TECHNICAL MANUAL

IL-246-BIL-246-B

IL-246-BIL-246-B

IL-246-B

(Replaces IL-246-A)

January - 2008

IMPORIMPOR

IMPORIMPOR

IMPORTT

TT

TANTANT

ANTANT

ANT: Before using this equipment,: Before using this equipment,

: Before using this equipment,: Before using this equipment,

: Before using this equipment,

carefully read SAFETY PRECAUTIONS,carefully read SAFETY PRECAUTIONS,

carefully read SAFETY PRECAUTIONS,carefully read SAFETY PRECAUTIONS,

carefully read SAFETY PRECAUTIONS,

starting on page 1, and all instructions instarting on page 1, and all instructions in

starting on page 1, and all instructions instarting on page 1, and all instructions in

starting on page 1, and all instructions in

this manual. Keep this Tthis manual. Keep this T

this manual. Keep this Tthis manual. Keep this T

this manual. Keep this Technical Manualechnical Manual

echnical Manualechnical Manual

echnical Manual

for future reference.for future reference.

for future reference.for future reference.

for future reference.

ITW RANSBURGITW RANSBURG

ITW RANSBURGITW RANSBURG

ITW RANSBURG

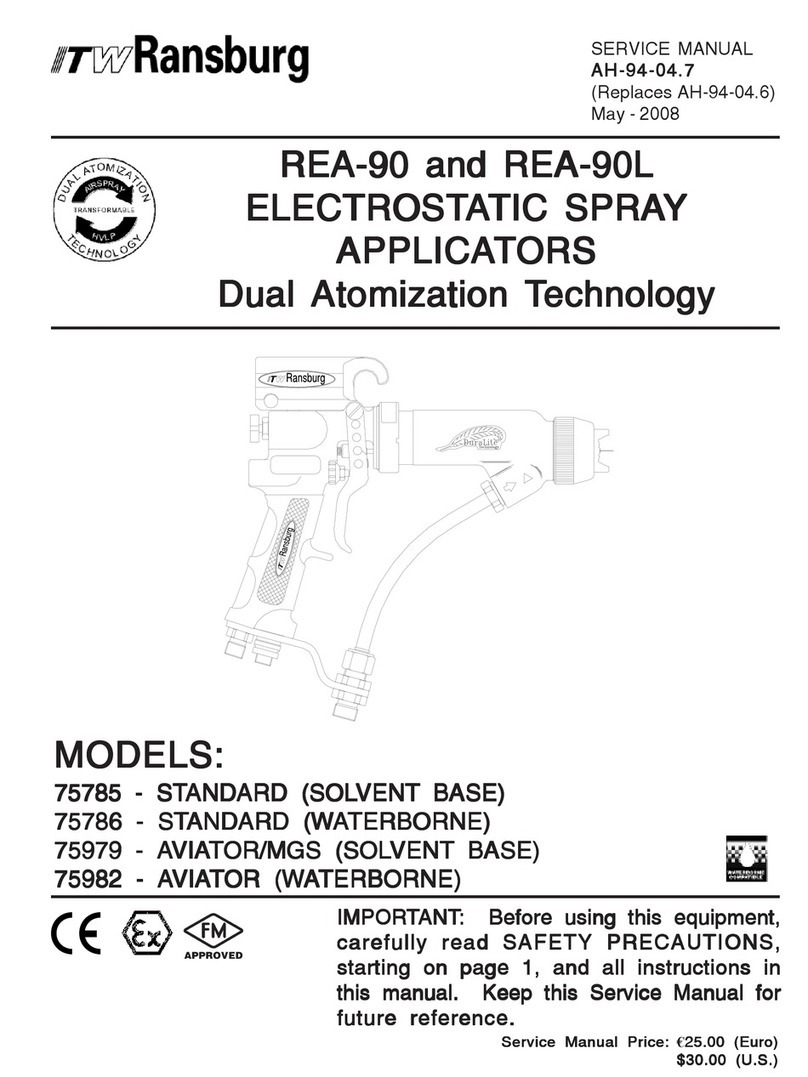

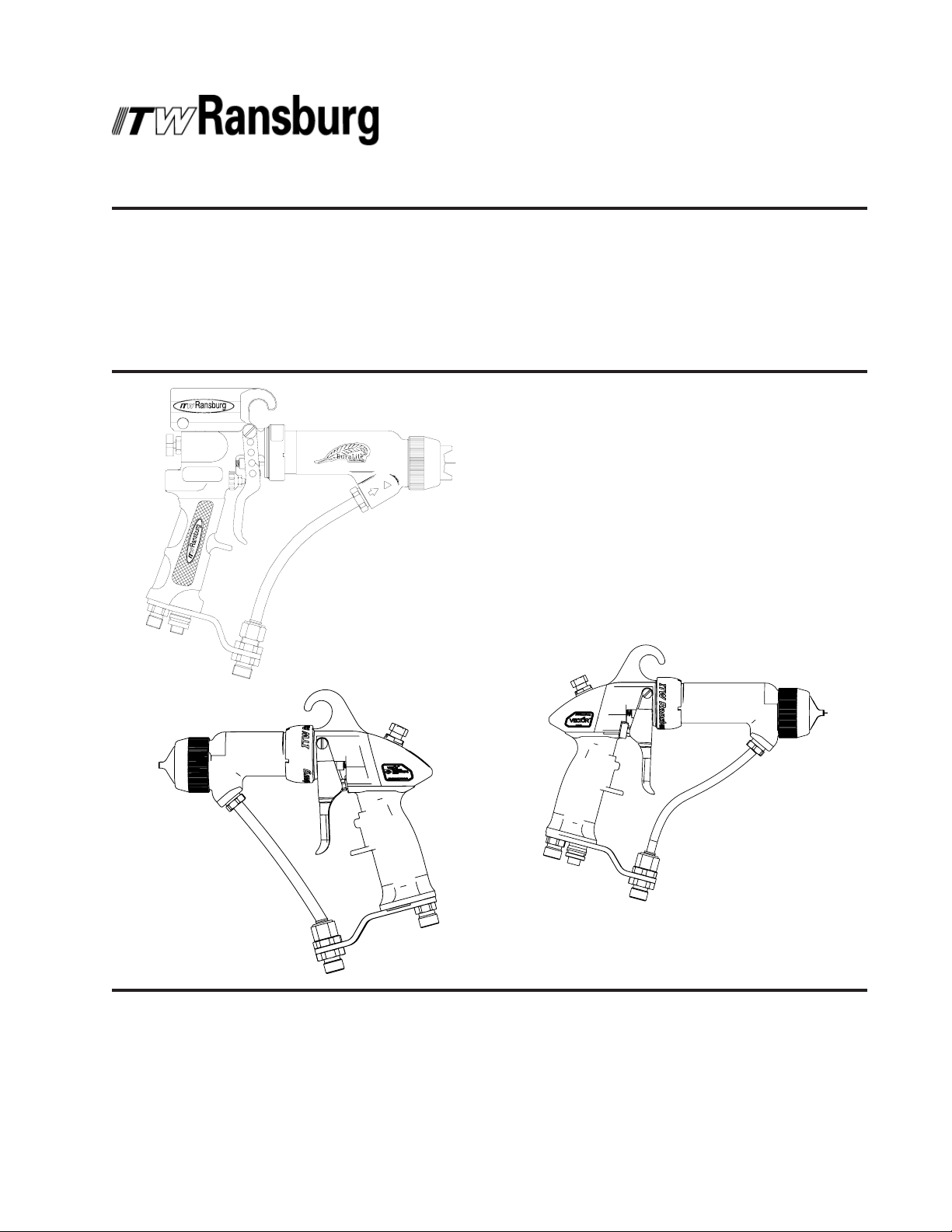

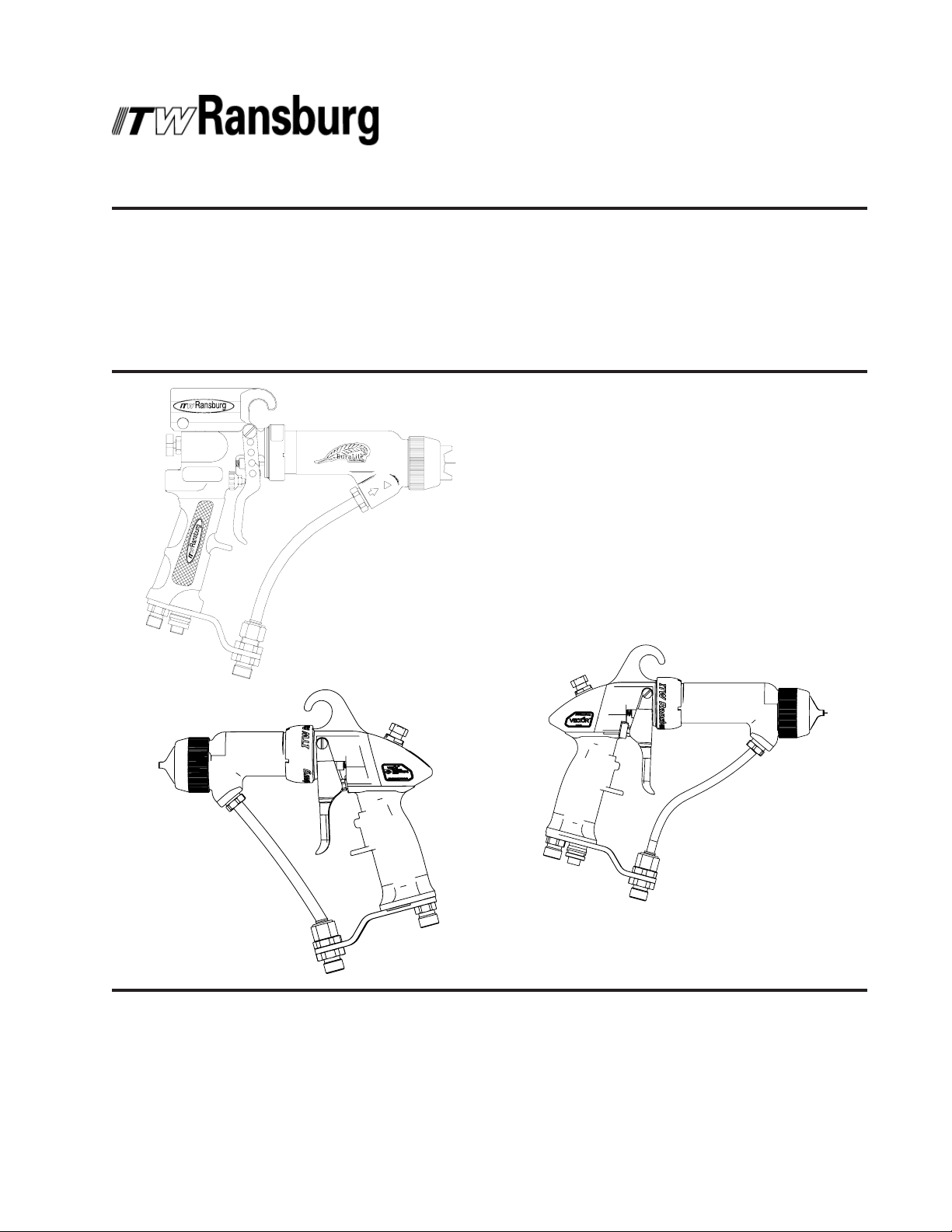

REA™ AND VECTREA™ AND VECT

REA™ AND VECTREA™ AND VECT

REA™ AND VECTOR™OR™

OR™OR™

OR™

APPLICAAPPLICA

APPLICAAPPLICA

APPLICATT

TT

TORSORS

ORSORS

ORS

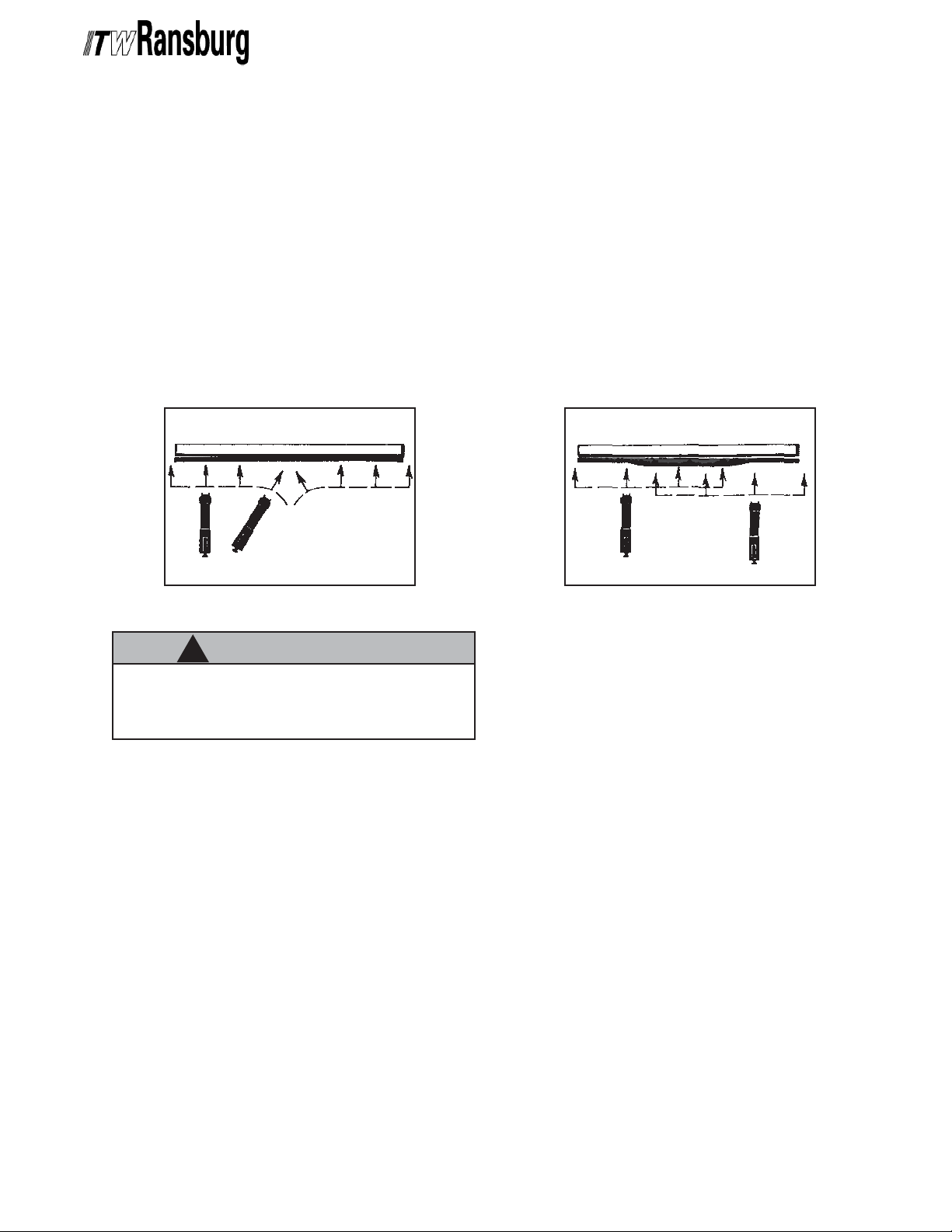

ELECTROSTELECTROST

ELECTROSTELECTROST

ELECTROSTAA

AA

ATICTIC

TICTIC

TIC

SPRASPRA

SPRASPRA

SPRAYY

YY

Y

TECHNIQUESTECHNIQUES

TECHNIQUESTECHNIQUES

TECHNIQUES

TT

TT

Technical Manual Price:echnical Manual Price:

echnical Manual Price:echnical Manual Price:

echnical Manual Price: €15.00 Euro)15.00 Euro)

15.00 Euro)15.00 Euro)

15.00 Euro)

$20.00 (U.S.)$20.00 (U.S.)

$20.00 (U.S.)$20.00 (U.S.)

$20.00 (U.S.)