Content

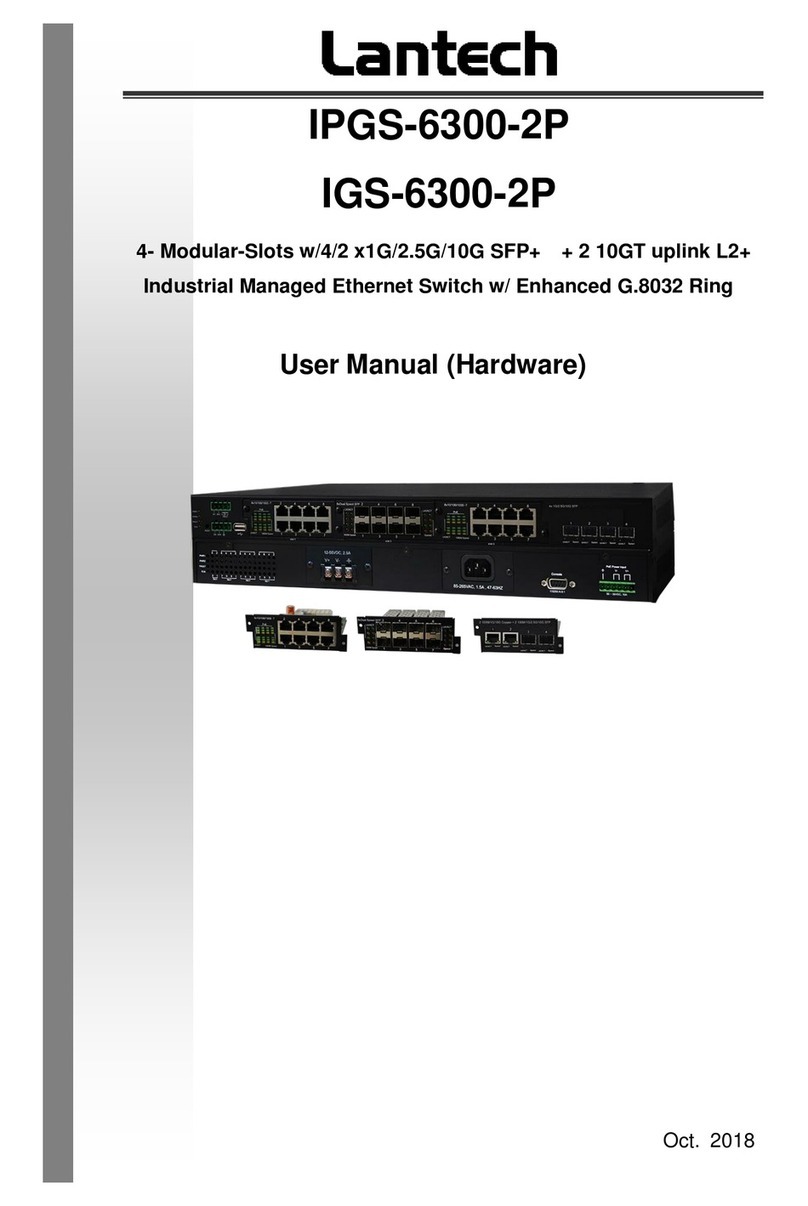

Chapter 1 Introduction ........................................... 5

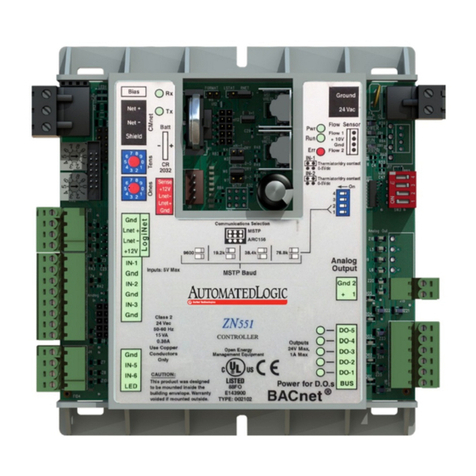

Chapter 2 Hardware Description............................ 5

2.1 Physical Dimension....................................... 5

2.2 IP Protection................................................. 6

2.3 LED Indicators .............................................. 9

2.4 Bypass design .............................................10

Chapter 3 Hardware Installation .......................... 11

3.1 Rack Mounting.............................................12

3.2 Power input M12 connector..........................13

3.2 Console & USB dongle M12 connector........15

3.3 10/100/1000T interface M12 connector........16

3.4 10G interface M12 connector.......................17

3.5 10G interface Q-ODC connector..................19

3.6 DI/DO M12 connector ..................................20

Chapter 4 Network Application............................ 22

ITU G.8032 Scheme..............................................22

Ring Coupling ..........................................................22

Multiple Rings..........................................................23

Dual Homing ...........................................................24

Chain......................................................................25

Chapter 5 Console Management.......................... 27

5.1 Connecting to the Console Port....................27

5.2 Login in to the Console Interface..................27