Aerosmith GT38LI-EXIF Quick start guide

OPERATIONAL MANUAL

GT38LI-EXIF INSULATION GAS TOOL

AEROSMITH INSULATION GAS TOOL OPERATIONAL MANUAL

2

battery.

2. To install the battery, insert the battery

cartridge until hearing a “click”.

3. To remove the battery, grip the buttons on

both side of battery cartridge and pull out.

C. Battery Light Indicator

LED Battery Level

All LEDs 100%

1 Green and 1 Red LED 50%

1 Red LED 25%

NOTE:

• After using the tool, remove the battery from

the tool to prevent the tool from being fi red.

D. Preparing the fuel cell

Caution !

• Never attempt to use fuel cell from other

manufacturer.

• Do not remove the cap when it is unused.

• Never drill a hole on the fuel cell.

• Do not inhale the gas. Breathing in the gas

could cause sleepiness, dizziness or nausea.

• The fuel cell is not refi llable, do not attempt

to refi ll the gas.

Steps:

First ensure to use the corect colour valve, Please

refer to the technical specifi cations.

1. Detach the cap, attach the valve by pushing

in the front edge.

1 - OPERATIONS

A. Charging

Steps:

1. Plug the battery charger into the proper AC

voltage source, green light will be flashing.

2. Insert the battery into charger, red light will

alight indicating the battery is charging.

3. It takes about 60 minutes for charging.

4. When fully charged, green light will remain

alight.

5. After charging, unplug the charger from the

power source.

• If orange light is blinking, remove the battery

cartridge and plug again.

• If this happens continuously, the battery

cartridge or charger may be damaged.

Consult authorized serviceman for

replacement of new battery cartridge.

NOTE:

• Never attempt to open the charger or battery

cartridge.

• The battery charger is for charging specifi c

battery pack. Never attempt to charge battery

pack from other manufacturer’s battery

cartridge. Unsuitable battery cartridges may

cause fi re that causes injury.

• When the battery charger is being used,

keep out of direct sunlight.

• To get better cooling effect, keep the exhaust

area clean.

B. Installing and removing the battery

Steps:

1. Empty fasteners from the barrel and make

sure the trigger is not pulled while installing the

3

AEROSMITH INSULATION GAS TOOL OPERATIONAL MANUAL

AEROSMITH INSULATION GAS TOOL OPERATIONAL MANUAL

AEROSMITH INSULATION GAS TOOL OPERATIONAL MANUAL

2. Pushing the rear edge until it has “clicked”.

NOTE:

• Make sure the fuel cell valve is attached

fi rmly, if not, gas leakage may occur and

create hazards to users and bystanders.

E. Installing/Removing fuel cell

Caution !

• Make sure the trigger is not held while

inserting fuel cell.

• Empty fasteners from the barrel before

installing fuel cell.

• Do not press on the surface ground while

installing.

Steps:

1. Push up and pull to open the fuel door.

2. Insert the fuel cell, direct the jet nozzle into

the adaptor.

3. Put the can door over the valve and push it

down to latch.

4. For removing fuel cell, reverse the above

steps.

F. Installing and removing barrel

Caution !

• Make sure the trigger is not held while

inserting barrel.

• Do not press on the surface ground while

installing.

• Do not cover the barrel with your hand while

installing.

Steps:

1. Make sure the adapter is in unlock position.

2. Insert the barrel into the adaoter.

3. Rotate the adapter to lock position until you

hear “click”.

G. Loading the pins

Caution !

• Make sure the trigger is not held while

loading the pins.

• Do not press on the surface ground while

loading.

Steps:

1. Insert the insulation fastener into the barrel

until it reaches the tip of pin guide.

2. For removing the insulation fastener, simply

pull the fastener out from the barrel.

H. Driving the pins

Caution !

• Please READ and UNDERSTAND the

section “General Safety Instructions” for

personal and working environment safety.

• If you spot of any abnormality about the tool,

contact nearest authorized serviceman for

inspection and repairing.

Steps:

1. Press the tool with suitble length of insulation

fasteners through the insulation material.

2. Press the Nose of the contact arm against

working surface (90° against the surface) fi rmly

until you hear the fan motor is working.

3. Pull the trigger, the pins are driven to the

AEROSMITH INSULATION GAS TOOL OPERATIONAL MANUAL

4

object.

4. Release the trigger and lift the tool.

I. Cleaning Filter

The fi lter at the back of the tool acts crucially to

suck in air into the chamber. For maintaining the

best performance of the tool users should always

keep it clean.

1. Unscrew four screws on the back cover

2. Take out the back cover and clean the mesh

with brush or air.

3. Put the back cover on the machine and fasten

with four screws.

NOTE:

• Do not attempt to use water to clean the

mesh. The cover and mesh must be dry

when operating the tool. If wet it may easily

cause malfunction to the tool.

5

AEROSMITH INSULATION GAS TOOL OPERATIONAL MANUAL

AEROSMITH INSULATION GAS TOOL OPERATIONAL MANUAL

AEROSMITH INSULATION GAS TOOL OPERATIONAL MANUAL

2 - TROUBLESHOOTING

WARNING:

To reduce the risk of serious

personal injury, ALWAYS

unload the battery, the pins

and fuel cell from the tool

before all repairs.

A. Battery/Charger Problems

SYMPTOM 1

Battery Cell does not appear to accept charge.

Green charger light does not come on after sev-

eral hours.

Possible

reasons

Services

Inoperative

indicator lights on

charger.

Try Battery in tool after

1 hour on charge cycle.

If tool functions properly

charger lights are not

working correctly. Replace

charger, or monitor time to

ensure Battery Cell has ad-

equate time for recharging.

It’s normal for Battery to

feel warm after properly

charging.

Damaged

charger.

Discontinue use imme-

diately and unplug from

power source. Replace

charger and tag or dispose

of charger to prevent acci-

dental reuse or connection

to power source.

SYMPTOM 2

Red LED on charger is blinking.

Possible

reasons

Services

Battery is hot. Remove battery from

charger and allow to cool.

Inspect battery charger

and cartridge.

SYMPTOM 3

Orange LED on charger is blinking.

Possible

reasons

Services

Charger

damaged.

Replace Charger.

B. Normal Stage of Operation

SYMPTOM 1

Fan does not run.

Possible

reasons

Services

Battery is not

charged.

Charge Battery

according to

Operating Manual.

Battery

Terminals or

Handle

battery contacts

are oily, dirty, or

corroded.

Clean Battery Cell termi-

nals Clean Handle Battery

Cell contacts as required.

There is electrical

short some-

where.

The tool must be looked

into by Authorized Service-

man.

SYMPTOM 2

Fan does not run, or runs slower than normal.

Possible

reasons

Services

Battery is dis-

charged.

Charge Battery Cartridge.

SYMPTOM 3

Fan runs intermittently.

Possible

reasons

Services

Battery is loose

or contacts are

bent.

Snap battery back into its

locked position. Bend

contacts back into proper

position by Authorized

Serviceman.

AEROSMITH INSULATION GAS TOOL OPERATIONAL MANUAL

6

C. Pre-Combustion/Combustion Stage

of Operation

SYMPTOM 1

Contact Arm does not depress fully, tool does not

operate.

Possible

reasons Services

The nose piece is

bent, or is stuck

with dirt.

Inspect if the nose piece is

clean. If it is damaged, con-

sult authorized serviceman

for repair and replacement

of the parts.

Cylinder head

O-Ring pinched.

Contact authorized service-

man for repair.

SYMPTOM 2

Failure to install fasteners to nose piece.

Possible

reasons Services

Piston positioned

wrongly.

Return piston to

original position

with a rod or screwdriver.

O-Ring is

damaged and

causing

leakage of gas.

Contact authorized ser-

viceman for repair.

Damaged valve

plate or reed of

the cylinder body.

Contact authorized ser-

viceman for repair.

SYMPTOM 3

Tool will not cycle - fan runs.

Possible

reasons

Services

Fuel Cell is

empty.

Replace Fuel Cell.

Spark does not

occur.

Contact authorized ser-

viceman for repair.

SYMPTOM 4

Fail to drive fasteners.

Possible

reasons Services

Water vapour

surrounding

spark causing

short circuit.

Dry the spark area or con-

tact authorized serviceman

for repair.

Sealing ring

damaged.

Contact authorized ser-

viceman for repair.

Piston guide

stuck with dirts.

Contact authorized ser-

viceman for repair.

D. Power/Exhaust Stage of Operation

SYMPTOM 1

Tool operates properly, but fasteners do not drive

fully.

Possible

reasons

Services

Battery is dis-

charged.

Charge battery.

Fuel Cell is low. Replace fuel cell

according to

User Manual

SYMPTOM 2

Operation of the tool is not stable.

Possible

reasons Services

Fuel Cell is low. Replace fuel cell according

to User Manual.

Spark Plug wire

is loose.

Contact authorized ser-

viceman for repair.

Filter

element is dirty,

causing tool to

overheat.

Remove fi lter

element and clean accord-

ing to User Manual.

7

AEROSMITH INSULATION GAS TOOL OPERATIONAL MANUAL

AEROSMITH INSULATION GAS TOOL OPERATIONAL MANUAL

AEROSMITH INSULATION GAS TOOL OPERATIONAL MANUAL

Tool sleeve or O-

Rings are dirty.

Contact authorized ser-

viceman for repair.

SYMPTOM 4

Unstable performance.

Possible

reasons Services

Built-up dirt and

debris

inside cylinder

Contact authorized ser-

viceman for repair.

SYMPTOM 5

Diminishing power.

Possible

reasons Services

Damaged piston

or cylinder.

Contact authorized ser-

viceman for repair.

E. Returning/Purging Stage of

Operation

SYMPTOM 1

Tool operated and drove fastener, but piston did

not return to up position.

Possible

reasons Services

Mushrooming of

Piston Tip.

Contact authorized ser-

viceman for repair.

Exhaust ports on

the sleeve are

dirty or clogged

Contact authorized ser-

viceman for repair.

Tool (Sleeve) or

O-Rings are dirty.

Contact authorized ser-

viceman for repair.

SYMPTOM 2

Combustion Chamber does not drop after tool

cycles.

Possible

reasons Services

Contact arm is

bent, or tool is

dirty.

Clean tool or replace con-

tact arm as require

AEROSMITH INSULATION GAS TOOL OPERATIONAL MANUAL

8

3 - COPYRIGHT

Copyright:

Aerosmith Fastening Systems

5621 Dividend Road,

Indianapolis, IN 46241

United States

Passing on and duplication of this document,

exploitation and disclosure of its contents

are forbidden unless expressly approved.

Violations render the offender liable to

damages. All rights reserved for the event

of patent, utility model or registered design

applications.

This operating manual has been drawn

up with the greatest care. Nevertheless,

Aerosmith Fastening Systems assumes

no liability for possible errors in this

operating manual and their consequences.

Furthermore, no liability is assumed for

direct or consequential damages resulting

from the improper use of the tool.

The national safety and occupational safety

regulations and the safety precautions given

in this operating manual must be observed

when using the tool. All product designations

and brand names are the property of their

owners and are not explicitly marked as

such.

Amendments to content reserved.

4 - DISPOSAL

Separate collection. Local

regulations may provide for

separate collection of electrical

products from the household, at

municipal waste sites or by the

retailer when you purchase the

new product.

Separate collection of packag-

ing and failed rechargeable

battery in accordance with the

recycling regulations applicable

in your country.

5621 Dividend

Road,

Indianapolis,

IN 46241

United States

Tel: 800.528.8183

Web: http://www.aerosmithfastening.com/

Table of contents

Other Aerosmith Tools manuals

Popular Tools manuals by other brands

Elaflex

Elaflex ZVA Slimline Installation and operating manual

Gippsland Aeronautics

Gippsland Aeronautics GA8 Owners and Pilots Information Manual

Panduit

Panduit PPTMT Operation instructions

Rothenberger Industrial

Rothenberger Industrial 072990E Instructions for use

Sealey

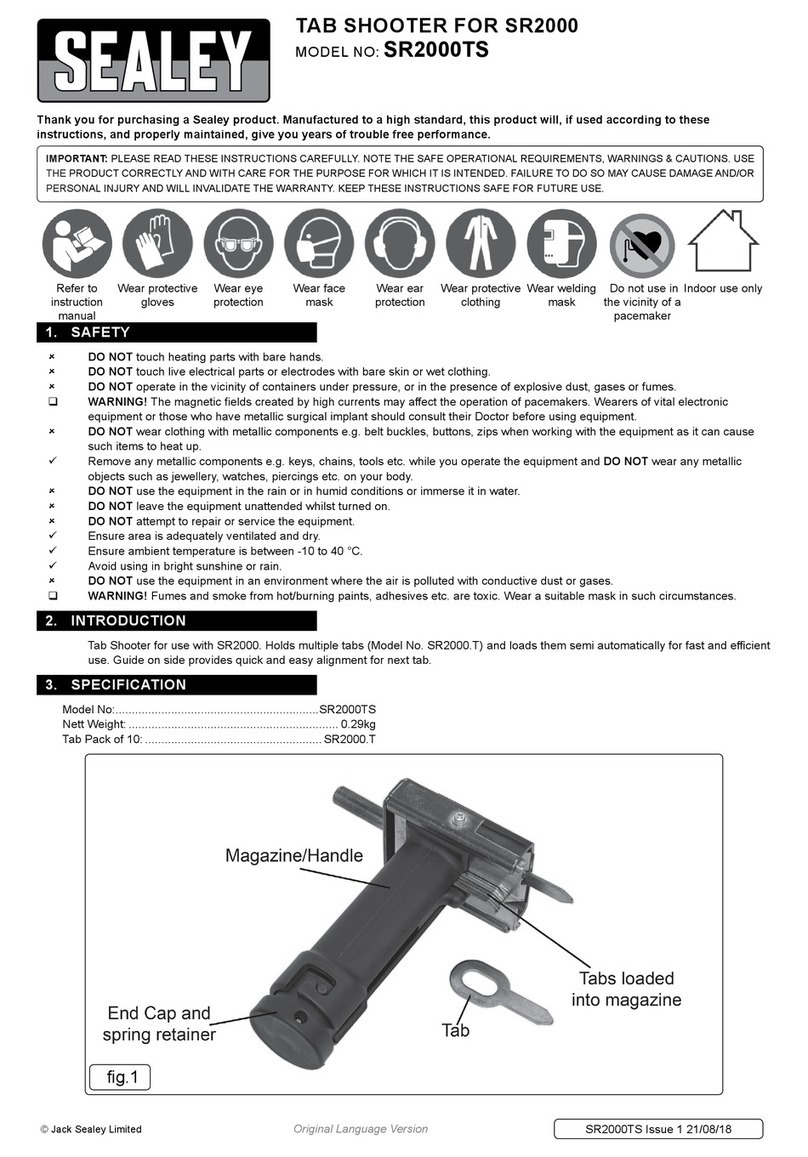

Sealey SR2000TS instructions

Rivet King

Rivet King RK-280-NP12 instruction manual