Aeronavics SkyJiB X4 XL Manual

1

Bu i l d M a n u a l

1.0 FLIGHT-OPS AND SAFETY

3Operation and Safety

5Pre-Flight Safety Check

6Do’s and Dont’s

2.0 PRE-BUILD CHECKLISTS

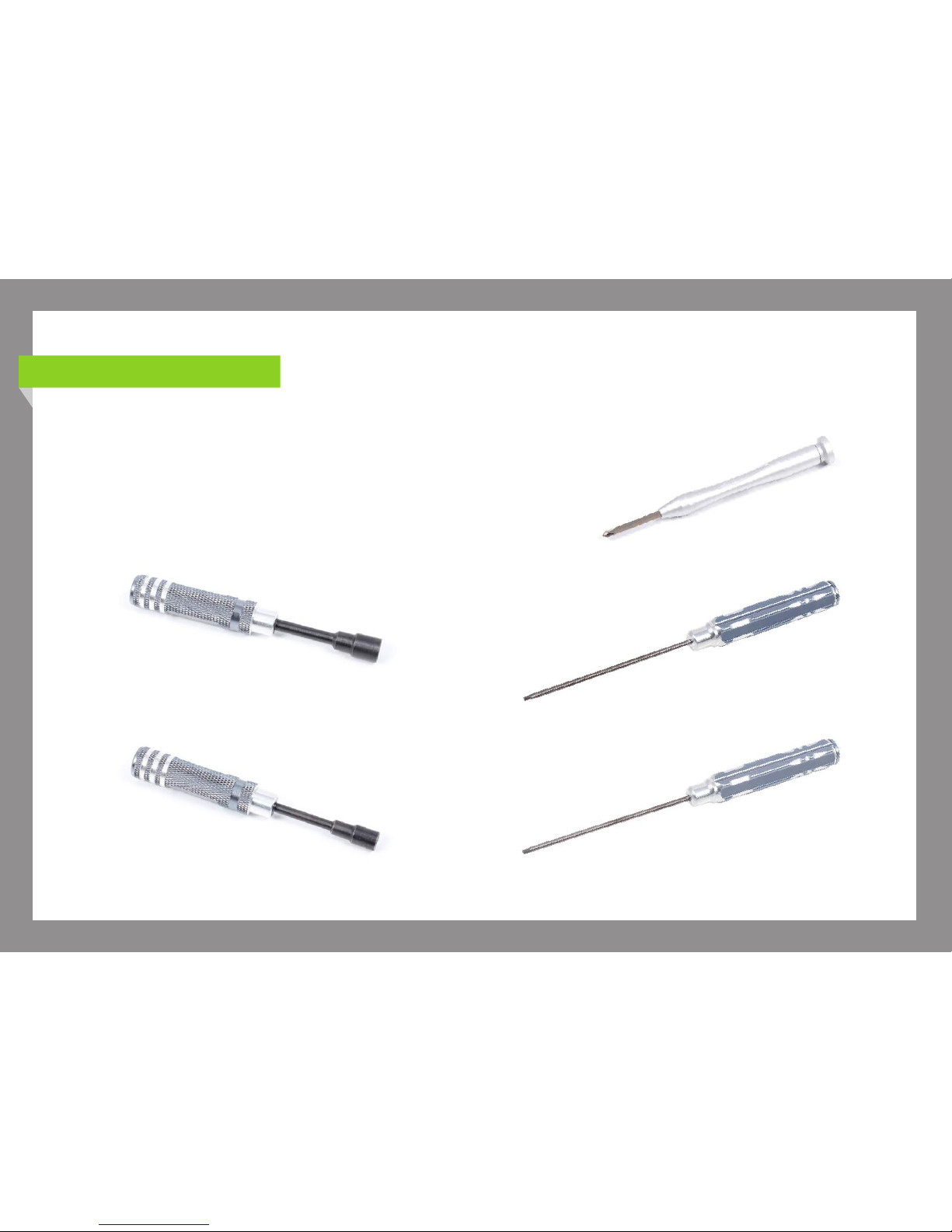

8Required Tools

3.0 ASSEMBLY INSTRUCTIONS

9Center Plate and Boom Assembly - Part 1

13 Coaxial Engine Mount Asssembly

17 Center Plate and Boom Assembly - Part 2

21 Standard Landing Gear

27 Retractable Landing Gear

30 Attach Landing Gear to Center Plate

32 Gear Rail Assembly

39 Crash Cage & Dome Assemblies

44 Quick Release Cams

2

Contents

This is a quick guide for those new to MultiRotor craft oering

some basic safety and operational procedures...and are

recommended standard operating procedures for those piloting

Aeronavics or any MultiRotor craft.

Please read the instructions for the relevant Flight Control

electronics before proceeding. Go to the website of your ight

control system and make yourself well acquainted with the

correct procedure for the electronics installation and software

operation.

Caution: never connect and start the engines for the rst

time with the propellers attached....and always balance your

propellers; unbalanced propellers can cause excessive vibration

which may lead to material fatigue.

Note: check the orientation of the ight controller you are

using (which way is front) and also the engine assignment

conguration; for instance which is engine 1,2,3 etc. and check

also that your propellers, clockwise and counter clockwise, are

also installed correctly before your rst ight.

Your rst test ight should be in an open eld in low or zero

wind. A sports eld (not currently in use) is a good option;

choose a site with short or mown grass. Do not takeo from

dry dusty sites. Make sure any onlookers or spectators do not

gather around you…if so ask them to move away from you in a

perimeter not less than 50m (150 feet) diameter around you.

Make sure that you have fully charged your transmitter and

onboard battery packs. Make sure that the antenna of your

Radio (TX) is up and correctly positioned; make sure the

receiver (RX) for your craft is well positioned within the craft and

secured and that the antenna is facing downward and to the

back of your craft and not touching any part of the craft.

Place the craft on level ground and turn on your transmitter –

check that you have the correct model selected on your TX.

Set the transmitter timer to about 80% of the known ight

duration. Connect the battery to your crafts FC inputs and wait

for the engine controller beeps to stop.

3

operation and s afety

Stand at least 5m away from your craft and behind the craft with

the craft facing directly away from you. Check the 50m ight

safety perimeter you have established, also checking behind you

for children running in to see what you are doing.

Survey the area; look for obstacles that you might not have seen

previously, like power-lines and overhead wires. Never y your

craft near a controlled aerodrome or in controlled airspace.

Check the weather conditions, the wind speed and direction.

Do not y in gusty strong wind at any time. Always try and y

the craft with the wind at your back so the craft will drift directly

away from you.

Always keep your eyes on the craft when in ight – if people

approach you inside your safety perimeter to talk to you or to

ask questions whilst you are ying the craft do not engage in the

conversation and ask them to stand well clear of you until you

have landed.

Re-check your perimeter and raise the throttle slowly and

check to see if the craft wants to tilt to one direction or another;

sometimes you may need to adjust the trim on your TX to get

a level ight, however most times the craft will y perfectly rst

time if you have installed the electronics and the software has

been set correctly—check with the Flight Control manufacturer

for standard or beginner settings for the craft.

Takeos are sometimes easier with a short burst of power to

lift the craft o the ground. Hold the craft in a controlled hover

directly in front of you about 2-3m o the ground away from

“ground eect” prop wash. When you have mastered this hover

position you can then move on to rolling the craft gently from

side to side and forward and backward.

Make sure that you always stand behind the craft, this makes

for easy orientation of the ight controls. Repeat this exercise

several times before you take the craft any higher.

Always y the craft well away from people and / or property.

Always check for children nearby.

4

Thoroughly check the craft before every ight…

• Check to see if any wires have come o

•Check for loose bolts on the assembly

•Check that the batteries are secure

•Check the battery voltage, and if you have more than one battery, check your spares too

•Check the propellers for marks and nicks

•Check the propeller nuts or bolts, make sure they are tight

•Check the engine mounts and the bolts and nuts for tightness

•Check the Transmitter battery voltage; never y the craft with a low voltage reading on your transmitter

(check with the manufacturer of your equipment for minimum and maximum voltage readings).

•Check that the transmitter antenna is not damaged.

•Check that the craft receiver module is well connected and that the antenna’s are properly positioned.

•Take a good look over the craft from all sides to make sure that nothing appears unusual or out of place.

•Check your ight perimeter.

•Check for power-lines and overhead obstacles.

•Assess the weather conditions, wind direction and speed. An anemometer (hand held wind speed meter) is a good tool

to have, otherwise use some dry grass or a tissue, throwing in the air to gauge the wind direction.

•Do not y in gusty and turbulent conditions.

•Set your transmitter timer to 80% of the known battery duration.

DISCLAIMER:

Aeronavics Limited disclaims all warranties, whether express or implied, including but not limited to the implied warranties of merchantability and tness for a particular purpose. Aeronavics Limited

does not assume any lyability, whether direct or indirect, from the use of Aeronavics craft. Aeronavics Limited shall not be liable for any direct, indirect, special, incidental, punitive, contingent or

consequential damages to persons or property caused by Aeronavics craft. In no event shall Aeronavics Limited be liable for personal injury up to and including death.

5

pr e - f light s afety C h e C k

•

Never y in strong wind – the operational safe wind speed for these craft is about 10-15 knots.

•

In the event of a crash or a hard landing, always check the craft for damage before taking o again. In this instance, you must also

check that you do not have dirt or grit in the engines; this can cause an engine or engines to overheat and fail in ight resulting in an

out of control craft and serious damage or injury to the craft , other people and their property.

•

Your launch eld should preferably be open and at with short grass. If it is necessary to take o in a eld which only has long grass,

manually atten a 1.5m diameter take o perimeter with your feet.

•

Always have a ight plan – visualize your ight path and check again for obstacles.

•

Never y the craft out of direct line of sight and always keep your eyes on the craft whilst it is in the air.

•

Never y the craft above 400 feet in height (the length of a football eld).

•

Never y near people – A 50m (150 ft) perimeter around and above people is a recommended minimum and operational law in

most countries.

•

Always set your transmitter timer before each ight to about 80% of the known ight duration for the battery pack’s you have installed in the craft.

•

Never turn your transmitter o in ight.

•

First person view ights are against the law in some countries – check the relevant aviation safety authority in your country before ying FPV.

Always have a “spotter” with you if you do y FPV.

•

Never let friends y your craft unless they are well schooled in the discipline.

•

Never y under the inuence of any substance or alcohol. Whilst there is a minimum blood alcohol level allowed for driving an

automobile in most countries, the law for pilots in command of ying craft around the globe is universal…there is a zero limit tolerance.

•

Always turn your transmitter on before connecting the battery to the craft...and always disconnect the battery from the craft before

turning your transmitter o.

6

do’sand d ont’s:

7

Pr e -B u i l d C h e C k l i s t

8

M4 3mm Hex Screw Driver

M4 Hex Driver

3mm Phillips Head Driver

M3 2.5mm Hex Screw Driver

re q u i r e d t o o l s

M3 Hex Driver

9

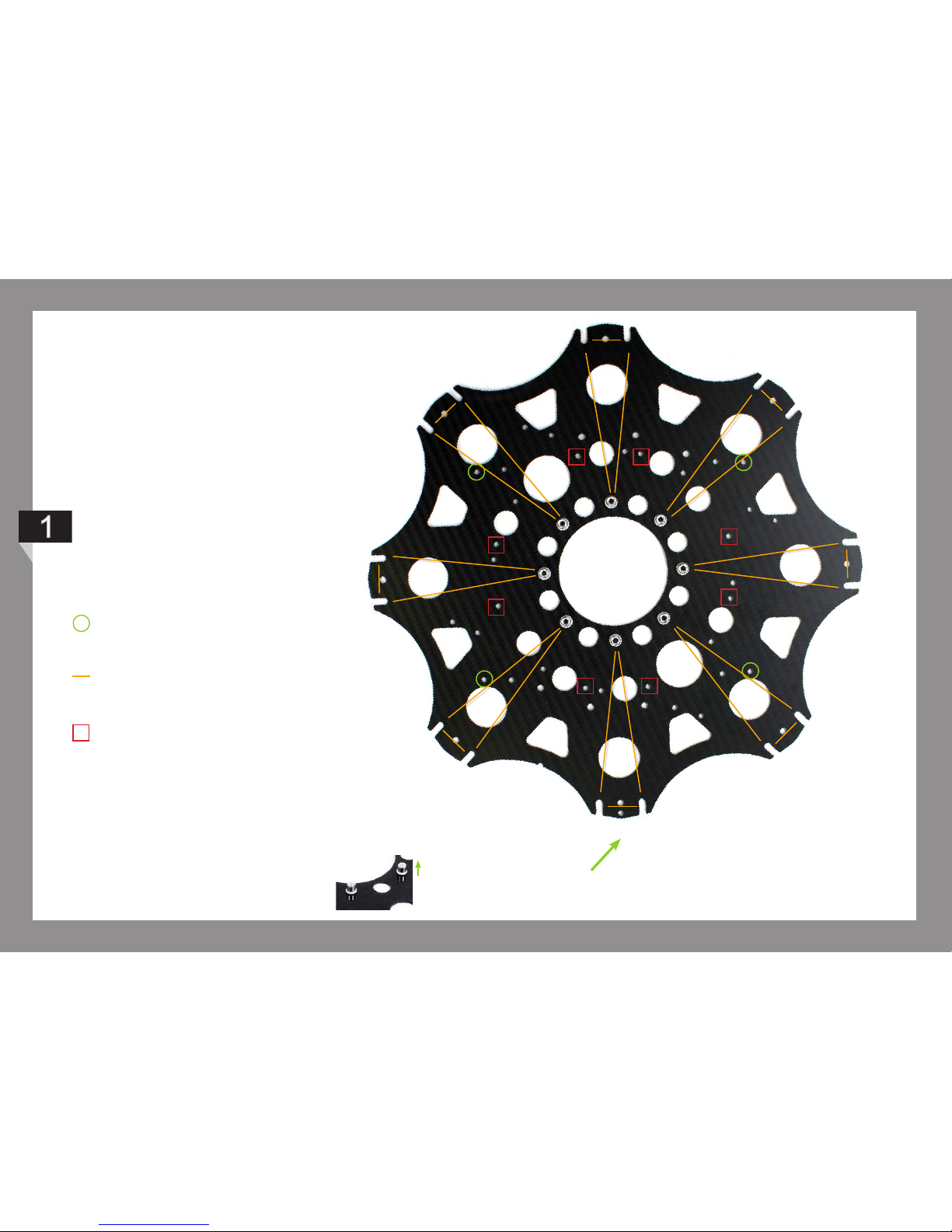

CENTER PLATE AND BOOM ASSEMBLY INSTRUCTIONS - Part 1

1

1

1

1

8

16

8

1

8

1

16

Center Plate Top 2.0mm SJ X4

Center Plate Bottom 2.0mm SJ X4

Universal FC Adaptor Plate

FC Adaptor Plate - DJI Wookong

Boom Bracket Inner

Gear Rail Center Plate Spacer

Stando Threaded

Decal Set SkyJib

Stando Threaded M3x12.7mm

Socket Head Cap Screw M4x40mm Ti

M4 Washer Stainless Steel

4

4

4

18

4

4

4

12

4

(1)

(1)

(1)

(1)

(1)

(2)

(1)

(1)

(1)

Socket Head Cap Screw M4x35mm

Socket Head Cap Screw M4x40mm s/s

Socket Head Cap Screw M4x35mm Ti

Machine Screw M3x6mm

Machine Screw M3x4mm

Stando Rubber Threaded

Nylon Nut M3

Locking Washer M4

Socket Head Cap Screw M4x40 Ti

Parts + SparesParts + Spares

2505-0110

2505-0120

2510-0160

2506-0140

2506-0480

2506-0230

2506-0180

2505-0200

2510-0100

Product Code Product Code

1205-0039

1205-0049

1206-0021

1206-0030

1205-0064

1505-0010

2503-0070

1205-0050

2506-0220

2510-0170

2510-0090

10

15

8

4

4

1

1

8

1

4

4

4

Standos Threaded M3x20mm M/F

Standos Threaded M3x20mm F/F

Nyloc Nut M4 Stainless Steel

Boom Bracket Outer 20mm

Wire Protector Plate SJ X4

Battery Strap

50mm Insulating Bush

Rubber Grommet 9.5mm

Assembled Quick Release Cam

Boom Folding Cam Nut 20mm

Boom Folding Cam 20mm

8

8

2

2

2

4

(1)

Socket Head Cap Screw M4x40mm

Boom Bracket Outer OD=20mm Black

Partially Assembled Q R Cams

Boom Folding Cam Nut 20mm

Boom Folding Cam 20mm

Socket Head Cap Screw M4x40mm Ti

Parts + SparesParts + Spares

2510-0170

1205-0084

1205-0210

1205-0200

2510-0170

Product Code Product Code

2503-0060

2503-0070

2505-0160

1205-0084

1205-0270

1406-0060

2506-0660

2503-0080

1205-0211

1205-0200

CENTER PLATE AND BOOM ASSEMBLY INSTRUCTIONS - Part 1

11

Rivnuts facing up

Take a moment to familiarise yourself

with the centre plate setup to get an

understanding which holes relate to

which parts. Take the top plate and

lay it out with the double hole at the

bottom and the notch to the left.

Circles show the holes used

for small dome xing.

Lines indicate the boom

mount triangle pattern used

for all models.

Droidworx Flight Control

Adaptor Plate

Front X4 XL

Turn the bottom plate upside down (rivnuts will be facing

up) and place the locking washer and at washers on to

the following screws as shown below. Push the M4x35mm

black Alloy Screws through the holes indicated with a green

circle below. Push the M4x35 Ti through the remaining holes.

Flip plate over and slot the Boom Bracket Inners onto the Ti

screws. Put Center Plate Spacers over the remaining black

screws. NOTE: For this model the

curve of boom brackets face

inward following the curvature

of the plate.

12

Place the remaining Boom Bracket Inners on top of the Booms

through the screws.

Lay the booms over the protruding screws as shown. You

will notice both ends have holes drilled.

Please ensure you use the holes that are closest to the

end of the boom. These holes are 11mm from the edge.

Flip the setup over, place the top centerplate on and fasten

the boom cluster screws. Be carefull that all brackets stay in

place.

TIP: Slide a piece of cardboard underneath to ip over.

OR: Instead of ipping the setup over you can slide each bolt

to the edge of your bench and tighten from underneath.

M3x8mm Screw

M4 Nyloc Nut

M3x6mm Button Head SCS

Heat Shrink Black

Engine Mount Shield Coax

Coax EM Shield Attachment

8

2

4

2

1

2

M4x35mm ‘Titanium’

Engine Mount Bracket M4 (50mm)

Engine Mount Disk M4 Coax

Threadlock (not included)

2

2

2

Parts + SparesParts + Spares

2510-0070

1205-0100

1205-0166

Product Code Product Code

2510-0240

2505-0160

2506-0070

2505-0010

1205-0172

1205 - 0180

13

COAXIAL ENGINE MOUNT ASSEMBLY

Apply the heat shrink to all engines. NOTE: Use treadlocking solution when putting in the screws.

Ax the engine to the engine mount disk by slotting the

desired machine screws through the chamfered side of the

disk and into the rewall mount holes of the engine.

(Repeat 8x)

x8

Press the Composite Brackets onto the Engine Mount

Disks. (8x)

x8

x4

Push the M4x35mm Titanium SHC Screws

through the holes either side of one of the

disks for each coaxial assembly. (4x in total)

14

Feed your engine wires through the boom then ex your shield

and slide it over the M4x35mm Titanium SHC Screws.

Place your Boom onto the Engine Mount Bracket

making sure the tab locks into the hole of the boom.

Add the second Engine assembly.

Ax with the M4 Nyloc Nut SS. Repeat these steps for all

the engine assemblies.

Assemble the Engine Mount Shield as shown below.

x2

x4

15

Your nal setup should now look like this.

16

Insert M3x6mm Nylon Screws into the stand o holes in your

Center Plate using either your hands or attach a little bit of Blu-

Tak on your tool. Then wind the Stando M3x20mm onto the

screw. (Repeat 8x)

Insertthe4rubbergrommetsintothegrommet-holesintheWire

Protector Plate. Then insert the 50mm insulating bush into the

Wire Protector Plate. Your assembly should now look like this:

x4

17

Sit the completed plate over the vertical facing rivnuts on the

top SkyJib centre plate with the bulk of the insulating bush

facing down into the core of the craft.

Attach a Power Hungry Power Distributer together using

M3x10mm M/F standos and Nylon nuts then attach the

Universal Flight Controller Adapter Plate to the distributer

using 10mm rubber standos as shown below.

CENTER PLATE AND BOOM ASSEMBLY INSTRUCTIONS - Part 2

Place the ESC mounting plate on to the standos and x

with 20mm F/F nylon standos.

NOTE: You should now mount your ESCs to this plate.

18

Place your Power Distribution assembly

on top of the standos and x with

M3x6mm nylon screws.

NOTE: You should now plug your

engine wires into the distributor.

Next place your Wookong adaptor plate on to the rubber

standos and x with the M3x6mm nylon screws as shown

below.

Your assembly should now look like this:

19

Push the M4x40mm Ti screw through the center plates and

spacer and x with M4 nyloc nut s/s as shown below. Repeat

this step on the other side.

Your assembly should now look like this.

20

Other Aeronavics Drone manuals