London Emblem Ltd., 4 Sherwood Road, Aston Fields Industrial Estate, Bromsgrove, Worcestershire, B60 3DR

T

el:

+44

(0)1329

822900

•

Fax:

+44

(0)1329

82900

•

Email:

[email protected]om

•

ww

w

.londonemblem.com

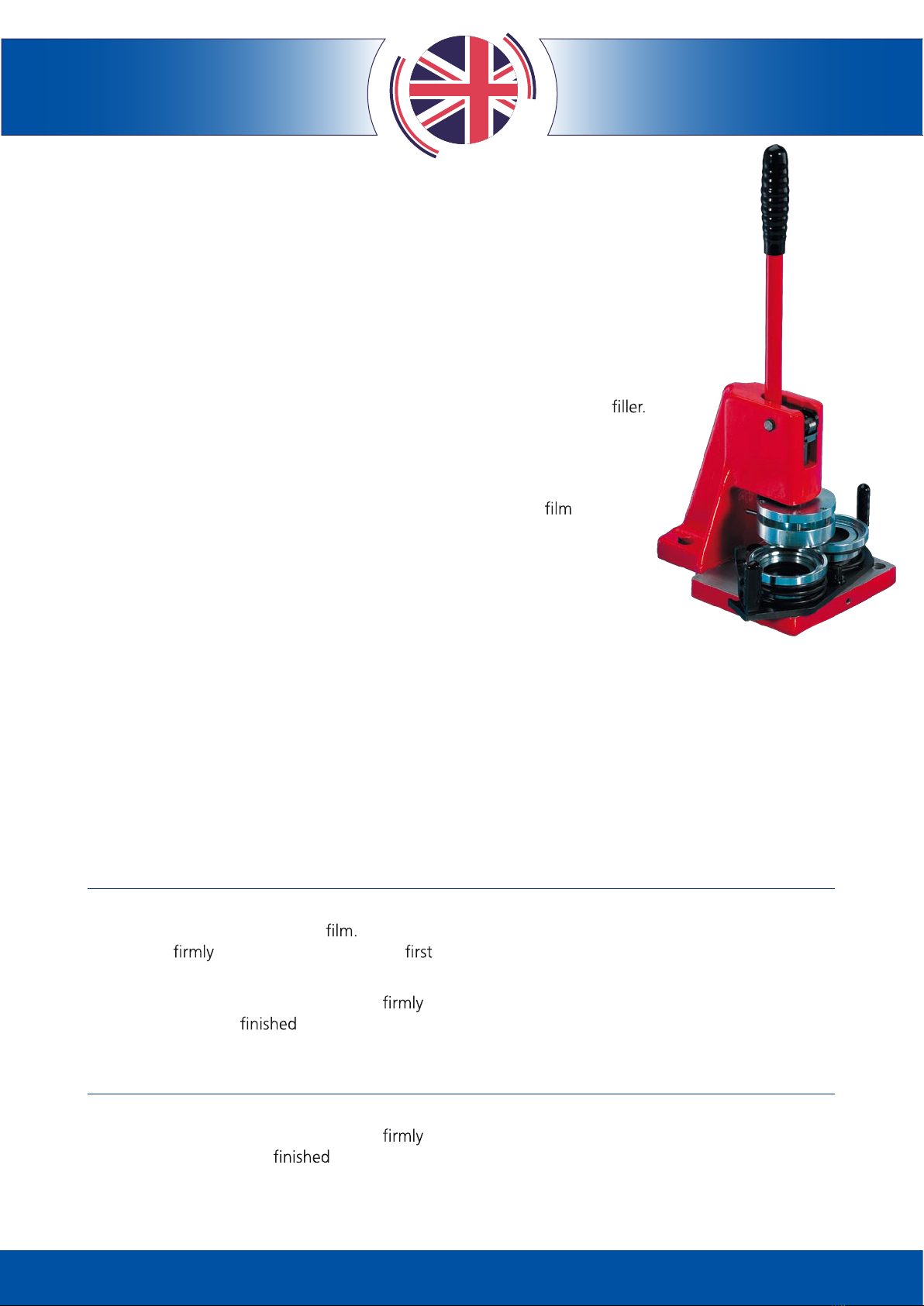

TROUBLESHOOTING

If a badge does not make up properly, check:

• That only one top or plastic seal has been used. If two tops or seals are stuck in the top die, they

can be ejected by operating the second stage of badgemaking with the die empty.

• That pressure has been used on the second stage of badgemaking. To ensure perfect

crimping of the badge, pull handle towards you.

CHANGING THE DIE

• Remove bottom die set from base of machine by undoing grub screw (5/29) and lifting out hinge

pin (5/32). Die set can now be lifted o.

• Locate allen screw in underpart of top die and remove by turning in a clockwise direction with allen

key provided.

• Take the required size top die and with obtruding pin towards back of machine, locate the die onto

shaft and ensure that locating pin on top of the die is into the hole at the end of the shaft

and tighten.

• Place required size bottom die set onto base of machine. Locate hinge pin (5/32) through the hole

in the base plate into base of machine. Push down and hold whilst tightening retaining grub

screw (5/29). Do not overtighten.

MAINTENANCE

As with all production machinery, the working surfaces of the machine should be kept clean and free

from dust. Only the very minimum of lubrication, using grease, is advised and this should be applied

only to the surfaces of the shaft assembly and roller on base of handle assembly. It is important to

regularly tighten all screws and bolts. Do not overtighten.

INSTRUCTIONS FOR CHANGING BLADES ON LONDON EMBLEM AND

BADGEWORX CUTTERS

• Turn rotary cutter over.

• Unlock screw in base of main shaft using allen key provided.

• Retract adjustment shaft complete with blade so that grub screw holding retaining pin is accessible.

• Unlock grub screw holding pin.

• Remove blade with retaining pin from the shaft.

• Replace new blade, with side facing inwards, onto retaining pin, relocate into adjustment shaft

and lock down with grub screw, making sure that cutting blade rotates freely.

• Reset adjustment shaft to size required.