Aerotec 2005700 User manual

MINI HVLP paint spray

MINI HVLP paint sprayMINI HVLP paint spray

MINI HVLP paint spray

gun

gun gun

gun

English

© pro)SALES GmbH

pro)SALES GmbH pro)SALES GmbH

pro)SALES GmbH -

--

-

Ferdinand

FerdinandFerdinand

Ferdinand-

--

-Pors he

Pors hePors he

Pors he-

--

-Straße 16

Straße 16 Straße 16

Straße 16 -

--

-

63500 Seligenstadt

63500 Seligenstadt63500 Seligenstadt

63500 Seligenstadt

Art. no. 2005700

Art. no. 2005700Art. no. 2005700

Art. no. 2005700

in a plasti ase

in a plasti asein a plasti ase

in a plasti ase

in l. 3 + 6

in l. 3 + 6in l. 3 + 6

in l. 3 + 6

mm ollet

mm ollet mm ollet

mm ollet

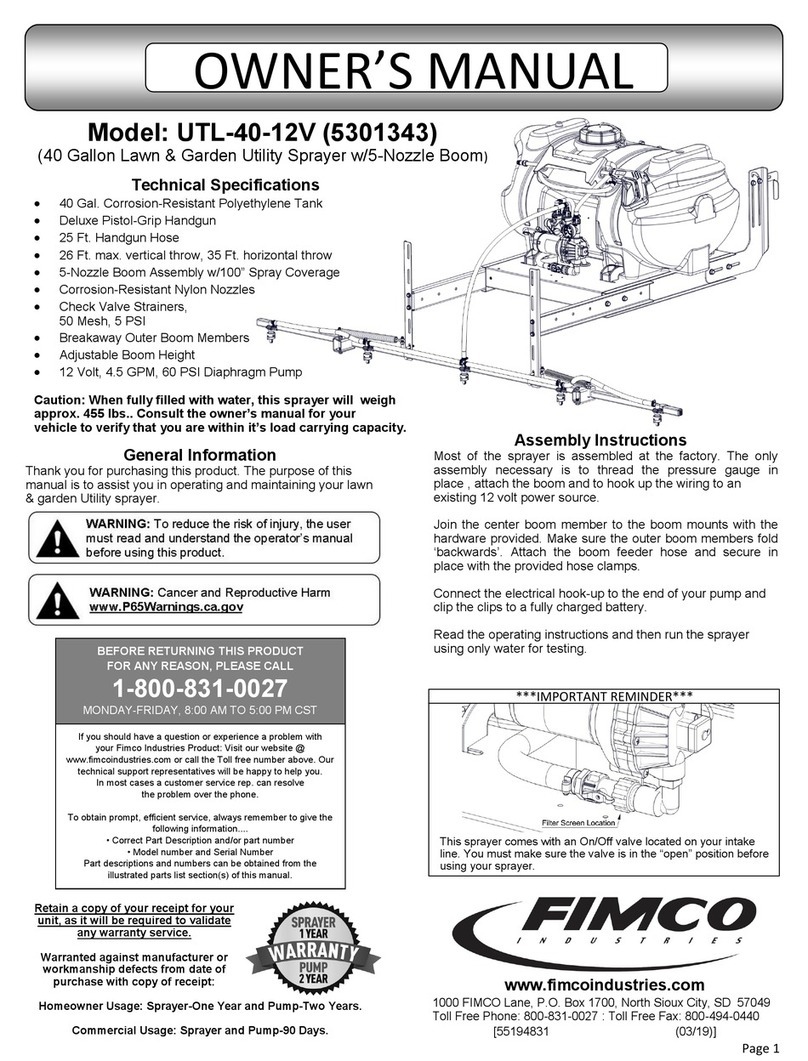

Labelling:

Labelling:Labelling:

Labelling:

Produ

ProduProdu

Produ t safety

t safety t safety

t safety –

––

–

prohibition signs:

prohibition signs:prohibition signs:

prohibition signs:

A ording to

European Union

standards

Prohibition sign

Wearing loose-

fitting lothes is

prohibited!

Wearing jewellery

et . is prohibited.

Warning

Warning Warning

Warning –

––

–

mandatory signs:

mandatory signs:mandatory signs:

mandatory signs:

ATTENTION/WAR

NING

Observe

operating

instru tions

Wear hearing

prote tion

Wear prote tive

goggles

Environment safety:

Environment safety:Environment safety:

Environment safety:

Do not dispose

of waste into

the environment

Cardboard pa kaging an be

returned to the designated

re y ling points.

Damaged and/or disposable

ele tri or ele troni

equipment must be returned

to the designated re y ling

points.

EN

ENEN

EN Complaints/spare-part orders will be pro essed qui kly and

unbureau rati ally. Please use the following onta t details

Phone: +49 61 82 / 99387

Phone: +49 61 82 / 99387Phone: +49 61 82 / 99387

Phone: +49 61 82 / 99387-

--

-

0

00

0

Fax: +49 61 82 /99387

Fax: +49 61 82 /99387 Fax: +49 61 82 /99387

Fax: +49 61 82 /99387 -

--

-

20

2020

20

E-mail:

info@aerote .info

info@aerote .infoinfo@aerote .info

info@aerote .info

Please read this operating manual arefully

Please read this operating manual arefully Please read this operating manual arefully

Please read this operating manual arefully

prior to ommissioning the devi e.

prior to ommissioning the devi e.prior to ommissioning the devi e.

prior to ommissioning the devi e.

EC D

EC DEC D

EC De laration of Conformity

e laration of Conformity e laration of Conformity

e laration of Conformity

Herewith, we,

pro)SALES GmbH

Ferdinand-Pors he-Straße 16

63500 Seligenstadt

Germany

de lare that the devi es des ribed below, on the basis of their design and onstru tion,

as well as in the version that we have pla ed on the market, orresponds with the

relevant fundamental health and safety requirements of the EC dire tives.

This ertifi ate be omes void if the devi es are modified without our approval.

This ertifi ate be omes void if the devi es are modified without our approval.This ertifi ate be omes void if the devi es are modified without our approval.

This ertifi ate be omes void if the devi es are modified without our approval.

Devi e designation:

Aero MINI HVLP paint spray gun Art. no. 2005700

Date/Manufa turer signature: 16/11/2010

Relevant EC dire tive:

Relevant EC dire tive: Relevant EC dire tive:

Relevant EC dire tive:

2006/42 EG

Applied harmonised standards:

Applied harmonised standards:Applied harmonised standards:

Applied harmonised standards:

EN 792; EN 50144

Devi e:

MINI HVLP paint spray gun

Spe ifi ations:

MINI HVLP paint spray gun

Operating pressure:

Operating pressure: Operating pressure:

Operating pressure:

1,5

1,5 1,5

1,5 -

--

-

max.

max.max.

max.3

33

3

bar

barbar

bar

Air onsumption:

Air onsumption: Air onsumption:

Air onsumption:

120 l/min

120 l/min120 l/min

120 l/min

Air

Air Air

Air onne tion:

onne tion:onne tion:

onne tion:

SK

SKSK

SK

Gravity up volume:

Gravity up volume: Gravity up volume:

Gravity up volume:

125

125125

125

mm

mmmm

mm

Suppl.hose diameter:

Suppl.hose diameter:Suppl.hose diameter:

Suppl.hose diameter:

6 mm

6 mm6 mm

6 mm

Arti le no. 2005700

Arti le no. 2005700Arti le no. 2005700

Arti le no. 2005700

Delivery s ope:

1 x HVLP paint spray gun / 0.8 mm nozzle

1 x Nozzle set 0.5 mm

1 x Operating manual

General safety information:

Safety information!

Safety information!Safety information!

Safety information!

Fa

FaFa

Failure to observe the

ilure to observe the ilure to observe the

ilure to observe the

following information may

following information may following information may

following information may

lead to injuries.

lead to injuries.lead to injuries.

lead to injuries.

Read the pneumati tool

instru tions very arefully prior to

ommissioning.

All operators must be fully and

suffi iently informed on how to

operate pneumati tools.

Only qualified and trained

te hni ians are allowed

to arry out servi ing and repair

work.

Paint spray guns may only be

used in a well ventilated working

environment. During paint

spraying, always wear a paint

mask.

Make sure that you have a stable

and se ure standing position prior

to using the tool.

Che k the pneumati hose and all

onne tions regularly for signs of

wear or damage.

Hold the tool by the handle only,

never by the hose.

Never ex eed the re ommended

maximum operating pressure (3

bar)

The tool is neither earthed nor

ele tri ally insulated.

Never use the tool where it

ould ome into onta t with

ele tri ity.

It is advisable to dis onne t the

air supply when repla ing paint

spray nozzles; The release must

not be a tuated during this

pro ess.

If you noti e any malfun tions or

irregular power prior to use,

stop using the tool immediately

and

maintain or repair the tool.

Do not use overly long hoses

whi h may pose tripping hazards.

Read the ompressor operating

manual and observe the safety

instru tions for operating the

ompressor.

ALWAYS use ertified prote tive

goggles and hearing prote tion.

Take off wat hes, rings or other

interfering items.

Loose lothing or jewellery ould

get entangled in the air

ompressor or the air devi e

whi h ould ause severe

injuries.

The trigger must not be

operated when the devi e is

onne ted to the air supply.

Dis onne t the air supply from

the devi e when it is not in use.

NEVER repla e a essory parts

and NEVER exe ute maintenan e

work when the devi e is

onne ted to the air supply.

Maintain the devi e thoroughly

and follow the instru tions on

lubri ation and maintenan e.

Do not damage the hoses and

onne tors by arrying the

devi e by the hose or

dis onne ting the hose by

tugging from the air supply.

Prevent the hose from being

exposed to heat or sharp edges.

The hose should be repla ed if it

is damaged or worn.

NEVER operate the devi e with

NEVER operate the devi e with NEVER operate the devi e with

NEVER operate the devi e with

an air pressure ex eeding 3 bar.

an air pressure ex eeding 3 bar.an air pressure ex eeding 3 bar.

an air pressure ex eeding 3 bar.

Use a pressure regulator that

redu es the pressure to 3 bar.

Operate the devi e at a safe

distan e from people and animals

AT ALL TIMES.

Prior to start-up:

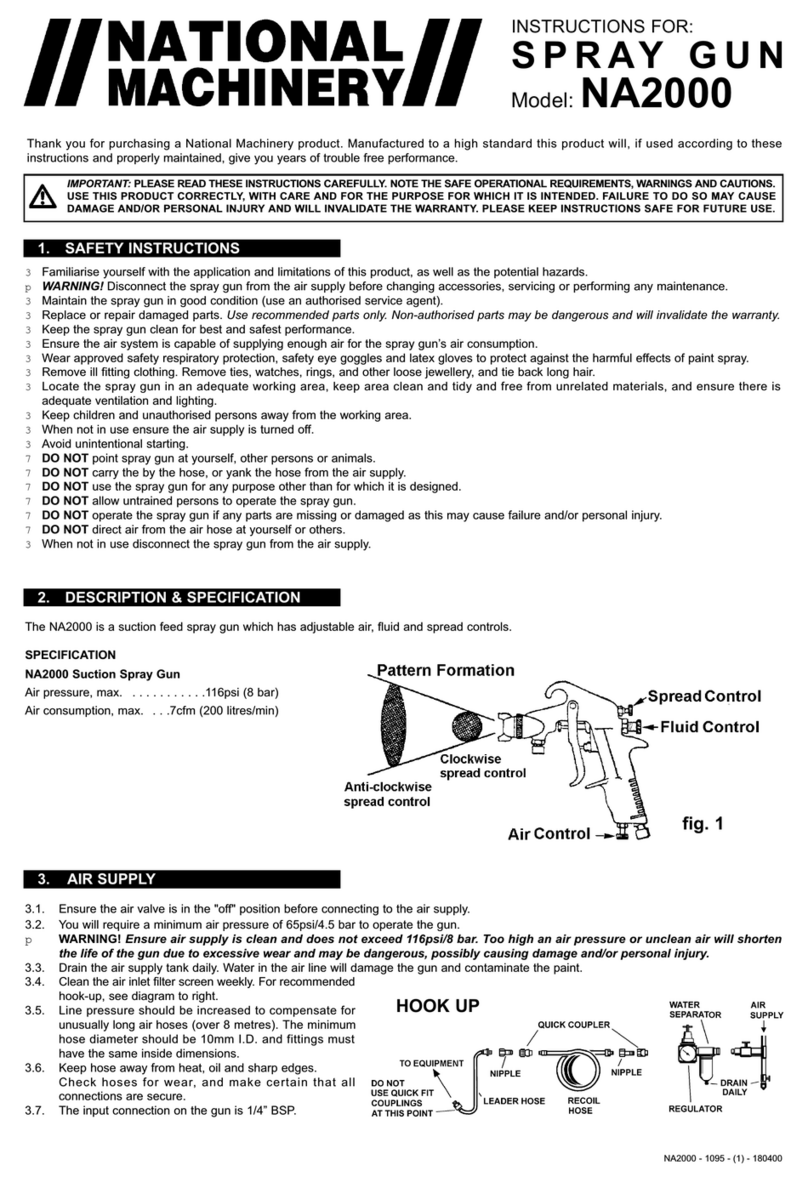

Air supply:

Air supply:Air supply:

Air supply:

Make sure to use a water trap to

Make sure to use a water trap to Make sure to use a water trap to

Make sure to use a water trap to

ensure an optimum spray pattern

ensure an optimum spray patternensure an optimum spray pattern

ensure an optimum spray pattern

Assembly:

Assembly:Assembly:

Assembly:

Ensure that the nozzle is properly

Ensure that the nozzle is properly Ensure that the nozzle is properly

Ensure that the nozzle is properly

atta hed and slightly lubri ate the

atta hed and slightly lubri ate the atta hed and slightly lubri ate the

atta hed and slightly lubri ate the

sealings after leaning the spray

sealings after leaning the spray sealings after leaning the spray

sealings after leaning the spray

gun to keep the seal

gun to keep the sealgun to keep the seal

gun to keep the sealing rubber

ing rubber ing rubber

ing rubber

smooth.

smooth.smooth.

smooth.

Safety information!

Safety information!Safety information!

Safety information!

Wear prote tive goggles!

Wear prote tive goggles!Wear prote tive goggles!

Wear prote tive goggles!

Wear hearing prote tion!

Wear hearing prote tion!Wear hearing prote tion!

Wear hearing prote tion!

Make sure that only ompressed

air free of ondensate is used for

operation.

It is suffi ient to slot in a water

trap filter.

Start the air ompressor.

The maximum operative air

pressure for the tool is 6.3 bar;

The operative pressure an be

adjusted via a pressure regulator

at your ompressor.

We re ommend setting the

operating pressure while test

spraying to ensure optimum

settings.

This way, pressure differen es

an be ompensated for.

Maintenan e and are:

Cleaning

CleaningCleaning

Cleaning:

::

:

Complying with the maintenan e

instru tions spe ified in this

se tion ensures a long servi e

life and faultless operation of

this high quality produ t.

Carefully lean and maintain the

paint spray gun immediately

after paint spraying.

Cleaning the paint spray gun

ensures faultless handling when

next using it.

Do not use hydro arbon halogen

Do not use hydro arbon halogen Do not use hydro arbon halogen

Do not use hydro arbon halogen

solvents (1.1.1 Tri hloromethyl,

solvents (1.1.1 Tri hloromethyl, solvents (1.1.1 Tri hloromethyl,

solvents (1.1.1 Tri hloromethyl,

Chloromethane et .) as these

Chloromethane et .) as these Chloromethane et .) as these

Chloromethane et .) as these

lead to hazardous hemi al

lead to hazardous hemi al lead to hazardous hemi al

lead to hazardous hemi al

rea tions with ertain

rea tions with ertain rea tions with ertain

rea tions with ertain materials

materials materials

materials

of the paint spray gun.

of the paint spray gun.of the paint spray gun.

of the paint spray gun.

Caution!

Caution!Caution!

Caution!

Do not immerse the paint spray

Do not immerse the paint spray Do not immerse the paint spray

Do not immerse the paint spray

gun ompletely in a solvent bath

gun ompletely in a solvent bath gun ompletely in a solvent bath

gun ompletely in a solvent bath

as this may destroy the

as this may destroy the as this may destroy the

as this may destroy the

sealings.

sealings.sealings.

sealings.

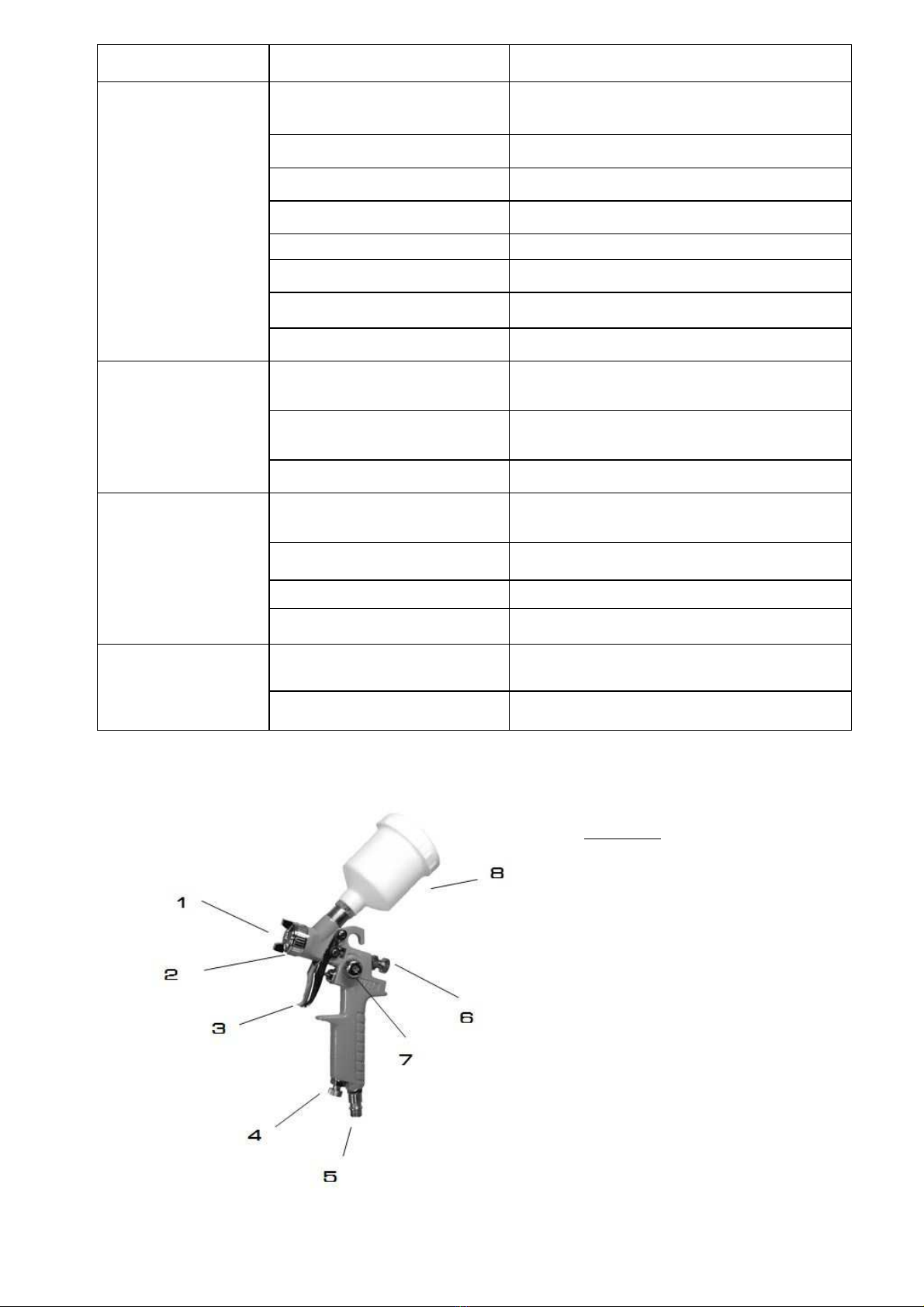

Problem:

Problem:Problem:

Problem:

Possible auses:

Possible auses:Possible auses:

Possible auses:

Corre tive a tions:

Corre tive a tions:Corre tive a tions:

Corre tive a tions:

The paint spray

jet is interrupted

or intermittent:

1

Insuffi ient paint in

the ontainer: Fill it.

2.

Holding the spray

gun at an angle: Change angle.

3.

Blo ked paint line:

Clean it.

4.

Loose / damaged

nozzle:

Tighten or repla e the nozzle set.

5. Ex essive vis osity: Redu e vis osity.

6. Blo ked opening in

the over: Clean it.

7.

Worn needle sealing

or loose ore:

Repla e and adjust the needle.

8. Insuffi ient operating

pressure (flow

pressure):

In rease operating pressure (flow

pressure).

In omplete spray

pattern:

1.

A

ir head

ontaminated or

damaged:

Clean or repla e the omplete

nozzle set.

2.

Paint is sti king to

the nozzle or parts

are damaged:

Clean or repla e the omplete

nozzle set.

3.

Nozzle needle

damaged:

Repla e omplete nozzle set.

Irregular paint

pattern with

drops:

1

Nozzle

ontaminated or

damaged:

Clean or repla e the omplete

nozzle set.

2

In rease operating

pressure (flow

pressure).

In rease operating pressure (flow

pressure).

3 Ex essive vis osity: Redu e vis osity.

4 Contaminated air

head:

Clean air head.

Irregular material

a umulation:

1

Ex essive operating

pressure:

Redu e operating pressure (flow

pressure).

2.

Paint blo ks the air

head and the nozzle: Clean it.

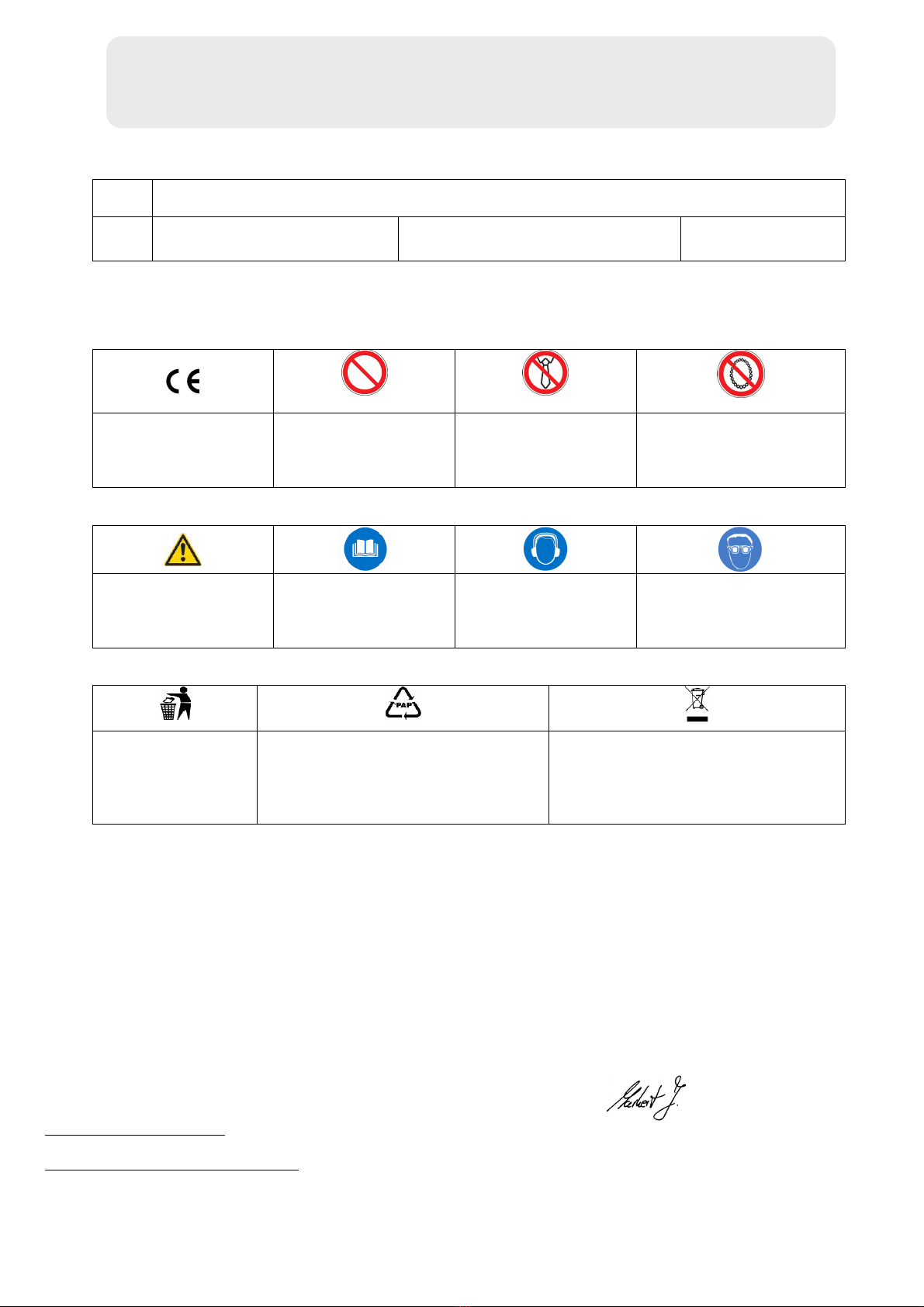

Details:

Details:Details:

Details:

1. Nozzle head

2. Nozzle thread

3. Operating lever

4. Fine adjustment

5. SK onne tor

6. Paint flow ontrol

7. Air flow ontrol

8. 125 ml gravity up

Other manuals for 2005700

1

This manual suits for next models

1

Other Aerotec Paint Sprayer manuals

Popular Paint Sprayer manuals by other brands

WAGNER

WAGNER CONTROL PRO 250 M owner's manual

Titan Tool

Titan Tool 1140ix owner's manual

AIRLESSCO

AIRLESSCO LP 400 Service & operation manual

NATIONAL MACHINERY

NATIONAL MACHINERY NA2000 instruction manual

Black & Decker

Black & Decker BDPH400 instruction manual

WAGNER

WAGNER TempSpray H126 operating manual