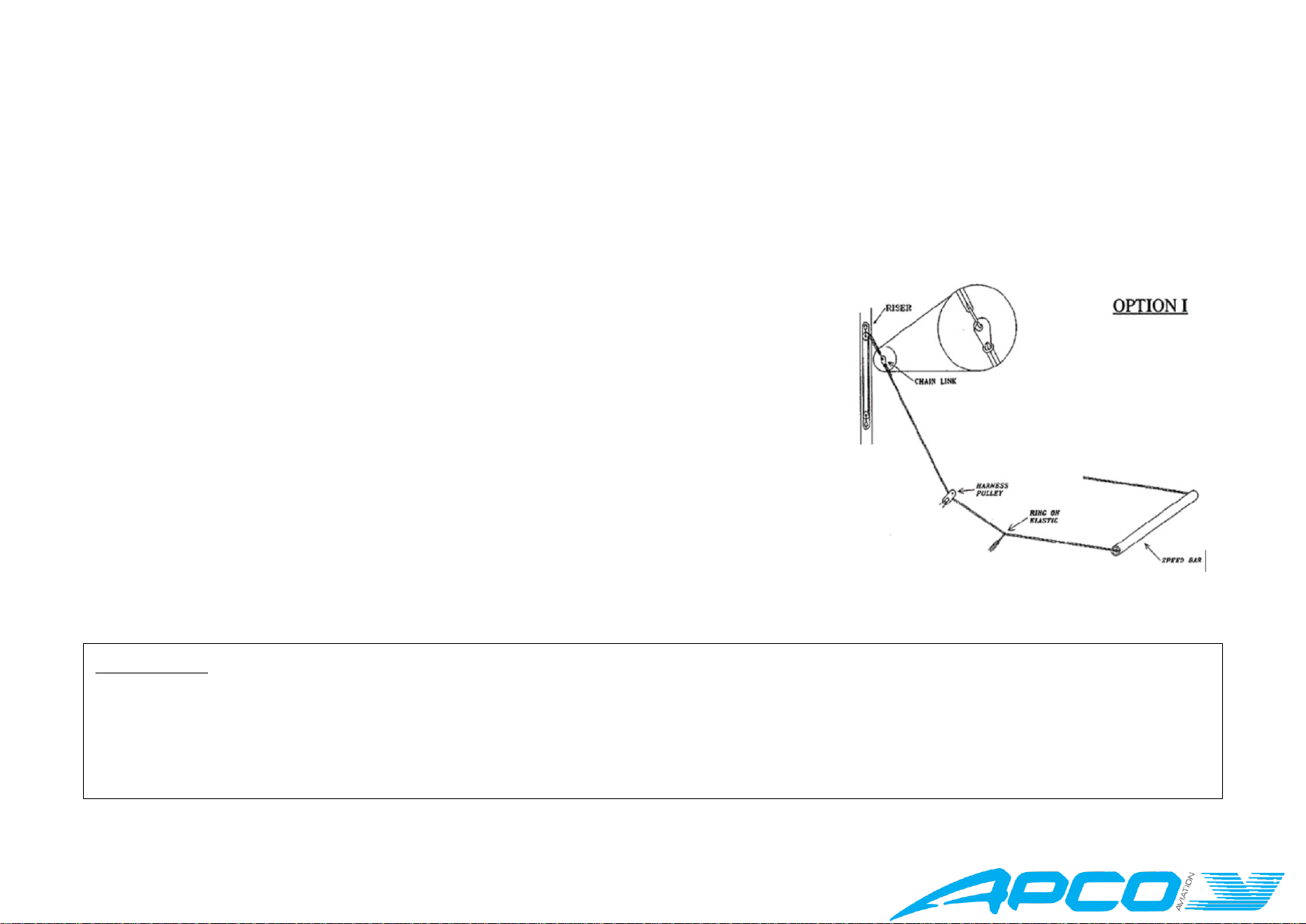

The riser / speed system / trim system was re-designed to incorporate all of Apco’s ground-breaking

technologies, and has a greater usable range than any wing we have built before, meaning you can

launch and land at reasonable speeds, but open up with comfort for the race, or the perfect long

distance XC flight you’ve been dreaming about –but, be warned, unless your friends are on the F1 too,

you will be flying alone.

Although the F1 is not a dual-use wing, with the trimmers closed, the F1 will thermal much like a

paraglider, and has exceptional glide ratio too, so if you like to mix it up on a good day, idle or cut the

motor and crank it up to cloudbase with ease.

Handling is precise and predictable, with the ability to turn anything from a flat low sink rate

thermaling turn, to slalom perfection.

Inflation is very easy, and does not tend to overfly the pilot.