Aerotech Automation1 iPC Series User manual

Revision 1.00

Automation1 iPC Intelligent Industrial PC

HARDWAREMANUAL

GLOBALTECHNICALSUPPORT

Go to https://support.aerotech.com/servicedesk/customer/portal/1 for information

and support about your Aerotech, Inc. products. The website supplies software,

product manuals, Help files, training schedules, and PC-to-PC remote technical support.

If necessary, you can complete Product Return (RMA) forms and get information about

repairs and spare or replacement parts. To get help immediately, contact a service office

or your sales representative. Include your customer order number in your email or have

it available before you call.

This manual contains proprietary information and may not be reproduced, disclosed, or

used in whole or in part without the express written permission of Aerotech, Inc.

Product names mentioned herein are used for identification purposes only and may be

trademarks of their respective companies.

Copyright © 2020, Aerotech, Inc., All rights reserved.

Table of Contents

Automation1 iPC Intelligent Industrial PC 1

Table of Contents 3

List of Figures 4

List of Tables 4

EU Declaration of Conformity 5

Agency Approvals 7

Chapter 1: Automation1 iPC 9

1.1. Specifications 10

1.2. Remote Server Operation 12

1.3. Dimensions 14

1.4. AC Power Setting 18

1.5. DVIMonitor Configuration (-R103, -R402, -DT01 PCOptions) 18

1.6. Environmental Specifications 18

Appendix A: Warranty and Field Service 19

Appendix B: Revision History 21

Index 23

www.aerotech.com 3

Automation1 iPC Hardware Manual Table of Contents

List of Figures

Figure 1-1: -CC04/-CC05 Connector View (typical) 12

Figure 1-2: -DT01 Connector View (typical) 12

Figure 1-3: -R103 Connector View (typical) 13

Figure 1-4: -R402 Connector View (typical) 13

Figure 1-5: Desktop Computer Dimensions (-DT01) 14

Figure 1-6: Control Cabinet Dimensions (-CC04/-CC05) 15

Figure 1-7: 4U Rack Mount Chassis Dimensions (-R402) 16

Figure 1-8: 1U Rack Mount Chassis Dimensions (-R103) 17

List of Tables

Table 1-1: Ordering Options 9

Table 1-2: Automation Motion Server Specifications (Control Cabinet / Desktop PC) 10

Table 1-3: Automation Motion Server Specifications (Rack Mount PCs) 11

Table 1-4: BIOSSettings 18

Table 1-5: Environmental Specifications 18

List of Figures Automation1 iPC Hardware Manual

4 www.aerotech.com

EU Declaration of Conformity

Manufacturer Aerotech, Inc.

Address 101 Zeta Drive

Pittsburgh, PA 15238-2811

USA

Product Automation1 iPC

Model/Types Control Cabinet PCs:-CC04, -CC05

Desktop PC:-DT01

1URack Mounted PC:-R013

4URack Mounted PC:-R402

This is to certify that the aforementioned product is in accordance with the applicable requirements of

the following Directive(s):

2014/30/EU Electromagnetic Compatibility (EMC)

2014/35/EU Low Voltage Directive

EU 2015/863 Directive, Restricted Substances

and has been designed to be in conformity with the applicable requirements of the following Standard(s)

when installed and used in accordance with the manufacturer’s supplied installation instructions.

-CC04/-CC05 (Control Cabinet PCs)

EN 55011: 2009 +A1: 2010 (Group 1, Class A)

EN 55032: 2015 +AC: 2016 (Class A)

CISPR 32: 2015 +COR1: 2016 (Class A)

EN 61000-6-4: 2007 +A1:2011

EN 61000-3-2: 2014 (Class D) / EN 61000-3-3:2013

EN 55024: 2010 +A1: 2015 / EN 61000-6-2: 2005 +AC:2005

EN 61000-4-2:2009 / EN 61000-4-3: 2006 +A1: 2008 +A2: 2010

EN 61000-4-4:2012 / EN 61000-4-5: 2014 / EN 61000-4-6: 2014 +AC:2015

EN 61000-4-8:2010 / EN 61000-4-11:2004

-DT01 (Desktop PC)

EN 55011: 2009 +A1: 2010 (Group 1, Class A)

EN 55032: 2015 +AC: 2016 (Class A)

EN 61000-6-4: 2007 +A1:2011

CISPR 32: 2015 +COR1: 2016 (Class A)

EN 61000-3-2: 2014 (Class A) / EN 61000-3-3:2013

EN 55024: 2010 +A1: 2015 / EN 61000-6-2: 2005 +AC:2005

EN 61000-4-2:2009 / EN 61000-4-3: 2006 +A1: 2008 +A2: 2010

EN 61000-4-4:2012 / EN 61000-4-5: 2014 / EN 61000-4-6: 2014 +AC:2015

EN 61000-4-8:2010 / EN 61000-4-11: 2004 +A1:2017

www.aerotech.com 5

Automation1 iPC Hardware Manual EU Declaration of Conformity

-R103 (1URack Mounted PC), -R402 (4URack Mounted PC)

EN 55011: 2009 +A1: 2010 (Group 1, Class A)

EN 55032: 2015 +AC: 2016 (Class A)

EN 61000-6-4: 2007 +A1:2011

EN 61000-3-2: 2014 (Class D) / EN 61000-3-3:2013

EN 55024: 2010 +A1: 2015 / EN 61000-6-2: 2005 +AC:2005

EN 61000-4-2:2009 / EN 61000-4-3: 2006 +A1: 2008 +A2: 2010

EN 61000-4-4:2012 / EN 61000-4-5: 2014 / EN 61000-4-6: 2014 +AC:2015

EN 61000-4-8:2010 / EN 61000-4-11:2004

Authorized Representative: Simon Smith, European Director

Address: Aerotech Ltd

The Old Brick Kiln, Ramsdell, Tadley

Hampshire RG26 5PR

UK

Name / Alex Weibel

Position Engineer Verifying Compliance

Location Pittsburgh, PA

Date 7/24/2020

EU Declaration of Conformity Automation1 iPC Hardware Manual

6 www.aerotech.com

Agency Approvals

Manufacturer Aerotech, Inc.

Address 101 Zeta Drive

Pittsburgh, PA 15238-2811

USA

Product Automation1 iPC

Model/Types Control Cabinet PCs:-CC04, -CC05

Desktop PC:-DT01

1URack Mounted PC:-R013

4URack Mounted PC:-R402

This is to certify that the aforementioned product(s) is in accordance with the applicable requirements of

the following Standard(s):

FCC Part 15, Subpart B

ANSI C63.4-2014

ICES-003 Issue 6: 2016

CISPR 22: 2008

CAN/CSA-CISPR 22-10

www.aerotech.com 7

Automation1 iPC Hardware Manual Agency Approvals

This page intentionally left blank.

Agency Approvals Automation1 iPC Hardware Manual

8 www.aerotech.com

Chapter 1: Automation1 iPC

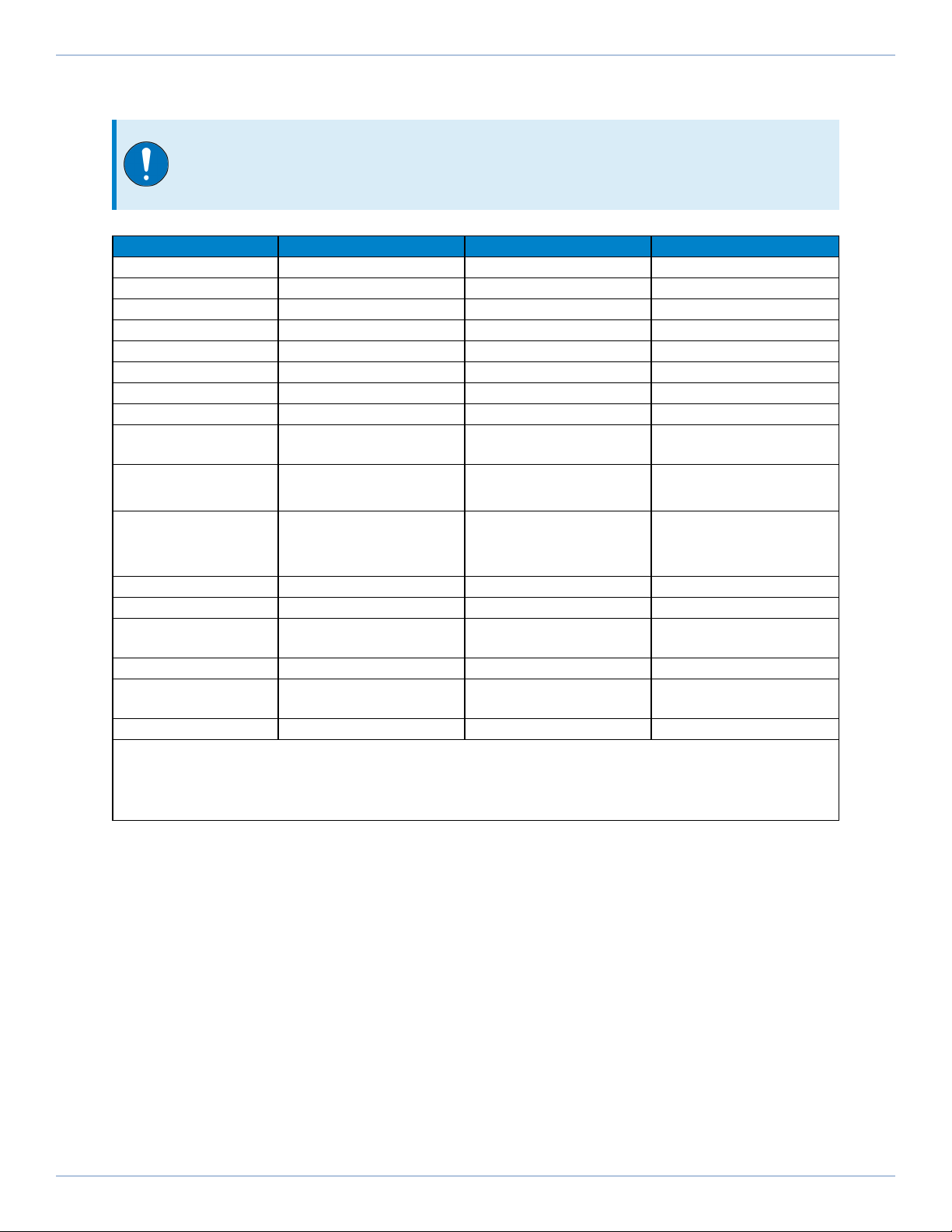

IMPORTANT: All specifications and illustrations are for reference only and were complete

and accurate as of the release of this manual. To find the newest information about this

product, refer to www.aerotech.com.

Table 1-1: Ordering Options

Hardware

-CC05 Control cabinet iPC; i7 processor; SSD; HyperWire 6.03 minimum

-CC04 Control cabinet iPC; i5 processor; SSD; HyperWire 6.03 minimum

-R402 4U 19" rack mount iPC; i7 processor; SSD; HyperWire 6.03 minimum

-R103 1U 19" rack mount iPC; i7 processor; SSD; HyperWire 6.03 minimum

-DT01 Desktop tower IPC; i7 processor; SSD; HyperWire 6.03 minimum

Software

-MDK01 Automation1-MDK is installed (default).

-MDK00 No Automation1-MDK software is installed.

-SMC01 Automation1-iSMC is installed (default).

-SMC00 No Automation1-iSMC controller is installed.

Operating System (Required)

-OS03 Windows 10 LTSC 64-bit operating system (default)

Motion Bus Hardware

-MB03 HyperWire motion bus through a PCIe interface card

-MB00 No motion bus interface card

Automation Bus Hardware

-AB04 EtherCAT interface card - HyperWire-PCIe add-on

-AB03(3) EtherCAT interface card and Ethernet expansion card

-AB01(3) Ethernet expansion card

-AB00 No EtherCAT/PROFINET interface card or Ethernet expansion cards (default)

(3)Ethernet expansion card can be used for PC Modbus connections

HMIPackage

-HMI04 24” LED monitor, USB keyboard with integral touch pad

-HMI03 24” LED monitor, USB keyboard, and mouse

-HMI02 USB keyboard with integral touch pad

-HMI01 USB keyboard and mouse

-HMI00 No HMI package (default)

ACAdapter

-AC1 ACAdapter for PCpower

-AC0 No ACAdapter

Line Cord

-LC0 No line cord (default)

-LC1 US 115 VAC line cord

-LC2 US 230 VAC line cord

-LC3 UK compatible line cord

-LC5 Israel compatible line cord

-LC6 India compatible line cord

-LC7 Australia compatible line cord

www.aerotech.com 9

Automation1 iPC Hardware Manual Chapter 1: Automation1 iPC

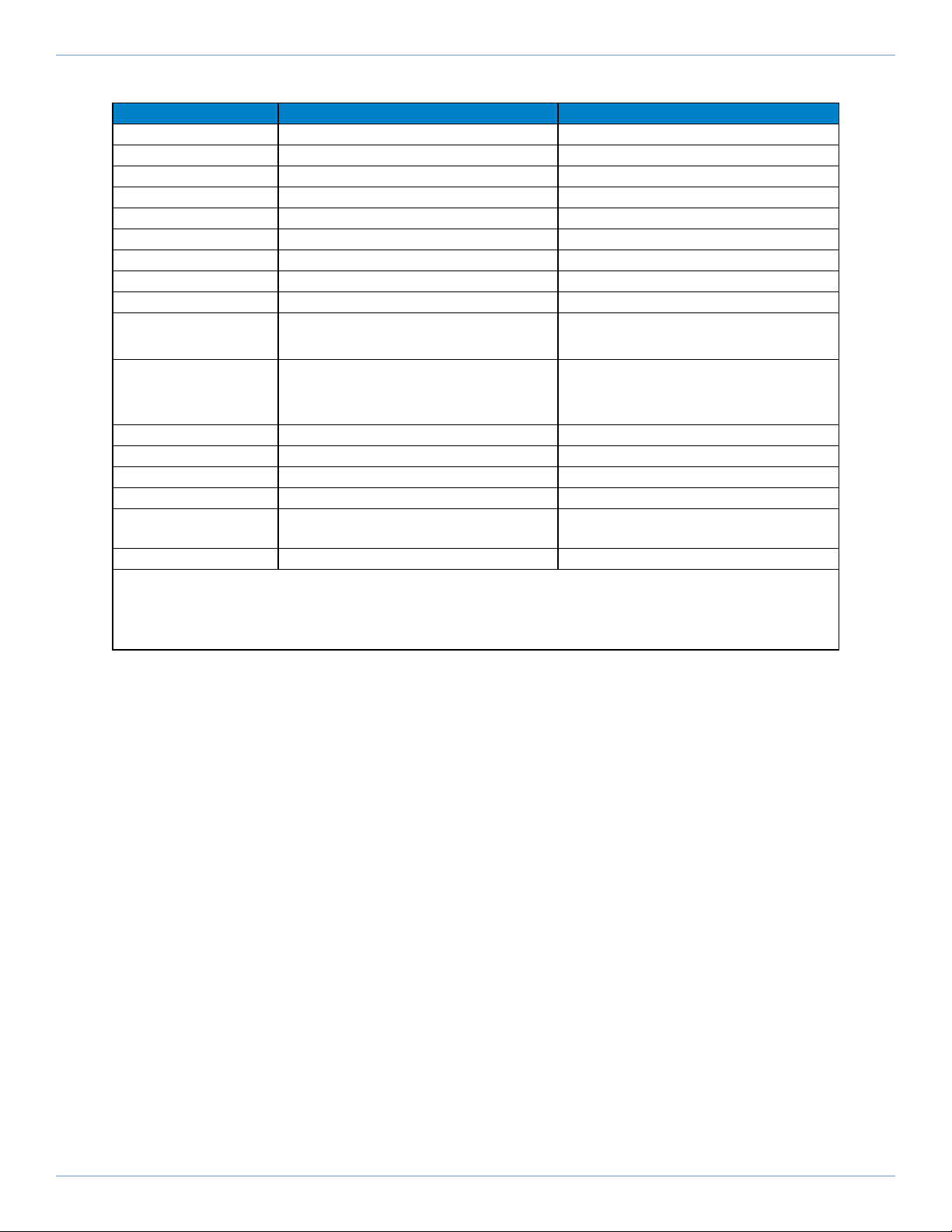

1.1. Specifications

IMPORTANT: PC specifications subject to change without notice. Please contact factory

for most up to date information. Refer to your third-party motherboard documentation to

determine your current specifications.

Table 1-2: Automation Motion Server Specifications (Control Cabinet / Desktop PC)

-CC05 -CC04 -DT01

Description Control cabinet PC Control cabinet PC Desktop PC

A3200 Version 6.x and above 6.x and above 6.x and above

Processor Intel i7-7700 Intel i5-7500 Intel i7-7700

RAM 16 GB 16 GB 16 GB

Operating System(1) Windows 10 LTSC Windows 10 LTSC Windows 10 64-bit

Hard Disk Space 256 GB SSD 128 GB SSD 512 GB SSD

USB 3.0 Connections 4 4 4

USB 2.0 Connections N/A N/A N/A

Input Power 24 VDC 24 VDC 100-240 V, 2-4 A,

50-60 Hz

Display Connections Display Port

HDMI

Display Port

HDMI

VGA

DVI-D(2)

Available PCI/PCIe

Expansion Slots (3) N/A N/A

1 x PCIe x16

2 x PCIe x4

3x PCI

DVD Drive No No Yes

Drive Interface HyperWire HyperWire HyperWire

LAN 10/100/1000 Mbit

(Qty. 2)

10/100/1000 Mbit

(Qty. 2)

10/100/1000 Mbit

(Qty. 2)

Modbus Support Yes (Ethernet) Yes (Ethernet) Yes (Ethernet)

EtherCAT/PROFINET

Support Available Available Available

Power Supply Optional ACAdapter Optional ACAdapter 180 W

(1) To avoid machine disruption, Aerotech disables automatic updates on Windows PCs that are shipped from Aerotech.

To customize your update settings, refer to Microsoft’s Windows documentation or Aerotech’s User Guide to Windows 10

Updates.

(2) Refer to Section 1.5. for configuration details.

(3) After the HyperWire card is installed.

1.1. Specifications Automation1 iPC Hardware Manual

10 www.aerotech.com

Table 1-3: Automation Motion Server Specifications (Rack Mount PCs)

-R103 -R402

Description 1U rack mount 4U rack mount

A3200 Version 6.x and above 6.x and above

Processor Intel i7-7700 Intel i7-7700

RAM 16 GB 16 GB

Operating System(1) Windows 10 64 bit Windows 10 64 bit

Hard Disk Space 256 GB SSD 512 GB SSD

USB 3.0 Connections 4 4

USB 2.0 Connections N/A N/A

Input Power 100-240 V, 2-4 A, 50-60 Hz 100-240 V, 2-4 A, 50-60 Hz

Display Connections • VGA

• DVI-D(2)

• VGA

• DVI-D(2)

Available PCI/PCIe

Expansion Slots (3) N/A

• 1 x PCIe x16

• 2 x PCIe x4

• 3 x PCI

DVD Drive Yes Yes

Drive Interface HyperWire HyperWire

LAN 10/100/1000 Mbit (Qty. 2) 10/100/1000 Mbit (Qty. 2)

Modbus Support N/A Yes (Ethernet)

EtherCAT/PROFINET

Support N/A Available

Power Supply 350 W 400 W

(1) To avoid machine disruption, Aerotech disables automatic updates on Windows PCs that are shipped from Aerotech.

To customize your update settings, refer to Microsoft’s Windows documentation or Aerotech’s User Guide to Windows 10

Updates.

(2) Refer to Section 1.5. for configuration details.

(3) After the HyperWire card is installed.

www.aerotech.com 11

Automation1 iPC Hardware Manual 1.1. Specifications

1.2. Remote Server Operation

Only one of the available Ethernet ports will be configured for use with the remote server. Refer to the

figures below to determine which port you should use for each Automation1 iPC hardware

configuration.

Figure 1-1: -CC04/-CC05 Connector View (typical)

Figure 1-2: -DT01 Connector View (typical)

1.2. Remote Server Operation Automation1 iPC Hardware Manual

12 www.aerotech.com

Figure 1-3: -R103 Connector View (typical)

Figure 1-4: -R402 Connector View (typical)

www.aerotech.com 13

Automation1 iPC Hardware Manual 1.2. Remote Server Operation

1.3. Dimensions

IMPORTANT: Aerotech continually improves its product offerings; listed options may be

superseded at any time. All drawings and illustrations are for reference only and were

complete and accurate as of this manual’s release. Refer to www.aerotech.com for the

most up-to-date information.

Figure 1-5: Desktop Computer Dimensions (-DT01)

1.3. Dimensions Automation1 iPC Hardware Manual

14 www.aerotech.com

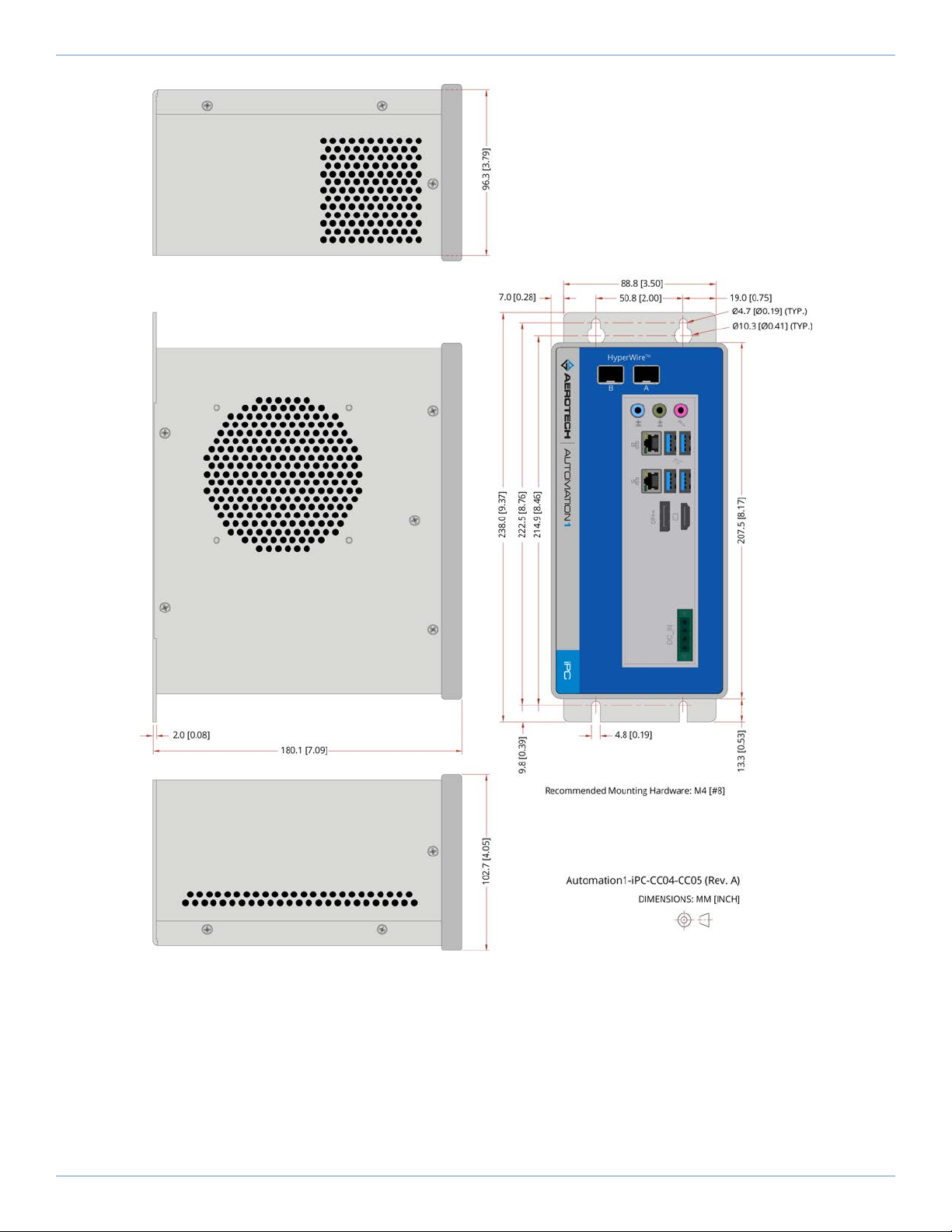

Figure 1-6: Control Cabinet Dimensions (-CC04/-CC05)

www.aerotech.com 15

Automation1 iPC Hardware Manual 1.3. Dimensions

Figure 1-7: 4U Rack Mount Chassis Dimensions (-R402)

1.3. Dimensions Automation1 iPC Hardware Manual

16 www.aerotech.com

Figure 1-8: 1U Rack Mount Chassis Dimensions (-R103)

www.aerotech.com 17

Automation1 iPC Hardware Manual 1.3. Dimensions

1.4. AC Power Setting

You can change the BIOS setting on the PC so that, in the event of a power failure, you will not need to

access the PC to manually turn the PCback on. Use this item to select AC power state when power is re-

applied after a power failure.

Table 1-4: BIOSSettings

PCType BIOSCategory Settings

-CC04

-CC05 State after G3 Power On

-R103 Restore ACPower Loss S0 State

-R402 Restore ACPower Loss S0 State

-DT01 Restore ACPower Loss S0 State

1.5. DVIMonitor Configuration (-R103, -R402, -DT01 PCOptions)

To let the Windows OS operate without a monitor connected, both the AIMB-785 motherboard and the

standard Advantech-provided BIOSare configured to report to the Windows OS that a VGAmonitor is

always connected as the default primary display. If you connect a single DVI monitor to one of the rack

mount (-R103 or -R402) or desktop (-DT01) computers, the BIOS will continue to report to Windows that

the VGA monitor is also connected. You will need to update the Windows Display settings to get the

system to correctly identify the DVI monitor. Either duplicate the Windows desktop to both monitors or

identify and set the DVI monitor as the primary display.

1.6. Environmental Specifications

Table 1-5: Environmental Specifications

Ambient

Temperature

Operating: 0° to 40°C

Storage: -30° to 85°C

Humidity

Non-condensing

The maximum relative humidity is 80% for temperatures that are less

than 31°C and decreases linearly to 50% relative humidity at 40°C.

Operating Altitude

0 m to 2,000 m above sea level.

If you must operate this product above 2,000 m or below sea level,

contact Aerotech, Inc.

Pollution Pollution Degree 2

Typically only nonconductive pollution occurs.

Operation Use only indoors

1.4. AC Power Setting Automation1 iPC Hardware Manual

18 www.aerotech.com

Appendix A: Warranty and Field Service

Aerotech, Inc. warrants its products to be free from harmful defects caused by faulty materials or poor

workmanship for a minimum period of one year from date of shipment from Aerotech. Aerotech’s

liability is limited to replacing, repairing or issuing credit, at its option, for any products that are returned

by the original purchaser during the warranty period. Aerotech makes no warranty that its products are

fit for the use or purpose to which they may be put by the buyer, whether or not such use or purpose

has been disclosed to Aerotech in specifications or drawings previously or subsequently provided, or

whether or not Aerotech’s products are specifically designed and/or manufactured for buyer’s use or

purpose. Aerotech’s liability on any claim for loss or damage arising out of the sale, resale, or use of any

of its products shall in no event exceed the selling price of the unit.

THE EXPRESS WARRANTY SET FORTH HEREIN IS IN LIEU OF AND EXCLUDES ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, BY OPERATION OF LAW OR OTHERWISE. IN NO EVENT SHALL AEROTECH BE

LIABLE FOR CONSEQUENTIAL OR SPECIAL DAMAGES.

Return Products Procedure

Claims for shipment damage (evident or concealed) must be filed with the carrier by the buyer. Aerotech

must be notified within thirty (30) days of shipment of incorrect material. No product may be returned,

whether in warranty or out of warranty, without first obtaining approval from Aerotech. No credit will be

given nor repairs made for products returned without such approval. A "Return Materials Authorization

(RMA)" number must accompany any returned product(s). The RMA number may be obtained by calling

an Aerotech service center or by submitting the appropriate request available on our website

(www.aerotech.com). Products must be returned, prepaid, to an Aerotech service center (no C.O.D. or

Collect Freight accepted). The status of any product returned later than thirty (30) days after the

issuance of a return authorization number will be subject to review.

Visit https://www.aerotech.com/global-technical-support.aspx for the location of your nearest Aerotech

Service center.

Returned Product Warranty Determination

After Aerotech's examination, warranty or out-of-warranty status will be determined. If upon Aerotech's

examination a warranted defect exists, then the product(s) will be repaired at no charge and shipped,

prepaid, back to the buyer. If the buyer desires an expedited method of return, the product(s) will be

shipped collect. Warranty repairs do not extend the original warranty period.

Fixed Fee Repairs - Products having fixed-fee pricing will require a valid purchase order or credit

card particulars before any service work can begin.

All Other Repairs - After Aerotech's evaluation, the buyer shall be notified of the repair cost. At

such time the buyer must issue a valid purchase order to cover the cost of the repair and freight, or

authorize the product(s) to be shipped back as is, at the buyer's expense. Failure to obtain a

purchase order number or approval within thirty (30) days of notification will result in the product(s)

being returned as is, at the buyer's expense.

Repair work is warranted for ninety (90) days from date of shipment. Replacement components are

warranted for one year from date of shipment.

www.aerotech.com 19

Automation1 iPC Hardware Manual Appendix A: Warranty and Field Service

Rush Service

At times, the buyer may desire to expedite a repair. Regardless of warranty or out-of-warranty status,

the buyer must issue a valid purchase order to cover the added rush service cost. Rush service is subject

to Aerotech's approval.

On-site Warranty Repair

If an Aerotech product cannot be made functional by telephone assistance or by sending and having the

customer install replacement parts, and cannot be returned to the Aerotech service center for repair, and

if Aerotech determines the problem could be warranty-related, then the following policy applies:

Aerotech will provide an on-site Field Service Representative in a reasonable amount of time,

provided that the customer issues a valid purchase order to Aerotech covering all transportation and

subsistence costs. For warranty field repairs, the customer will not be charged for the cost of labor

and material. If service is rendered at times other than normal work periods, then special rates

apply.

If during the on-site repair it is determined the problem is not warranty related, then the terms and

conditions stated in the following “On-Site Non-Warranty Repair” section apply.

On-site Non-Warranty Repair

If any Aerotech product cannot be made functional by telephone assistance or purchased replacement

parts, and cannot be returned to the Aerotech service center for repair, then the following field service

policy applies:

Aerotech will provide an on-site Field Service Representative in a reasonable amount of time,

provided that the customer issues a valid purchase order to Aerotech covering all transportation and

subsistence costs and the prevailing labor cost, including travel time, necessary to complete the

repair.

Service Locations

http://www.aerotech.com/contact-sales.aspx?mapState=showMap

USA, CANADA, MEXICO

Aerotech, Inc.

Global Headquarters

Phone: +1-412-967-6440

Fax: +1-412-967-6870

CHINA

Aerotech China

Full-Service Subsidiary

Phone: +86 (21) 5508 6731

GERMANY

Aerotech Germany

Full-Service Subsidiary

Phone: +49 (0)911 967 9370

Fax: +49 (0)911 967 93720

TAIWAN

Aerotech Taiwan

Full-Service Subsidiary

Phone: +886 (0)2 8751 6690

UNITEDKINGDOM

Aerotech United Kingdom

Full-Service Subsidiary

Phone: +44 (0)1256 855055

Fax: +44 (0)1256 855649

Have your customer order number ready before calling.

Appendix A: Warranty and Field Service Automation1 iPC Hardware Manual

20 www.aerotech.com

This manual suits for next models

5

Table of contents

Other Aerotech Industrial PC manuals

Popular Industrial PC manuals by other brands

Contec

Contec IPC SERIES Operational manual

Advantech

Advantech MIC-1816 Series user manual

Neousys Technology

Neousys Technology Nuvo-7162GC Series user manual

IBASE Technology

IBASE Technology AMS310 user manual

Siemens

Siemens SIMATIC IPC847D Product information

GIGAIPC

GIGAIPC QBiX-Pro-ADLA1255H quick start guide

Chipsee

Chipsee PPC-A72-150-P manual

Moxa Technologies

Moxa Technologies V2406-24I Series Hardware user manual

National Instruments

National Instruments VXIpc-870 user manual

Asus

Asus Aaeon BOXER-8254AI user manual

IEI Technology

IEI Technology IVS-300-ULT3-i5/4G user manual

DFI

DFI DT122-SB installation guide