Aeronix AE101264-002 User manual

1775 West Hibiscus Blvd, Suite 200

Melbourne, FL 32901

(321) 984-1671

www.Aeronix.com

Gigabit Ethernet Switch (GES)

Quick Start Guide

GES – Quick Start Guide

______________________________________________________________________

______________________________________________________________________

Page ii

Note:

This manual applies to the Aeronix

AE101264-002

12-Port Gigabit Ethernet Switch

This Quick Start Guide is Part Number AE301098-001

Aeronix places no restriction on the duplication or distribution of this document;

however, it must remain unaltered and in its entirety.

Copyright 2013©by Aeronix, Inc. All rights reserved

GES – Quick Start Guide

______________________________________________________________________

______________________________________________________________________

Page iii

Table of Contents

1. OVERVIEW ..........................................................................................................1

2. BLOCK DIAGRAM ...............................................................................................1

3. ELECTRICAL CONNECTIONS............................................................................2

3.1. J1 CONNECTOR...................................................................................................2

3.2. J2 CONNECTOR...................................................................................................2

3.3. INTERFACE PORT DETAILS....................................................................................4

3.3.1. Ethernet Ports ............................................................................................4

3.3.2. Serial and Programming Ports ...................................................................4

3.3.3. Management Processor .............................................................................4

3.3.4. Input Power................................................................................................4

4. CONTROL INTERFACES ....................................................................................4

4.1. MENU INTERFACE ................................................................................................4

4.2. IN-BAND INTERFACE.............................................................................................5

5. SWITCH MANAGEMENT CAPABILITY ..............................................................5

6. HARDWARE MOUNTING ....................................................................................6

7. INDICATORS .......................................................................................................6

8. QUALIFICATIONS ...............................................................................................7

9. PERFORMANCE PARAMETERS........................................................................8

10. WARRANTY .........................................................................................................9

11. PRODUCTS AND SERVICES............................................................................10

GES – Quick Start Guide

______________________________________________________________________

______________________________________________________________________

Page 1 of 11

1. Overview

Designed and produced by Aeronix, Inc. of Melbourne, Florida, the Gigabit Ethernet

Switch (GES) is designed for use in extremely harsh environments including fighter

aircraft.

The GES is a lightly managed switch with twelve 10/100/1000BaseT Ethernet ports, and

two RS-232 management ports. Its rugged monolithic design is intended to operate in

severe environments without the need for forced air cooling.

This document is intended to provide a quick reference to the features and capabilities of

the Aeronix Gigabit Ethernet Switch (GES) hardware.

The part number of the Aeronix 12-Port Gigabit Ethernet Switch is AE101264-002.

2. Block Diagram

The basic functional blocks within the GES and their basic interactions are shown in

Figure 2-1.

Mil-Std-704A

Power Supply

Front End

16 Port

SGMII

Layer 2/3+

Packet

Processor

MII

Low-Voltage

Power Supply J2

J1

RS-232

Line Drivers &

Receivers

Two

RS-232

Serial

Ports

2 Gb

Ports

J2

J1

Aircraft Power

3.3V

Power Supply

Switch Control

MDC/MDIO

Power

LED

ARM 9

CPU

Dual

Gb

Magnetics

Dual

Gb

Magnetics

Dual

Gb

Magnetics

Gb PHY

Gb PHY

Gb PHY

Gb PHY

Gb PHY

Gb PHY

Dual

Gb

Magnetics

Dual

Gb

Magnetics

Dual

Gb

Magnetics

Gb PHY

Gb PHY

Gb PHY

Gb PHY

Gb PHY

Gb PHY

SGMII

SGMII

SGMII

SGMII

SGMII

SGMII

SGMII

SGMII

SGMII

SGMII

SGMII

SGMII

2 Gb

Ports

2 Gb

Ports

2 Gb

Ports

2 Gb

Ports

2 Gb

Ports

PHY Control

MDC/MDIO

Figure 2-1: GES Block Diagram

GES – Quick Start Guide

______________________________________________________________________

______________________________________________________________________

Page 2 of 11

3. Electrical Connections

The GES has two electrical connectors, J1 and J2.

3.1. J1 Connector

J1 is a 100 pin M38999 Series II connector, Part Number MS27508E22B35P.

An example mating cable connector for J1 is Part Number MS27473E22B35S.

J1 contains the following electrical interfaces:

•Six Ethernet Ports (0 – 5)

•Two RS-232 Serial Ports

oDEV1 – Dedicated Maintenance Port for the Management Processor

oDEV2 – Designed to be programmed as an Ethernet to Serial Bridge

3.2. J2 Connector

J2 is a 100 pin M38999 Series II connector Part Number MS27508E22B35PA.

An example mating cable connector for J2 is Part Number MS27473E22B35SA.

J2 contains the following electrical interfaces:

•Six Ethernet Ports (6 – 11)

•Input Power (nominal 28 VDC per MIL-STD-704A)

GES – Quick Start Guide

______________________________________________________________________

______________________________________________________________________

Page 3 of 11

J1 J2

Pin

Signal

Pin

Signal

Pin

Signal

Pin

Signal

1

Chassis Ground

51

Chassis Ground

1

Chassis Ground

51

Chassis Ground

2

Port 0 - A(+)

52

Chassis Ground

2

Port 6 - A(+)

52

Chassis Ground

3

Port 0 - C(-)

53

Port 3 - A(+)

3

Port 6 - C(-)

53

Port 9 - A(+)

4

Port 0 - D(+)

54

Port 3 - C(+)

4

Port 6 - D(+)

54

Port 9 - C(+)

5

Port 0 - D(-)

55

Port 3 - D(-)

5

Port 6 - D(-)

55

Port 9 - D(-)

6

Chassis Ground

56

RX_FROM_DEV1

6

Chassis Ground

56

28VRTN

7

Port 1 - A(+)

57

TX_TO_DEV1

7

Port 7 - A(+)

57

28VRTN

8

Chassis Ground

58

Chassis Ground

8

Chassis Ground

58

Chassis Ground

9

Chassis Ground

59

Port 2 - B(+)

9

Chassis Ground

59

Port 8 - B(+)

10

Port 0 - A(-)

60

Port 2 - C(-)

10

Port 6 - A(-)

60

Port 8 - C(-)

11

Port 0 - C(+)

61

Port 2 - D(+)

11

Port 6 - C(+)

61

Port 8 - D(+)

12

Chassis Ground

62

Chassis Ground

12

Chassis Ground

62

Chassis Ground

13

Port 1 - A(-)

63

Port 3 - A(-)

13

Port 7 - A(-)

63

Port 9 - A(-)

14

Port 1 - C(+)

64

Chassis Ground

14

Port 7 - C(+)

64

Chassis Ground

15

Port 1 - D(-)

65

Chassis Ground

15

Port 7 - D(-)

65

Chassis Ground

16

Reserved

66

Chassis Ground

16

28V

66

Chassis Ground

17

Chassis Ground

67

RX_FROM_DEV2

17

Chassis Ground

67

28VRTN

18

Chassis Ground

68

TX_TO_DEV2

18

Chassis Ground

68

Reserved

19

Port 0 - B(+)

69

Chassis Ground

19

Port 6 - B(+)

69

Chassis Ground

20

Chassis Ground

70

Chassis Ground

20

Chassis Ground

70

Chassis Ground

21

Port 1 - B(+)

71

Port 2 - C(+)

21

Port 7 - B(+)

71

Port 8 - C(+)

22

Port 1 - B(-)

72

Port 2 - D(-)

22

Port 7 - B(-)

72

Port 8 - D(-)

23

Port 1 - C(-)

73

Chassis Ground

23

Port 7 - C(-)

73

Chassis Ground

24

Port 1 - D(+)

74

Chassis Ground

24

Port 7 - D(+)

74

Chassis Ground

25

Reserved

75

Port 5 - D(-)

25

28V

75

Port 11 - D(-)

26

GND

76

Port 5 - D(+)

26

Reserved

76

Port 11 - D(+)

27

Reserved

77

GND

27

Chassis Ground

77

28VRTN

28

Port 0 - B(-)

78

Chassis Ground

28

Port 6 - B(-)

78

Chassis Ground

29

Chassis Ground

79

Port 4 - A(+)

29

Chassis Ground

79

Port 10 - A(+)

30

Chassis Ground

80

Chassis Ground

30

Chassis Ground

80

Chassis Ground

31

Chassis Ground

81

Chassis Ground

31

Chassis Ground

81

Chassis Ground

32

Chassis Ground

82

Chassis Ground

32

Chassis Ground

82

Chassis Ground

33

Chassis Ground

83

Port 5 - A(+)

33

Chassis Ground

83

Port 11 - A(+)

34

Chassis Ground

84

Port 5 - C(+)

34

Chassis Ground

84

Port 11 - C(+)

35

Reserved

85

Port 5 - C(-)

35

28V

85

Port 11 - C(-)

36

Reserved

86

Chassis Ground

36

28V

86

Chassis Ground

37

Chassis Ground

87

Chassis Ground

37

Chassis Ground

87

Chassis Ground

38

Chassis Ground

88

Port 4 - A(-)

38

Chassis Ground

88

Port 10 - A(-)

39

Chassis Ground

89

Port 4 - D(-)

39

Chassis Ground

89

Port 10 - D(-)

40

Port 2 - A(+)

90

Port 4 - D(+)

40

Port 8 - A(+)

90

Port 10 - D(+)

41

Chassis Ground

91

Chassis Ground

41

Chassis Ground

91

Chassis Ground

42

Port 3 - B(+)

92

Port 5 - A(-)

42

Port 9 - B(+)

92

Port 11 - A(-)

43

Port 3 - B(-)

93

Port 5 - B(+)

43

Port 9 - B(-)

93

Port 11 - B(+)

44

Port 3 - C(-)

94

Chassis Ground

44

Port 9 - C(-)

94

Chassis Ground

45

Port 3 - D(+)

95

Port 4 - B(+)

45

Port 9 - D(+)

95

Port 10 - B(+)

46

Reserved

96

Port 4 - B(-)

46

Reserved

96

Port 10 - B(-)

47

GND

97

Port 4 - C(+)

47

Reserved

97

Port 10 - C(+)

48

Chassis Ground

98

Port 4 - C(-)

48

Chassis Ground

98

Port 10 - C(-)

49

Port 2 - B(-)

99

Chassis Ground

49

Port 8 - B(-)

99

Chassis Ground

50 Port 2 - A(-) 100 Port 5 - B(-) 50 Port 8 - A(-) 100 Port 11 - B(-)

Table 1 - GES Pinouts

GES – Quick Start Guide

______________________________________________________________________

______________________________________________________________________

Page 4 of 11

3.3. Interface Port Details

3.3.1. Ethernet Ports

All connections in Table 3-1 that have a white background are Ethernet Port

connections.

3.3.2. Serial and Programming Ports

All connections in Table 3-1 that have an Orange background are Serial Port

connections.

The DEV1 serial port is a dedicated GES Management Processor Maintenance Port.

The DEV2 serial port was designed for future expansion such as an in-band Ethernet to

Serial Bridge.

3.3.3. Management Processor

The GES provides an application processor for both internal and customer specified

functions. This processor is in-band allowing control by any device on the Ethernet

network that is connected to the GES.

This processor is lightly loaded after initialization of the GES allowing customer specified

functions to use most of the available processing power if required.

The primary purpose of this processor is to:

•Initialize the Ethernet Switch IC for GES default operation

•PBIT and CBIT

•Customer specific functions if required

3.3.4. Input Power

The connections shown in Table 3-1 with a Red background are Power Connections.

The input power requirements are as specified in MIL-STD-704A:

•Aircraft, 28 VDC, Category B (curves 2 &3 of Fig. 9)

During normal operations the average power consumption with all 12 ports connected at

1 GB speed is 17 watts. Input current is internally limited to 2 amps.

4. Control Interfaces

4.1. Menu Interface

The GES Menu Interface is used for out-of-band control of the GES via DEV1. It

provides the ability to customize configurations such as port mirroring, VLAN’s and

status monitoring.

GES – Quick Start Guide

______________________________________________________________________

______________________________________________________________________

Page 5 of 11

4.2. In-Band Interface

The GES In-Band Interface is used for control of the GES via an attached Ethernet

device. It provides the ability to execute and retrieve BIT data, retrieve GES status, and

processor reprogramming.

The GES management processor supports ARP, ICMP (ping), and UDP

communications. UDP traffic is supported on port 3500.

5. Switch Management Capability

The following list is a sub-set of the capabilities of the Switch IC:

•Egress tagging/untagging - selectable per port or by 802.1Q VLAN ID

•Port Based VLANs - supported in any combination or 802.1 VLAN support for

4096 VIDs

•Port States and BPDU handling for spanning tree

•802.1X Source MAC address authentication

•Quality of Service - switch architecture provides non-blocking switching in all

traffic environments

•Link Aggregation (802.3ad) - allows two or more links to be trunked to increase

the total bandwidth and provide a failsafe if one of the links fails

•A high speed, non-blocking, QoS switch fabric with support for four traffic classes

based on:

oPort

oIEEE 802.1p

oIPv4’s TOS or Diff-Serv

oIPv6’s Traffic Class

o802.1Q VID

oDA MAC address

oSA MAC Address

•Back-pressure flow control on half-duplex ports

•Pause-frame flow control on full-duplex ports

•Lookup engine supports 16384 MAC address entries with learning and aging

•Auto-MDI/MDIX and polarity correction

Aeronix can create custom loads for the Management Processor that will allow increased

GES management functionality and/or customer defined custom applications that would

be hosted on this processor.

GES – Quick Start Guide

______________________________________________________________________

______________________________________________________________________

Page 6 of 11

6. Hardware Mounting

The GES weighs 2 pounds 12 ounces and is mounted via its four 10-32 captive screws.

The recommended clearance for the mounting hardware below the mounting surface is

0.750”. The GES mounting screws extend 0.665” below the bottom of the chassis.

Previous versions of the GES had shorter mounting screws. The current (longer) screws

can be easily recognized because they are Allen head screws with a black oxide coating.

The rectangular mounting pattern for the attachment points is 3.55” x 7.71” as shown in

Figure 6-1.The overall external dimensions are 8.25” L x 5.15” W x 1.38” H.

Figure 6-1: External Dimensions

The Center of Gravity (CG) is also shown in Figure 9-1. It is indicated by the letters “CG”

before the dimension.

7. Indicators

The GES has one green LED on the front panel labeled PWR.

This LED is illuminated when input power is applied to the GES.

5.15

CG 2.40

CG 4.30

CG 0.60

5/32

HEX (4 PLACES)

10-32 2A NF THREAD (4 PLACES)

3/4" MIN. DEPTH

8.25

7.71

0.27

1.38

1.31

1.75

2.00

1.95

3.55

0.80

GES – Quick Start Guide

______________________________________________________________________

______________________________________________________________________

Page 7 of 11

8. Qualifications

Characteristic

Ports

Dimensions

Weight

Management

Connectors

Military Specification

Test Detail Comment/Tailoring

MIL-HDBK-5400

Cooling Air Free Air, unmounted Does not use the aircraft structure as a heat sink

MIL-STD-810F Method 500.4 Procedure I

Storage Procedure I: -57°C @ 40,000 feet

MIL-STD-810F Method 500.4 Procedure II

Operational Procedure II : -40°C @ 40,000 feet

MIL-STD-810F Method 500.4 Procedure IV

Explosive Decompression Procedure IV: 8,000 feet to 23,100 feet in 0.008mSec

MIL-STD-810F Method 501.4 Procedure I

Storage Procedure I: +95°C

Operational Procedure II: +55°C

Operational Procedure II: +71°C for 30 Minutes

MIL-STD-810F Method 502.4 Procedure I

Storage Procedure I: -57°C

MIL-STD-810F Method 502.4 Procedure II

Operational Procedure II: -40°C

MIL-STD-810F Method 503.4, Procedure I

Temperature Shock -40°C - +55°C at 20°C/Minute

MIL-STD-810F Method 506.4 Procedure III

Rain

MIL-STD-810F Method 507.4

Humidity

Operating and non-operating effects of humidity, including conditions wherein condensation takes place in and on

the equipment

MIL-STD-810F Method 508.5

Fungus Designed with certified fungus inert materials

MIL-STD-810F Method 509.4 Procedure I

Salt Fog Operating and non-operating exposure to salt-sea atmosphere

MIL-STD-810F Method 510.4 Procedure I & II

Sand and Dust

MIL-STD-810F Method 511.4 Procedure I

Explosive Atmosphere At site and 40,000ft altitudes

Limit Loads Performance at ±10.0G applied individually along the three axes

Ultimate Loads Withstand without structural failure ±15.0G applied individually along the three axes

Crash Landing Remain captive, 40G forward, 20G aft and down, 14G left/right, 10G up

MIL-STD-810F Method 514.5 Performance

Vibration Performance 0.025 G2/Hz 300 - 1000 Hz, Overall 4.4Grms

MIL-STD-810F Method 514.5 Endurance

Vibration Endurance 0.06 G2/Hz 300 - 1000 Hz, Overall 9.2Grms

MIL-STD-810F Method 514.5 Gunfire

Vibration Gunfire Sine Sweeps Up to 15G

MIL-STD-810B Method 515.1 Category B

Acoustical Noise 140db

MIL-STD-810F Method 516.5, Procedure VI

Bench Handling

MIL-STD-810F Method 516.5 Procedure I

Functional As modified: eighteen (18) blows, terminal peak sawtooth, 20g, 11ms

MIL-STD-810F Method 516.5, Procedure V

Crash Safety

TPS (terminal peak sawtooth), 40g, 11 millisecond shock as modified by MIL-STD-810B, Method 516, Procedure

III Figure 516-1

MIL-STD-810F Method 520.2 Procedure III

Temperature Altitude Operational at 60,000 feet from -40°C to +23°C, 33,000 feet at +55°C

MIL-HDBK-217 FN2, Method I, Case 3 using part stress

calculations. 100% Duty Cycle

MTBF 8,474 hours @ +55°C, Airborne Uninhabited Fighter Environment

Transportability Transportation by rail, truck, air and/or ship at altitudes up to 45,000 ft.

Service Life >10,000 hours

Mounting Self locking, Retained

MIL-STD-704A 28VDC Category B Curve 2 and Curve 3 of Figure 9 < 22Watts

CE101

Power leads, 30Hz to 10KHz

CE102

Power leads, 10 kHz to 10MHz

CS101

Power leads, 30Hz to 150 kHz

CS114

Bulk cable injection, 10 kHz to 200MHz

CS115

Bulk cable injection, impulse excitation

CS116

Damped sinusoidal transients, cables and power leads, 10kHz to 100MHz

RE101

Electric field, 30Hz to 100KHz

RE102

Electric field, 2MHz to 18GHz

MIL-STD-461F RS103

Radiated Susceptibility 20 V/m from 30MHz to 1GHz - 60V/m from 1GHz to 18GHz

SAE ARP 1870 Electrical Bonding

DC resistance measured from the equipment case to the aircraft structure < 2.5mΩ

DC resistance measured between each power input line and the safety grounding contact > 1MΩ

Detail

12 - 1000Mbps full duplex,10Mbps or 100Mbps full or half duplex

8.25" x 5.1" x 1.38"

Management Processor available for custom configurations

Radiated Emissions

MIL-C-38999 (Signal and Power)

2 lb 12 oz (1.25 kg)

Environmental

Altitude

MIL-STD-461F

Conducted Susceptibility

Chassis Grounding

MIL-STD-810F Method 501.4 Procedure II

MIL-STD-461F

Primary Power

Low Temperature

High Temperature

MIL-STD-810F Method 513.5 Procedure I

Acceleration Load Factors

Electromagnetic Compatibility

Shock

MIL-STD-461F

Conducted Emissions

GES – Quick Start Guide

______________________________________________________________________

______________________________________________________________________

Page 8 of 11

9. Performance Parameters

Dimensions

8.25" x 5.1" x 1.38"

Operating Temperature

-40°C to +71°C

Non-Operating Temperature

-57°C to +95°C

Cooling

Radiant Cooling (Requires only ambient air)

Weight

2 Lb. 12 Oz (1.2 kg)

Power Requirements

< 22 watts operating

Input Voltage

12VDC to 33VDC (28VDC Nominal)

Operating Altitude

60,000 Ft Continuous

GES – Quick Start Guide

______________________________________________________________________

______________________________________________________________________

Page 9 of 11

10. Warranty

a. Seller expressly warrants that all goods and services shall be free from defects,

shall be of good materials and workmanship, and shall conform to applicable

specifications, drawings, samples, and performance specifications.

b. The Seller warranty shall remain in effect for a period of one year after the item

is shipped, or the service is completed, from or by the Seller.

c. In the event Seller is required to replace or correct any component of any item,

the running of the warranty period for the items of which the defective

component is a part shall be suspended from the date Seller receives the item

until the date the item is replaced or corrected, and this warranty shall apply to

such replacement or corrected items furnished for the unexpired portion of the

warranty period.

d. Seller shall not be responsible for any liabilities, loss, costs, damages, and/or

expense resulting from any breach of any, or all, of Seller’s warranties, express,

or implied. Seller shall not be responsible for any cost of removing such items

from property, equipment, or products, and/or any additional costs of

disassembly, fault isolation, failure analysis, reinstallation, reinspection, retesting

in which such items have been incorporated and/or transportation to or from the

Seller.

The GES does not contain any user serviceable parts. Any modification or use other

than consistent with the intended design shall void the warranty. Owner must contact

Aeronix at (321) 984-1671 and be issued a Return Material Authorization (RMA) number

before returning a unit for warranty repair.

GES – Quick Start Guide

______________________________________________________________________

______________________________________________________________________

Page 10 of 11

11. Products and Services

Aeronix offers an extensive line of Engineering Services including the creation and

implementation of custom management configurations for the GES.

Visit the Aeronix web site at www.Aeronix.com for additional information about our

products and services.

GES – Quick Start Guide

______________________________________________________________________

______________________________________________________________________

Page 11 of 11

1775 West Hibiscus Blvd, Suite 200

Melbourne, FL 32901

(321) 984-1671

www.Aeronix.com

Copyright Aeronix, Inc. 2013

Table of contents

Popular Network Router manuals by other brands

Lantech

Lantech TPGS-L6408XFTR user manual

Cisco

Cisco Catalyst 4000 Preparing to install

Niobrara

Niobrara MEB II Installation and programming manual

TRENDnet

TRENDnet TEW731BRV2 user guide

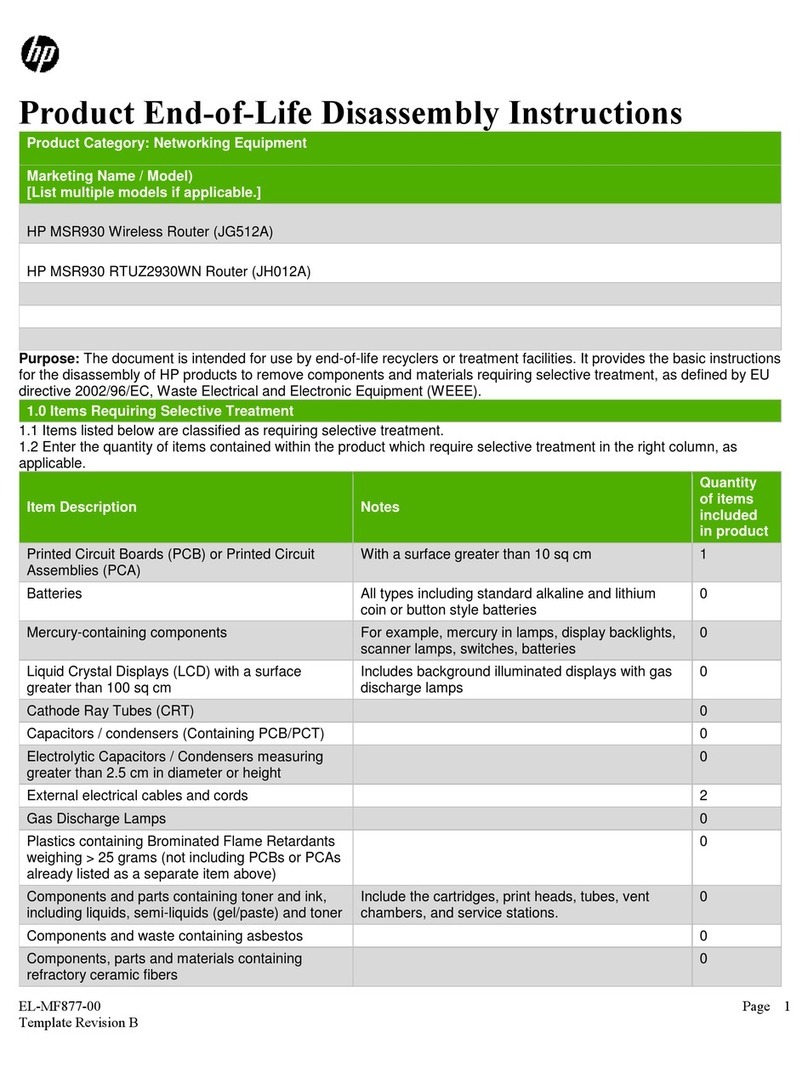

HP

HP MSR930 Series Product End-of-Life Disassembly Instructions

Cisco

Cisco Catalyst IR1800 Rugged Series installation guide