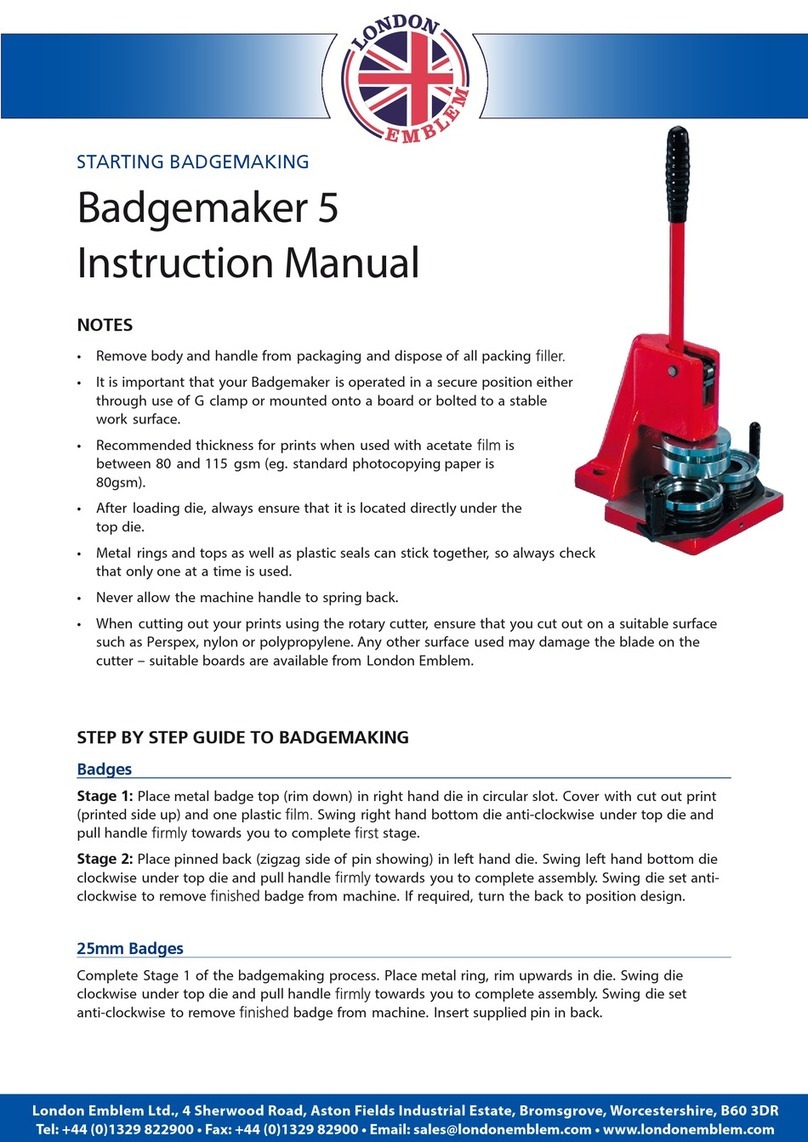

Aerostar Aircraft Corporation 600 User manual

1

AIRCRAFT

CORPOR

A'T

1

O^t^'j^j^^^j^^^^--

Arc

AEROSTAR

MAINTENANCE

MANUAL

CARD

1

OF 7

AEROSTAR

AEROSTAR 601

AEROSTAR 601P

AEROSTAR 602P

AEROSTAR 700P

Q

^T NUMBER 761 732)

1A1

1

J

AEROSTAR

AIRGRAFT

600/601/601P/602P/700P

MAINTENANGE,

MANUAL

INTRODUCTION.

This

AEROSTAR

AIRCRAFT Maintenance Manual is prepared in accprdan.ce,withtheGAMA (General

Aviation Mariufacturers Association) format. This maintenance manual is divided intoVarious Groups wh1c

enable a broad separation of contents (Chapters)

within

each group.

The various Chapters are broken down into major systems such as Electrical Power,, Flight Controls,

Fuel,

Landing Gear, etc. The System/Chapters are arranged more or less alphabetically rather,than.by.prece-

dence

or importance. All System/Chapters are

.assigned

a number, which becomes the firstvelement of a stan-

dardized numbering system. Thus the element "32" of the number series

32-00-(Db,

refers to the.System/Chapter

on

"Landing Gear." All information pertaining to the landing gear

will

be covered in this Systenn/Chapter. :

The major Systeni/Chapters are then broken down into

Sub-System/Sectiohs.

These sections.are identi-

fied by the second element of the standardized numbering system. The number "40" of the basic number series

32r40-00

is for the "Wheels and Brakes" portion of the landing gear. •

The individual units

within

a Sub-System/Section may be identified by a third element of the standardized

numbering

system,

such as

32-40-01.

This number

could

be assigned by the-manufacturer to fit the coverage

requirements'of the publication.

Example:

CHAPTER/SYSTEM

LANDINGGEAR

SUB-SYSTEMS

WHEELSANDBRAKES

32-40-01

INDIVIDUAL

UNITS

NOSEWHEELREMOVAL

This

manual does not contain hardware callouts for installation. Hardware callouts are only indicated

where

a special application is required. To confirm the correct hardware

used,

refer to the Parts Catalog

P/N 761 731, and FAR 43 for proper utilization.

1A2

Introduction

Page

-1

Issued: June 1, 1995

V

AEROSTAR

AIRCRAFT

600/601/601P/602P/700P

MAINTENANCE

MANUAL

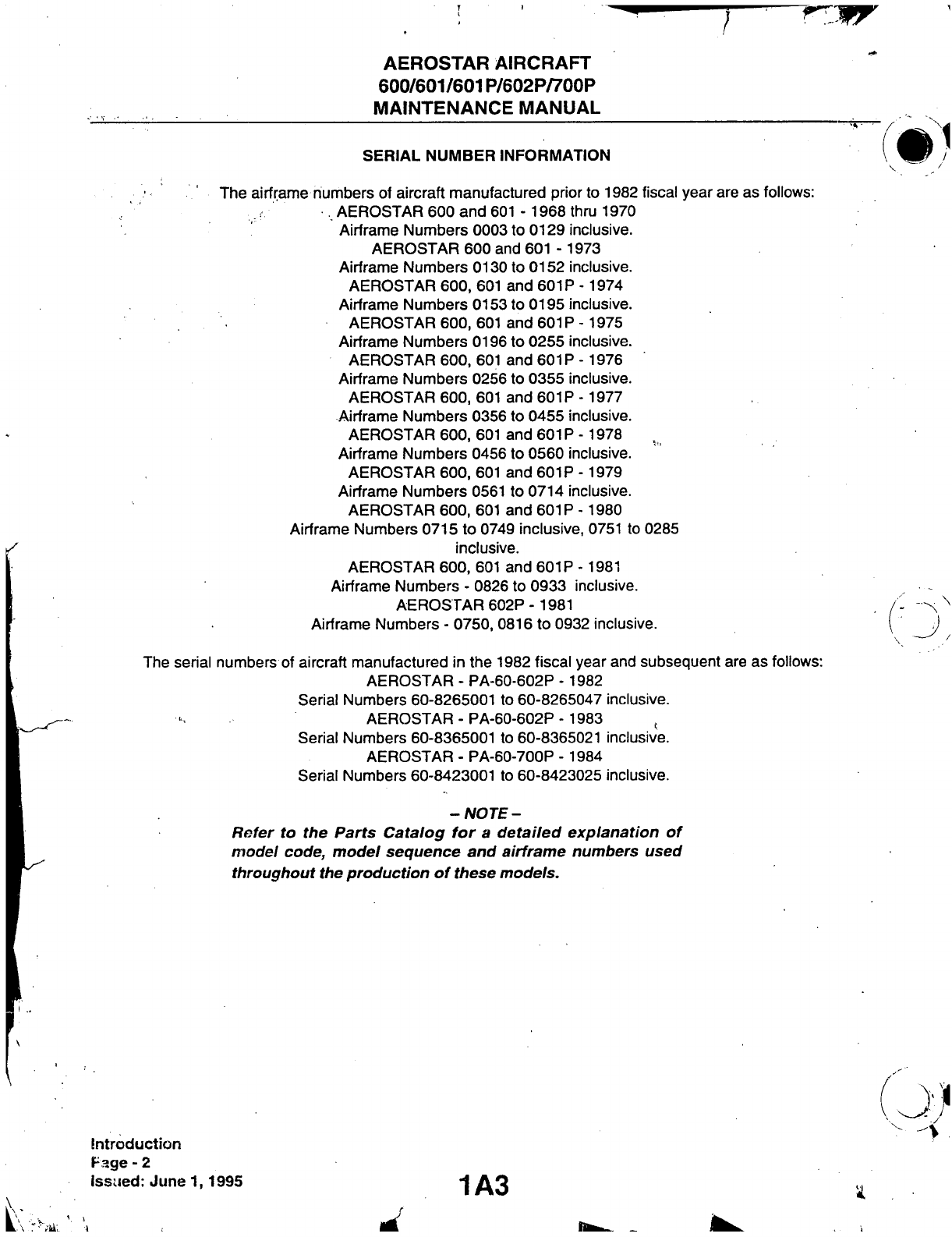

SERIAL

NUMBER INFORMATION

The

airframe numbers

of

aircraft manufactured prior

to 1982

fiscal year

are

as follows:

AEROSTAR

600

and 601

-

1968 thru

1970

Airframe Numbers

0003 to

0129

inclusive.

AEROSTAR

600

and

601

- 1973

Airframe Numbers

0130 to 0152

inclusive.

AEROSTAR

600,

601

and 601P

-1974

Airframe Numbers

0153 to

0195

inclusive.

AEROSTAR

600,

601

and

601P

-1975

Airframe Numbers

0196 to 0255

inclusive.

AEROSTAR

600,

601

and 601P

- 1976

Airframe Numbers

0256 to 0355

inclusive.

AEROSTAR

600,

601

and 601P

-1977

Airframe Numbers

0356 to 0455

inclusive.

AEROSTAR

600,

601

and

601P

- 1978

Airframe Numbers

0456 to 0560

inclusive.

AEROSTAR

600,

601

and 601P

- 1979

Airframe Numbers

0561

to 0714

inclusive.

AEROSTAR

600,

601

and 601P

-1980

Airframe Numbers

0715 to

0749

inclusive,

0751 to 0285

inclusive.

AEROSTAR

600,

601

and 601P

-1981

Airframe Numbers

-

0826 to 0933

inclusive.

AEROSTAR

602P-

1981

Airframe Numbers

-

0750, 0816

to

0932

inclusive.

The

serial numbers

of

aircraft manufactured

in the 1982

fiscal year and subsequent

are as

follows:

AEROSTAR

-

PA-60-602P

- 1982

Serial

Numbers

60-8265001 to 60-8265047

inclusive.

AEROSTAR-PA-60-602P-

1983 ,

Serial

Numbers

60-8365001 to 60-8365021

inclusive.

AEROSTAR

-

PA-60-700P

- 1984

Serial

Numbers

60-8423001 to 60-8423025

inclusive.

-NOTE-

Refer

to the

Parts

Catalog

for a

detailed

explanation

of

model

code,

model

sequence

and

airframe

numbers used

throughout

the

production

of

these

models.

Introduction

Page-2

issued:

June

1,1995

1 A3

AEROSTAR

AIRCRAFT

600/601/601P/602P/700P

MAINTENANCE

MANUAL .

AEROFICHE

EXPLANATION AND REVISION

STATUS

Maintenance manual information incorporated in

ttiis

set of Aerofictie cards is arranged in accordance

witti

ttie

specifications of Aerofictie adopted by

ttie

GenerarAviation Manufacturers

Association.

Information

com-

piled in

ttiis

Aerofictie Maintenance Manual is

kept

current by revisions distributed periodically, ttiese revisions

supersede

all previous revisions and are complete Aerofiche card replacements and shalhsupersede Aerofiche

cards

of the same number in the set.

Identification

of revised material:

Revised

text

and illustrations are indicated by a black verticalline along the left-hand margin of the frame, oppo-

site revised and added material. Revision lines indicate only current revisions

with

changes and additions to exist-

ing

text

and illustrations. Changes in capitalization, spelling, punctuation, indexing, the physical location of the

material, or complete page additions are not identified by revision lines.

A

reference and record of the

material

revised is included in each chapter's Table of Contents/Effectivity. The

code

used in the effectivity colurhns of eachchapter is defined as follows:

TA-BLE

OF

CONTENTS/EFFECTIVITY

CODES

Original Issue: None

First

Revision:

Revision Identification, (1R Month-Year)

Second

Revision: Revision Identification, (2R Month-Year)

All

subsequent revisions

will

follow

with

consecutive revision numbers

such

as 3R, 4R, etc., along

with

the appropriate month-year.

Added

Subject: Revision Identification, (A Month-Year)

Revisions

to Maintenance Manual 761 732 reissued June

1,1995,

are as follows:

Revisions

Date

Aerofiche Card Effectivity

Reissued

June

1,1995

1, 2, 3, 4, 5, 6, and 7

the

date

on Aerofiche cards must not be earlier than the

date

noted for the respective card effectivity.

Consult

the latest Aerofiche card in this series for current Aerofiche card effectivity.

1A4

Introduction

Page-3

Issued: June

1,1995

AEROSTAR

AIRCRAFT

600/601/601P/602P/700P

MAINTENANCE

MANUAL

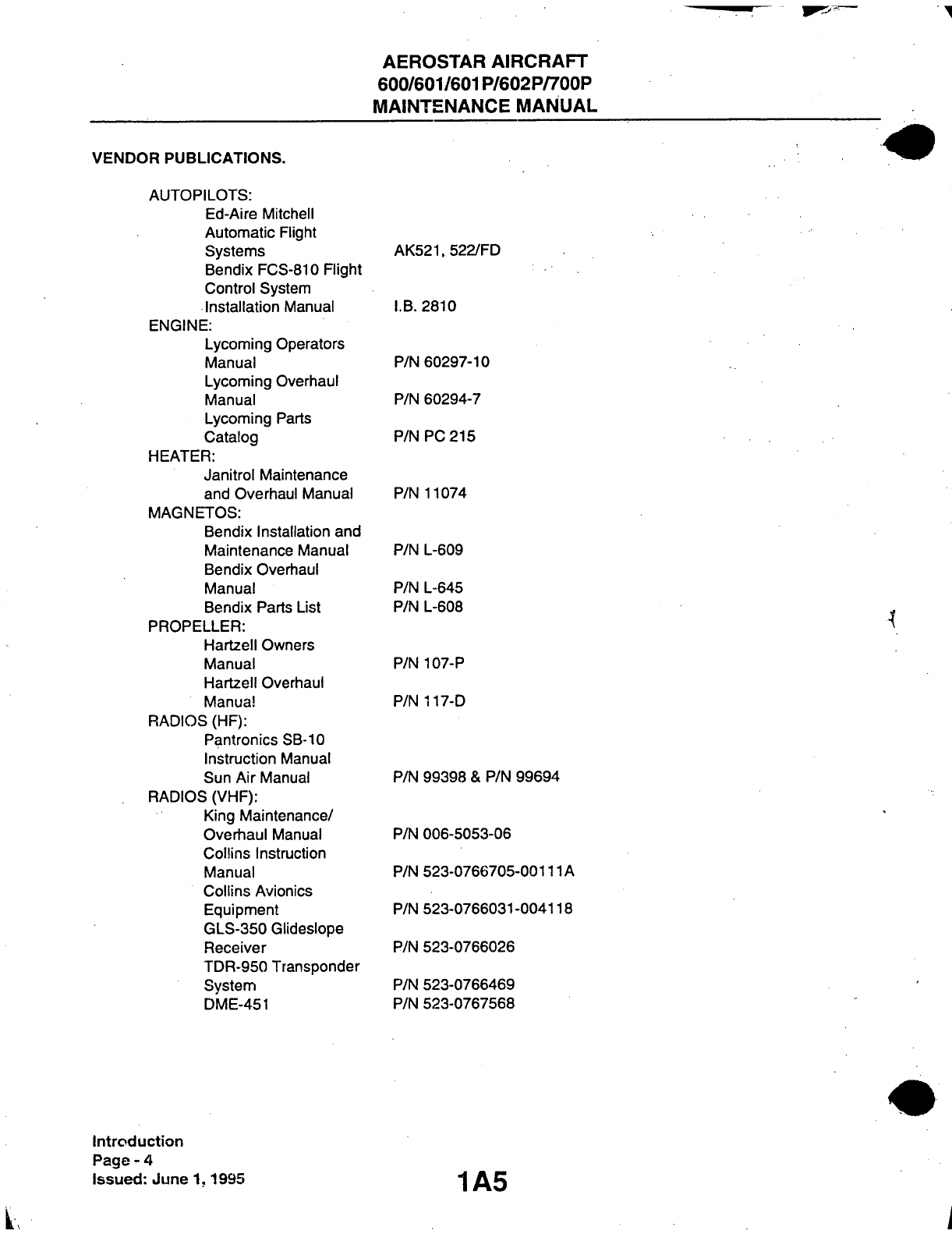

VENDOR

PUBLICATIONS.

AUTOPILOTS:

Ed-Aire

Mitchell

Automatic Flight

Systems

Bendix

FCS-810 Flight

Control

System

Installation

Manual

ENGINE:

Lycoming

Operators

Manual

Lycoming

Overhaul

Manual

Lycoming

Parts

Catalog

HEATER:

Janitrol Maintenance

and

Overhaul Manual

MAGNETOS:

Bendix

Installation

and

Maintenance Manual

Bendix

Overhaul

Manual

Bendix

Parts List

PROPELLER:

Hartzell Owners

Manual

Hartzell Overhaul

Manual

RADIOS

(HF):

Pantronics

SB-10

Instruction Manual

Sun

Air

Manual

RADIOS

(VHF):

King

Maintenance/

Overhaul

Manual

Collins

Instruction

Manual

Collins

Avionics

Equipment

GLS-350

Glideslope

Receiver

TDR-950 Transponder

System

DME-451

AK521,

522/FD

I.B. 2810

P/N

60297-10

P/N

60294-7

P/N PC

215

P/N

11074

P/N

L-609

P/N

L-645

P/N

L-608

P/N

107-P

P/N

117-D

P/N

99398 & P/N 99694

P/N

006-5053-06

P/N

523-0766705-00111A

P/N

523-0766031-004118

P/N

523-0766026

P/N

523-0766469

P/N

523-0767568

Introduction

Page

- 4

Issued:

June

1,1995

1A5

Addendum

to

Aerostar

Maintenance

Manual

Please

note:

Conair

Aviation

Ltd.

fias

added

a section to the end of

ttiis

manual

called:

CAL-WMS

This addendum

CAL-WMS

is a

Alternator

Wiring

Modification

for the

Wiring

l\/lanual

Supplement

issued by Conair Aviation Ltd.

As per the instructions of Dick Kopp, Sr. Inspector, on the

8'"

of December, 1998,

this

section is to incorporated

into

the

Aerostar

Maintenance

Manual

and

will

act as a supplement

this

manual.

Any revision or additions, amendments, etc. of

this

section of the Maintenance

Manual are to be updated on the Record of Revisions as applicable.

This addendum is dated the 8'" of

January,

1999 at

Abbotsford,

British

Columbia by the Technical

Library.

Conair

Aviation Ltd. Technical Library

^.Record

of Revisions (as recorded by Conair)

^

^

Revision Date

Page(s)

Inserted Inserted By Date Inserted

0 u

/

I

h:\publicat\library\REVCOVER.XLS NOTE: Always refer

to

manufactures status report for latest revisions!

AEROSTAR

AIRCRAFT

600/601/601P/602P/700P

MAINTENANCE

MANUAL

AEROSTAR

PUBLICATIONS.

Parts Catalog

761 731

Aerostar

Aircraft

Corp.

3608

S.

Davison Boulevard

Spokane,

WA 99204

Aerostar Programmed

Inspection

N^anual

761 749

Aerostar

Aircraft

Corp.

3608

S.

Davison Boulevard

Spokane,

WA 99204

Aerostar Periodic

Inspection

Report Form

230 1043

Aerostar

Aircraft

Corp.

3608

S.

Davison Boulevard

Spokane,

WA 99204

1A6

Introduction

Page

••

5

Issued: June

1, 1993

AEROSTAR

AIRCRAFT

600/601/601P/602P/700P

MAINTENANCE

MANUAL

VENDOR-SUPPLIER

INFORMATION.

A

partialiist

of

companies,

tfieir

address and pfione numbers

are

provided

to

aid service personnel

in

obtaining information about components

not

manufactured

by

Aerostar Aircraft Corporation.

C

& D

Airmotive Products Heaters

-

Environmental Systems

4445

Shiawnee Road

Berrien Springs,

Ml 49103

(616) 695-7469

Bendix/King Radio Corporation

All

King and Bendix Avionics

400

Northi Rogers Road

Olattie,

Kansas

66061

(913) 782-0400

Edo-Aire

Mitcfiell Autopilots

P.O.

Box

610

Mineral Wells, Texas

76007

(817) 325-2517

Textron Lycoming Williamsport Engines

Division

652

Oliver

Street

Williamsport,

PA 17701

Hartzell

Propeller,

Inc.

Propellers, Governors

Piqua,

Ofiio

45356

(513) 773-7411

Scott Aviation Oxygen Components

225

Erie

Street

Lancaster,

New

York

14086

(716)683-5100

Collins

Radio Group Avionics

350

Collins Road

NE

Cedar Rapids,

lA 52406

Sun

Air

Electronics,

Inc.

Radios

(HF)

3101 S.W. 3rd

Avenue

Ft. Lauderdale, Florida

33315

Introduction

Page

- 6

Issued: June

1,1995

1A7

AEROSTAR

AIRCRAFT

600/601/601P/602P/700P

MAINTENANCE MANUAL

THIS

PAGE

INTENTIONALLY LEFT BLANK

1A8

AEROSTAR

AIRCRAFT

600/601/601P/602P/700P

MAINTENANCE MANUAL

THIS

PAGE

INTENTIONALLY LEFT BLANK

1A9

AEROSTAR

AIRCRAFT

600/601/601P/602P/700P

MAINTENANCE MANUAL ^

GAMA

SYSTEM/CHAPTER

INDEX

GUIDE

-NOTE-

The

following

Chapters are not covered

within

this

Maintenance

Manual:

31, 37, 38, 49, 60, 70, 72, 75, 83, 95.

SYST

SUB-SYST AEROFICHE

CHAP

SECTION TITLE

GRID

NO.

4 AIRWORTHINESS

LIMITATIONS

1B5

5

TIME

LIMITS/MAINT

CHECKS

IBS

6

DIMENSIONS

AND

AREAS

1017

7

LIFTING

AND SHORING

IDIO

8 LEVELING AND

WEIGHING

1E3

9 TOWING AND

T/VXIING

1E11

10 PARKING AND MOORING 1E21

11 REQUIRED PLACARDS 1F4

12 SERVICING 1G11

20 STANDARD PRACT - AIRFRAME 117

21 ENVIRONMENTAL SYSTEM & PNEUMATIC

SYSTEM

, 2B4

22 AUTOFLIGHT 211

23 COMMUNICATIONS 215 . ,

.

- - ^

24 ELECTRICAL POWER V 385

25 EQUIPMENT/FURNISHINGS

3C22

26 FIRE PROTECTION

3E20

27 FLIGHT CONTROLS ' 3F2

28 FUEL 312

IntroducHon

Pago - 9

Issued: .June 1,

•i995

/

I

t

AEROSTAR AIRCRAFT

600/601/601P/602P/700P

MAINTENANCE MANUAL

GAMA SYSTEM/CHAPTER

INDEX

GUIDE

(cont)

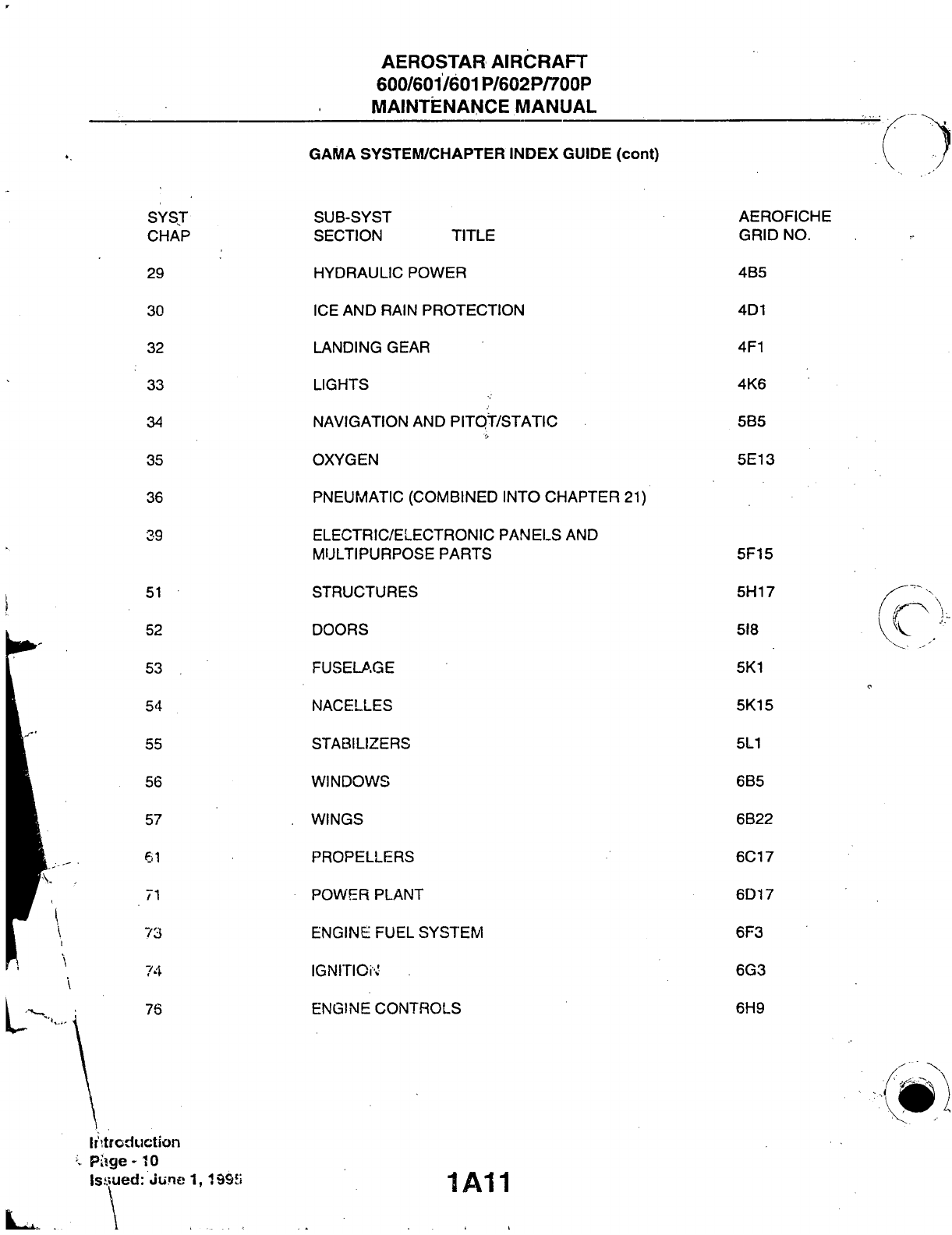

SYSJ

CHAP

29

30

32

33

34

35

36

39

51

52

53

,

54

55

56

57

61

71

73

74

76

SUB-SYST

SECTION

TITLE

HYDRAULIC POWER

ICE AND

RAIN

PROTECTION

LANDING

GEAR

LIGHTS

NAVIGATION

AND

PITQT/STATIC

OXYGEN

PNEUMATIC

(COMBINED

INTO

CHAPTER

21)

ELECTRIC/ELECTRONIC PANELS AND

MULTIPURPOSE PARTS

STRUCTURES

DOORS

FUSELA.GE

NACELLES

STABILIZERS

WINDOWS

WINGS

PROPELLERS

POWER PLANT

ENGINE

FUEL SYSTEM

IGNITIOi\'

ENGINE

CONTROLS

AEROFICHE

GRID

NO.

4B5

4D1

4F1

4K6

5B5

5E13

5F15

5H17

518

5K1

5K15

5L1

6B5

6B22

6C17

6D17

6F3

6G3

6H9

Irtr

eduction

Piige-10

ls.'.5ued:

June

1,19911

1A11

AEROSTAR

AIRCRAFT

600/601/601P/602P/700P

MAINTENANCE

MANUAL

GAMA

SYSTEM/CHAPTER

INDEX

GUIDE

(cont)

SYST

SUB-SYST AEROFICHE

CHAP

SECTION TITLE

GRID

NO.

77 - ENGINE

INDICATING

611

78 EXHAUST 6119

79 OIL 6J3

80 STARTING

6J20

81 TURBINES . 7B5

91 CHARTS AND

WIRING

DIAGRAMS 7C9

) :

Introduction

Page -11

"lAIZ

Issued: June

1,1995

AEROSTAR

AIRCRAFT

600/601/601P/602P/700P

MAINTENANCE

MANUAL

LIST OF ILLUSTRATIONS

FIGURE

NO.

SUBJECT

GRID NO.

5-1.

Pressurized

Cabin, Extended Inspection 1011

5-2.

Pressure

Bulkheads 1012

5-3. Window Fasteners and Retainers 1013

5-4.

Cabin

Interior

Structure 1C14

6-1.

'

General Dimensions 1023

6-2. Station Reference Lines 1D2

6-3.

Access

Covers and Panels 1D4

7-1. Wing Jack Points and Jack Pad 1D13

7-2.

Tools

and Equipment 1D14

7-3.

/

Jack Adapter 1D15

7-4.

Tools

and Equipment Required for Jacking

One Main Landing Gear V/heel 1D16

7-5. Lifting Nose Down Airplane 1D17

7-6.

Tools

and Equipment Required for Emergency Lifting 1D18

7-7. One Main Gear Retracted 1D19

7-8. Pneumatic Bag Lifting 1D21

7-9. Lifting Airplane

With

Straps 1D22

7-10.

Fuselage

and Wing Shoring 1D23

8-1.

Tools

and Equipment Required for Leveling 1E5

8-2. Positioning Level 1E6

8-3.

Tools

and Equipment Required for Weighing 1E8

8-4. Positioning Airplane on Scales 1E9

9-1. Minimum Turning Dimensions 1E14

9-2. Tum Limit - Tow Bar Attachment - Strut Extension 1E16

9-3. Towing Equipment 1E17

9-4. Weight Locations - Towing Attach Points 1E18

10-1. Parking Equipment 1E24

10-2. Control Lock 1E24

10-3. Mooring Equipment 1F1

10-4. Mooring Tie Down Points and External Surface Lock 1F3

11-1.

Identification

and Location, Exterior Placards 1F7

11-2.

Nose

Wheel Turn Limit Placard

Installation

1F13

11-3. Power Plant

Instruments

- Model 600 Only 1F14

11-4.

Airspeed

Indicator

- Model 600 Only 1F16

11-5. Power Plant

Instalments

- Model 601 Only 1F18

11-6.

Airspeed

Indicator

- Model 601 Only 1F20

11-7. Power Plant

Instruments

- Model 601P Only 1F22

11-8.

Airspeed

Indicator

- Model 601P Only 1F24

11-9. Powerplant Instruments,

602P

1G2

11-10.

Airspeed

Indicator,

602P/700P

1G3

11-11.

Manifold Pressure, Tachometer and Fuel

Level

Indicators 1G4

11-12.

Identification

and Location,

Interior

Placards 1G6

12-1.

Sen/ice

Points 1G14

12-2. Reservoir Capacities and Usable Weights 1G16

Introduction

Page-12

Issued: Junel, 1995 1 A1 3

AEROSTAR

AIRCRAFT

600/601/601P/602P/700P

MAINTENANCE

MANUAL

LIST OF ILLUSTRATIONS

(cont)

FIGURE NO.

SUBJECT

,

GRID

NO.

12-3. Fuel Drain Hose Connections 1G19

12-4. Oil Selection 1G22

12-5. Oil Filter Assembly 1G23

12-6. Hydraulic Reservoir, Accumulator and Brake Resen/oir 1H1,,

12-7. Tire Pressures 1H3

12-8. Batteries 1H4

12-9.

Alcohiol

Deice Reservoir 1H5

12-10.

Nose Landing Gear Service Points 1H7

12-11.

Main Landing Gear Service Points 1H10

12-12.

Dry Nitrogen Equipment for Sen/icing Main Landing

Gear Struts 1H10

12-13.

Oxygen System 1H11

12-14.

Lubrication Points 1H14

12-15.

Lubrication Chart (Landing Gear, Nose) 1H15

12-16.

Lubrication Chart (Doors, Emergency

Exit)

1H19

12-17.

Lubrication Chart

(Main

Landing Gear, Flap Tracks,

Doors,

Trim Tabs and Console) 1H21

12-18.

Lubrication Chart

(Flight

Controls) 1H23

12-19.

Suggested Cleaners 111

12-20.

Suggested Polish and Wax 112

12-21.

Suggested Plastic Polish 112

20-1. Cherrylock Rivet Removal 1111 '

20-2. Hose/Line Markings 1113

20-3. Flareless - Tube Fittings 1114

20-4. Maximum Distance

Between

Supports for Fluid Tubing 1115 .

20-5. Maximum Allowable Resistance Values 1116

20-6. Sealant Application -

Wire

Bundles and Connectors 1121

20-7. Sealant Curing

Information

1123

20-8. Sealant Applications 1J2

20-9. Sealant Filling of Cavities 1J4 •

20-10.

Fillets, Rivets, Nuts and Bolts Sealing 1J6

20-11.

Rework

of Damaged or Faulty Fillet 1J7

20-12.

Duct Sealing Methods 1J8

20-13.

Application vs

Material

Use 1J10

20-14.

Sealant Mixing Ratio - . 1J11

20-15.

Firewall

Sealing 1J13 •

20-16.

Finish

Coating Precaution Areas 1J16

20-17.

Spray

Patterns

1K3

20-18.

Improper

Spraying 1K5

20-19.

Proper and

Improper

Method 1K6

20-20.

Spraying Comers 1K6

21-1. Environmental Systems Schematic 2C1

21-2. Flow Control Assembly

(601P)

2C10

21-3. Pressurization Systems Distribution Components 2C14

21-4. Cabin Leak Test Set Up 2C19

21-5. Pneumatic System Schematic 2D3

1A14

Introduction

Page-13'

issued:

June

1,1995

AEROSTAR

AIRCRAFT

600/601/601P/602P/700P

MAINTENANCE

MANUAL

LIST OF ILLUSTRATIONS

(cont)

FIGURE NO.

SUBJECT

GRID

NO.

21-6. Pneumatic System Components 2D5

21-7. Pneumatic System Air Pumps 2D8

21-8. Pneumatic System Test Setup 2D15

21-9. Door Seal Pressure Switch Test Setup 2D21

21-fb.

Vent Fan Blower and Plenum Box Assembly 2E1

21-11.

R/H Distribution Duct Assembly 2E5

21-12.

L/H Distribution Duct Assembly 2E7

21-13.

Fan Blower

(Instrument

Panel Radios) 2E11

21-14.

Pressurization Controls 2E12

21-15.

Outflow and Safety Valve 2E15

21-16.

Nose Landing Gear Squat Switch 2E18

21-17.

Cabin Altitude Controller Resetting Procedure 2E21

21-18.

Heater,

Blower and Plenum Assemblies 2F5

21-19.

Combustion Air Blower Assembly 2F15

21-20.

Heater

Relays 2F18

21-21.

Spark Plugs 2F21

21-21

A.

Ground Electrode Fixture

2F22

21-22.

Heat

Duct Switch and Control 2G4

21-23.

Fuel Pump Assembly, Fuel Pressure Regulator and

Shutoff Valve 2G6

21-24.

Regulator and Shutoff Valve Test Setup 2G11

21-25.

Windshield Defrost Blower Assembly 2G12

21-26.

Air

Conditioning System 2G15

21-27.

Compressor

Mounted Sen/ice Valves

(York

Compressor) 2G19

21-28.

Evacuation Hookup 2G19

21-29.

Test Gauge and Manifold Set

2G22

21-30.

Manifold Set Operation

2G23

21-31.

Charging Hookup 2H1

21-32.

Charging Stand 2H4

21-33.

Positioning Sankyo Compressor

Internal

Parts 2H11

21-34.

Fabricated Dipsticks for Compressor

Oil Check 2H12

21-35.

Sankyo Compressor Mounting Angle 2H12

21-36.

Magnetic Clutch

(York

Compressor) 2H16

21-37.

Magnetic Clutch Assembly (Sankyo Compressor) 2H16

23-1.

VHF

Interconnecting Diagram (Collins) 2112

23-2.

VHF

250/251

Communications Transceiver

Interconnect

Wiring Diagram 2113

23-3.

VHF

System Locator 2115

23-4.

VHF

Transceivers and Audio Switching Panel 2117

2?>-5.

PWC-150 Power Converter Locator 2119

23-6.

VHF

COMM-1 Antenna 2121

23-7.

VHF

COMM-2 Antenna 2121

23-8. SB-10 Transceiver Interconnecting Diagram 2J3

Introduction

Page-14

issued:

June

1,1995

1A15

AEROSTAR

AIRCRAFT

600/601/601P/602P/700P

MAINTENANCE

MANUAL

LIST OF ILLUSTRATIONS

(cont)

FIGURE

NO.

SUBJECT

GRID NO.

23-9. SB-10 Transceiver Interconnecting and HF Reel .

Diagram 2J5

23-10.

HF Locator 2J7

23-11.

ASB-100A, HF Interconnecting Diagram 2J20

23-12.

ASB-100A. HF System Locator 2J21

23-13.

Fixed Antenna

Installation

2J23

23-14.

ELT

Installation

2K1

23-15.

Removal of Microptione Switcti 2K6

23-16.

AMR 350 Audio/Marker Panel Controls and

Indicators 2K8

23-17.

Audio/Marker Panel Interconnecting Diagram 2K12

23- 18. Static Disctiarge InsL (TYP) 2K15.

24- 1. AC System 3B18

24-2. Electrical System Locator 3B19

24-3. Jumper Strap

Installation

3B23

24-4. Master Electrical Panel 3C2

24-5. Power Circuit Breakers ' 3C6

24-6. Battery

Installation

3C8

24-7. Equipment Circuit Breakers 3C16

24- 8. Avionics Relay 3C18

25- 1. Seat Arrangement - Standard

Interior

3D4

) 25-2. Seat Arrangement - Executive

Interior

3D5

25-3. Seat Hardware 3D9

25-4. Recline Mectianism

(Left

Center and Left Rear Seats) 3D12

25-5. Recline Mectianism

(Rigtit

Side Seats) 3D13

25-6. Pilot Seat Break-Over Bracket 3D15 ,

25-7. Seat Back Armrest 3D17

25-8. Swivel Seat Break-Over Bracket and "Hydrolok" 3D19

25-9. Swivel Mectianism

3D20

25-10.

Table Assembly 3D21 ,

25-11.

Inertia

Reel (Cover Removed)

3D23

25-12.

Sun Visors

3D24

25-13.

Glarestiield Angle Bracket 3E1

25-14.

Armrest Panel

Installation

3E3

25-15.

Interior

Trim 3E6

25-16.

Application of Double Sided Tape

Attactiing Emergency Exit Window

Moulding 3E12

25-17.

Application of Double Sided Tape Attactiing

Cabin

Door Window Moulding 3E15;-

25-18.

Baggage Compartment Furnishings 3E16

25-19.

Standard Baggage Compartment Light 3E17

25-20.

Covered Baggage Compartment Light 3E18

)

Introduction

Page-15

-j g Issued: June

1,1995

AEROSTAR

AIRCRAFT

600/601/601P/602P/700P

MAINTENANCE

MANUAL

LIST OF ILLUSTRATIONS

(cont)

FIGURE NO.

SUBJECT

GRID

NO.

26-1. Fire Detector

3E24

26-2. Portable Fire Extinguisfier 3F1

27-1. Control Column Assembly 3F14

27-2. Aileron Control Linkage Sctiematic 3F18

27-3. Aileron

Idler

Arm, F.S.

146.80

3F22

27-4. Aileron Bellcrank, F.S.

64.78

3F23

27-5. Aileron Lower Bellcrank, F.S.

202.90

3F24

27-6. Aileron Upper Bellcrank, F.S.

202.90

3G1

27-7. Aileron Bellcrank, W.S.

153.00

3G2

27-8. Rudder Pedal Assembly 3G6

27-9. Rudder Control Linkage Sctiematic 3G8

27-10.

Rudder Torque Tube 3G11

27-11.

Rudder Bellcrank, F.S.

77.60

3G13

27-12.

Rudder Bellcrank, F.S.

97.00

3G14

27-13.

Rudder

Idler

Arm, F.S.

202.80

3G15

27-14.

Rudder

Idler

Arm, F.S.

330.90

3G16

27-15.

Rudder Torque Tube Free-Play Ctieck 3G18

27-16.

Rudder Trim Controls

3G20

27-17.

Elevator Control Linkage Schematic

3G22

27-18.

Elevator Fonward Torque Tube Assembly

3G24

27-19.

Elevator Aft Torque Tube 3H1

27-20.

Elevator Bellcrank, F.S.

64.87

3H4

27-21.

Elevator

Idler

Arm, F.S.

146.80

3H5

27-22.

Elevator

Idler

Arm, F.S.

202.80

3H6

27-23.

Elevator

Idler

Arm, F.S.

330.90

3H7

27-24.

Elevator Torque Tube Free-Play Check 3H8

27-25.

Elevator Trim Controls 3H11

27-26.

Flap Position Transmitter (L.

Wing)

3H15

27-27.

Flap Rigging Check 3H16

27-28.

Linkage Carry-Through

Boots.

F.S.

176.88

(TYP.)

3H20

27-29.

Stall Waming System

(700P

Only)

3H23

27-30.

Lift

Transducer Force Applicator Kit 311

28-1. Fuel System Schematic 3111

28-1 a. Fuel System Schematic for Option

#260

3111

28-2. Component Location 3112

28-3. Fuel System,

Detail

A, B, C and D 3113

28-4. Fuel Leak Size

Patterns

: 3120

28-5. Fuel Leak Evaluation 3121

28-6. Pull Force Measurement

(Shaw

Aero Filler Cap Only) 3123

28-7. Control Station and Manometer Setup 3J1

28-8. Wing Tank - As Viewed From Top 3J4

28-9.

Vent

System 3J7

28-10.

Fuselage Fuel Tank 3J9

28-11.

Control Station and Manometer Setup, Fuselage

Tank Pressure Test 3J12

Introduction

Page-16

Issued: June

1,1995

1A17

AEROSTAR

AIRCRAFT

600/601/601P/602P/700P

MAINTENANCE

MANUAL

LIST OF ILLUSTRATIONS

(cont)

FIGURE NO.

SUBJECT

GRID

NO.

28-12.

Fuel Sumps (A/F 0001

-0485)

3J14

28-13.

Fuel Sumps (A/F

0486

& Up) 3J17

28-14.

Boost

Pump, Filter, Flow Transducer and Sump

Drain Valve 3J23

28-15.

Signal Conditioner 3K8 '

29-1. Hydraulic System Schiematic 4B10

29-2. Main Hydraulic Power Components - Locations

and

Identification

4B12

29-3. Component Locator (Ctianging Fluid) 4B17

29-4. Hydraulic Reservoir, Pressure Regulator and

Relief Valve

4B23

29-5. Hydraulic Stiutoff Valve 4C1

29-6. Engine Driven Hydraulic Pump and Ground

403' r.

Service Unit Connection 403' r.

29-7. Pressure Regulator and Relief Valve 4C5 '

29-8. Accumulator 4C8

29-9. Auxiliary Hydraulic Sctiematic 4C11

29-10.

Electrical Component Location and Sctiematic 4C12

29-11.

Auxiliary Hydraulic Pump

Installation

4C20

30-1. Surface Deicing System 4D14

30-2.

Installing

Deicer Boot 4D16 -

30-3. Surface Deicing System Timer 4D18

30-4. Deice Components in Left Wheel

Well

4D19

30-5. Test Pressure Gauge

Installation

4D20

30-6.

Pitot

Head

4D22

30-7.

Alcohol

Shutoff Valve

4D24

30-8.

Alcohol

Windshield Deicing System 4E3

30-9.

Alcohol

Pump 4E5

30-10.

Electric Windshield

Anti-Ice

Panel 4E8

30-11.

Detail

of Electric Windshield

Anti-Ice

Panel 4E8 '

30-12.

Propeller Deicing System 4E11

30-13.

Placement of Deicer Onto Propeller Blade 4E13

30-14.

Application of Filler/Positioning Nylon Strap 4E14

30-15.

Rolling Deicer 4E15

30-16.

Area For Use of

Metal

Stitcher 4E16

30-17.

Installation

of Strap Retainer 4E17

30-18.

Lead Strap Connections/Cushion

Material

Installation

4E18

30-19.

Brush

Block Alignment 4E19

30-20.

Propeller Deicing System Timer 4E21

32-1. Landing Gear Hydraulic System Schematic 4F17 •

32-2. Main Landing Gear Door and Linkage

4F20

32-3. Rigging Tool 2

4F22

32-4. Main Landing Gear Door Seal

Installation

4F22

Introduction

Page-17

•^yy-^g

Issued: June

1,1995

This manual suits for next models

4

Table of contents